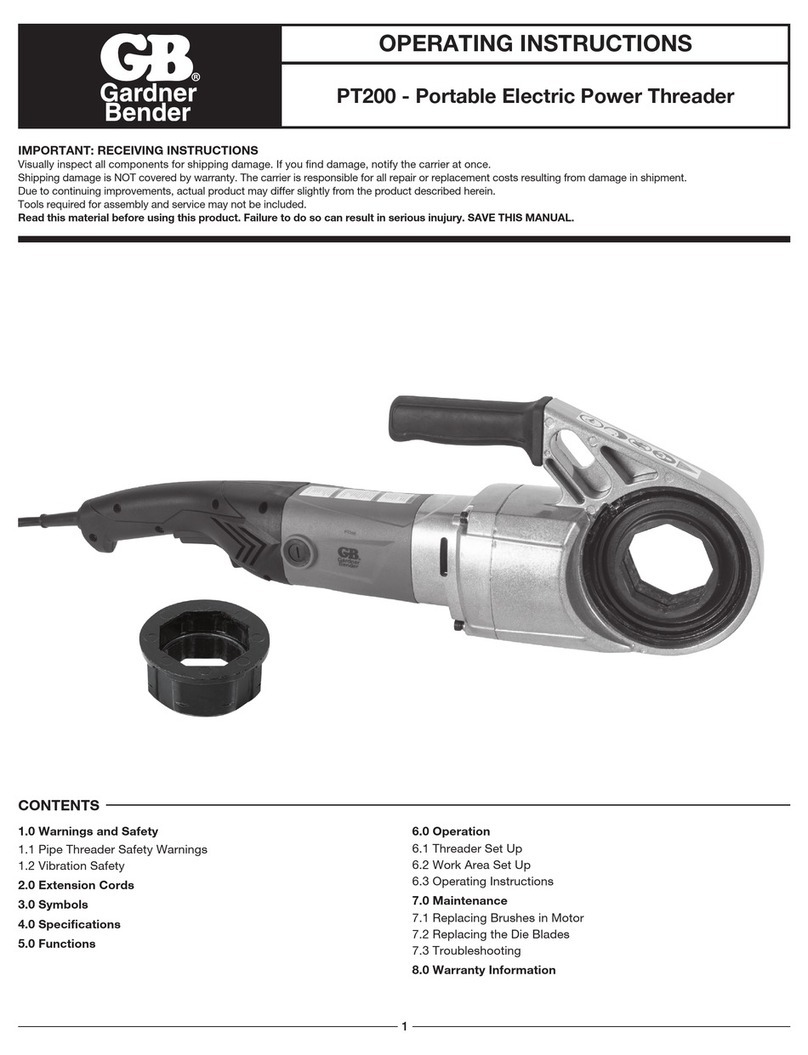

Norwood LumberMax HD38 User manual

HYDRAULIC LOG CLAMPING SYSTEM

LM34-HD-41600

ORIGINAL INSTRUCTIONS

SYSTÈME HYDRAULIQUE

DE RETENUE DE BILLES

INSTRUCTIONS ORIGINALES

HYDRAULINEN TUKIN

KIINNITYSJÄRJESTELMÄ

ALKUPERÄISET OHJEET

HYDRAULISCHES

STAMMKLEMMSYSTEM

URSPRÜNGLICHE ANLEITUNG

HYDRAULISK

STOKKHOLDERSYSTEM

ORIGINAL ANVISNINGER

SISTEMA DE

ABRAÇADEIRA DE

TORAS HIDRÁULICA

INSTRUÇÕES ORIGINAIS

SISTEMA DE SUJECIÓN

HIDRÁULICA DE TRONCOS

INSTRUCCIONES ORIGINALES

MONTERING - STOCK

FASTSPÄNNING SYSTEMET

BRUKSANVISNING ORIGINAL

»LumberMax HD38

»LumberPro HD36V2, HD36

EN–1 Hydraulic Log Clamping System

EN–1 Safety Instructions

EN–4 Box Contents and Parts List

EN–6 Installation: Log Rest

EN–8 Installation: Log Clamp

EN–9 Installation: Log Clamp Hoses

EN–11 Installation: Log Rest Hoses

EN–15 Operating Instructions

FR–1 Système hydraulique de retenue de

billes

FR–1 Instructions de sécurité

FR–4 Contenu des boîtes

FR–6 Installaton: Support de bille

FR–8 Installation: Systeme de serrage

FR–9 Installation: Pinces à billes

FR–11 Installation: Tuyaux de support de

billes

FR–15 Utilization

FI–1 Hydraulinen tukin

kiinnitysjärjestelmä

FI–1 Turvallisuusohjeet

FI–4 Pakkauksen sisältö ja osaluettelo

FI–6 Asennus: Tukkipidike

FI–8 Asennus: Tukin kiinnike

FI–9 Asennus: Tukin kiinnikkeen letkut

FI–11 Asennus: Tukkipidikkeen letkut

FI–15 Käyttöohjeet

DE–1 Hydraulisches Stammklemmsystem

DE–1 Sicherheitshinweise

DE–4 Box Contents and Parts List

DE–6 Montage: Stammstütze

DE–8 Montage: Stammklemme

DE–9 Montage: Schläuche der

Stammklemme

DE–11 Montage: Schläuche der Stammstütze

DE–15 Betriebsanweisungen

NO–1 Hydraulisk stokkholdersystem

NO–1 Sikkerhetsinstruksjoner

NO–4 Innholdet i esken

NO–6 Montering: Stokkstøtte

NO–8 Montering: Stokkholder

NO–9 Montering: Stokkholderslanger

NO–11 Montering: Stokkstøtteslanger

NO–15 Drift

PT–1 Sistema de Abraçadeira de Toras

Hidráulica

PT–1 Instruções de Segurança

PT–4 Conteúdo da Caixa e Lista de Peças

PT–6 Instalação: Escorador de Tora

PT–8 Instalação: Braçadeira de Tora

PT–9 Instalação: Mangueiras da Braçadeira

de Tora

PT–11 Instalação: Mangueiras do Escorador

de Tora

PT–15 Instruções de Operação

ES–1 Sistema de sujeción hidráulica de

troncos

ES–1 Instrucciones de Seguridad

ES–4 Contenido de la caja y lista de piezas

ES–6 Instalación: Soporte para troncos

ES–8 Instalación: Abrazadera para troncos

ES–9 Instalación: Mangueras de la

abrazadera para troncos

ES–11 Instalación: Mangueras del soporte

para troncos

ES–15 Instrucciones de uso

SE–1 Montering - stock fastspänning

systemet

SE–1 Säkerhetsinstruktioner

SE–4 Lådans innehåll

SE–6 Installation: Stockstöd

SE–8 Installation: Stocklåsning

SE–9 Installation: Slangar för stocklåsning

SE–11 Installation: Slangar för stockstöd

SE–15 Drift

LM34-HD-41600

Telephone: +1-705-325-0030

E-mail: info@NorwoodSawmills.com

Website: www.NorwoodSawmills.com

Norwood Industries Inc.

35 Reid Drive

Barrie, ON L4N 0M4

Canada

Norwood Enterprise Inc.

730 Young Street, Suite 900

Tonawanda NY 14150

United States of America

Text: S. Cabrit

First Edition: 2013-06-05

Latest Revision: 2023-05-24

Copyright © 2013, 2022, 2023 Norwood Industries

Inc. All rights reserved. No part of this publication may

be reproduced in any form or by any means without

permission in writing from the publisher, Norwood

Industries Inc.

The trade-names Norwood®, LumberMax®, LumberPro®, LumberMate®,

LumberMan®, LumberLite®, LM Pro®, HD38®, HD36®, LM30®, LM29®,

MN27®, MN26®, PortaMill®, Frontier®, OS®, OS23®, OS27®, OS31®,

BladeMate®, Duradeck®, IntelliSet®, MultiMate®, Omega®, SabreBar®,

SabreChain®, SabreTooth®, Sawmill TV®, Sawyer-Assist®, SkidMate®,

Trekker®, the LumberJack®mascot, “Forest. Fun. Freedom.”®, the

“chevron” graphic, and the color orange (as related to sawmills, edgers,

skidders & related equipment) are registered trademarks owned

by Norwood Industries Inc. in multiple jurisdictions. Functional and

design elements of Norwood sawmills and log handling equipment

are protected by registered patents and pending patents in multiple

jurisdictions.

U.S. Patent Nos. 6,932,555, 9,102,074, 7,784,387, 8,215,216,

8,261,645, 8,261,647, 8,276,493, 8,820,727, 9,676,116, 10,843,370,

D816742, D818013, D834623, D831711, D639,319, D654,101,

D638,040 & 8,479,628 — Canada Patent Nos. 2,432,863, 2,488,216,

132823, 2,541,734, 2,687,619, 2,687,622, 2,687,623, 2,688,407,

2,696,974, 2,782,909, 2,806,456, 2,800,791, 2,969,794, 3,037,006,

3,097,733, 3,092,814, 3,101,140, 134185, 133049, 169785, 169786,

169787, 196297 & 169788 — EU Patent Nos. EP 2,746,009 B1,

EP 2,332,706 B1, EP 2,332,683 B1, EP 2,684,631, EP 2,332,704,

EP 2,759,384, 1117196-0001; 001212393-0001; 001217277-0001,

001214662-0001, 003736255-0001, 003736255-0002, 003736255-

0003, 003736255-0004, 008465066-0001 — UK Patent Nos. 6124839,

6138704, 6151320 — Brazil Patent Nos. BR30 2012 003601-1, BR10

2013 025882-2, BR10 2013 025883-0, PI 1004044-7, PI 1010352-

0, DI 7001877-4, DI 7001876-6 & PI 1009180-7 — Australia Patent

Nos. 202111414, 201710613, 201710614, 201710616, 201710615 &

202016960; China Patent Nos. 4192870, ZL202130153443.5. Other

patents pending in multiple jurisdictions.

Norwood Industries Inc. is constantly developing its equipment.

Wereserve the right to make changes to the design, construction and

finish of our equipment without notice.

Photographs and illustrations in this manual may show optional

attachments or previous models and parts.

®

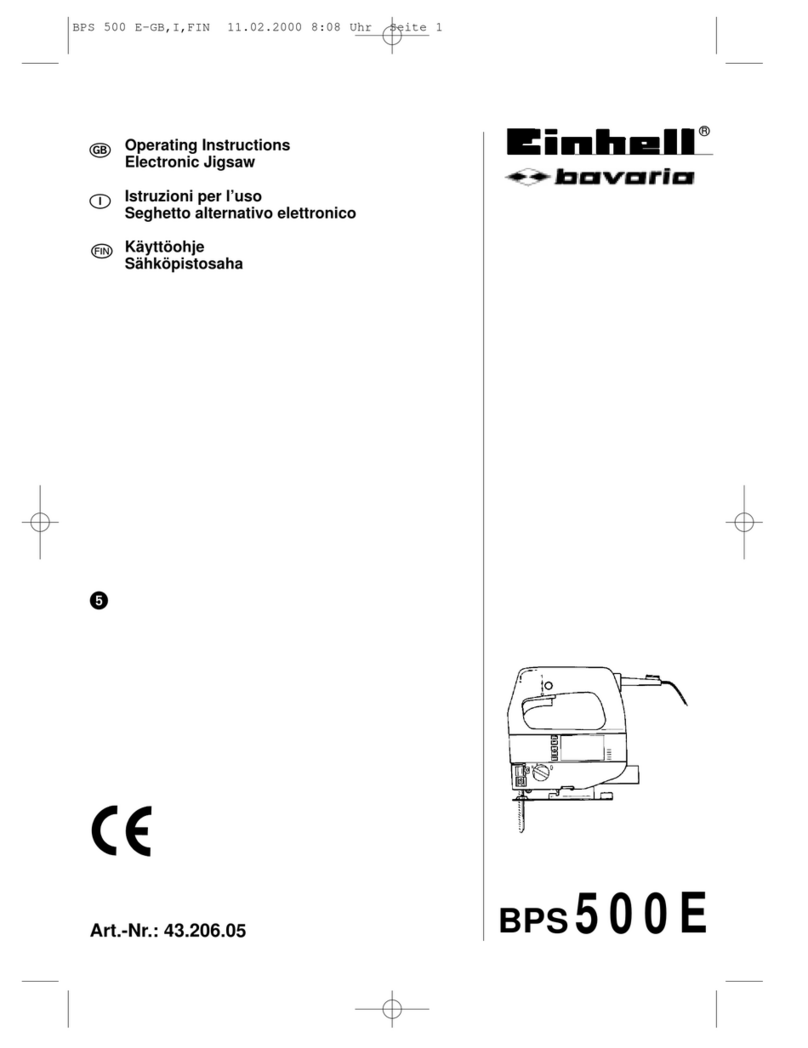

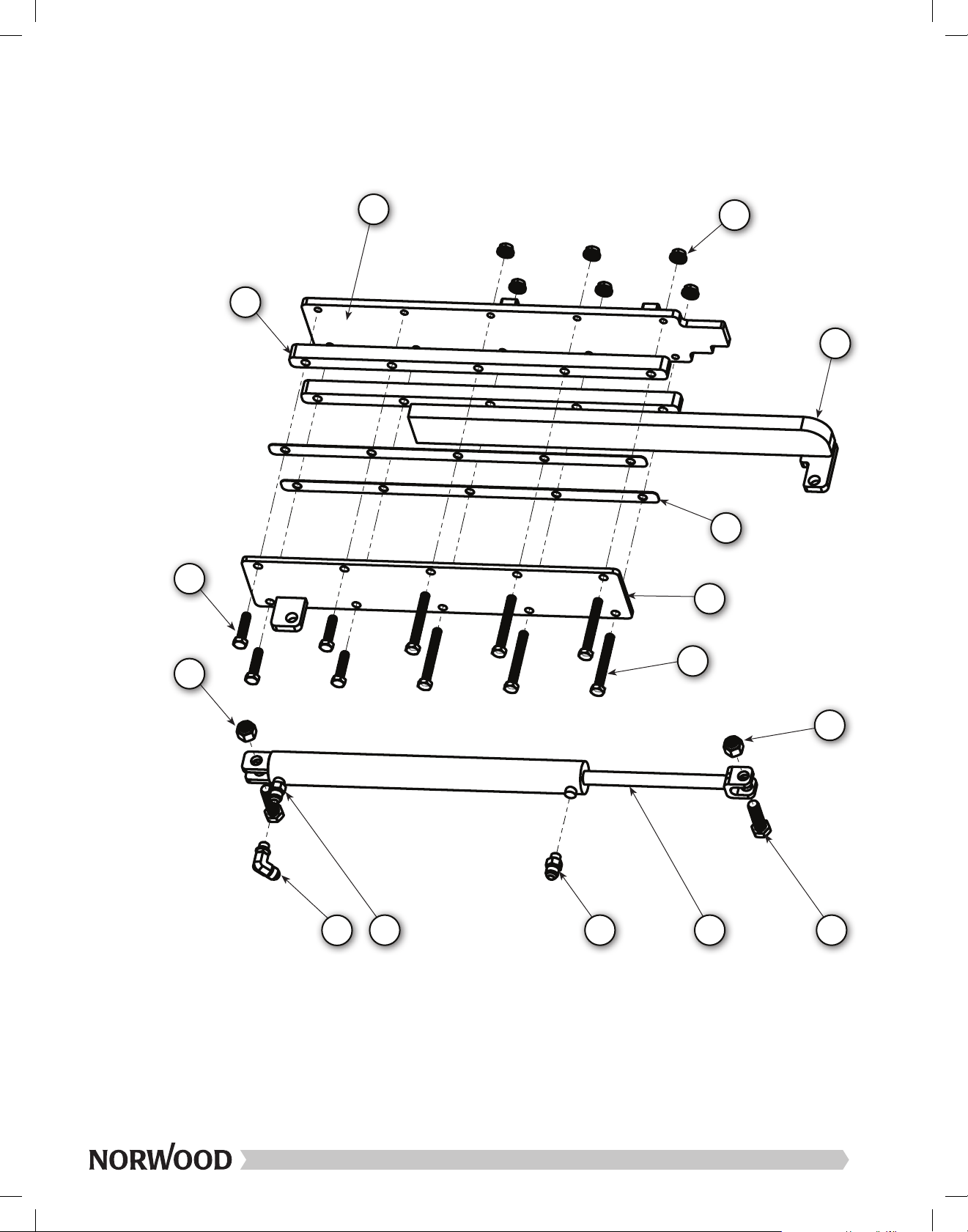

16

15

15

11

2

3

3

9

38

40

39

41

4 1

1

Front

Back

5

27 29 2 40

38

5

4

41

1

12

301631

15

2

33

35

28

11

16

4

6

26

25

16

16 25 16

7

21

20

13

20

24

23

16

16

21

19

16

18

22

20

20

22

18

23

24

I

23

DETAIL J

DETAIL I

44

8

The sawmill, its options, accessories,

engine and blades (the “equipment”)

are extremely dangerous and can

cause severe injury or death. To avoid

serious injury, the equipment must always be

handled, operated and stored with the utmost

care and good judgment and in accordance

with all warnings, cautions, instructions and

procedures contained in this manual, in the

engine manual, in the instructions enclosed

with optional accessories and on the decals

posted on the equipment. Failure to use good

judgment or to follow any of these warnings,

cautions, instructions and procedures can

result in severe injury or death.

WARNING! This symbol means “Pay Extra

Attention” and is always followed by a warning

about a danger that can cause severe injury.

This symbol means “Pay Attention” and is

always followed by a caution or warning of

great importance for safety or sawing results.

For your own safety and the safety of others,

do not begin working with this equipment

before having read and understood this entire

manual, the engine manual, the instructions

enclosed with optional accessories and the decals

posted on the equipment.

Save all instructions for future reference. Keep all decals

in place, clean and readable. Replace any damaged or

missing decals without delay.

DISCLAIMER

Norwood Industries Inc. and Norwood

Enterprise Inc. disclaim any responsibility or

liability, in negligence or otherwise, for any

injuries, damages or losses of any kind arising

during the course of assembling, operating or

handling this equipment, options, accessories

or blades howsoever caused.

Responsibility for final inspection of the

sawmill parts and components, and the

assembly, maintenance and safe use of the

equipment, lies solely with the person(s) who

assembles and operates the equipment and

handles blades.

Persons under the age of 18 may not work with the

equipment or handle blades.

Only persons who meet all of the following

requirements are qualified to operate the equipment

or handle blades.

Qualified operators:

a. Have read and fully understood all the warnings,

cautions, instructions and procedures in this manual,

the engine manual and all instructions enclosed with

optional accessories, and on all decals posted on

the equipment,

b. Are well rested,

c. Are in good physical health with good eyesight,

d. Have not consumed alcohol or drugs, and

Safety Instructions

EN–1EN–1

EN

Hydraulic Log

Clamping System

e. Are not taking medication that can impair judgment,

reaction times, mobility, alertness or otherwise cause

negative side effects.

Persons who fail to meet any of these requirements are

not qualified to use the equipment or handle blades.

Wear protective gloves when working with the

equipment or handling blades. Risk of cutting

injuries when handling blades. Blades and

engine can be hot immediately after sawing.

Wear approved hearing protection when

operating the equipment. Hearing can

be permanently impaired after only short

exposure to high-frequency sounds.

Wear approved close-fitting safety goggles

when working with the equipment or handling

blades.

Wear approved protective footwear with saw

protection, steel toe-cap and non-slip sole

when working with the equipment or handling

blades.

Wear full-length protective pants when working

with the equipment or handling blades. Never

wear loose-fitting clothing, scarves, jewelery

or similar long items that can get caught when

working with the equipment. Always secure loose hair

before working with the equipment.

Wear respiration protection when working

with the equipment. Long term inhalation of

sawdust and the engine’s exhaust fumes can

represent a health risk.

Many hydraulic operation fluids are flammable, so

do not use open flame and do not perform welding

in the vicinity of hydraulic devices and equipment.

Failure to follow this precaution creates the risk of

fire.

Do not exceed the operational limitations of the

system. Failure to do so can cause an accident or

injury.

Before each use, check for electrical wire damage

and replace if necessary

Before each use, check for damage to hydraulic

hoses and hydraulic components, loose fittings and

signs of leaks.

To avoid personal injury, keep hands and feet away

from cylinders and work pieces during operation.

Never set the relief valve to a higher pressure than

the maximum rated pressure of the pump (2500 psi

or 172 bars). Higher settings may result in equipment

damage and/or personal injury. Do not remove relief

valve.

Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin, causing serious

injury. If oil is injected under the skin, contact a

physician immediately.

Before replacing the hydraulic operating fluid, allow

the fluid in the system to cool sufficiently. Hot fluid

creates the risk of burn injury.

Should you ever notice abnormal noise, abnormal

heat, abnormal vibration, leaking oil, smoke,

abnormal odor, or any other abnormal operation

in a valve, pump, or motor, immediately shut down

operation and take the necessary steps to correct

the condition. Continued use under the above

conditions creates the risk of damage, fire, and

personal injury

Always stay behind the sawhead after the engine is

started.

Always keep remote control wires clear of the

sawmill, including carriage and sawhead.

Do not exceed equipment rating. Overloading causes

equipment failure and possible injury. The pump is

designed for a maximum pressure of 2500 psi (172

bars).

Avoid damaging hydraulic hoses. Avoid sharp bends

and kinks when routing hydraulic hoses. Using a

bent or kinked hose will cause severe back pressure.

Sharp bends and kinks will internally damage the

hose leading to premature hose failure.

Do not lift hydraulic equipment by the hoses or swivel

couplers.

Use the proper type of hydraulic operating fluid,

ensuring that fluid temperature, viscosity,

contaminant level, and other factor are all within

prescribed ranges. Using hydraulic operating fluid

outside of its prescribed ranges creates the risk of

fire due to operational problems, mechanical

damage, and fluid leaks.

Before each use, check the fluid temperature, fluid

level and fluid color (for discoloration and

deterioration). Any abnormalities create the risk of

malfunction and breakdown.

Whitish fluid indicates that water has contaminated

the fluid, and blackish fluid indicates that the fluid

has been subjected to high temperatures. Replace

the operating fluid whenever these symptoms are

noticed.

Make sure to avoid splashing hydraulic operating

fluid on you or others. Should fluid get on your skin,

wash the area thoroughly with soap and water.

Allowing hydraulic operating fluid to remain on the

skin creates the risk of skin irritation.

EN–2

Never attempt any unauthorized modifications of the

hydraulic systems.

Whenever changing to another type of hydraulic

operating fluid, be sure to thoroughly flush out the

interior of the circuit. Never mix hydraulic operating

fluids of different types. Continued use creates the

risk of malfunction of, and damage to, the equipment.

Allowing the hydraulic operating fluid level in the tank

to become too low creates the risk of malfunction

and breakdown.

Always check hydraulic devices for looseness of

internal components that may have occurred during

transport and check to make sure that all

components are fitted securely.

Wipe up any hydraulic operating fluid that gets on

the product or floor. Failure to do so creates the risk

of personal injury due to the product slipping out of

your hand and falling, and due to someone slipping

on the fluid left on the floor.

Valve, pump and motor casing can become very hot

during operation. Do not touch them.

Never climb onto, strike, tip over, or apply excessive

force to a product. Doing so creates the risk of

malfunction, damage, fluid leaks, etc.

Never allow cutting oil, grinding oil, clippings, water

or other similar matter to get on or in hydraulic

devices.

Make sure installation holes and surfaces are clean.

Insufficient bolt tightening torque can allow fluid

leaks.

Always make sure to release all residual pressure

before starting disassembly work. Performing

disassembly work without releasing residual

pressure creates the risk of accident due to spurting

fluid, actuator free running, or dropping, and also

creates the risk of malfunction and breakdown.

For optimum performance, do not expose equipment

to temperature of 65 °C (150 °F) or higher.

If the system will not be operated for long periods, be

sure to take proper anti-rust measures.

Not operating the system for long periods without

taking anti-rust measures creates the risk of

malfunction and breakdown due to rust.

Be sure to flush the system before using it again

after long periods of non-use. Failure to flush out

rust inhibitors creates the risk of malfunction and

breakdown.

Seals may need to be replaced before using a

product for the first time after long storage.

EN–3

EN–4

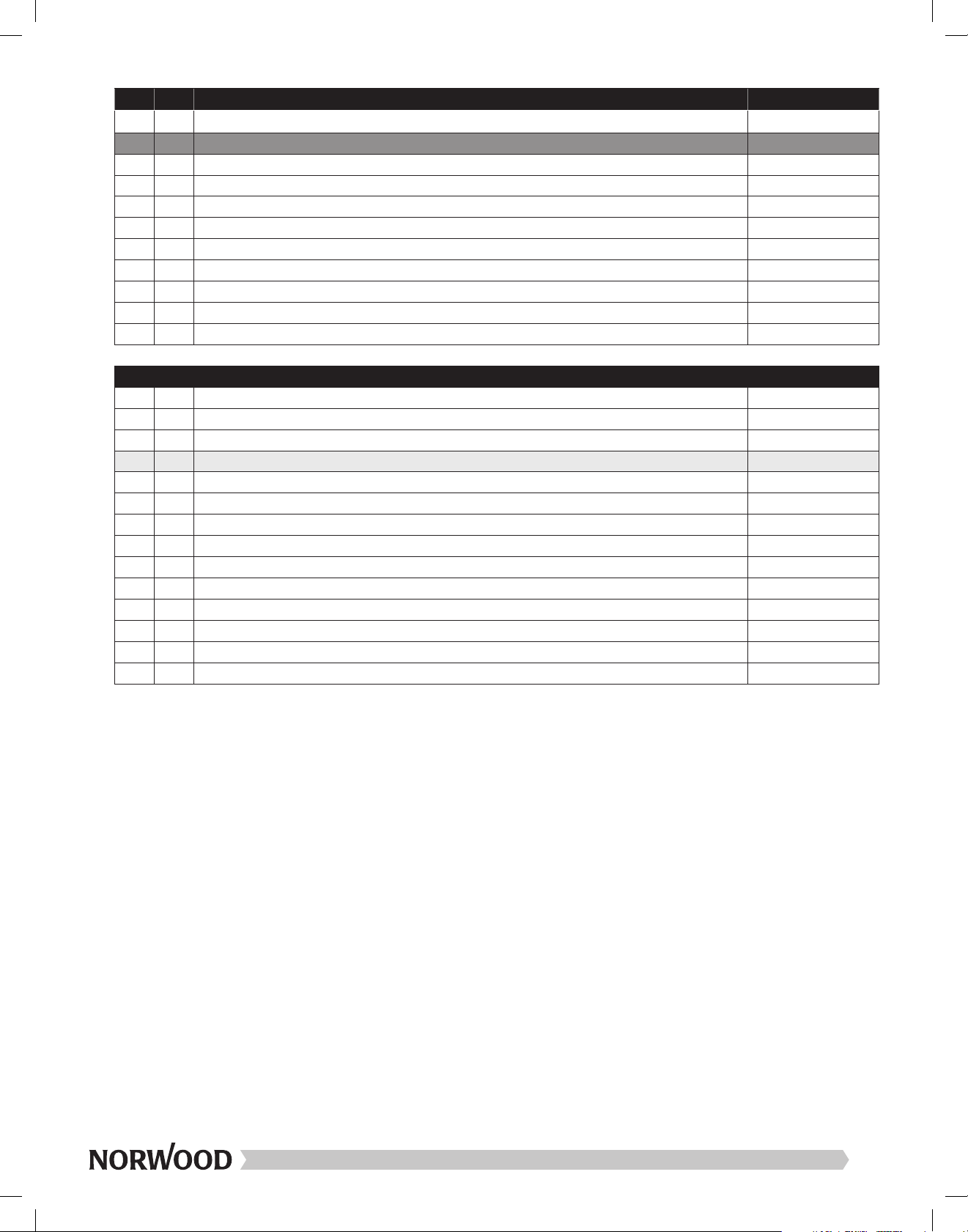

Box Contents and Parts List

Item Qty. Description Norwood No.

LM34-HD-LC #1 (Hydraulic Log Clamping Box #1)

25 2 Hydraulic hose - Valve to horizontal clamp cylinder NOR006-0009

Dog Bar Assembly #1 (factory-assembled):

1 1 1/2 nut - nylon lock nut FASN-12NLN

2 1 1/2 x 1 3/4" bolt - hex bolt FASB-12134H

28 1 Hydraulic log dog - Bar LM34-H-LD-0008

Dog Bar Assembly #2 (factory-assembled):

1 1 1/2 nut - nylon lock nut FASN-12NLN

2 1 1/2 x 1 3/4" bolt - hex bolt FASB-12134H

12 1 Hydraulic cylinder (20” stroke, 1-1/8” bore, 1/2” pin holes, retracted length 25.3 CYL-20-118-25.3

30 1 Hydraulic log dog - Cylinder slider mount bracket LM34-H-LD-0020

LM34-HD-LC #2 (Hydraulic Log Clamping Box #2)

26 2 Hydraulic hose - Valve to vertical clamp cylinder NOR006-0010

Vertical Dog Assembly (factory-assembled):

1 2 1/2 nut - nylon lock nut FASN-12NLN

2 2 1/2 x 1 3/4" bolt - hex bolt FASB-12134H

4 14 3/8 x 1 1/2" bolt - regular hex bolt FASB-38112

5 2 3/8 x 1 1/4" bolt - regular hex bolt FASB-3814H

11 1 Hydraulic cylinder (12" stroke, 1-1/8" bore, 1/2" pin holes, retracted length 17.3 CYL-12-118-17.3

27 1 Hydraulic log dog - Back plate LM34-H-LD-0018

29 1 Hydraulic log dog - Clamp LM34-H-LD-0007

31 1 Hydraulic log dog - Front plate - Horizontal LM34-H-LD-0014

38 1 Hydraulic log rest - Front plate LM34-H-LR-0101

33 2 Hydraulic log dog - Shim - Horizontal LM34-H-LD-0021

40 2 Hydraulic log rest - Shim LM34-H-LR-0113

35 1 Hydraulic log dog - Spacer - Horizontal LM34-H-LD-0015

41 2 Hydraulic log rest - Spacer - Vertical LM34-H-LR-0106

LM34-HD-LC #3 (Hydraulic Log Clamping Box #3)

23 1 Hydraulic hose - Valve to "T" NOR006-0003

24 1 Hydraulic hose - Valve to flow divider NOR006-0006

Log Rest Assembly (factory-assembled):

1 2 1/2 nut - nylon lock nut FASN-12NLN

2 2 1/2 x 1 3/4" bolt - hex bolt FASB-12134H

4 4 3/8 x 1 1/2" bolt - regular hex bolt FASB-38112

9 6 3/8 x 3" bolt - full thread hex bolt FASB-38X3FTH

11 1 Hydraulic cylinder (12” stroke, 1-1/8” bore, 1/2” pin holes, retracted length 17.3 CYL-12-118-17.3

37 1 Hydraulic log rest - Back plate LM34-H-LR-0103

38 1 Hydraulic log rest - Front plate LM34-H-LR-0101

39 1 Hydraulic log rest - Log post LM34-H-LR-0102

40 2 Hydraulic log rest - Shim LM34-H-LR-0113

41 2 Hydraulic log rest - Spacer - Vertical LM34-H-LR-0106

Item Qty. Description Norwood No.

LM34 Bag: Hydraulic Log Clamping Bag (LM34 BAG: HD-LC-BAG #1)

3 12 3/8 nut - flanged (regular) FASN-38RFL

13 1 Hydraulic fitting - "T" 3/8 MJ X 3/8 MJ X 3/8 MJ LM34-H-FT-01

14 1 Hydraulic fitting - #8 SAE plug LM34-H-FT-04

15 3 Hydraulic fitting - 3/8 MJ X #4 SAE male LM34-H-FT-07

16 5 Hydraulic fitting - 3/8 MJ X #4 SAE male, 90 degrees LM34-H-FT-08

17 3 Hydraulic fitting - 3/8 MJ X #8 SAE male LM34-H-FT-10

18 1 Hydraulic flow divider/combiner - 50:50, 1/2" SAE ports HYD-FLODIV

— 1 Instructions - Hydraulic Log Clamping System LM34-HD-41600-INST

43 1 Hydraulic flow divider/combiner - 6-12GPM 3500 PSI HYD-FLOBODY

LM34-HD-LC #4 (Hydraulic Log Clamping Box #4)

20 2 Hydraulic hose - "T" to rear log rest retract NOR006-0005

21 1 Hydraulic hose - Flow divider to front log rest extend NOR006-0007

22 1 Hydraulic hose - Flow divider to rear log rest extend NOR006-0008

Log Rest Assembly (factory-assembled):

1 2 1/2 nut - nylon lock nut FASN-12NLN

2 2 1/2 x 1 3/4" bolt - hex bolt FASB-12134H

4 4 3/8 x 1 1/2" bolt - regular hex bolt FASB-38112

9 6 3/8 x 3" bolt - full thread hex bolt FASB-38X3FTH

11 1 Hydraulic cylinder (12” stroke, 1-1/8” bore, 1/2” pin holes, retracted length 17.3 CYL-12-118-17.3

37 1 Hydraulic log rest - Back plate LM34-H-LR-0103

38 1 Hydraulic log rest - Front plate LM34-H-LR-0101

39 1 Hydraulic log rest - Log post LM34-H-LR-0102

40 2 Hydraulic log rest - Shim LM34-H-LR-0113

41 2 Hydraulic log rest - Spacer - Vertical LM34-H-LR-0106

EN–5

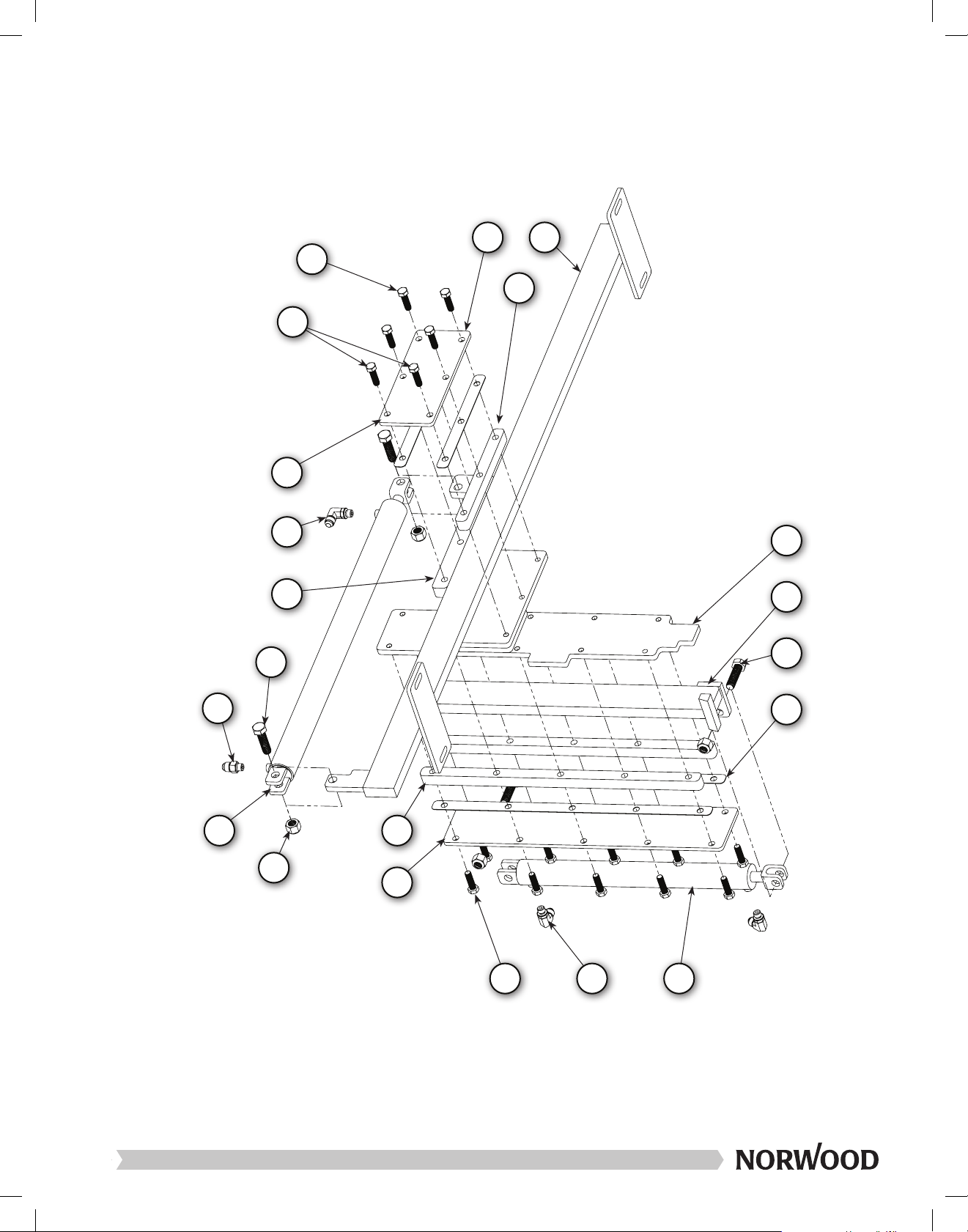

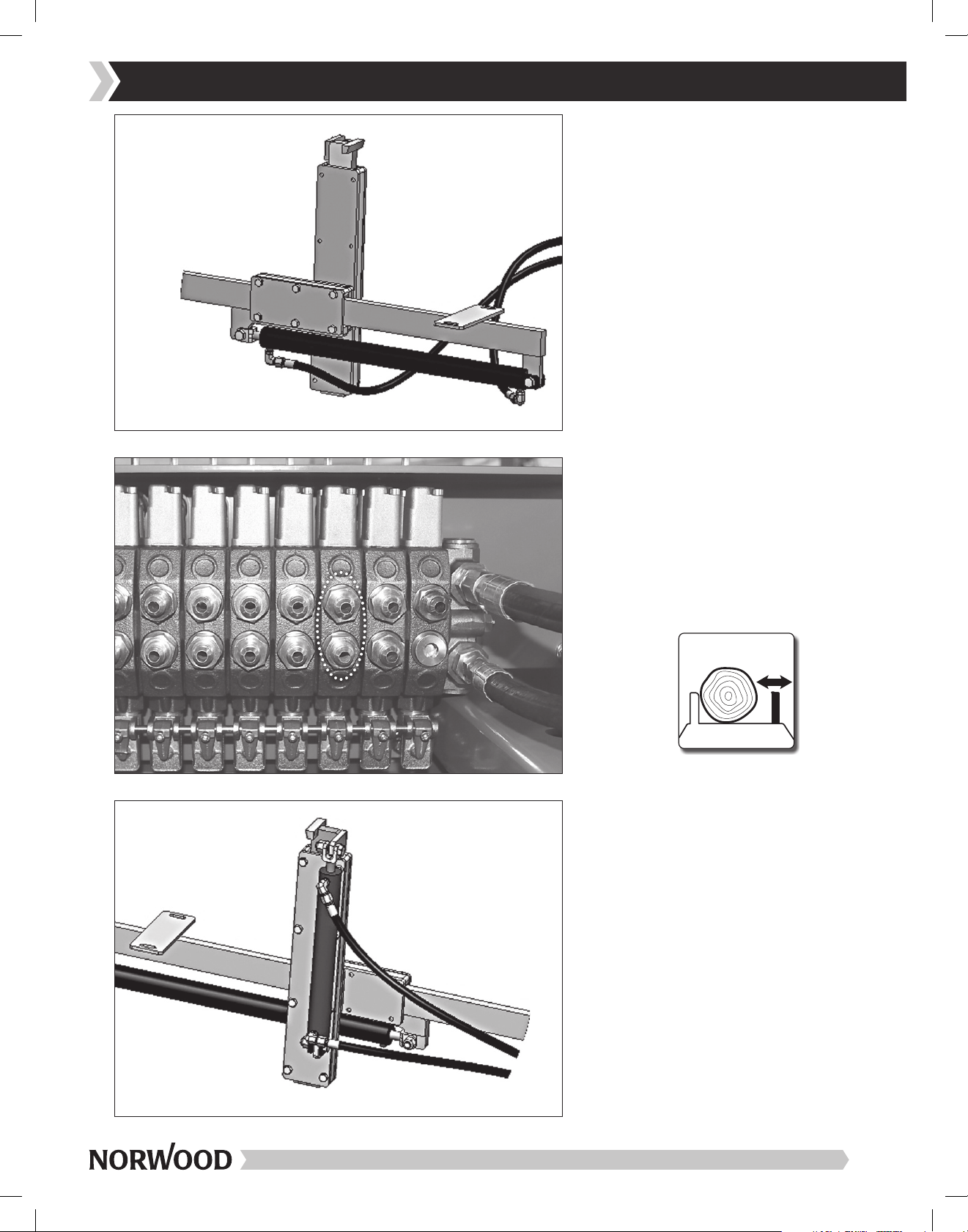

Install the log rest assembly to the cross

bunk, using the 3/8” nut (item #3). See

illustration for location.

NOTE:

The Log Loader mounting

bracket should be installed at

this time using 3/8" x 2 1/2"

bolt (Item 5). (If purchased.)

NOTE:

The log rests and the log dog can be positioned

at your convenience. The locations shown in this

page are just a recommendation for an average

size log.

Step 11:

Install log dog at hole #18 & 19.

Hole #1

EN–6

Installation: Log Rest

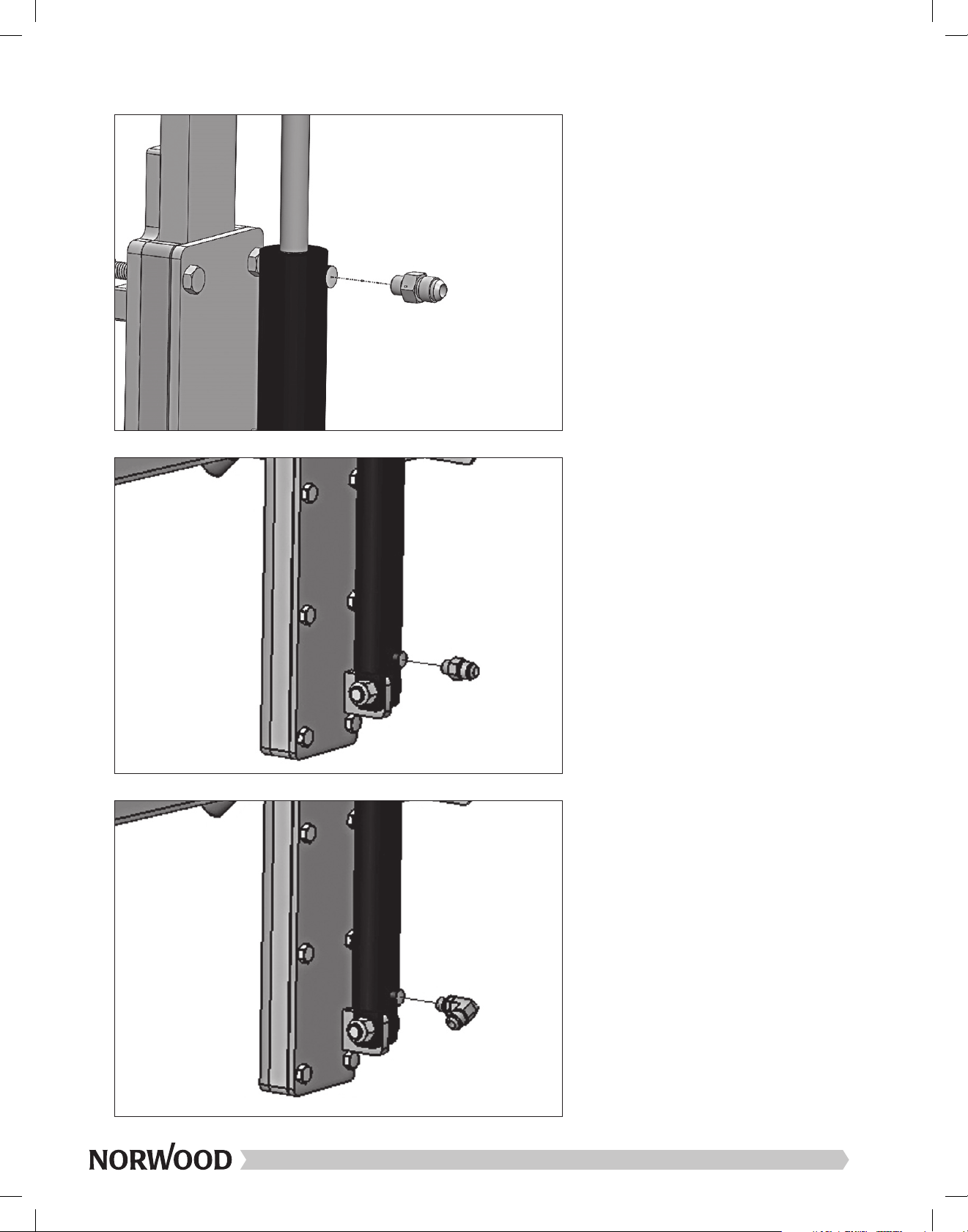

Install the 3/8 MJ x #4 SAE male 90

degrees hydraulic fitting (item #16) to the

log rest cylinder bottom port (item #11)

located at the back of the sawmill.

Install the 3/8 MJ x #4 SAE male

hydraulic fitting (item #15) to the log rest

cylinder bottom port (item #11) located at

the front of the sawmill.

Install the 3/8 MJ x #4 SAE male,

hydraulic fitting (item #15) to the log rest

cylinders top port (item #11).

EN–7

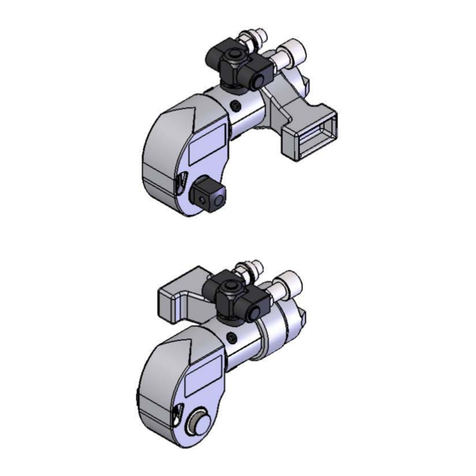

Install the 3/8 MJ x #4 SAE male 90

degrees hydraulic fittings (item #16).

(four places)

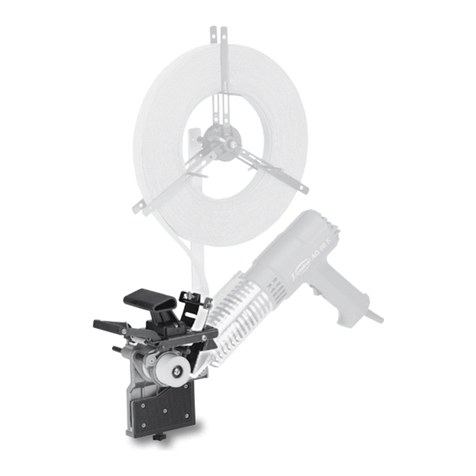

Install the hydraulic cylinder (item #12)

onto the log dog bar (item #28) using

the 1/2” x 1 3/4” bolts (item #2) and nuts

(item #1). See left picture for cylinder

orientation.

Assemble the factory assembled

hydraulic clamp sub-assembly with

the horizontal shim (item #33) and the

cylinder slider mount bracket (item #30)

using the 3/8” x 1 1/2” bolts (item #4).

Note: Do not forget the shims (item #33).

EN–8

Installation: Log Clamp

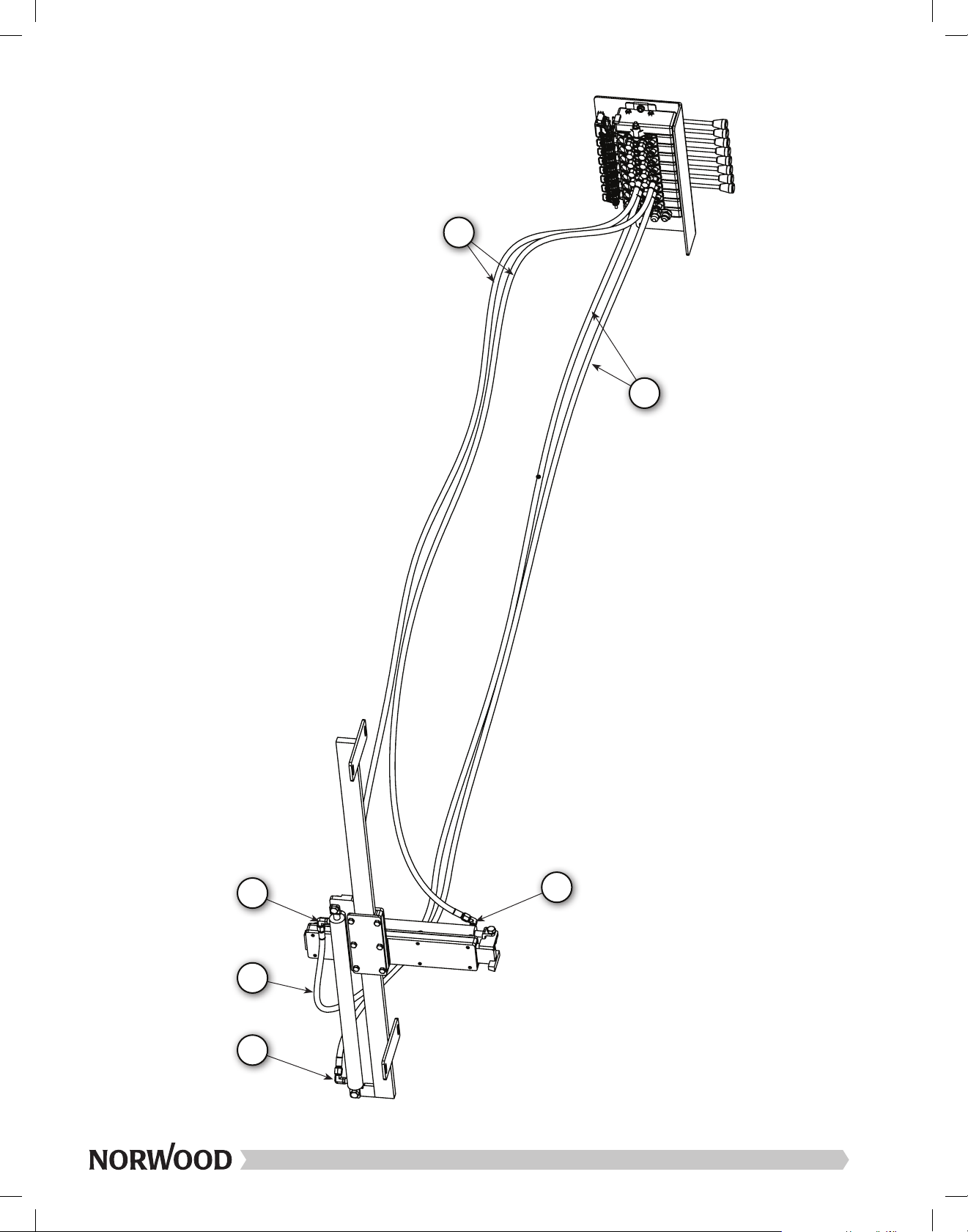

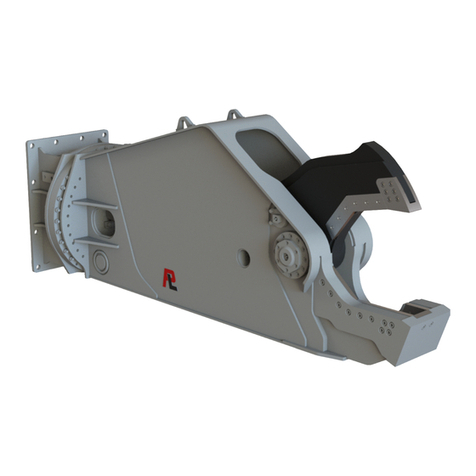

Connect the 136” horizontal log clamp

hoses (item #25 labeled NOR006-0009)

to the horizontal cylinder (item #12).

Connect the log clamp hoses (item

#25 labeled NOR006-0009) from the

horizontal cylinder to the hydraulic valve

section.

Note: Connect the cylinder retraction

hose to the bottom valve section port.

Connect the 140” vertical log clamp

hoses (item #26 labeled NOR006-0010)

to the vertical cylinder (item #11).

EN–9

Installation: Log Clamp Hoses

Connect the log clamp hoses (item #26

labeled NOR006-0010) from the vertical

cylinder to the hydraulic valve section.

Note: Connect the cylinder retraction

hose to the bottom valve section port.

EN–10

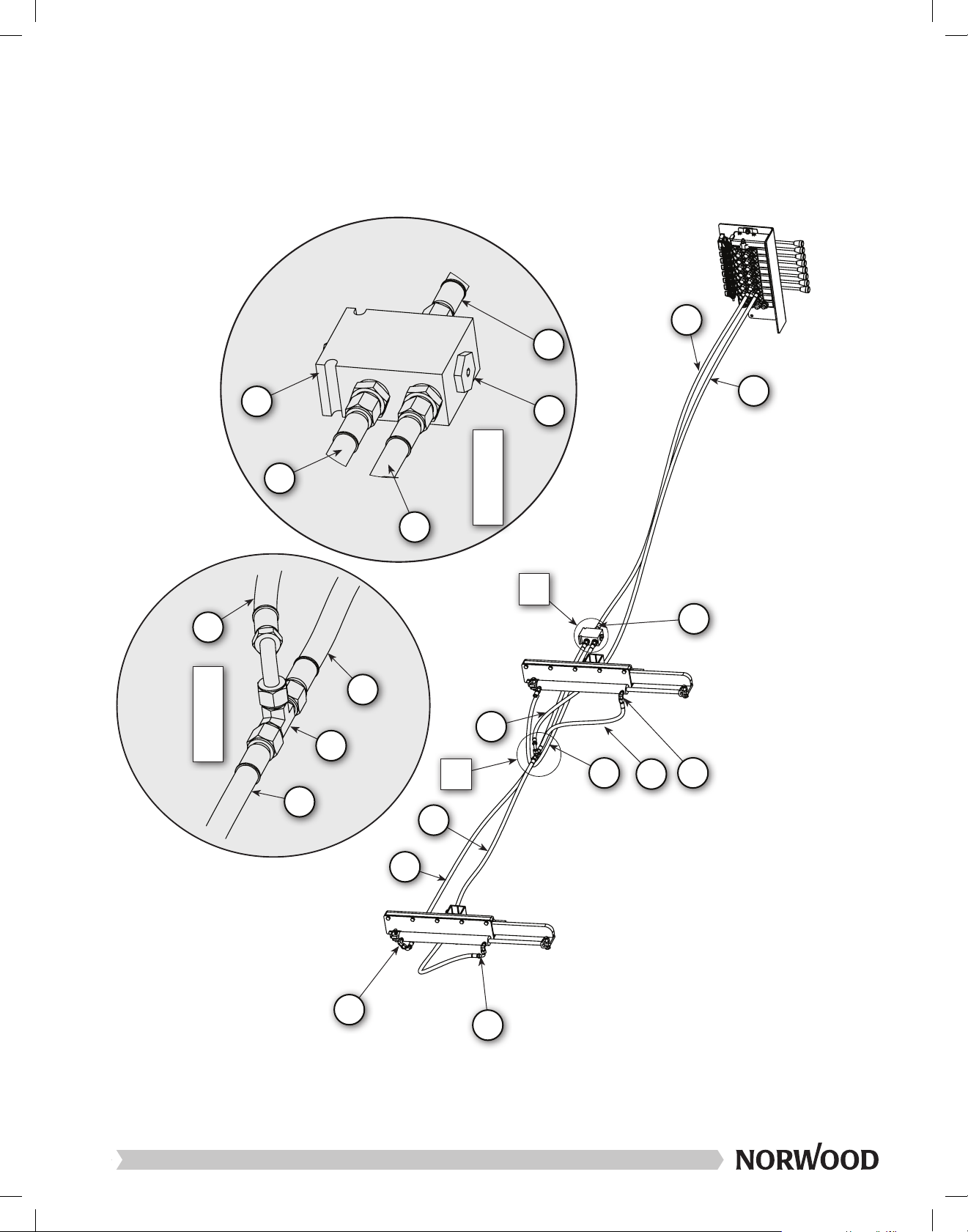

Connect the 48” hydraulic log rest hose

(item #21 labeled NOR006-0007) to the

flow divider (item #18), as shown in the

picture.

Then, connect the other end of the log

rest hose (item #24 labeled NOR006-

0006) to the hydraulic flow divider (item

#18), as shown in the picture.

Connect the 91” log rest hose (item #24

labeled NOR006-0006) to the correct

valve section (bottom port).

EN–11

Installation: Log Rest Hoses

Then, connect the other end of the log

rest hose (item #22 labeled NOR006-

0008) to the bottom port of the rear rest

hydraulic cylinder (item #11), located at

the back of the sawmill.

Connect the 93” hydraulic log rest hose

(item #22 labeled NOR006-0008) to the

flow divider (item #18), as shown in the

picture.

Then, connect the other end of the log

rest hose (item #21 labeled NOR006-

0007) to the bottom port of the log rest

hydraulic cylinder (item #11), located at

the front of the sawmill.

EN–12

Other manuals for LumberMax HD38

5

This manual suits for next models

3

Table of contents

Languages:

Popular Power Tools manuals by other brands

Metabo

Metabo SSW 650 operating instructions

Pladdet

Pladdet PSS230 Operation and maintenance manual

Milwaukee

Milwaukee 0881-20 Operator's manual

Virutex

Virutex AG98E operating instructions

Parkside

Parkside PAMFW 20-LI A1 Translation of the original instructions

Milwaukee

Milwaukee C12 MT-0 Original instructions