IC-03.1 Card Capture Reader

9

5.4 Control

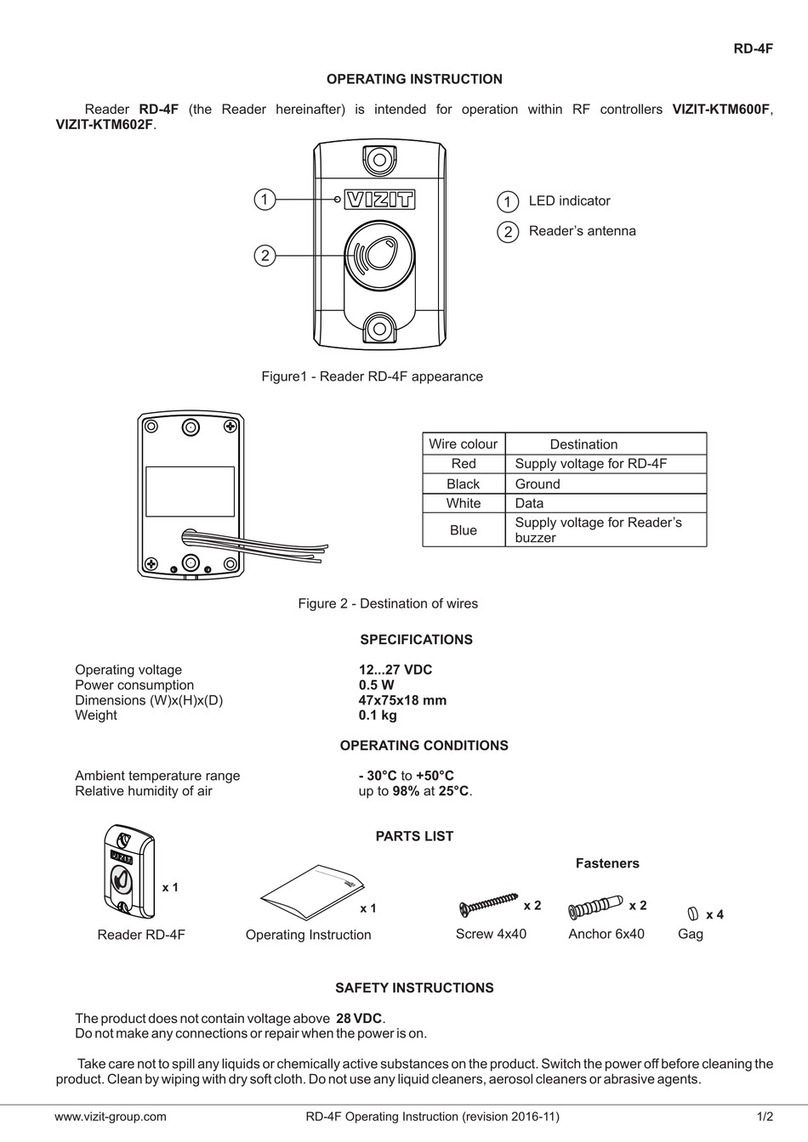

Wiegand interface lines of the reader located from internal side of the card capture reader

cover are intended for connection to the ACS controller (see Figure 8).

An ACS controller controls the card capture reader by sending a signal to the “Capture

card” input of the card capture reader control board (contact 1of the connector block XT1).

Card capture reader generates a “Card captured” signal (contact 1of the connector block

XT2) and in certain cases – signal “Fault” (contact 2of the terminal block XT2).

The “Capture card” input is controlled by output of “dry contact” type or “open collector” of

the ACS controller. The input is “normal open”, i.e. when a control signal is given the ACS

controller closes it to the “GND” contact (contact 2 of the connector block XT1).

Input parameters:

•voltage at the open contact relative to “GND” ............................................. 5±0.5 V

•voltage at the closed contact relative to “GND” .......................................max. 0.8 V

•current via closed contact ....................................................................max. 1.5 mA

The “Card captured” and “Fault” outputs – of “dry contact” type. Each of these outputs is

one of two relay contacts. Other relay contacts are banded and connected to the “COM”

output (contact 3of the connector block XT2). The outputs are “normal open”, i.e. while

producing a signal the corresponding output is connected to “COM” contact.

Output parameters:

•max. voltage between the corresponding output and “COM” contact ......... 42 V

•max. switched current ............................................................................. 200 mA

If an access card inserted into the (3) slot requires to be captured the ACS controller gives

a signal to the “Capture card” input.At this signal the electromagnet opens the shutter that

prevents an access into the card capture reader and the card falls into the card container

(6), i.e. the card capturing occurs. If the optic sensor sees that the card at the slot is

missing then the electromagnet will not actuate and the access into the card capture

reader will remain shut.

At the card falling into the card container the optic sensor registers the fact of card

capturing. Only in this case the card capture reader gives the “Card captured” signal to the

ACS controller. On receiving this signal the ACS controller deactivates the “Capture card”

signal after which the card capture reader deactivates the “Card captured” signal.

On cards capturing the container gets full. When it is full further cards capturing is blocked

till the captured cards are extracted from the container. In this case the card capture

reader generates the “Fault” signal for the ACS controller.

To resume capturing of guest cards it is necessary to extract the full container from the

card capture reader and empty the cards.

If the container is free from cards but the card capture reader is still blocked a likely reason

for this could be failure of the card capture reader units. It is recommended to apply to the

PERCo Technical Support Department.