Nortrac 40XTD User manual

40XTD Bulldozer

Owner’s Manual

WARNING: Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury.

Item #819299

Page 2/ 48

Thank you very much for choosing a NorTrac™product!

For future reference, please complete the owner’s record below:

Serial Number/Lot Date Code: ________________________________

Purchase Date: ____________________________________________

Save the receipt, warranty, and this manual. It is important that you read

the entire manual to become familiar with this product before you begin

using it.

This bulldozer is designed for certain applications only. Northern Tool

and Equipment is not responsible for issues arising from modification or

improper use of this product such as an application for which it was not

designed. We strongly recommend that this product not be modified

and/or used for any application other than that for which it was designed.

For technical questions, please call 1-800-521-0438.

Page 3/ 48

Table of Contents

Intended Use....................................................................................................................................4

Packaging Contents ........................................................................................................................4

Technical Specifications.................................................................................................................4

Important Safety Information ..........................................................................................................6

Specific Operation Warnings..........................................................................................................8

Grounding......................................................................................................................................10

Safety and Product Labels............................................................................................................10

Before Each Use............................................................................................................................14

Operating Instructions ..................................................................................................................16

After Each Use...............................................................................................................................33

Maintenance...................................................................................................................................33

Troubleshooting ............................................................................................................................39

Parts Diagram................................................................................................................................44

Parts List........................................................................................................................................44

Replacement Parts ........................................................................................................................45

Limited Warranty ...........................................................................................................................46

Page 4/ 48

Intended Use

The NorTrac 40XTD Bulldozer is incredibly strong and versatile, perfect for tough earth moving, ground

leveling, road carving, and deforestation jobs for estate owners, landscape contractors, and builders. The 3-

cylinder, diesel engine provides enough power to move tons of dirt, gravel, and other materials around your

jobsite. The manual 8-forward and 2-reverse speed transmission provides the right gear for any situation.

Engine performance is monitored by the fuel, oil pressure, and temperature gauges, as well as the amp meter

and tachometer. With a category 1 rear hitch, the bulldozer can be used with implements such as a backhoe,

post hole digger, cultivator, and more. Includes a heavy-duty seat and easy-to-use controls.

Packaging Contents

•40XTD Bulldozer

•Bulldozer Owner’s Manual

•Bulldozer Parts List

•Tool Set

•Spare Part Set

•Bulldozer Packing List

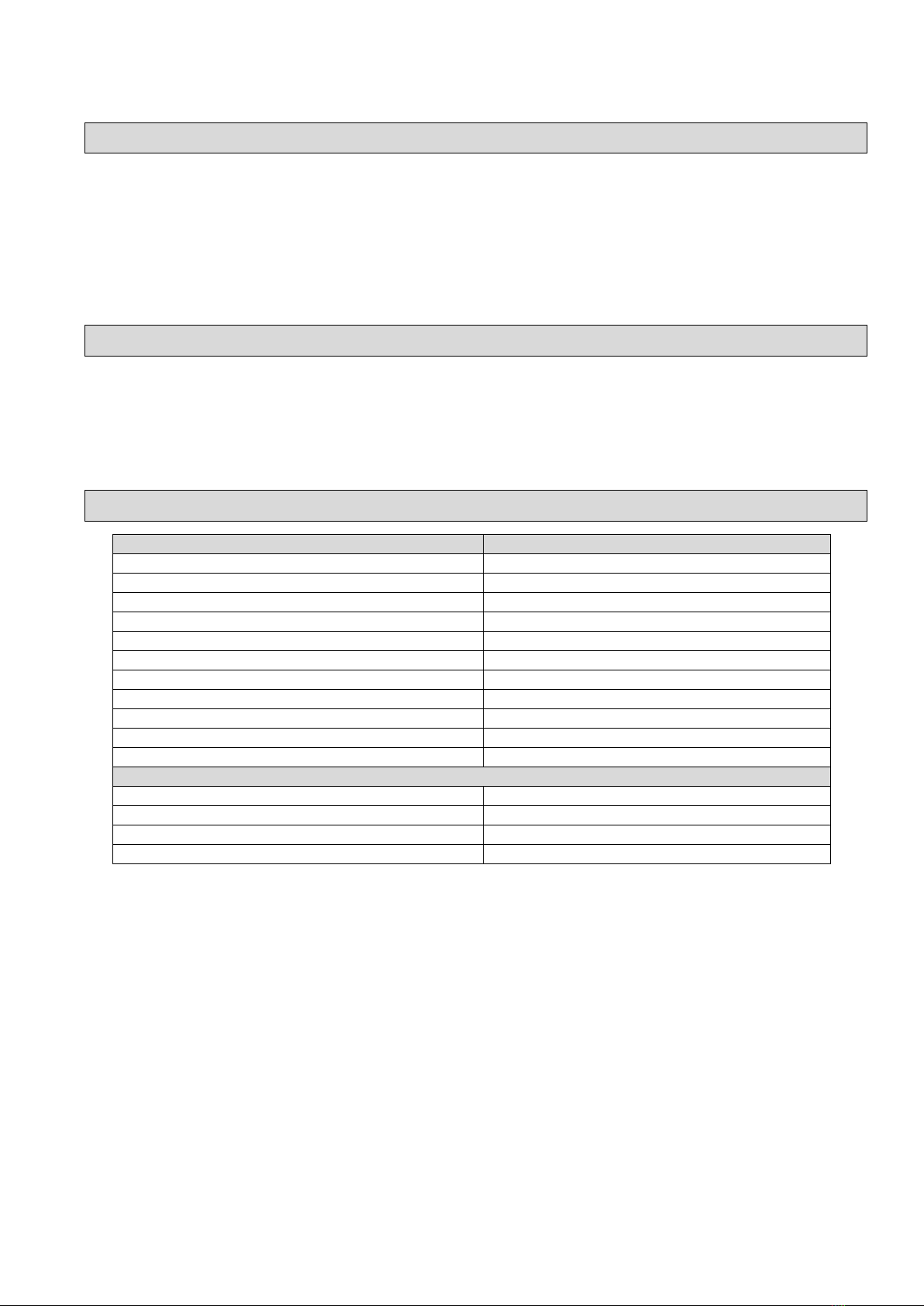

Technical Specifications

Dozer Dimensions

Specification

Overall length, with blade or loader (mm)

2960

Overall length, no blade or loader (mm)

2260

Overall width, with straight blade or loader (mm)

1650

Overall width, no blade or loader (mm)

1440

Overall height to top of ROPS (mm)

2270

Ground contact length (mm)

1400

Track gauge (mm)

1150

Shoe width (mm)

290

Ground clearance (mm)

240

Operating weight (lb.)

6569.78

Max. drawbar pull (lb.)

5423.37

Six-Action Blade

Height of blade (mm)

675

Lift height of blade (mm)

500

Max. digging depth of blade (mm)

80

Blade capacity (m3)

0.67

Page 5/ 48

Performance

Part

Property

Specification

Engine

Model

403F-E17T (Perkins)

Type

3-cylinder, turbo-charged

Cylinder bore

84 mm

Piston stroke

100 mm

Displacement

1.7 L

Max. power

29 kw @ 2800 RPM

Max. torque

120 Nm @ 1800 RPM ± 5%

Fuel

Diesel

Idling

800 r/min

Direction of rotation

Counter-clockwise

Post-processing system

DOC

Emission certificate

EPA tier 4 final

Model

403F-E17T (Perkins)

Transmission

Clutch

Single dry disk diaphragm spring clutch

10”, pedal control

Gearbox

2-shaft, sliding gear shift, 8 fwd+2 rev

Main drive

Spiral bevel gear

Final drive

Externally meshed spur gear

Brake & Steering

(interconnected)

Steering clutch

Dry, ceramic-metallic, multi-disk clutch

Brakes

Brand brakes controlled by pedals

Under Carriage

System

Under carriage frame

Semi-rigid

Track roller (each side)

5+1

Tension device

Helical spring, adjusted by screw

Number of shoes

39 (1pitch=109mm)

Hydraulic Blade and

3-point Hitch

System

Gear pump

Spline Clockwise 26/32DP

Rated capacity

29.4 LPM (7.7 GPM)

(depending on rotation speed of engine)

Rated pressure of relief valve

16MPa (2230 PSI)

Control valve

6-spool

Blade control

Lift: raise, hold, lower, float

Angle: right, hold, left

Tilt: right, hold, left

Blade lift cylinder bore X

stroke/number

Double action 50mm X285mm / 2

Blade angle cylinder bore

X stroke/number

Double action 63mm X280mm / 2

Blade tilt cylinder bore

X stroke/number

Double action 63mm X50mm / 1

Hitch control –1 level

Raise, hold, lower (float)

Cylinder bore X

stroke/number

63mm X 90mm / 1

Lift capacity @ hitch point

7350 N (1650 lb.)

Lifting height @ hitch point

720 mm

Type of hitch

Rear 3-point, category I

Electrical System

Voltage

12V

Alternator

12V 85A

Starter

12V/2 KW

Battery (free maintenance)

90 Ah

Front headlamp/number

30 w/ 2

Roof front/rear led

light/number

30 w/ 4

Power Take-off

Type

Mechanical, dependent

Page 6/ 48

Part

Property

Specification

Two rotary speeds

540 RPM @ engine 1812 RPM

1000 RPM @ engine 1772 RPM

Shaft diameter

35mm (13/8”), 6 splines

Service Capacity

Fuel

28 l (7.4 gal)

Engine oil sump

5.5 l (1.6 gal)

Gearbox

11 l (2.9 gal)

Hydraulic system

26 l (6.8 gal)

Coolant

9 l (2.3 gal)

Final drives (each)

2 l (0.5 gal)

Important Safety Information

⚠WARNING

Read and understand all instructions. Failure to follow all instructions may result in serious injury or

property damage.

The warnings, cautions, and instructions inthis manualcannot cover all possible conditions or situations

that could occur. Exercise common sense and caution when using this tool. Always be aware of the

environment and ensurethat the tool is used in a safe and responsible manner.

Do not allow persons to operate or assemble the product until they have read this manual and have

developed a thorough understanding of how it works.

Do not modify this product in any way. Unauthorized modification may impair the function and/or safety

andcould affect the lifeof theproduct.Therearespecificapplicationsfor whichthe product wasdesigned.

Use the right tool for the job. DO NOT attempt to force small equipment to do the work of larger industrial

equipment. There are certain applications for which this equipment was designed. This product will be

safer and do a better job at the capacity for which it was intended. DO NOT use this equipment for a

purpose for which it was not intended.

Industrial or commercial applications must follow OSHA requirements.

⚠WARNING

PROP 65

Breathing diesel engine exhaust exposes you to chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm.

•Always start and operate the engine in a well-ventilated area.

•If in an enclosed area, vent the exhaust to the outside.

•Do not modify or tamper with the exhaust system.

•Do not idle the engine except as necessary.

Page 7/ 48

⚠WARNING

WORK AREA SAFETY

Inspect the work area before each use. Keep work area clean, dry, free of clutter, and well-lit. Cluttered,

wet, or dark work areas can result in injury. Using the product in confined work areas may put you

dangerously close to cutting tools and rotating parts.

Do not use the product where there is a risk of causing a fire or an explosion; e.g., in the presence of

flammable liquids, gases, or dust. The product can create sparks, which may ignite the flammable liquids,

gases, or dust.

Do not allow the product to come into contact with an electrical source. The tool is not insulated and

contact will cause electrical shock.

Keep children and bystanders away from the work area while operating the tool. Do not allow children to

handle the product.

Be aware of all power lines, electrical circuits, water pipes, and other mechanical hazards in your work

area. Some of these hazards may be hidden from your view and may cause personal injury and/or

property damage if contacted.

⚠WARNING

PERSONAL SAFETY

Stay alert, watch what you are doing, and use common sense when operating the tool. Do not use the

tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention

while operating the tool may result in serious personal injury.

Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Air

vents on the tool often cover moving parts and should be avoided.

Wear the proper personal protective equipment when necessary. Use ANSI Z87.1 compliant safety

goggles (not safety glasses) with side shields, or whenneeded, a face shield. Use a dust mask in dusty

work conditions. Also use non-skid safety shoes, hardhat, gloves, dust collection systems, and hearing

protection when appropriate. This applies to all persons in the work area.

Do not overreach. Keep proper footing and balance at all times.

Remove keys or wrenches before connecting the tool to an air supply, power supply, or turning on the

tool. A wrench or key that is left attached to a rotating part of the tool may cause personal injury.

Secure the work with clamps or a vise instead of your hand when practical. This safety precaution

allows for proper tool operation using both hands.

⚠CAUTION

BULLDOZER USE AND CARE

Do not force the bulldozer. Products are safer and do a better job when used in the manner for which

they are designed. Plan your work and use the correct product for the job.

Check for damaged parts before each use. Carefully check that the product will operate properly and

Page 8/ 48

perform its intended function. Replace damaged or worn parts immediately. Never operate the product

with a damaged part.

Do not use a product with a malfunctioning switch. Any power tool that cannot be controlled with the

power switch is dangerous and must be repaired by an authorized service representative before using.

Disconnect the power/air supply from the product and place the switch inthe locked or off position before

making any adjustments, changing accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting thetool accidentally.

Store the product when it is not in use. Store it in a dry, secure place out of the reach of children. Inspect

the tool for good working condition prior to storage and before re-use.

Use only accessories that are recommended by the manufacturer for use with your product. Accessories

that may be suitable for one product may create a risk of injury when used with another tool. Never use

an accessory that has a lower operating speed or operating pressure than the tool itself.

Keep guards in place and in working order. Never operate the product without the guards in place.

Do not leave the tool running unattended.

Specific Operation Warnings

⚠WARNING

•To prevent serious injury or property damage, read and understand owner’s manual before operating.

•Always wear the proper protective equipment including ANSI Z87.1 compliant eye protection, hearing

protection, steel toed boots, heavy-duty work gloves, and hard hat.

•Keep hands clear of all rotating parts and hot surfaces.

•Follow all start up procedures before each use.

•Before each use, inspect track tension and adjust if needed.

•To prevent personal injury or property damage, retighten the nuts on driven wheel per working 50 hours.

Torque is 160-180 Nm.

•When operating on slopes, do not make sharp turns.

•Operate all controls from the operator’s position.

•Keep all safety shields and enclosures in place when operating this equipment.

•Do not operate around children.

•Vehicle is frequently reversing. Keep workers and bystanders clear from behind the dozer while

operating.

•Keep all bystanders at least 20 feet away from work area.

•EXPOLSION HAZARD. Lead acid batteries create hydrogen gas. No smoking, sparks, or open flames

•HIGH-PRESSURE FLUID HAZARD

•Inspect hydraulic system regularly for leaks.

•Hydraulic fluid escaping through even a pin-size hole opening can puncture skin and cause blood

poisoning.

Page 9/ 48

•Wear proper hand and eye protection when searching for leaks. Never check for leaks with your

hand while system is pressurized. Use wood or cardboard instead of hands

•Relieve pressure on hydraulic system before servicing or disconnecting hoses.

•Seek medical attention immediately if injured by escaping fluid.

•FIRE HAZARD

•Do not fuel at the worksite

•Refuel machine on a hard, level surface.

•Keep open flames and sparks away from the machine while fueling.

•Do not smoke while fueling.

•Do not fill beyond the overfill marking. Expansion of fuel from heat of sun or normal operation may

cause tank spillage if overfilled.

•Clean up any fuel spills before starting engine.

•ENTANGLMENT HAZARD. To prevent serious injury or death from rotating driveline:

•Keep hands, feet, clothing, and hair away from rotating driveline.

•Do not operate without all driveline, tractor, and equipment shields in place.

•Do not operate without driveline securely attached at both ends.

•Do not operate without driveline shields that turn freely on driveline.

•CRUSH AND DISMEMBERMENT HAZARD. Keep hands and feet away from track when engine is on.

Shut engine off before servicing track.

•ELECTROCUTION HAZARD. Serious injury or death can result from contact with electric lines.

•Check overhead clearance before driving under electric lines.

•Check with utility company for underground utilities before excavating.

•FALL HAZARD. On entry and exit of the dozer:

•Maintain 3 points of contact at all times.

•Climb up forwards, exit backwards

•Never jump down from this machine

•Ensure the steps are clean

•Do not climb in or out of the dozer while in motion.

•FALL HAZARD

•Maximum of one person per seat.

•Do allow riders on machine or its attachments.

•Wear seatbelt at all times.

•To avoid property damage, remove backhoe if not in use while operating machine.

•Follow all shutdown procedures and read manual before servicing.

Page 10 / 48

Grounding

⚠WARNING

The coolant heater must be grounded while in use to protect the operator from electrical shock. The

plug MUST be plugged into a matching receptacle that is properly installed and grounded in

accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PROVIDED PLUG. If it will not fit the receptacle, have the proper receptacle

installed by a qualified electrician.

CHECK with a qualified electrician or service person if you do not completely understand the grounding

instructions, or if you are not sure the tool is properly grounded.

Grounded Tools: Tools with 3-Prong Plugs

The coolant is equipped with a heater which has a 3-prong plug. This needs to be grounded when plugged in to

a 110-volt wall socket.

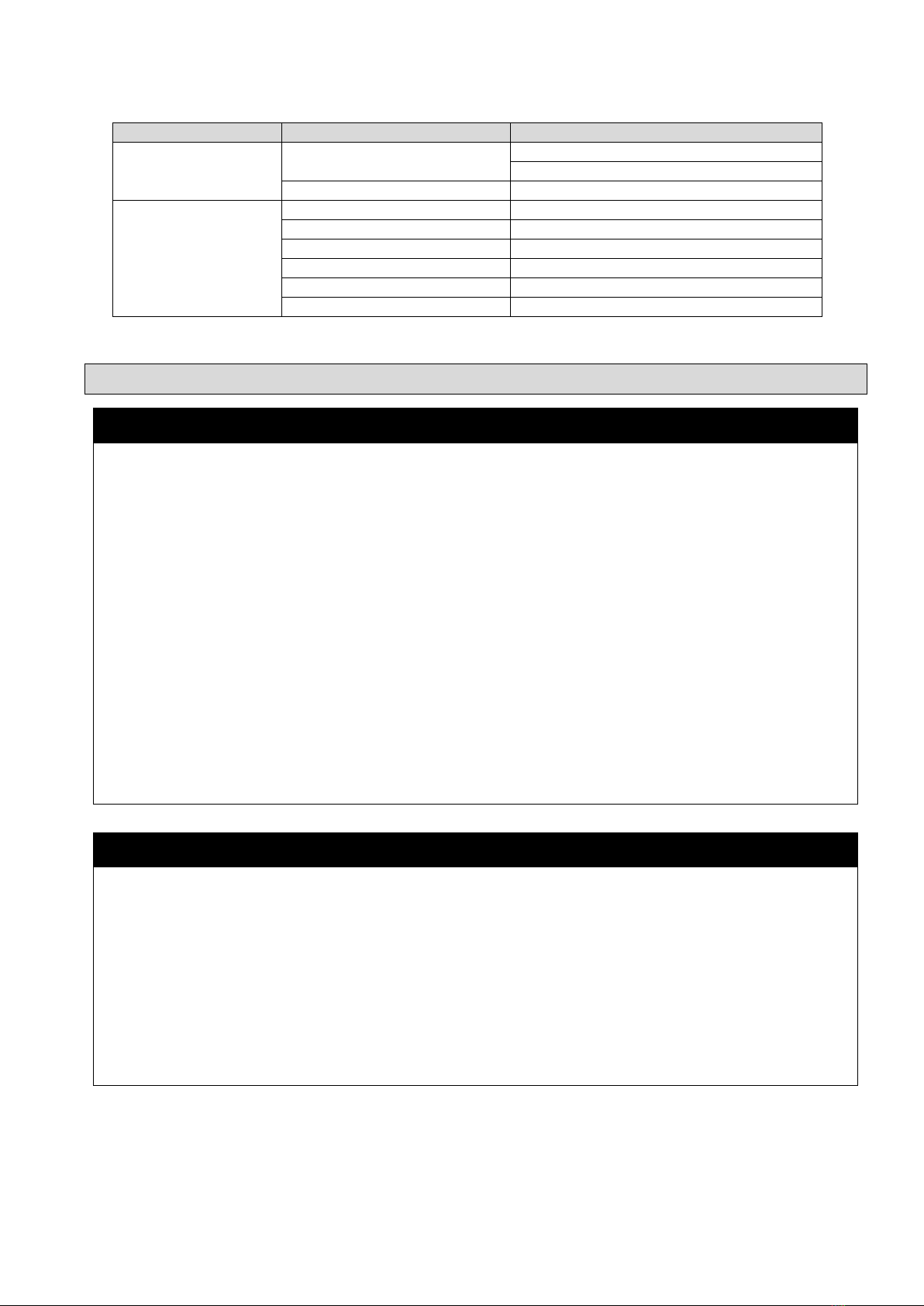

Safety and Product Labels

Ref.#

Description

Quantity

1

NorTrac Decal

2

2

Vehicle Reversing Warning Decal

1

3

Crush Hazard (Hand) Warning Decal

2

4

Crush Hazard (Body) Warning Decal

2

5

Fall Hazard Warning Decal

2

6

Entanglement Hazard Danger Decal

1

7

#1 Track Maintenance Warning Decal

2

8

Burn Hazard Warning Decal

1

9

#1 High-Pressure Fluid Hazard Warning Decal

2

10

Rotating Blade Hazard Warning Decal

1

11

Explosion Hazard Warning Decal

1

Page 11 / 48

Ref.#

Description

Quantity

12

Burn Hazard (Hot Coolant) Warning Decal

1

13

#2 High-Pressure Fluid Hazard Warning Decal

1

14

Hydraulic Filter Notice Decal

1

15

ROPS Warning Decal

2

16

Fire Hazard Danger Decal

1

17

#2 Track Maintenance Warning Decal

2

18

Start Up/Shut Down Procedure, Operational Warnings, Prop 65 Warning Decals

1

19

Electrocution Hazard Danger Decal, Fall Hazard Warning Decals, Engine Notice Decal

1

20

Diesel Fuel Decal

1

21

Diesel Fuel Drain Decal

1

22

Parking Brake Decal

1

23

Hood Instruction Decal

1

24

Hydraulic Oil Level Decal

1

25

Hydraulic Oil Drain Decal

1

26

Blade Control, Hitch Control, Rear Hydraulic Oil Control Valve Decal

1

27

Power Take Off Decal

1

28

#1 Work Lights Decal

1

29

#2 Work Lights Decal

1

30

Dashboard Decal

1

1.

2.

3.

4.

5.

6.

Page 12 / 48

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Page 13 / 48

18.

19.

20.

21.

22.

23.

24.

25.

Page 14 / 48

26.

27.

28.

29.

30.

Before Each Use

⚠WARNING

•Always wear the proper protective equipment including ANSI Z87.1 compliant eye protection, hearing

protection, steel toed boots, heavy-duty work gloves, and hard hat.

•Follow all start up procedures before each use.

•Before startup, check all fluids including engine oil, hydraulic oil, and coolant.

•Before each use, inspect track tension and adjust if needed.

•Keep all bystanders at least 20 feet away from work area.

•To avoid property damage, remove backhoe if not in use while operating machine.

Precautions Before Run-in

1. Clean the area around the dozer.

2. Check and retighten all outer connections, such as bolts and nuts.

3. Check and fill the lubricant, water, fuel, and hydraulic oil to sufficient levels.

Page 15 / 48

Dozer Run-in

10 Minutes Run-in of the Engine at Idle Speed

Start up the engine and increase the engine speed to raise coolant temperature and the engine oil pressure.

Check if there is any oil or water leaking. Pay attention to the sound of the engine running and notice the

indication of the ammeter, water thermometer, and the oil pressure gauge. Continue the next run-in

procedure only after this 10 min run-in.

10 Minutes Run-in of Hydraulic Hitch System

After an implement has been mounted, the hitch is raised and lowered smoothly for more than 10 min, when

the engine is running at rated speed in order to keep run-in smooth, the implement cannot be raised or

lowered on the hard ground.

Two-hour Run-in Without Load

The dozer should be in run-in according to normal use and the operator should do the following.

Shifts

F-low 1

F-low 2

F-low 3

f-high 1

R 1

Time (min)

20

30

30

30

10

In this run-in, the operation of both sides of the steering system and the brake should be carried out. It’ s

necessary to pay attention to the following items.

•Listen to the engine and transmission.

•Check whether the clutch, brake, and gearshift levers are normal.

•Check whether the gauges and electrical system work normally.

If abnormal occurs during the run-in, address it before continuing the run-in process.

48-hour Run-in Under Load Conditions

‘Run-in with load’means that it’s necessary to run the dozer with different loads. The load should be

increased gradually from light to heavy while increasing the speed from low to high.

Measures After Run-in

After the run-in, if any impurities are found in the engine oil sump, gearbox, or hydraulic system, it must be

removed. Also, replace all lubricants and the hydraulic oil. After the essential maintenance, the dozer can be

put into normal use The maintenance steps are as follows:

•Drain out the engine oil when it’s hot, just after the engine is shut off. Then clean the sump with clean

diesel fuel and replace the engine oil filter element. Lastly, refill the engine oil.

•Drain out the oil from the gearbox and final drive cases when it’s hot, just after the engine is shut off.

Then, refill with clean diesel fuel and run the dozer for 3-5 minutes at lowest speed. Drain diesel and fill

with the appropriate amount of clean oil.

•Replace the fuel filter element.

•Drain out the oil from the hydraulic system and refill with the appropriate amount of clean hydraulic oil.

•Replace engine’s coolant.

•Fill grease into the lubricating points in accordance with indication of lubricating drawing.

•Check the tension of the tracks. If the sag exceeds 2.5mm (1in.), adjust.

•Inspect the brake and steering pedals’ free strokes, adjust if necessary.

•Inspect all fasteners and retighten any loose connections.

Page 16 / 48

Operating Instructions

⚠WARNING

•Always wear the proper protective equipment including ANSI Z87.1 compliant eye protection, hearing

protection, steel toed boots, heavy-duty work gloves, and hard hat.

•Keep hands clear of all rotating parts and hot surfaces.

•To prevent personal injury or property damage, retighten the nuts on driven wheel per working 50 hours.

Torque is 160-180 Nm.

•When operating on slopes, do not make sharp turns.

•Operate all controls from the operator’s position.

•Keep all safety shields and enclosures in place when operating this equipment.

•Do not operate around children.

•Vehicle is frequently reversing. Keep workers and bystanders clear from behind the dozer while

operating.

•Keep all bystanders at least 20 feet away from work area.

•EXPOLSION HAZARD. Lead acid batteries create hydrogen gas. No smoking, sparks, or open flames

•HIGH-PRESSURE FLUID HAZARD

•Inspect hydraulic system regularly for leaks.

•Hydraulic fluid escaping through even a pin-size hole opening can puncture skin and cause blood

poisoning.

•Wear proper hand and eye protection when searching for leaks. Never check for leaks with your

hand while system is pressurized. Use wood or cardboard instead of hands.

•Relieve pressure on hydraulic system before servicing or disconnecting hoses.

•Seek medical attention immediately if injured by escaping fluid.

•FIRE HAZARD

•Do not fuel at the worksite.

•Refuel machine on a hard, level surface.

•Keep open flames and sparks away from the machine while fueling.

•Do not smoke while fueling.

•Do not fill beyond the overfill marking. Expansion of fuel from heat of sun or normal operation may

cause tank spillage if overfilled.

•Clean up any fuel spills before starting engine.

•ENTANGLMENT HAZARD. To prevent serious injury or death from rotating driveline:

•Keep hands, feet, clothing, and hair away from rotating driveline.

•Do not operate without all driveline, tractor, and equipment shields in place.

•Do not operate without driveline securely attached at both ends.

Page 17 / 48

•Do not operate without driveline shields that turn freely on driveline.

•CRUSH AND DISMEMBERMENT HAZARD. Keep hands and feet away from track when engine is on.

Shut engine off before servicing track.

•ELECTROCUTION HAZARD. Serious injury or death can result from contact with electric lines.

•Check overhead clearance before driving under electric lines.

•Check with utility company for underground utilities before excavating.

•FALL HAZARD. On entry and exit of the dozer:

•Maintain 3 points of contact at all times.

•Climb up forwards, exit backwards.

•Never jump down from this machine.

•Ensure the steps are clean.

•Do not climb in or out of the dozer while in motion.

•FALL HAZARD

•Maximum of one person per seat.

•Do allow riders on machine or its attachments.

•Wear seatbelt at all times.

•To avoid property damage, remove backhoe if not in use while operating machine.

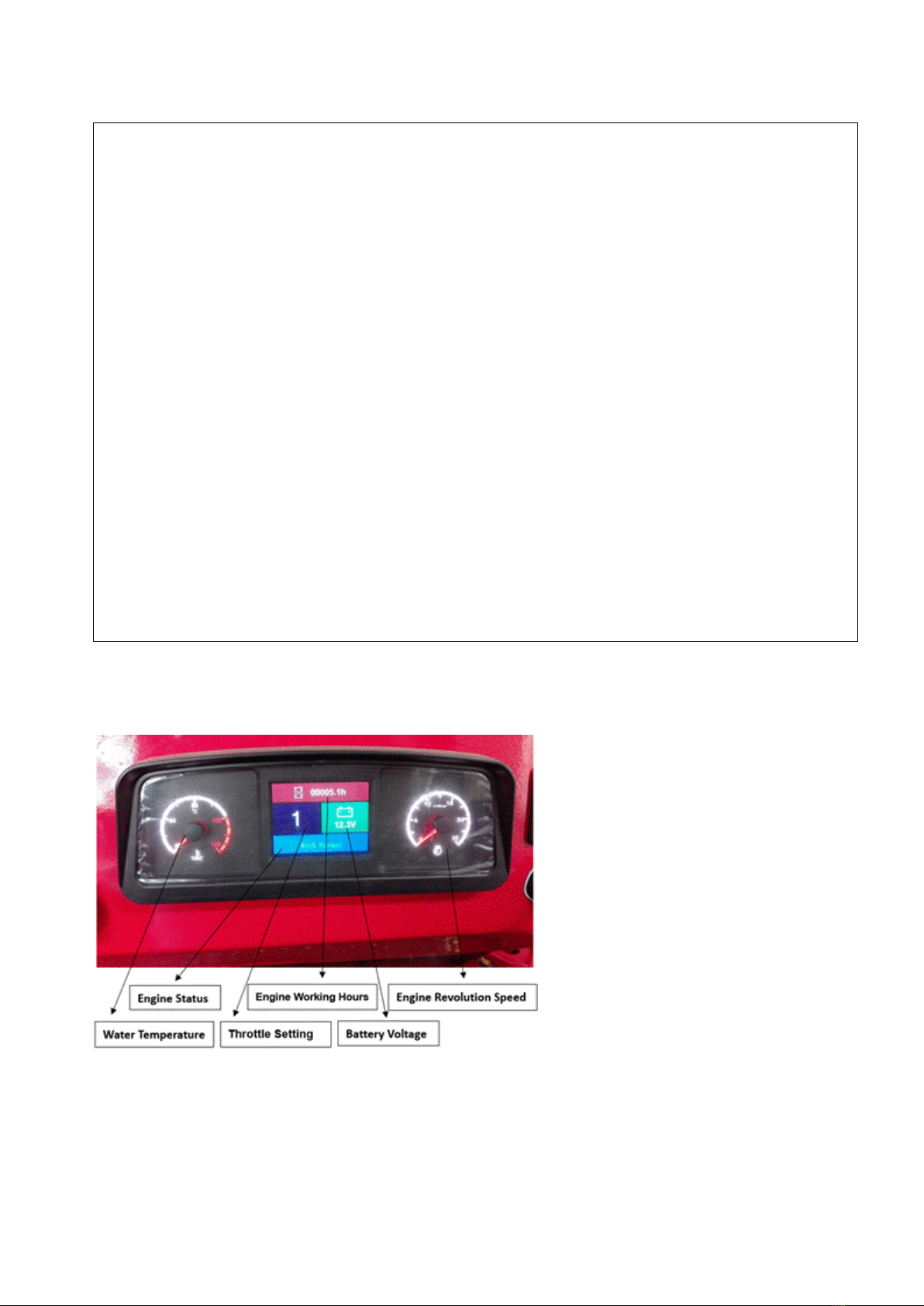

Controls, Gauges, and Switches on Dash Board

Page 18 / 48

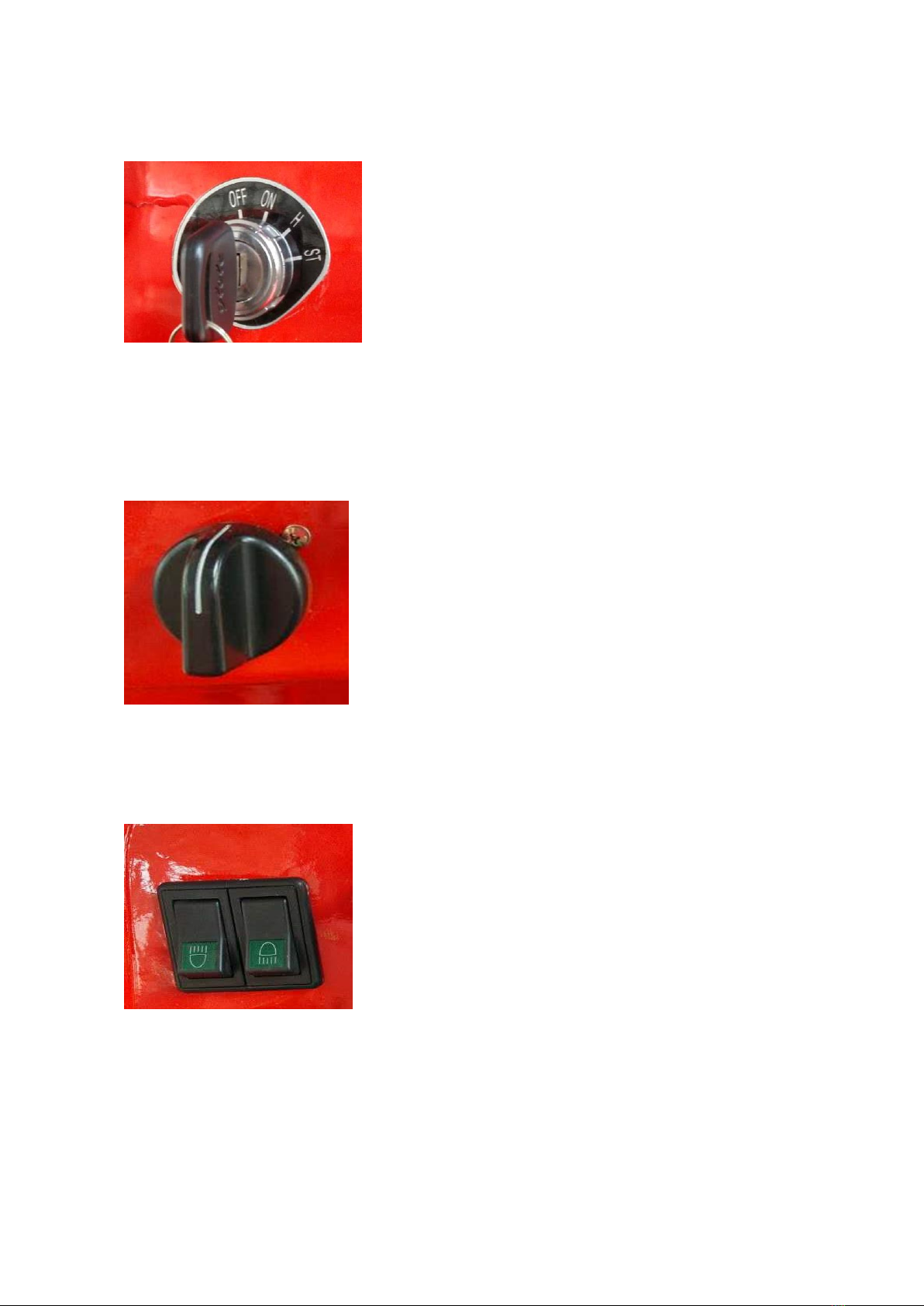

Warm-up and Start-up Switch: Choke Control

•When the key is in the OFF position, all circuits are off.

•Turn clockwise to ‘H’ to warm up the engine. Continue to ‘ST’ to start it up (after warm-up).

•When it’s turned clockwise to ON, all circuits, except warm-up and start-up circuit, are on (after start-up,

the key is kept in this position).

Throttle Control

•Turn clockwise to increase throttle (10 grades for accelerating adjustments showing on screen).

•Turn counter-clockwise to decrease throttle.

Lamp Switches (left side of meter)

•The left switch controls the head light on the front hood.

•The right switch controls the roof light on the cab.

Page 19 / 48

Throttle Setting Switch & Lamp Switch (right side of meter)

•The left switch defines the throttle adjustment range before the throttle control adjustment. Press and

hold for 15 seconds to set the throttle.

•The right switch controls the two head lights on the front cab.

PTO Control Handle

•Push the handle forward to increase speed.

•Push the handle backward to decrease speed.

•Put the handle in neutral so the PTO is not engaged. The clutch pedal must be pushed all the way in

before using the handle.

Driving Operation

Engine Start-up Preparations

Check the engine oil level in the sump and the gearbox. It’s very important that you keep the oil levels between

the upper and lower lines. Be sure there is sufficient coolant in the radiator and sufficient fuel in the tank.

PTO control handle at left

side of seat

Page 20 / 48

Check the hydraulic oil level in the tank.

Engine Oil Level in the

Engine

Step 1. Find the oil

dipstick.

Step 2. Pull out the

dipstick to check the oil

lever before starting

engine.

Pull out the transmission

fluid dipstick and check

the transmission fluid at

the floorboard before

starting the engine.

While it’s cold, open the

filler cap on top of the

radiator. Check the

coolant level. It should

be at the top.

Fuel tank gauge

Hydraulic Oil Level Gauge

Located on the right-side of the box.

This manual suits for next models

1

Table of contents

Other Nortrac Tractor manuals