Nortrac XT20 User manual

Nortrac XT20 and XT25 Tractors

Owner’s Manual

Sold By

Northern Tool & Equipment, Inc.

P.O. Box 1299

Burnsville, MN 55337

Tel.: 1-800-222-5381

www.northerntool.com

YFXT20-25MAN

Nortrac 20XT and 25XT Tractors

Product Identification Data Sheet

Product Part Number

Product Model

Machine Serial Number

Chassis Serial Number

Engine Model

Engine Serial Number

Date of Purchase

Where Purchased/Contact

Information

Owner Name

Complete this form carefully at purchase.

All SNs in this form should be recorded completely (including letters).

Distributed by

Northern Tool + Equipment Co., Inc.

Burnsville, MN 55306-6936

Made in China

User Notices

Thank You

Thank you for purchasing a NorTrac tractor from Northern Tool + Equipment Company. We value you as a

customer and wish you many years of safe and satisfied use of your tractor.

Using Your Owner’s Manual

This Owner’s Manual is an important part of your tractor and should remain with the tractor if you sell it.

Read this Owner’s Manual to help you and others avoid personal injury or damage to the tractor. This manual

provides information on the safest and most effective use of the tractor. It will help you and others you might

train to operate the tractor safely and correctly.

If you use the tractor with an implement or other attachment, use the safety and operating instructions in the

owner’s manual for that implement or attachment along with this Owner’s Manual so you can operate the

implement safely and correctly with the tractor.

While the tractor shown in this manual may differ slightly from your tractor model, the instructions in this manual

will apply to your manual unless otherwise stated.

Disclaimer

The 20XT and 25XT tractor and its components may be changed by the manufacturer at any time without notice

and may not correspond to the contents of this Owner’s Manual.

Overview

This manual describes safety precautions as well as running-in, proper usage, technical maintenance, adjustment,

faults and troubleshooting methods for various parts of the Nortrac XT tractors. The manual gives an in-depth

look and should be used as a reference tool for owners and maintenance personnel.

In this manual, the safety alert symbol prompts important safety information. When this

symbol is seen, you should be alert to possible injuries or affects to the service performance of the machine.

WARNING: Alerts you to safety hazards that could result in serious injury or even death.

NOTICE: Alerts you to actions that could result in minor injuries or could damage the tractor or

it’s implements and thus result in possible safety hazards.

IMPORTANT ISSUE: Issues that may result in damage to the tractor, related machinery and/or the

environment.

NOTE: Provides additional information on a given topic.

Please read the messages that follow the symbol carefully and make other operators aware of any potentially

hazardous situations. This manual is an integral part of the product and should be kept with the tractor.

Please keep it in a safe, dry place. If you encounter any sections that you do not understand while going

over the manual, please call 1-800-222-5381 for assistance.

Only those familiar with this manual and the characteristics of this machine should be allowed to

operate, service and maintain the tractor. In addition, some government regulations specify that no

one under the age of 16 may be employed to operate power machinery. (Refer to U.S. Department

of Labor, Employment Standards Administration, Wage and Hour Division, Child Labor Bulletin

#102)

In employment conditions, current OSHA regulations state in part: “At the time of initial

assignment and at least annually thereafter, the employer shall instruct every employee in the safe

operation and servicing of all equipment with which the employee is, or will be, involved.”

Observe the accident prevention rules as well as other safety regulations and local traffic rules at all times.

The manufacturer is not liable for any damage to the machine or personal injury resulting from any

unauthorized refitting of this machine or use of the tractor for tasks that are outside the scope of the tractors

usage guidelines.

Table of Contents

Table of Contents

1.Safety Precautions.....................................................................................................................................1

1.1 Safety rules and notices of use .................................................................................................................1

1.2 Safety warning symbols ...........................................................................................................................6

1.3 Preventing farm machine hazards...........................................................................................................10

2. Operating Instructions...........................................................................................................................14

2.1 Product description.................................................................................................................................15

2.2 Tractor operating mechanism and instructions.......................................................................................15

2.3 Starting the engine..................................................................................................................................20

2.4 Starting the tractor..................................................................................................................................22

2.5 Steering the tractor .................................................................................................................................22

2.6 Shifting the tractor..................................................................................................................................23

2.7 Differential lock operation......................................................................................................................23

2.8 Front drive axle operation ......................................................................................................................24

2.9 Tractor braking.......................................................................................................................................24

2.10 Tractor parking and engine shutdown ..................................................................................................25

2.11 Use, assembly and disassembly of the tire ...........................................................................................25

2.12 Use of counterweight............................................................................................................................25

2.13 Driver’s seat adjustment.......................................................................................................................26

2.14 Hydraulic suspension operation............................................................................................................26

2.15 Tractor break-in....................................................................................................................................33

2.16 Common faults and troubleshooting methods......................................................................................35

3. Accessories, Spare Parts and Consumables..........................................................................................43

3.1 Accessories.............................................................................................................................................43

3.2 List of consumables................................................................................................................................43

4. Maintenance Instructions......................................................................................................................44

4.1 Technical maintenance regulations.........................................................................................................44

4.2 Clutch adjustment and maintenance.......................................................................................................48

4.3 Brake adjustment and maintenance........................................................................................................50

4.4 Differential lock adjustment...................................................................................................................51

4.5 Steering system adjustment....................................................................................................................52

4.6 Front drive axle adjustment....................................................................................................................53

4.7 Hydraulic lifting mechanism adjustment................................................................................................54

Table of Contents

4.8 Battery Maintenance...............................................................................................................................55

4.9 Dry air cleaner instructions ....................................................................................................................56

4.10 Fan belt adjustment...............................................................................................................................56

4.11 Engine oil sump level check and oil replacement.................................................................................57

4.12 Fuel filter maintenance.........................................................................................................................57

4.13 Engine oil filter maintenance................................................................................................................58

4.14 Lifter hydraulic oil filter maintenance..................................................................................................58

4.15 Front drive oil level check....................................................................................................................58

4.16 Transmission mechanism maintenance ................................................................................................59

4.17 Lifter assembly maintenance................................................................................................................59

4.18 Maintenance of fuel tank......................................................................................................................60

4.19 Tire inflation pressure...........................................................................................................................60

4.20 Engine cooling system maintenance.....................................................................................................61

4.21 Bleeding the fuel system ......................................................................................................................61

5. Storage.....................................................................................................................................................62

5.1 Causes of damage...................................................................................................................................62

5.2 Tractor storage........................................................................................................................................62

5.3 Storage period maintenance of the tractor..............................................................................................63

5.4 Removing tractor from storage...............................................................................................................63

6. Transportation........................................................................................................................................64

7. Technical Specifications .........................................................................................................................65

7.1 Main technical specifications for XT series two-wheel drive tractors....................................................65

7.2 Main technical specifications for XT series four-wheel drive tractors...................................................68

8. Disassembly and Disposal......................................................................................................................70

9. Warranty Terms......................................................................................................................................71

10. Appendixes ............................................................................................................................................73

10.1 Tractors fuels, oils and solutions ..........................................................................................................73

10.2 Torque table of major bolts and nuts ....................................................................................................74

10.3 Tractor rolling bearing..........................................................................................................................75

10.4 Seals of the tractor chassis....................................................................................................................76

Safety Precautions

1

1. Safety Precautions

1.1 Safety Rules and Notices of Use

Reading Prior to Use

1 The instructions for use, maintenance, and the safety warning identifiers

should be fully read and understood.

2. The correct usage and operating method should be observed.

3. Local traffic rules and safety regulations must be observed at all times.

Fig. 1-1 Reading prior to use

AQualified Operator

1. When operating the machine, the driver must use sound judgment.

2. Never operate the tractor if you have been drinking or are tired.

3. The driver should read and understand this operators manual.

4. Drive slowly at first in order to test your skill level.

Clothing

During the operation, the driver should avoid loose fitting clothing. Baggy

and bulky clothes are not recommended.

Fig.1-3 Driver’s clothes

Fuel Usage

1. Diesel fuel is a combustible substance. Keep all fuel away from

open flames.

2. The engine should be shut down prior to refueling.

3. Smoking is strictly prohibited when the fuel system is being

refueled and overhauled.

4. Use a clean rag to wipe off any fuel or machine oil overflow.

5. The requirements set out in the “Appendix” must be strictly complied with for fuel and lubricating oil

quality assurance.

Fig.1-4 Use of fuel

Fig.1-2 A qualified operator

Safety Precautions

2

Waste Oil Placement

1.Used machine oil is a waste fuel substance. Do not discard at random.

2.The used acid from the battery is harmful to the environment. Do not discard at

random.

Fig.1-5 Waste oil placement

Pipeline Leaks

Do not use your hand to check for leaks in the high-pressure oil pipe. You may use a

paste- or wood-board to test for possible leaks.

Fig. 1-6 Pipeline leaks

Removing the Radiator Cap

Never remove the radiator cap when the engine is hot. Turn the engine off

and wait until the engine has cooled, then turn the cap to the first position.

Once pressure has been reduced, you can then remove the cap.

Fig. 1-7 Removing the radiator cap

Electric Parts Maintenance

1. Remove the ignition switch key.

2. Never service any of the tractor’s electrical components without first

removing the ground wire from the battery.

Fig. 1-8 Electric parts maintenance

In Case of Defects orAbnormal Operation

1. The tractor should not be operated “in spite of defects”. In case of a

lack of oil pressure, excessively low oil pressure, an overly high water

temperature or unusual sounds and smells, stop the tractor and

troubleshoot the problem.

2. During lubrication maintenance and for any on-field adjustment, the

engine should be shut down.

Fig. 1-9 In case of defects or abnormal operation

Safety Precautions

3

Emergency Procedures

1. In case of a brake failure, hold the steering wheel firmly, wait until the tractor has come to a complete stop

and then shut down the engine.

2. If the steering malfunctions, brake immediately and shut down the engine.

3. If fire should occur, immediately shut down the engine. If a fire extinguisher is available, put out the

flames at the source of the flame; if a fire extinguisher is not available, use sand or other non-flammable

substance to fight the fire.

4. After any safety incident, immediately dial any necessary emergency services (hospital, fire department)

according to the situation and administer first-aid as necessary.

Warning:

1. Always operate the tractor in a safe and responsible manner to avoid injury and possible death.

2. Pay special attention to any obstacles that may impede progress or cause an accident before

starting the tractor. Also check for obstacles and impediments that may be covered by the

tractor, an implements or a trailer.

3. Never leave the driver’s seat to start and operate the tractor. Prior to the startup, make sure that

various shift levers are in the neutral position, the throttle lever and the front drive control handle

are disengaged and the lifter operating handle is in neutral to prevent the sudden start up of

accessories.

4. Do not start the engine by bridging-over the solenoid. If you do this, the tractor could lose

control and cause a dangerous situation, which could lead to injury or death.

5. Make sure that the pedals are free from obstacles and able to move unhindered to their home

position. Never keep anything on the floor or around the pedals that could hinder treadle travel. An

extra foot blanket or non-standard floor mats should not be used as they can hinder pedal

movement and cause serious injury or damage.

6. Never get on or off the tractor while it is in motion.

7. Never climb under the tractor while the engine is running.

8. Always remove the keys, set all shift levels to neutral and lock the auxiliary brake handle

before exiting the cab to avoid accidental start up and to keep the tractor from moving

unattended.

9. Keep your speed under control at all times. Brake prior to turning in order to maintain your load

and avoid tipping.

10. When crossing a bridge or going through a tunnel, pay full attention to the load height.

11. Use the lowest gear with the clutch enabled on a down slope. Never put the tractor in neutral and

coast downhill as this can cause instability. Never change gears on a down slope as this can cause

instability and a possible rollover.

12. Avoid sudden turns at high speed or using unilateral braking to turn as this can result in

instability.

13. When driving on roads, obey all local traffic indicators and laws.

14. Keep a safe distance between the tractor and any other vehicles that may be on the road.

15. Roadbeds along the ditch line tend to be more fragile. Pay specific attention to the weight of

Safety Precautions

4

Caution:

your vehicle when riding on the road shoulder.

16. Never overload the tractor. Running the tractor over the specified limits can cause damage to

the tractor and can result in injury.

17. When driving at night, make sure that you have proper lighting to avoid any collisions.

18. When working in tall grass or hay, a spark-extinguishing device must be affixed to the exhaust pipe to

avoid accidental fires.

19. Always slow down when working in wet or rainy conditions to avoid slippage and instability.

20. Always operate the tractor at a safe speed.

21. When attaching implements, make sure all 3-Point hitch pins are securely fastened. When

disconnecting implements assure all 3-Point hitch pins are disconnected.

22. When lifting, reduce engine speed to avoid damage to tractor and personal injury.

23. Upon charging the battery, insure proper ventilation.

24. Beware of overhead high voltage transmission line!

1. Check nuts, bolts, nuts and other loose components regularly and tighten as required. This could

prevent a potentially dangerous situation.

2. When the tractor runs by power take-off (PTO), make sure that there is a safety shield installed.

Never approach the PTO shaft when it is running. Never take sudden turns when the PTO shaft is

under load, as this can damage the universal joint or the PTO shaft. When the PTO shaft is not in

use, the lever should be returned to the neutral position.

3. After parking and before shutting down the tractor, the driver should remove the key from the

ignition, set all gearshift levers to the neutral position, and lock the brake handle. This will

prevent the tractor from accidental startup and unattended movement.

4. When parking the tractor on an incline, the hand braking should be engaged and the engine shut

down. Put the tractor in gear, apply the auxiliary brake and use the triangle chocks to block the rear

wheels.

5. Tire installation and adjustment should be done by trained personnel only, using special tools.

Faulty installation may cause a serious accident or damage.

6. When cleaning the radiator, shut down the tractor and allow the tank to cool for.

7. Pay attention to all safety precautions when replacing or installing new parts on your tractor.

Safety Precautions

5

Important:

1. Always operate the tractor according to the specified running-in requirements. This will prolong

the life of your tractor.

2. Prior to starting the tractor, the oil system, cooling system and electric circuits must be examined.

After startup, strict attention should be paid to the various instruments.

3. Before activating the PTO shaft, make sure that the equipment is properly inspected. When using

PTO implements, the angle between the PTO shaft and the universal joint drive shaft should be

no more than a 15° angle; the hydraulic operating control should be neutral, and after the farm

tool has been lifted, the included angle between the power take-off shaft and the universal joint

drive shaft should be at no more than 20° angle. Never use the implement without checking for a

proper connection with the power take-off. This can cause damage to the implement and severe

damage to the tractor clutch and power train. To increase work efficiency, the power supply

should never be shut off at the curve and the lifting height must be maintain at 200mm above the

ground.

4. Hanging farm implements can shift tractor weight and should be low to the ground before

exiting the tractor.

5. Antifreeze should always be used in the cooling system.

6. The front driving axle of tractor should only be engaged in agricultural instances and when roads

are muddy. Overuse of the front drive axle may result in premature wear of the tires and

transmission problems.

7. Only use parts recommended by the manufacturer to replace worn or broken components.

8. Never rest your foot on the brake or clutch pedal when the tractor is in motion as this can cause

premature wear of the brakes and clutch system.

Safety Precautions

6

9. When detaching the tractor from any implements, the upper lever of the suspension unit should

be adjusted to the shortest travel and the limit lever adjusted to prevent the implements from

swinging out of control. The locking nuts on the upper and limit levers must be tighten in order

to guarantee travel safety and to avoid damage to the tractor and the machinery.

1.2 Safety Warning Symbols

Caution:

1. All safety identifiers should be visible and easy to read. When dirty, wash with soapy water and clean them

with a soft rag.

2. When the safety identifiers are lost or damaged, contact the sales department or the manufacturer for

replacement stickers.

3. When replacing parts with attached Safety warning symbols, the safety identifiers that correspond to that

specific part need to be updated as well.

4. To prevent injury, accidents and damage, always comply with safety warning identifiers.

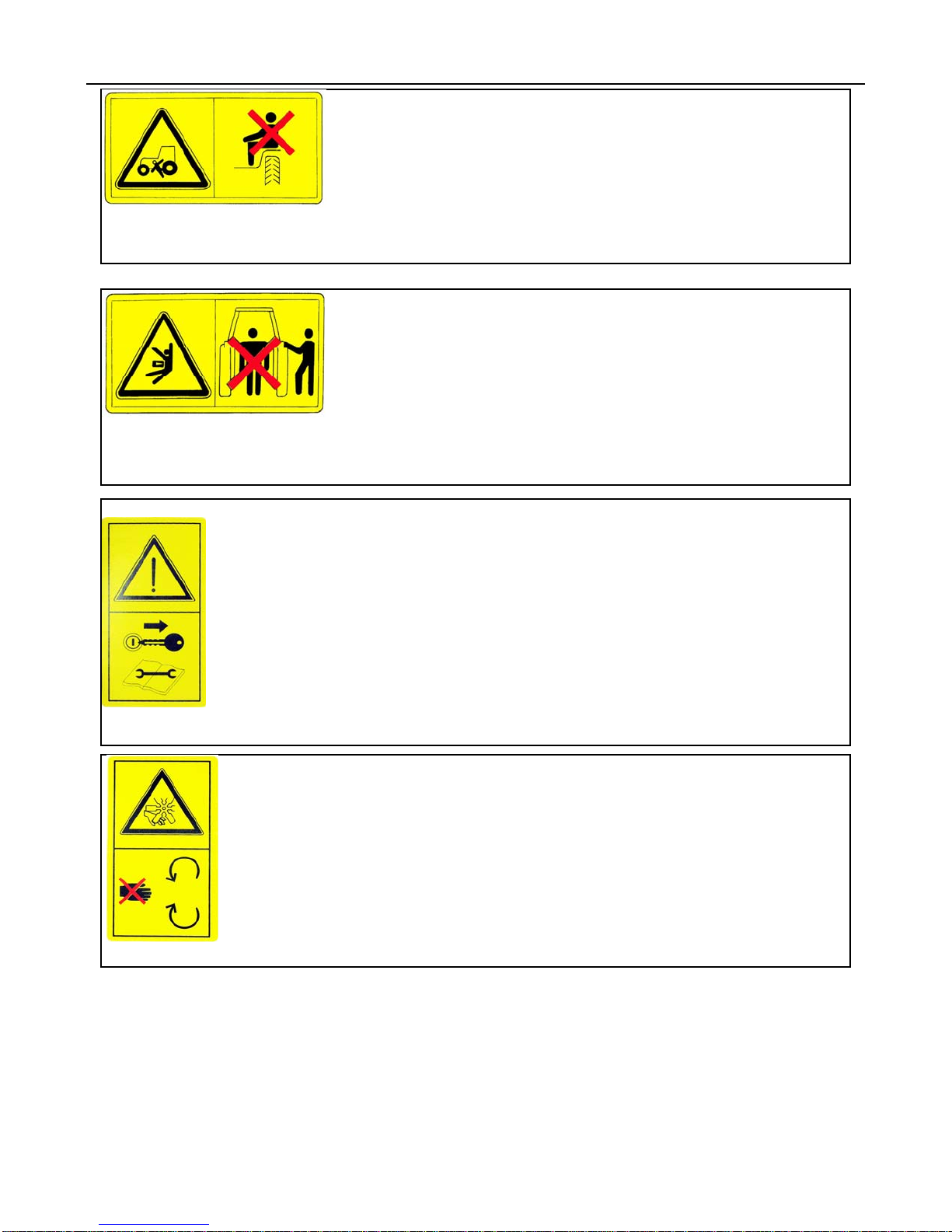

During machine operation, keep a safe distance from the hot surface of the

machine, as it can cause serious burns. Post position: outer side of damper,

water tank flank.

Fig. 1-10 Safety warning identifier IX

Please keep a safe distance from the tractor when it operating, to avoid

any personal injuries.

Post position: left from the rear side of mudguard.

Fig. 1-11 Safety warning identifier IX

Safety Precautions

7

Never sit on the fender when the tractor is operating as this could

result in falling from the vehicle and possible injury.

Post position: front side of the mudguard.

Fig. 1-12 Safety warning identifier VI

To avoid injury, stay a safe distance from the lifting lever when the lifting

lever control system is in operation.

Post position: right rear side of the mudguard

Fig.1-13 Safety warning identifier III

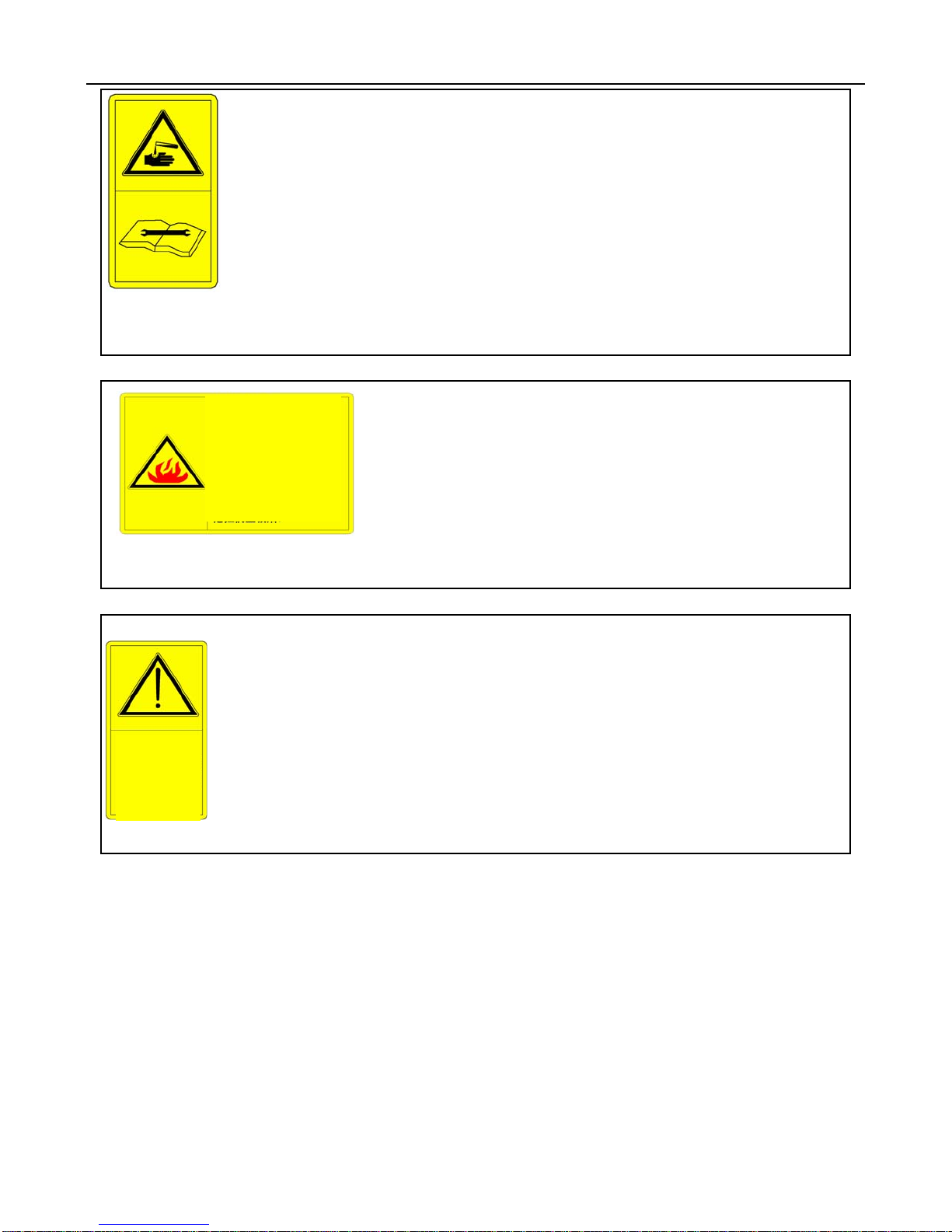

Always shut down the engine and remove the key prior to maintenance and adjustment.

Post position: in front of the instrument panel.

Do not open or dismantle the safety hood and keep your hands free of the engine when it is

running.

Post position: on the engine hood.

Fig. 1-15 Safety warning identifier IX

Fi

g

. 1-14 Safet

y

warnin

g

identifier IX

Safety Precautions

8

Always start the engine from a secure position in the pilot seat. Post position: in front of

the instrument panel.

Post position: in front of the instrument panel.

Read and understand all instruction for use, including the meaning of all non-lettered

safety symbols.

Post position: in front of the instrument panel.

Fig. 1-17 Reads the instruction identifiers

Never touch moving parts when the tractor is in motion.

Post position: on the PTO shield.

Fig. 1-18 PTO safety identifiers

Please follow the requirements for fuse connections, otherwise it may cause damage to the electric elements or

create a fire.

Post position: near the electric appliance box.

Fig. 1-19 Fuse safety warning symbol

Stop

Fig. 1-16 Safety startup symbol

Please follow the requirements for fuse

connections, otherwise it may cause

damage to the electrical elements or create

a fire.

Safety Precautions

9

In order to prevent

from the personal

injury, please install

the safety shield on

the PTO shaft when it

is not in use.

For battery service, carefully read the instruction for use to understand the correct

maintenance procedures.

Post position: on the surface of the battery.

Fig. 1-20 Battery symbol

Topreventtheriskoffire,neverrefuelthetractorwhileitisrunning.

Cleangrease,fuelandoilspillimmediately.Whenthetractorisfittedwith

apiggybackreaper,smokingisprohibited.

Postposition:nearthefueltank

Fig. 1-21 Refueling fire protection identifiers

To prevent personal injury, please install the safety shield on the PTO shaft when it is not in use.

Post position: on the pneumatic brake cylinder

Fig. 1-22 PTO safety identifiers

To prevent from fi

r

e

1 It is prohibited to refuel on the

work site and during the operation

of tractor

2 Stay far away from the kindling

while refueling.

3 grease traces on the oil tan

k

should be cleaned up.

4 When the tractor is fitted with the

piggyback reaper, it is prohi

b

ited to

smoke on the work site and on

board of tractor.

Safety Precautions

10

Preventing Farm Machine Hazards

The following article describes important general safety precautions for machinery such as the NT-204C/NT-254 tractor.

It is reprinted here with permission from Professor Thomas L. Bean, Safety Leader and Professor, Department of Food,

Agricultural, and Biological Engineering, The Ohio State University Extension, The Ohio State University.

AEX-593-91

Thomas L. Bean

Each year, 2,600 farm residents are killed and 230,000 disabled in farm-related injuries, many due to farm machinery.

Farm machinery uses mechanical power to do work. This creates a number of possible hazards for both operators

and bystanders. Even though manufacturers take many steps to make machinery safe, all hazards cannot be removed.

Some machine parts cannot be completely shielded and still do their job. For instance, a totally enclosed cutting

blade could not cut.

Many machinery-related accidents result from human error. The operator either forgot something, took a shortcut or

a risk, ignored a warning, wasn’t paying close attention, or failed to follow safety rules. In addition, guards removed

for maintenance often aren’t replaced.

There are many different kinds of farm machinery: mowers, tractors, shredders, harvesters, grinders, blowers, augers,

balers, etc. They all have similar characteristics and hazards. You can be cut, crushed, pulled in or struck by an

object thrown by these machines. They have cutting edges, gears, chains, revolving shafts, rotating blades, pinch

points and other hazards. You can also be injured if you fall while working on or near any of these machines.

Accidents with farm machinery are often serious, even fatal. It is important to recognize and be alert for machine

hazards and to take precautions to avoid injury.

Shear and Cutting Points

Shear points (Fig. 1 below) are created when the edges of two objects are moved together closely enough to cut a soft

material, as with a pair of shears or an auger. Cutting points are created when a single object moves forcefully or

rapidly enough to cut, as with a rotary mower blade.

Figure 1

Safety Precautions

11

Both shear and cutting points are created on machinery designed to cut, such as harvesters, and on those that are not

designed to cut, such as augers. They are hazardous because of their cutting force and they often move so rapidly

that they may not be visible, so it is easy to forget they are operating or to underestimate the hazard.

Because some shear and cutting points cannot be guarded, it is important to be aware of their hazard and stay alert

when they are operating. It is also important to warn others and to look out for their safety. This is especially true

if there is a danger of thrown objects while using cutting-type equipment.

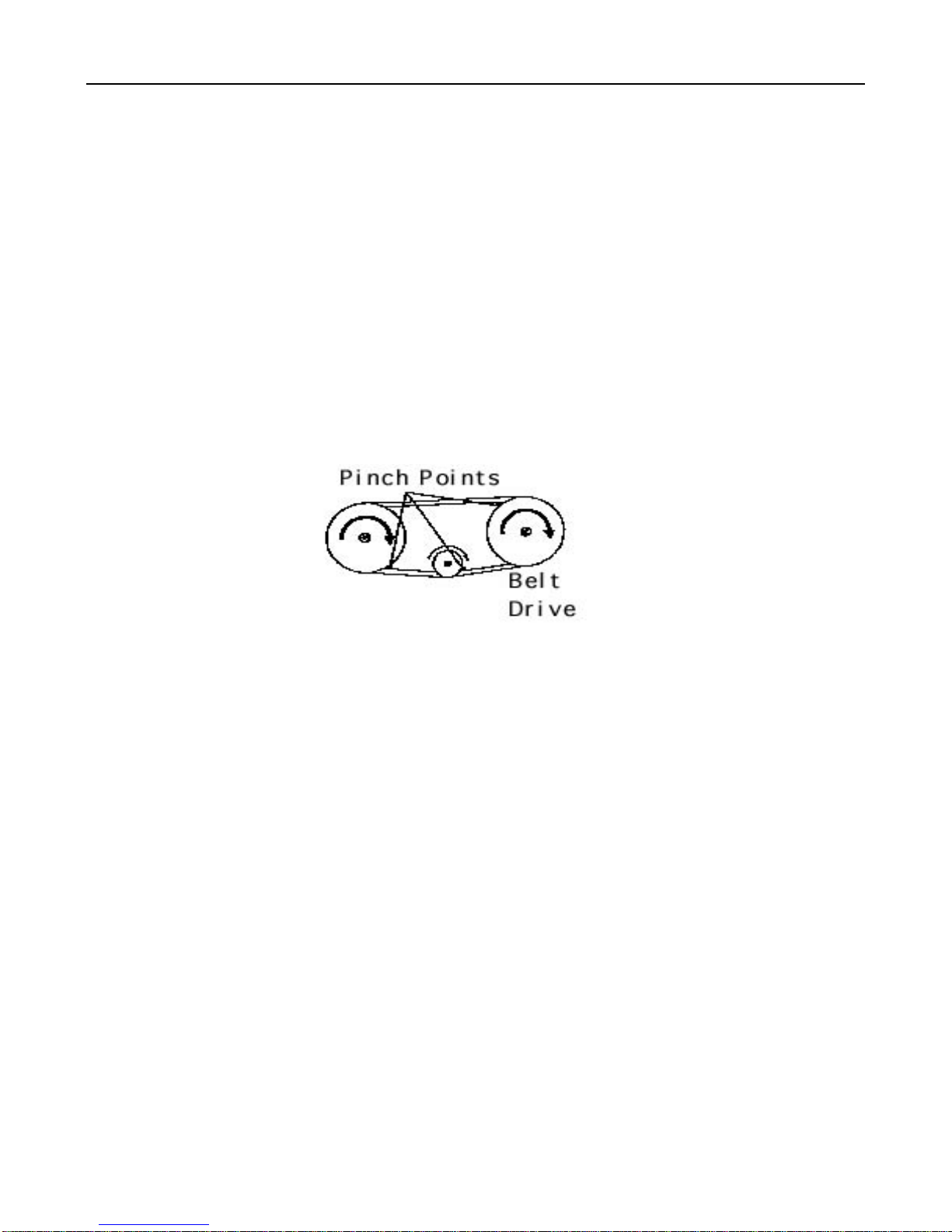

Pinch Points

Pinch points are another hazard of farm machinery (Fig. 2 below). Pinch points (which should be more

appropriately named mangled or maimed points) are formed when two rotating objects move together and at least one

of them moves in a circle. For example, the point at which a belt runs into a pulley is a pinch point. Belt drives,

chain drives, and gear drives are other sources of pinch points in power transmission devices. Feed rolls, gathering

chains and similar equipment designed to draw crops into the machine also create pinch points.

Fingers, hands and feet can be caught directly in pinch points, or they may be drawn into the pinch points by the

inertia of the moving part or loose clothing that becomes entangled. Contact may be made by falling or brushing

against unshielded parts. You can become entangled in pinch points if you take chances and reach or work near

rotating parts. Machines move too fast to get out of a pinch point once you become caught.

To avoid injury from pinch points, be aware where pinch points occur and avoid them. Wear clothing that fits well

and is not loose or floppy. Never reach over or work near rotating parts. Turn off machinery to work on it.

Always replace shields removed for maintenance.

Wrap Points

Rotating shafts are the most common source of wrap-point accidents, although any exposed machine part that rotates

can be a wrap point. A cuff, sleeve, pant leg, long hair or just a thread can catch a rotating part and result in serious

injury. Entanglement with a wrap point can pull you into the machine, or clothing may become so tightly wrapped

that you are crushed or suffocated. In other cases, you could be thrown off balance and fall into other machinery

parts.

Even a perfectly round shaft can be hazardous if there is enough pressure to hold clothing against the shaft. Hazards

Figure 2

Safety Precautions

12

increase with shafts that are not round. Clothing is more likely to catch if there is dried mud or manure on the shaft,

or if the shaft is nicked. Ends of shafts that protrude beyond bearings are also dangerous. Universal joints, keys

and fastening devices can also snag clothing.

Check all equipment for potential wrap points and, if possible, shield those that can be shielded. Replace any

damaged manufacturer-installed warning labels and place warnings on equipment parts not previously labeled. In

addition, consider painting them a bright color, perhaps with wide stripes. Be aware of wrap points and be alert to

their danger.

Crush Points

Crush points are created when two objects move toward each other or one object moves toward a stationary object.

For example, hitching tractors to implements (Fig. 3 below) creates a potential crush point.

Hitch accidents most commonly occur to fingers placed at the hitching point. Wait until the tractor has stopped

before stepping into the hitching position. If possible, arrange the hitch point so that the tractor can be backed into

position without anyone between. Always know what the other person is doing.

Failure to safely block up equipment can result in a fatal crushing injury. A jack may slip, a hose or overhead

support may break, or the equipment may roll. Take extra precautions when working with machinery that is raised

for any reason. The operator’s head or chest can be crushed between the equipment and a low beam or other part of

a farm building. These accidents usually occur when the machine is being operated in reverse. Tree limbs are also

potential hazards when working with tractors and other machinery.

To prevent being crushed or pinned, recognize and avoid potentially dangerous situations. Block all machinery

securely if you must work under it. If an implement can roll freely, block its wheels so it cannot roll.

Free-Wheeling Parts

Many machine parts continue to spin after the power is shut off, including cutter heads of forage harvesters, hammer

mills of feed grinders, rotary mower blades, fans and flywheels. Never touch these parts until they have stopped

moving. This could take 2 to 21/2 minutes.

Figure 3

Safety Precautions

13

Springs

Compressed springs (Fig. 4 below) will expand with great force when released, and springs that are stretched will

contract rapidly when released. Know what direction a spring will move and how it might affect another machine

part when released, and stay out of its path.

Burn Points

Be aware of burn points: mufflers, manifolds and even gear cases under adverse climatic conditions. They may not

be severe enough to seriously maim, but they can startle the operator enough to cause him or her to “jump” into more

deadly danger.

Hydraulic Systems

Hydraulic systems contain fluid under extreme pressure. Before loosening, tightening, removing or otherwise

working with any fittings or parts, relieve this pressure. Jet streams from even pinhole leaks can penetrate flesh. In

addition, the liquid is often hot.

Before attempting any service on hydraulic systems, shut off the engine that powers the hydraulic pump. Lower the

implement to the ground and relieve the pressure. Follow instructions in the operator’s manual because the specific

procedures for servicing the systems are very important to your safety.

Funded in whole or in part from Grant Number U05/CCU506070-01, "Cooperative Agreement Program for

Agricultural Health Promotion Systems," National Institute for Occupational Safety and Health.

Reviewed by Dr. Randall Wood and Dr. Warren Roller.

Figure 4

Operation Description

14

2. Operator Instruction

Note: operating the tractor properly can bring efficiency of the tractor into full play to reduce tractor wear

and prevent an accident and ensure operator to complete farm and road operations fast, efficiently, in low

consumption and safety mode

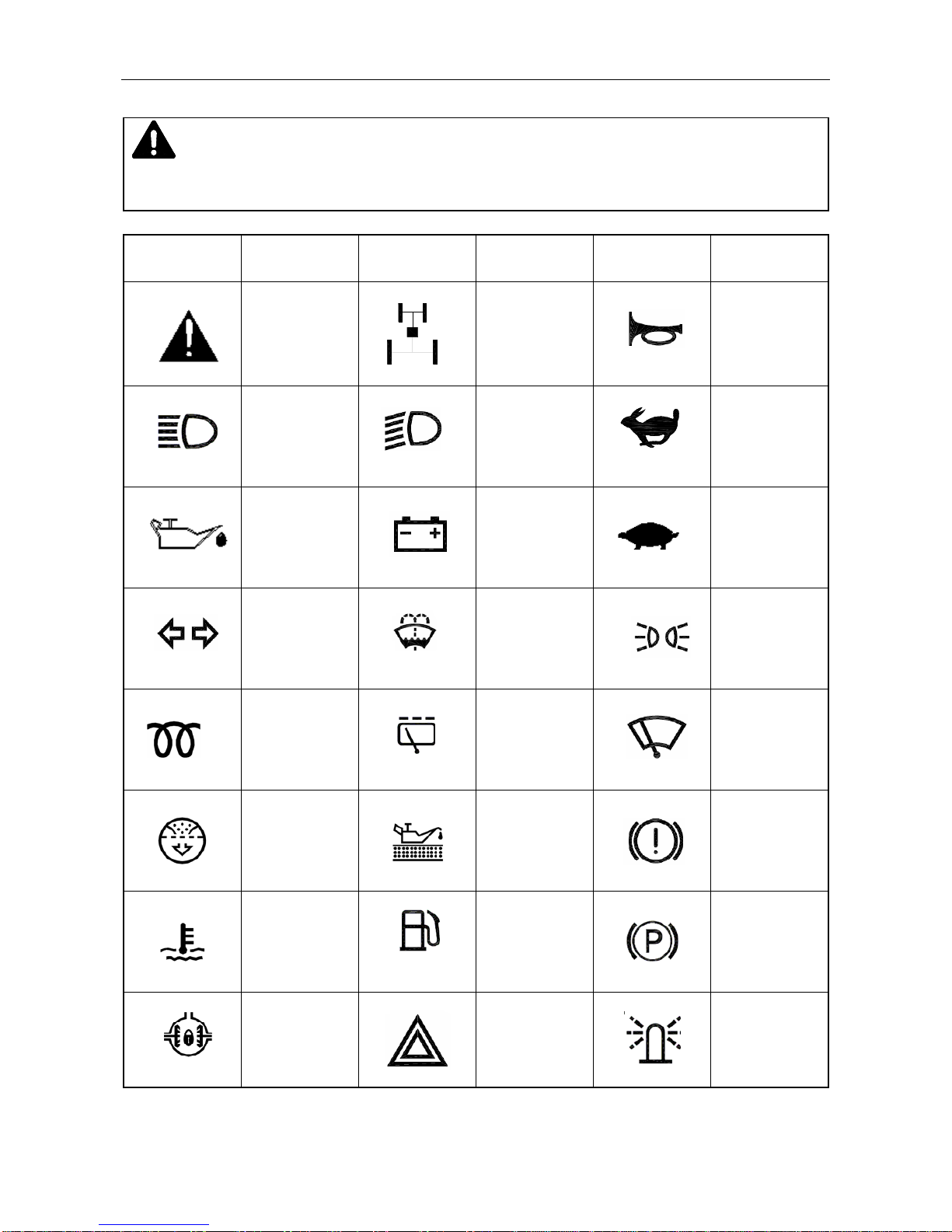

Table 2-1 Common symbols

Symbols Definition Symbols Definition Symbols Definition

Safety warning

identifier

Four-wheel

drive

Horn

High beam

Dipped

headlight

Quick

Engine oil

pressure

Charging and

discharging

indication

Slowly

Steering light

indicator

Syringe

Position lamp

Engine

preheated

Rear

windscreen

wiper

wiper

Air filter

blockage

warning

Hydraulic oil air

separator

Pneumatic

braking

invalid/failure

Engine coolant

temperature

Quantity of fuel

oil

Parking brake

Differential lock

Warning for

danger

Warning lamp

This manual suits for next models

1

Table of contents

Other Nortrac Tractor manuals

Popular Tractor manuals by other brands

Komatsu

Komatsu D275A-5R brochure

Cub Cadet

Cub Cadet 5252 Operator's manual

MacDon

MacDon M Series Unloading and assembly instructions

Wolf Garten

Wolf Garten Bluepower 92160 ? Original operating instructions

International

International 982 Operator's manual

Grouser Products

Grouser Products Ag Pro Plus installation instructions