NorthQ NQ-9021 User manual

NorthQPower & Gas Reader Revision: 2.2

1

NorthQ Power and Gas Reader

(NQ-9021)

Technical Integration

Z-Wave Commands

Document revision: 2.2

Date: January 30, 2015

NorthQPower & Gas Reader Revision: 2.2

2

Disclaimer:

This document is provided for information purposes only. NorthQ ApS may change the contents

hereof without notice. This document is not warranted to be error-free, nor subject to any

other warranties or conditions, whether expressed orally or implied in law, including implied

warranties and conditions of merchantability or fitness for a particular purpose. NorthQ ApS

specifically disclaims any liability with respect to this document and no contractual obligations

are formed either directly or indirectly by this document. The technologies, functionality,

services, and processes described herein are subject to change without notice.

NorthQPower & Gas Reader Revision: 2.2

3

Contents

I. Device Information .................................................................................................................................... 3

II. Functioning modes.................................................................................................................................... 4

III. Command classes..................................................................................................................................... 4

IV. Power Reader push button commands...................................................................................................8

V. Integrating the Power Reader with third party controllers...................................................................... 9

VI. Common setup to properly install a Power Reader ..............................................................................10

VII. Support .................................................................................................................................................11

I. Device Information

The Power Reader is a metering device capable of counting pulses from any electricity

or gas meters. The device stores timestamped consumption in its internal memory every 15

minutes.

Note: The Power Reader for electricity metering has different firmware than the Power Reader

for gas metering. Please make sure you have the appropriate firmware on your device before

you start integrating / installing it. The proper way of distinguishing between the two firmware

versions is by using the MANUFACTURER SPECIFIC command class.

Device presentation:

- NIF:

Generic device class: GENERIC TYPE METER

Specific device class: SPECIFIC TYPE SIMPLE METER

- SUPPORTED COMMAND CLASSES:

COMMAND_CLASS_BASIC

COMMAND_CLASS_BATTERY

COMMAND_CLASS_WAKE_UP

COMMAND_CLASS_FIRMWARE_UPDATE_MD_V2

COMMAND_CLASS_TIME_PARAMETERS

COMMAND_CLASS_METER_V2

COMMAND_CLASS_CRC_16_ENCAP

COMMAND_CLASS_CONFIGURATION

COMMAND_CLASS_MANUFACTURER_SPECIFIC_V2

COMMAND_CLASS_VERSION

COMMAND_CLASS_METER_TBL_MONITOR

NorthQPower & Gas Reader Revision: 2.2

4

- MANUFACTURER SPECIFIC for electricity firmware:

Manufacturer: 150

Product: 1

Product type: 1

- MANUFACTURER SPECIFIC for gas firmware:

Manufacturer: 150

Product: 1

Product type: 16

II. Functioning modes

The Power Reader has two functioning modes:

- Real-time mode

- Normal mode

In real-time mode, the Power Reader will keep the antenna always on. In normal mode,

the Power Reader will go to sleep and wake up as instructed by the WAKE UP SET command.

III. Command classes

In the following section each command class is described in detail. Make sure to read

the "Integrating with third party controllers" part of the document after going through the

command classes.

1. COMMAND_CLASS_BASIC

Using the command class basic, the controlling node can control the Power Reader's

LED. A basic set command will trigger the Power Reader's LED to light up. The Power Reader

will respond to the BASIC SET command with a BASIC REPORT representing the LED status.

The basic get command will return a BASIC REPORT with value 1.

2. COMMAND_CLASS_BATTERY

Using this command class, the Power Reader can be queried for battery level. The

battery level is reported according to the command class specification as a value between 0 and

100. Value 255 for low battery is not supported.

NorthQPower & Gas Reader Revision: 2.2

5

3. COMMAND_CLASS_WAKE_UP

Use this command class to specify how often the Power Reader should wake up when in

normal mode. The command class is implemented according to the command class

specification.

4. COMMAND_CLASS_FIRMWARE_UPDATE_MD_V2

The Power Reader is firmware updateable. Performing a firmware update will erase all

the historical consumption in the Power Reader's memory. The command class is implemented

according to the command class specification. If you want support for firmware updates on

your controlling device contact NorthQ directly for access to latest firmware.

The firmware update request get command must have the following parameters:

- vendor: 0x96

- product id: 0x0101

- checksum: the checksum is performed on the entire firmware file including headers. Initial crc

value is 0xFFFF.

5. COMMAND_CLASS_TIME_PARAMETERS

Use this command class to set the Power Reader's real-time clock. The command class is

implemented according to the command class specification.

NOTE: The Power Reader will not store any timestamped consumption until the real-time clock

is set.

6. COMMAND_CLASS_METER_V2

Use this command class to get the current total meter consumption. For the electricity

firmware the meter type reported is 0x01 (electricity). For gas firmware the meter type

reported is 0x02 (gas).

The scale for this command class is 0x00 (kWh - for electricity meter and m3for gas

meters).

7. COMMAND_CLASS_CRC_16_ENCAP

This command class is implemented according to the command class specification. Use

it only if the controlling device is placed in a noisy environment for extra security.

8. COMMAND_CLASS_CONFIG

Through the configuration command class, the controlling node will configure the Power

Reader.

NorthQPower & Gas Reader Revision: 2.2

6

Register 1 - Pulse factor (4 byte register) - In this register the controlling node must set the

meter's impulse or rotation factor x 10.

Ex: For a mechanical meter with a rotation factor of 150, the value for this register must be

set to 1500 (150 x 10). The rotation factor is usually written on the meter and its unit of

measurement is rot / kWh.

NOTE: Some mechanical meters express their rotation factor in rot / Wh instead of rot / kWh.

In this case the value must be converted to rot / kWh before multiplying by 10 and writing this

value in the register. In order to convert rot / Wh to rot / kWh to value has to be multiplied by

1000.

For an electronic meter with an impulse factor of 1000 the value for this register must

be set to 10000 (1000 x 10). The impulse factor is usually written on the meter and its unit of

measurement is imp / kWh.

NOTE: Some electronic meters express their impulse factor in imp / Wh instead of imp / kWh.

In this case the value must be converted to imp / kWh before multiplying by 10 and writing this

value in the register. In order to convert imp / Wh to imp / kWh the value from the meter has

to be multiplied by 1000.

For a gas meter read using the silver spot on one of the digits, the value written in this

register is calculated with the following formula:

value = Pow(10, x) where X is the index of the red digit that has the silver spot.

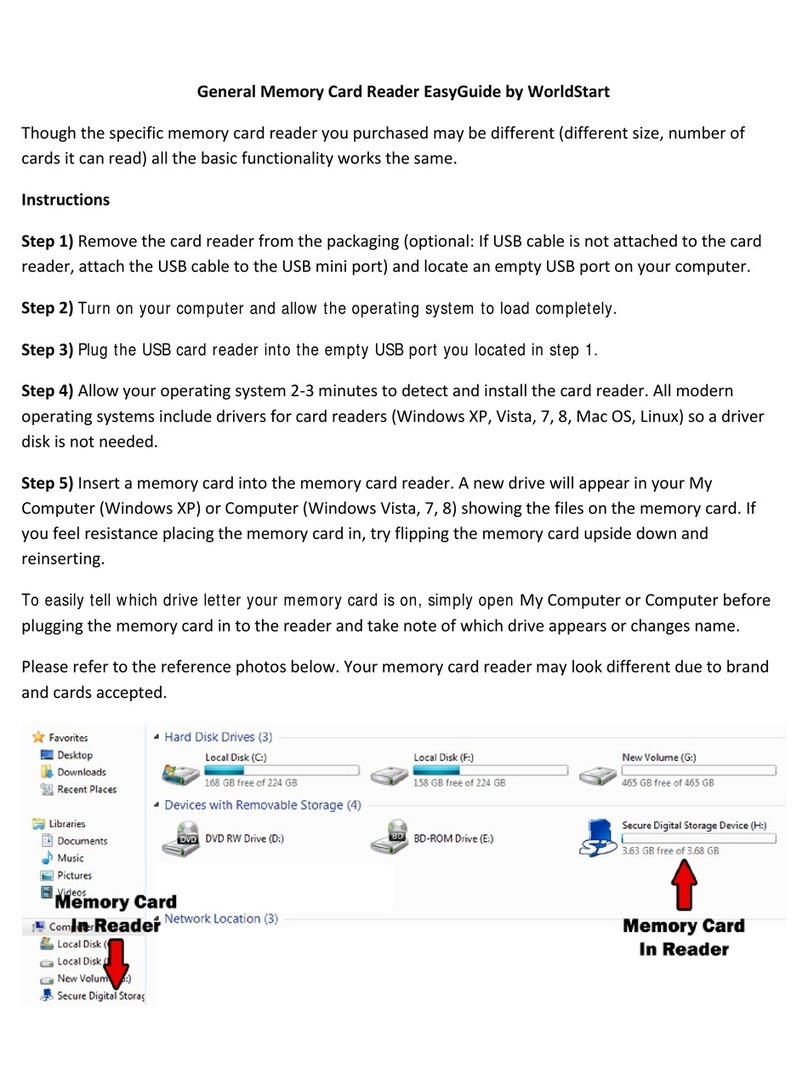

Figure 1 Determining the index of red digit with silver spot

For a gas meter read through magnetic contact, the value written in this register is

impulse factor * 10. The impulse factor is usually written on the meter and it's expressed in imp

/ m3.

Register 2 - sensor type (1 byte register) - In this register, the controlling node has to set the

meter type on which the Power Reader is placed.

For electricity firmware: set 0x01 to this register for electronic meter, or 0x02 for mechanical

meter. Mechanical meters can be distinguished by their rotating disk while the electronic

meters can be distinguished by their digital display and blinking LED.

NorthQPower & Gas Reader Revision: 2.2

7

For gas firmware: set 0x01 to this register for magnetic contact meters, or 0x02 for silver spot

meters.

Register 7 - filter inhibit threshold (1 byte register) - Set this register to 0 in order to make the

Power Reader start automatic calibration when placed on electricity mechanical meters.

This register is not used on Gas Readers.

Register 9 - pulse count (4 byte register) - This register holds the total number of pulses. Use

this register to set the total meter consumption. In order for the Power Reader to report the

proper total meter consumption, the value for this registered has to be initialized with

total_meter_consumption_stated_on_the_meter * impulse factor.

Ex: For a mechanical meter with a rotation factor of 150 and the total meter consumption

100.3, the value written in this register must be: 15045 (150 x 100.3). The total meter

consumption written on the meter can be a user input variable at installation.

Register 10 - keep alive period (2 byte register) - At every wake up notification, the Power

Reader stays alive for 3 seconds. If the controlling node can't guarantee a response for the

Power Reader within 3 seconds, then this register should be set to the number of seconds that

it will take the controlling node to send a response / request to the wake up notification.

Register 11 - real-time register (2 bytes) - This register notifies the controlling mode when the

real-time mode has started and when it ended. The configuration report contains the number

of seconds * 20 left until the real-time mode is over. A configuration report with value 0 notifies

the controlling node that the Power Reader is going to normal mode.

NOTE: The wake up no more information has no effect in real-time mode. In order to tell the

Power Reader to go to sleep from real-time mode, the controlling node has to set this register

to value 0.

Register 12 - serial number (4 bytes) - This register contains the serial number of the Power

Reader.

NOTE: The serial numbers written on the Power Reader are in HEX, not decimal.

Register 15 - calibration status (4 byte) - A configuration report with this register will inform

the controlling node of its current calibration status on the meter.

For Power Readers (electric):

The calibration progress is calculated as (value[1] - 65 + value[2] / value[3]) * 25

The calibration is finished successfully when value[0] = 2 and value[2] = value[3].

The calibration has failed if value[0] != 1 OR (value[0] = 2 AND value[2] != value[3])

NorthQPower & Gas Reader Revision: 2.2

8

For Gas Readers (gas):

Only applies to gas readers with firmware version 3.30 or higher configured for SILVER SPOT!

Setting the value 0 on this register will restart the calibration process will restart the calibration

process that occurs normally at power-up. The calibration process lasts aprox. 2 minutes.

Interrogating this register will return the current calibration percentage, from 0 to 100, value

100 indicating that the calibration has ended.

9. COMMAND_CLASS_MANUFACTURER_SPECIFIC

The Power Reader will respond to a MANUFACTURER SPECIFIC GET command with the

following information:

- MANUFACTURER SPECIFIC for electricity firmware:

Manufacturer: 150

Product: 1

Product type: 1

- MANUFACTURER SPECIFIC for gas firmware:

Manufacturer: 150

Product: 1

Product type: 16

10. COMMAND_CLASS_VERSION

This command class is implemented according to the command class specification.

11. COMMAND_CLASS_METER_TBL_MONITOR

The meter tbl monitor command class is implemented according to the command class

specification.

NOTE: The Power Reader will not report any data through this command class if the time

parameters are not set.

IV. Power Reader push button commands

The Power Reader can take commands by pressing the button. The following commands

are supported:

- By pressing the button 1 time the Power Reader will enter real-time mode. The proper

configuration reports will be sent to notify the controlling node.

- By pressing the button 2 times the Power Reader to wake up from sleep and send a wake up

notification.

NorthQPower & Gas Reader Revision: 2.2

9

- By pressing the button 3 times the Power Reader will send a Node Information frame.

- By pressing the button 5 times the Power Reader will start meter calibration on mechanical

meters.

- By pressing the button 5 times the Gas Reader will restart the calibration on silver spot

meters. Applies only to Gas Readers with firmware 3.30 or higher.

- By pressing the button 7 times the Power Reader will be reset to factory defaults.

V. Integrating the Power Reader with third party controllers

In order to properly integrate the Power Reader with a controller, the following steps

have to be taken:

At installation:

- make sure that the Power Reader's registers are configured properly with meter type /

impulse factor / pulse count.

- set the time parameters otherwise the Power Reader will not timestamp / store any data. If

you do not do this you will only the able to see total meter consumption through the meter

command class.

- set the wake up interval as a multiple of 15 minutes.

- a Power Reader with an already configured wake up node (i.e. wake up node != 255) most

probably has historical data in his storage. You can pull that from the Power Reader as the user

might want to see his historical consumption through your UI.

- use the basic command class or NOP commands to perform a range test on the Power Reader

and inform the user if the Power Reader is out of reach.

- make sure you don't forget to do a meter calibration if the Power Reader is placed on a

mechanical meter. Otherwise the measurements will be inaccurate. Check command class

configuration for details on how to do a calibration.

- the Power Reader's serial number has to be queried and displayed to the user.

- the Power Reader automatically enters real-time mode at pairing. Make sure the Power

Reader is sent to sleep as soon as possible after everything is installed.

At every wake up notification:

- do not ask more than the METER TBL MONITOR data at each wake up

- ask for the battery level only once per hour

- if the controlling node detects a missing wake up notification or a wake up notification too

early it has to set the time parameters again

- use low power transmission at each wake up notification. If the response doesn't arrive, then

switch to regular power transmission. If the controlling node and the Power Reader are placed

NorthQPower & Gas Reader Revision: 2.2

10

close together, using low power transmission will show a major battery lifetime improvement.

The communication software in the controller may chose not to try low power communication

for a longer period of time if the Power Reader failed to respond to a certain amount of low

power transmissions.

- sending wake up no more information will force the Power Reader to send an ACK to the

controlling node. Not sending wake up no more information actually improves battery lifetime

in this case. The Power Reader will go to sleep after the time in register 10 expires.

Misc:

- make sure your controller knows how to properly set the Power Reader to sleep from real-

time mode by setting register 11 to 0.

- make sure your controller's UI notifies the user that requesting live data from the Power

Reader (i.e. real-time mode requests) will cause the batteries to deplete very fast.

- the wake up interval must not be less than 15 minutes

- do not use CRC 16 command class unless it is absolutely necessary as it will require the

antenna to send more bytes than the regular command class. By sending more bytes, the

battery lifetime is affected.

- leave register 10 at 3 seconds

If all these requirements are fulfilled and the Power Reader is close to the gateway, the

battery lifetime with the original batteries is 8 months.

VI. Common setup to properly install a Power Reader

In order to properly install a Power Reader the controller node has to follow these steps:

- pair the Power Reader by enabling learn mode on the controller node and pressing the button

3 times

- immediately after pairing, the Power Reader will enter real-time mode

- get manufacturer specs to check for the firmware type

- get firmware version

- get serial number (configuration register 12)

- set time parameters

- set wake up interval

- set meter type and impulse factor registers

- ask user to place the Power Reader on the meter

- if the Power Reader is to be installed on an electricity meter mechanical type, then a

calibration is needed. Start a calibration by setting register 7 to 0. The Power Reader will start

sending unsolicited configuration reports to inform the controlling node of its calibration status.

NorthQPower & Gas Reader Revision: 2.2

11

If calibration has failed you must inform the user that he didn't place the sensor head

properly on the meter, he didn't plug the cable properly in the Power Reader or there is a very

low consumption on the meter and the meter disk spins very slow.

- set the pulse count register with the proper value (as described in

COMMAND_CLASS_CONFIG)

- show the user the real-time consumption using command class meter

- as soon as the user finished checking the real-time consumption send the Power Reader to

sleep

VII. Support

Any support requests have to be submitted by email to [email protected] (Christian) or

Table of contents