WARNING! DO NOT use the torque wrench if

damaged or thought to be faulty.

Ensure all workshop safety rules, regulations and

conditions are complied with when using the

torque wrench.

Maintain correct balance and footing. Ensure the

floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away

from the working area.

Avoid over-torquing the wrench (110% of

maximum torque range) as this will cause loss of

accuracy.

Keep the wrench away from magnets.

DO NOT use the wrench as a hammer or similar.

DO NOT subject the wrench to excessive force

or shocks.

DO NOT drop, throw, or violently shake the

wrench.

DO NOT operate the wrench in damp conditions.

DO NOT operate the wrench in dusty conditions.

DO NOT push on the LCD panel.

DO NOT use wrench until first instructed in its

use by a qualified person.

DO NOT leave the wrench in a place exposed to

excessive heat, humidity or direct sunlight.

DO NOT use organic solvents such as alcohol or

thinners to clean the wrench.

After use, clean with a soft dry cloth, place

torque wrench in its storage case, and store in a

safe, dry, childproof location.

Rugged and resilient digital torque wrench suitable

for workshop and factory use. LCD read-out with

LED/audible alarm indicates achieved and target

torque levels. Features angle mode, eliminating the

need for angle gauges and protractors providing the

most accurate and fastest way to measure torque

plus angle tightening sequences. Will also

accumulate angle measurement when multiple turns

are required, ideal for when access is limited.

Preset desired torque levels or track peak and

working torques using simple push-button menu.

Selectable read-out in Nm, lb.in, lb.ft, kgf.m or

degrees. Reversible Chrome Vanadium 72-tooth

ratchet allows torque reading in either direction.

Accurate to ±2% between 10% and 100% of

wrench’s stated capacity. Supplied with test

certificate and storage case.

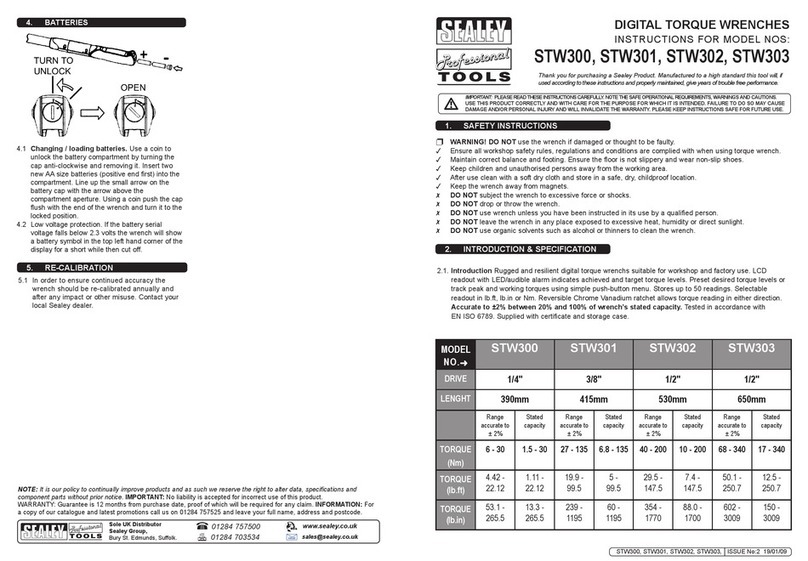

2.1 Specification.

Drive: ...............½”Sq

Overall Length:........610mm

Angle Range: .........1° - 360°

Torque Range: . . . . . . . . 20 - 200Nm

Torque Range: ........15 - 148lb.ft

Torque Range: ........177 - 1770lb.in

Torque Range.........2 - 20kgf.m

Accuracy.............±2%

(Clockwise and anti-clockwise of reading,

10% - 100% of full scale)

2.2 Re-calibration.

In order to ensure continued accuracy, the

wrench should be re-calibrated annually and

also after any impact, over-torquing or other

misuse. Contact your authorised Sealey

dealer to arrange this.

2.3 Repair Kit available.

Part No: STW306.RK

Contact your authorised Sealey dealer.

Thank you for purchasing a Sealey Product. Manufactured to a high standard this tool will, if used according to these instructions and

properly maintained, give years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

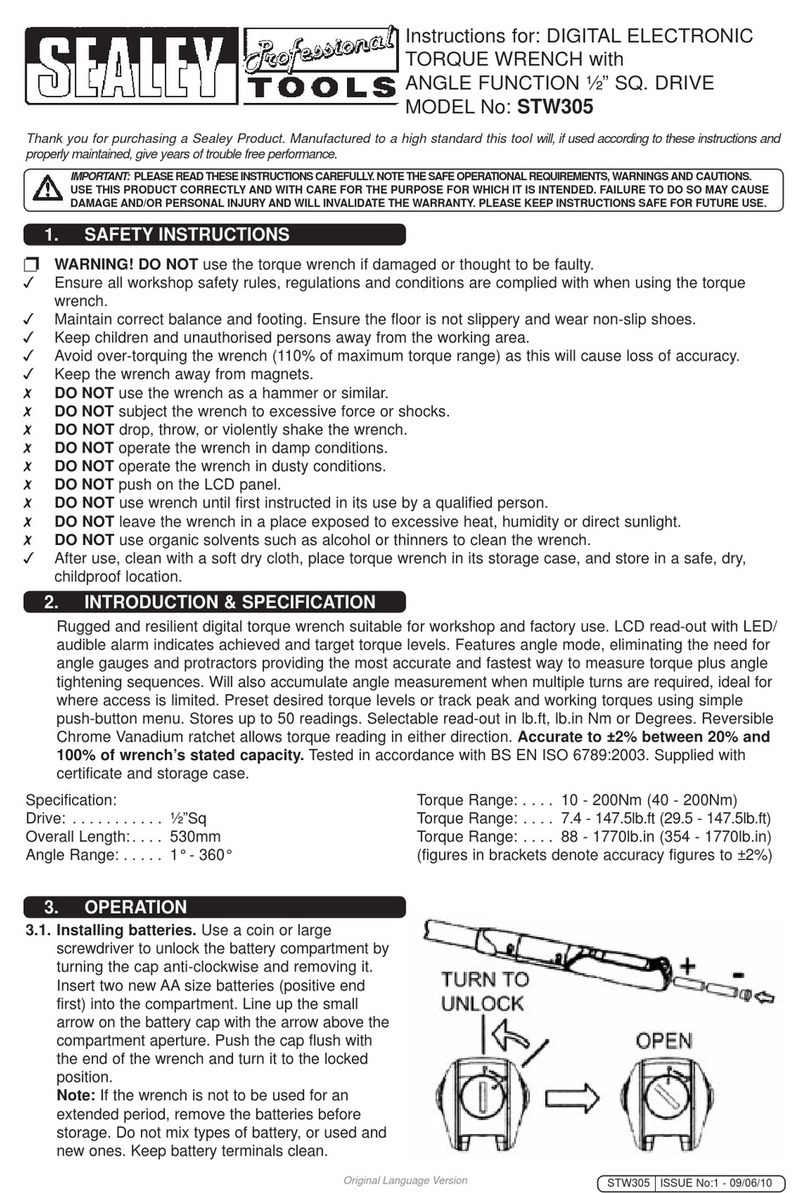

INSTRUCTIONS FOR:

DIGITAL ELECTRONIC TORQUE

WRENCH with ANGLE FUNCTION

MODEL No: STW306

1. SAFETY INSTRUCTIONS

2. INFORMATION & SPECIFICATION

3. SET-UP

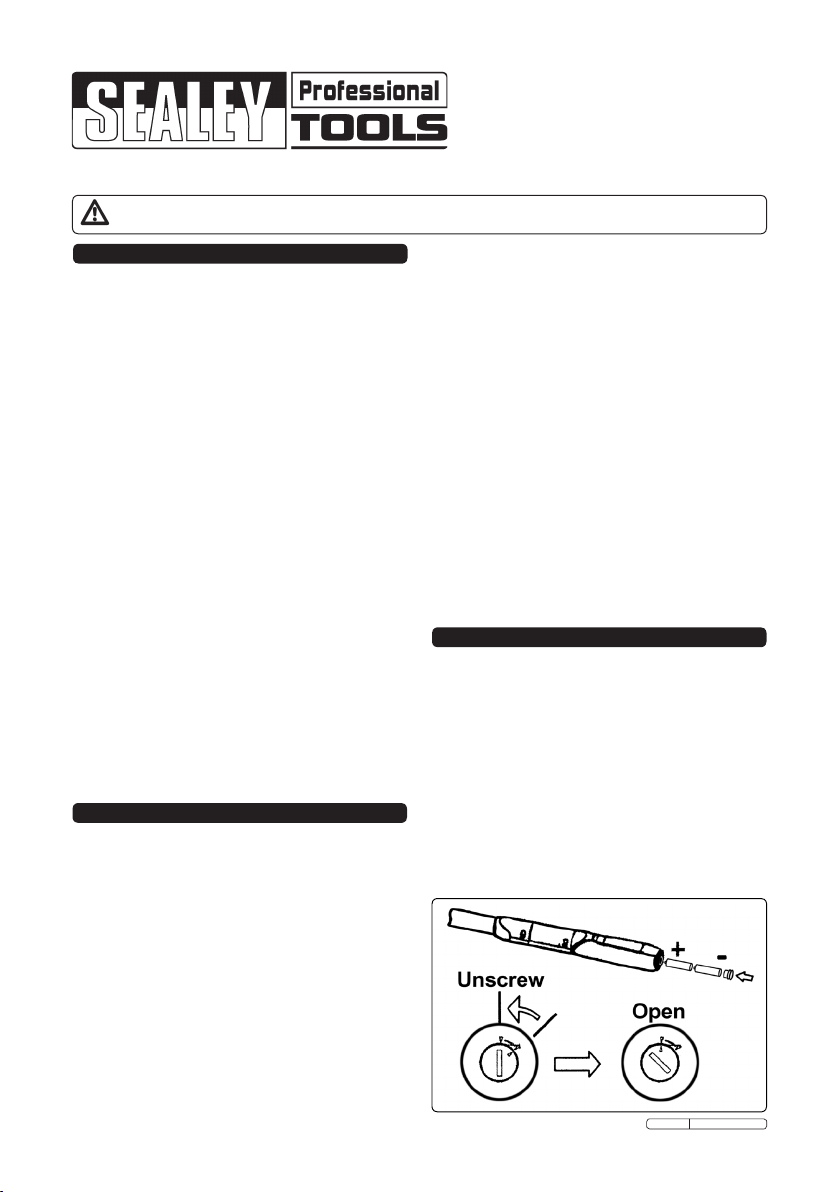

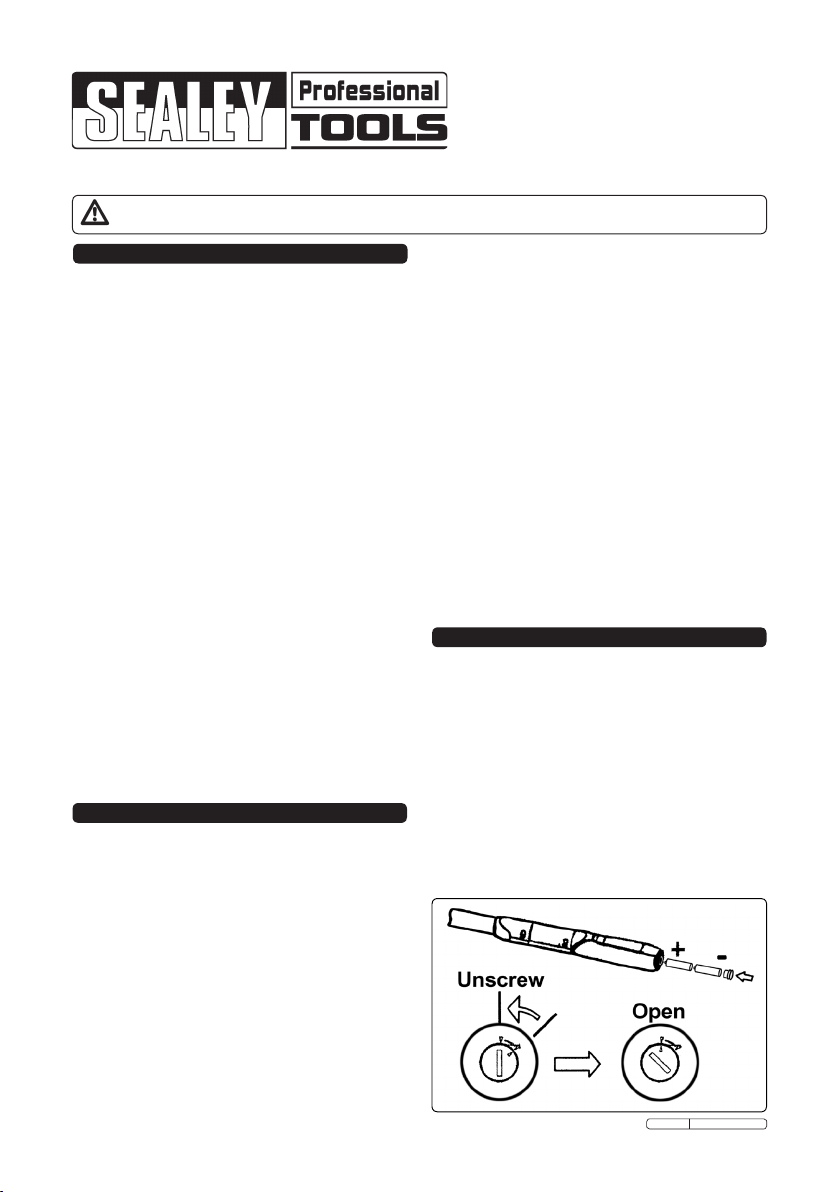

3.1 Installing batteries.

3.1.1 Unscrew the battery compartment cap

anti-clockwise

3.1.2 Insert four new AAA size batteries (positive

end first) into the compartment. Push the

battery cap on against the spring and screw

clockwise to lock

Note: If the wrench is not to be used for an extended

period, remove the batteries before storage.

Do not mix types of battery, or used and new

ones. Keep battery terminals clean.

Original Language Version STW306 Issue: 1 - 04/10/11