9

Operating Instructions

Read and understand the entire manual before operating the pressure washer.

Follow these instructions every time you use the pressure washer.

I.) Pre-Operation

;A.) Position the machine for easy access to all

controls.

;B.) Position the machine on a solid surface, with

less than a three degree slope, and so it is

protectedfrom external damage.

;C.) Position the machine so that ambient lighting is

sufficient for the surface you are cleaning to be

seen with ease. Use artificial lightif needed.

;D.) Checkhoses, fittings, wand,trigger gun and fuel

connections for signs of wear, cracks and

looseness, and replaceasrequired.

;E.) Checkand clean the nozzle orifice.

;F.) Check and clean the water inlet screen and

filter.

;G.) Read entire manual, especially the important

safety instructionslistedon page2.

;H.) Check and maintain proper oil levels in the

pumpand engine.

II.) Check Your Water Supply

;A.) Make sure the water supplyisclean. Debriscan

cause excess pump wear and reduce

performance.

;B.) An insufficient water supply will damage your

pump. Make sure the water supply is steady

and is 20% over the rated flow of your pump.

Use a stopwatchto timehowlongit takesto fill a

5 gallonbucket with yourgardenhose.

Example: If the ratedflowis= 4gpm

Then required flow= 4 x1.20= 4.8gpm

5gallons/ 4.8gpm =1.04minutes

1.04min x 60sec/min = 62 seconds

Therefore, youmust be able to fill a

5 gallonbucketin62 secondsor faster.

;C.) The water supply garden hose must have an

inside diameter of at least 5/8”. If the hose is

morethan100 ft. long, the diameter must be at

least 3/4”.

;D.) Never use a reservoir tank as a water source.

This pressure washer is designed for a

pressurized water source such as a city water

faucet. Sucking water out of a tank may cause

pump cavitation and damage to your pump.

However, the inlet pressure of the pump must

notexceed75 psi (5.25bar).

;E.) Alwaysuse a flexible rubber hose for your water

supply. Donotuse rigid piping.

;F.) Do not pump flammable liquids or liquids

containing incompatible chemicalsor solvents.

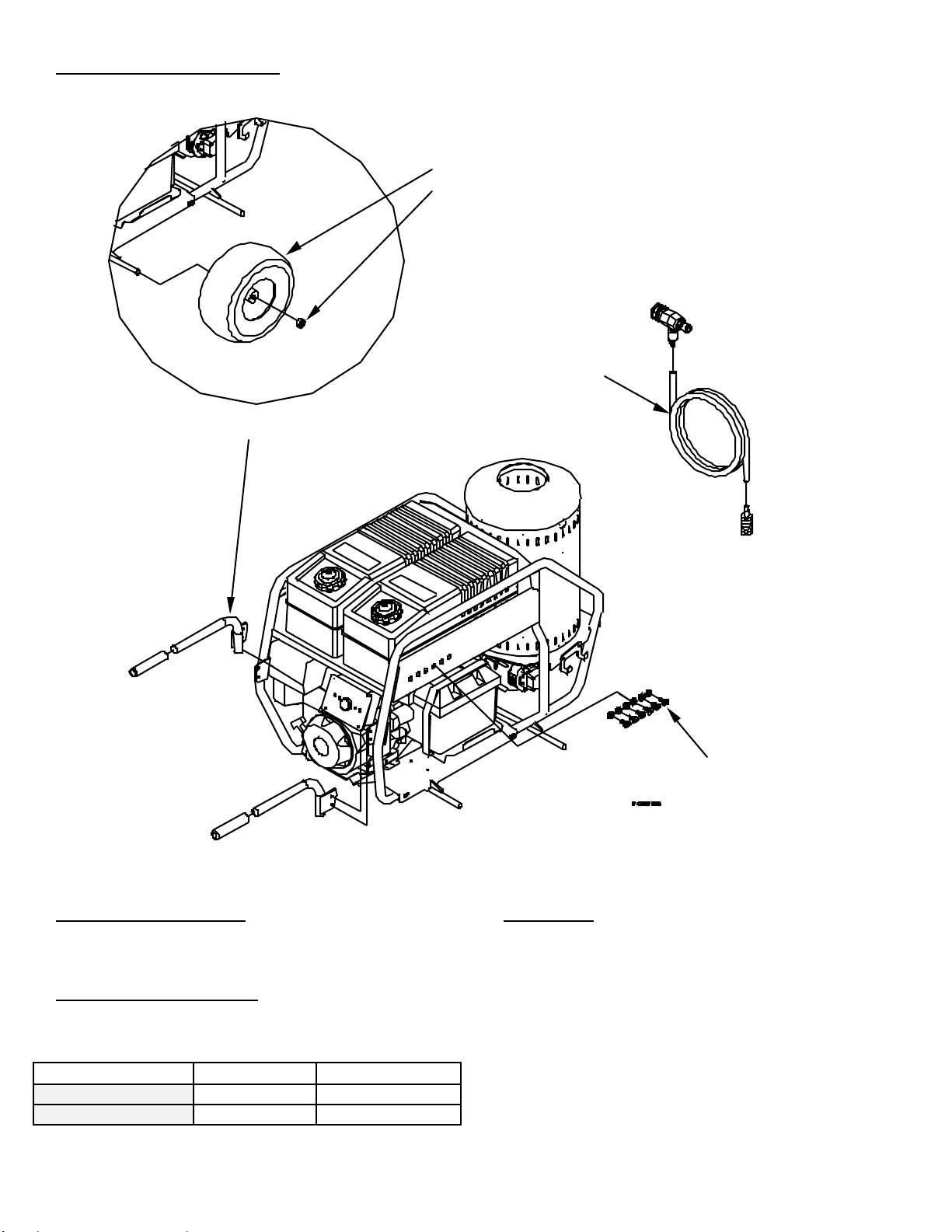

III.) Attach Garden Hose

Remove shipping plug from pump inlet and confirm

rubber washer is in place. Attach garden hose to water

inlet. See Machine ComponentIdentification forlocation

of water inlet.

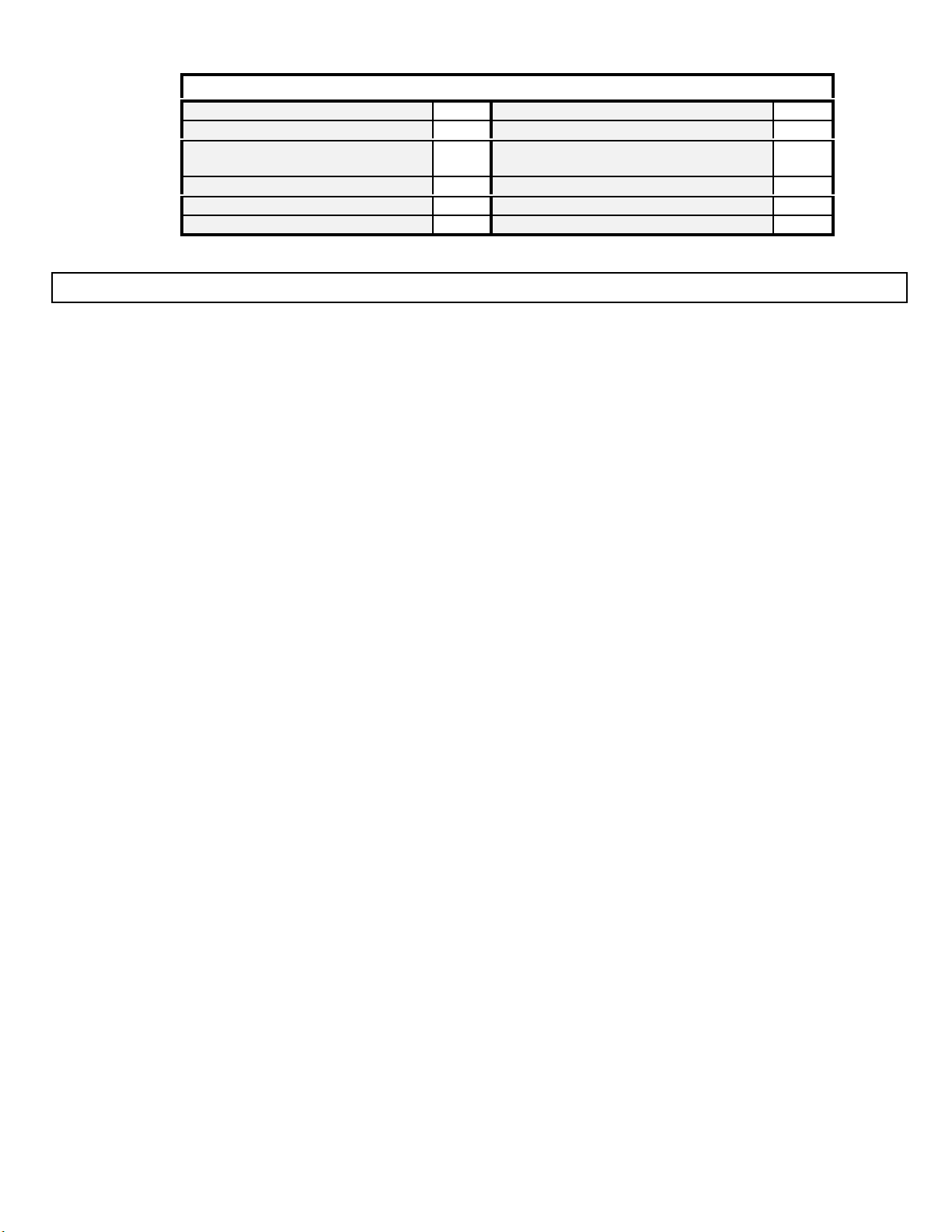

IV.) Attach High Pressure Hose

Your pressure washer hose is equipped with quick

couplers. Simply pull the collar back and push the

coupler onto the nipple. Make sure the collar slides over

theball bearings. Oncethe connection is made, pull on

thehose to assure a positive connection.

Colla

Couple

High Pressure

Output

CORRECT INCORRECT