Nosram MATRIX EVOLUTION ISTC User manual

A B C + -

C

B

A

+

-

A B C + -

3. SPECIFICATIONS

•

Mount

the speed

o

using the supplied thick/black doubled-sided tape

.

• Position the speed-control where it is protected in the event of a crash.

• Install the speed-control so that you have easy access to the connector and buttons.

•

Make sure there is enough clearance (about 3cm) between the speed-control, power-

wires

, antenna

and

receiver

.

Avoid any

direct contact between power components, the receiver or the antenna. This can

cause

interference. If interference occurs, position the components at a different place in the model.

• The aerial should be run vertically up and away from the receiver. Avoid contact with any parts made of

carbon fibre

or metal. If the aerial is too long, don’t coil up the excess length. It is better to cut it down

to a

length of about 35 cm. See also the instructions supplied with your radio control system.

• Make sure there are enough cooling slits in the body. This will increase the performance and life of all the

electronic

components.

4. INSTALLATION TIPS

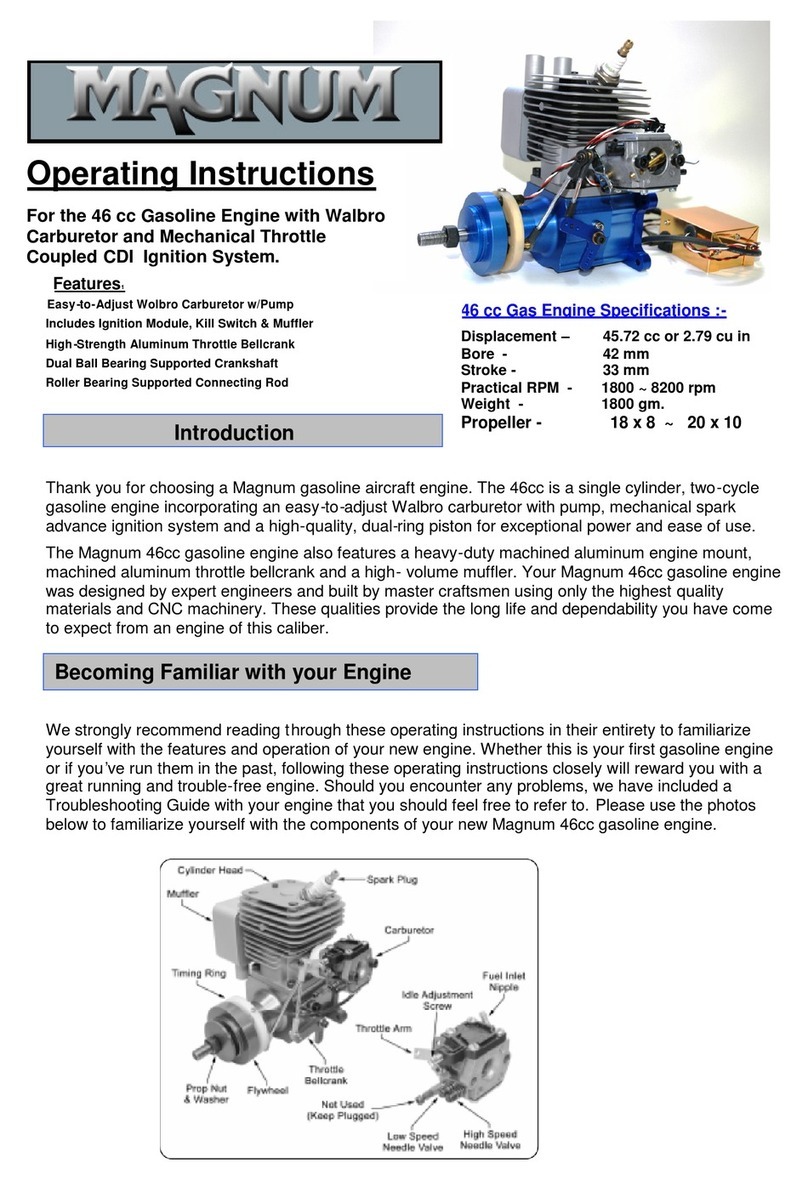

2. CONNECTIONS

1. INSTALLATION

* Transistors rating at 25°C junction temperature Specifications subject to change without notice.

** measured at 7.2V

USER MANUAL

5. SUPPRESSION

BRUSHLESS + BRUSHED

over 3T (brushless - star)

over 4T (brushed)

# 90750

for distributor address see packaging www.nosram.com

RA0018

3

BRUSHED MOTOR:

•

Bl

ue

/

Yellow power-w

ire

Speedo

MOT.A

/MOT.B

to

„Minus“

on

the mo

tor

.

•

Orange

power-wire

Speedo

MOT.

C

to

„Plus“

on the motor

.

BRUSHLESS MOTOR:

•

Blue power-wire

Speedo

MOT.A

to mo

tor

„A“

•

Yellow power-wire

Speedo

MOT.

B

to mo

tor

„

B

“

•

Oran

ge power-wire

Speedo

MOT.

C

to mo

tor

„

C

“

•

Connect the hall sensor cable to the speed-control and the motor.

orange

orange

orange

blue

yellow

yellow

blue

yellow

orange

Hall Sensor Wire

T

ogether to minus

yellow

On/Off

Swit

ch

Receiver

wire

Hall Sensor

Hall Sensor

Connector

Power Capacitor

RECEIVER CONNECTING WIRE:

RECEIVER CONNECTING WIRE:

This

NOSRAM

speed-control is equipped with an NOSRAM Multicon

speed-control is equipped with an NOSRAM Multicon

receiver

receiver

wire. As supplied, it will easily fit in all ordinary receivers.

H

ALL SENSOR WIRE

:

This bi-directional multipole wire (which comes with the motor and NOT the speed-control!) connects the

speed-control and the motor. Do not alter or modify this cable! There are replaceable

/optional

hall sensor

wires available:

•

#92510 (20cm)

•

#92520 (10cm)

POWER WIRES

:

For maximum performance,

1

2

AWG power wires

w

ithout any connectors

are used

.

The unique splitted

solder-tabs allow easy and convenient replacement of the power wires.

Nevertheless some soldering skills

are required

. A

void soldering longer then 5sec per soldering joint

to prevent possible damage to the speed-

control due to overheating of the components!

There is a

full 1

2

awg

replacement power wire set available:

#9250

6

HEATSINK

:

To achieve best

perfomance even under extreme

conditions, the heatsink has been directly

mounted to the speed-control. This ensures the best possible heat tr

ansfer away from the speed-control.

Caution

:

Never attempt to remove the he

atsink, because the speed-control will get damaged if you do this.

The heatsink is an integral part of the speed-control and therefore cannot be removed.

Because of the physical principles of brushless technology, the speed-controls do get a little hotter then

brushed systems. Therefore it is required to let the speed-control cool down completely after every run.

Mo

unt the power-capacitor in a position

unt the power-capacitor in a position

where it is protec

where it is protec

ted in the event of a crash.

T

he best place is right next to the speed-con-

he best place is right next to the speed-con-

trol (see picture)

trol (see picture)

. S

ecure it with doublesided

tape.

ONLY FOR BRUSHED MOTORS!

Motors with no capa-

citors or not enough capacitors may interfere with the

speed-control. To avoid this, solder the supplied capaci-

tors to your motor (see picture).

•

Doublec

heck all connections before connecting the speed-control to a battery

.

C

AUTION

:

If

battery is connected with reversed polarity it will destroy your speed-control!

•

Red power-wire

Speedo BA

T+ to battery „Plus“

•

Black

power-wire

Speedo BAT- to battery „Minus“

• The speed-control is now ready

to be set-up (see section 6)

.

The

NOSR

A

M MATRIX EVOLUTIO

N

IST

C

is supplied with

1

2

AWG power-wires without

connectors.

B

e very

careful with the correct wire sequence

/colors since an in

correct

connection

may

damage the speed-cont-

rol

! Avoid

creating

solder bridges

on the

solder-tabs and isolate

all

connections car

ef

ully.

C

aution

:

A

void soldering longer then 5sec per soldering joint when replacing the

power wires

on the spe

ed-

control and motor

to prevent possible damage due to overheating of the components!

•

Connect the speed-control to the receiver (position:

C

hannel 2)

Dear Customer,

t

hank you for your trust in this NOSRAM product. By purchasing a

NOSR

AM MATRIX EVOLUTIO

N ISTC

Brushless+Brushed

speed-

control,

you have chosen one of the most advanced speed-controls of today

.

This spe

ed-contr

ol with all of its high-tech features and specially selected electronic components

is one of

the best speed-controls for Touringcars currently available on the market.

• Optimized XPS.2 software

• Special TC software

•

Forward/Brake

• Low profile heatsink with integrated fan

•

Automatic Brushless/Br

ushed

adaption

• Smart-Temp-Readout-System

•

Launch Control

• Redesigned brake

• 4, 5 and 6 cell optimized

• Large Power capacitor

Please read the following instructions

to ensure, that your

NOSR

AM MATRIX EVOLUTIO

N ISTC

Brushless+Brushed

speed-control

always works up to your full satisfaction.

Please read and understand these instructions completely before you use this product!

With operating this product

, you accept the NOSRAM warranty terms

.

MOT.C (Orange)

MOT.C (Orange)

BAT + (Red)

MOT.B (Yellow)

MOT.B (Yellow)

BAT

-

(Black)

MOT.A (Blue)

Brushless

+

Brushed

yes

Voltage Input

4.8-7.4V

Brush

less + Brushed Adaption

AUTOMATIC

Weight (excl. wires)

45.0g

Forward/Reverse

yes

B.E.C.

5.8V/3.0A

Case Size

33.1x37.6x32.5mm

High Frequency

yes

Typ. Voltage Drop

(Brushless)*

@20A

0.017V /

p

hase

Sensored Brushless System

yes

Rated Current

(Brushless)*

400A /

p

hase

Multi-Protection-System

yes

Compatible winding styles (Brushless)

Star

Power Wires

12

awg

silicone flex

Rec. Motor Limit

for

Star winds (Brushless)**

for Star winds (Brushless)**for

over 3

t

urns

4, 5, 6 cell optimised

yes

Typ. Voltage Drop

(Brushed)*

@20A

0.012V

Smart-Temp-Readout-System

yes

Rec. Motor Limit (Brushed)

**

over

4 turns

Launch Control

yes

Rated Current (Brushed)*

400A

Integrated heatsink + fan

yes

4 adjustable Modes

(NiMH/LiPo, XPS.2/PMS.2 Power Profiles, Initial

- and

Automaticbrake

)

yes

6. RADIO / SPEED-CONTROL SET-UP 7. MODE PROGRAMMING

In setup mode the NOSR

AM MATRIX EVOLUTIO

N ISTC

stores every step when you press the SET button.

All the settings will be stored in the speed-controls memory even if the speed-control will be

disconnected

from the battery.

Throttle travel

High ATV, EPA

High ATV, EPA

maximum

Brake travel

Low ATV, EPA, ATL

maximum

Throttle exponential

Throttle exponential

EXP, EXPO

start with 0

Neutral trim

SUB Trim

centre

Servo reverse

Throttle reverse

any setting, don‘t change after set-up procedure!

any setting, don‘t change after set-up procedure!

TRANSMITTER SETTINGS

Setup the following basic functions on your transmitter (if available):

If your transmitter doesn‘t offer any of above functions, it‘s already in „basic setup“ mode.

• En

sure that the speed-control is not connected to the drive battery and is switched off.

•

Remove motor pinion or ensure that the wheel

s of the model are free to rotate.

•

Switch the transmitter on and set the transmitter throttle stick to neutral.

•

Connect

the speed

-control to the battery, and

switch the unit on.

•

Hold the SET button p

ressed for at least 3sec using the supplied plastic screwdriver.

You entere

d setup mode and the

SET LED flashe

s

blue

(it

will flash until the

setup is comp

le

ted).

•

Leave transmitter in neutral position

and press the SET button once.

Neutral setting is stored , MODE L

ED flashes yellow an

d the motor beeps.

•

Hold fu

ll throttle on transmitter

and press the SET button once.

Full-throttle setting is stored,

MODE LED flashes red.

•

Hold fu

ll brake on transmitter

and press the SET button once.

Bra

ke setting is stored, LED‘s glow red (MODE) and blue (SET)

.

•

This completes the setup pro

cedure and your NOSR

AM MATRIX EVOLUTIO

N ISTC

is ready to us

e.

•

If you make a mistake during the setup proce

dure, don‘t worry: Disconnect the battery for about 10sec

and

start

ag

ain from the first step.

•

At the end of each run

switch of the car

, and then switch off the transmitter.

•

At the start of each run switch on the transmitter first, then

switch on the car.

•

F

or storage of the car, disconne

ct the drive battery at any time!

FUNCTION

STATUS

MODE LED

SET LED

Neutral (automatic brake inactive)

--

off

blue

Neutral (automatic brake active)

--

red

off

Forward

partial throttle

partial throttle

yellow

yellow

off

Forward

full throttle

yellow

yellow

blue

Brake

partial brake

partial brake

red

off

Brake

full brake

red

blue

CHECKING THE FUNCTIONS:

Check

the

LED‘s when moving your throttle stick and you will see if everything is setup correctly.

All modes are available for brushless and brushed motors (

speedo adapts

automatically).

The NOSRAM

MATRIX EVOLUTIO

N ISTC

features 4 modes which enable you to adjust it to YOUR special requirements.

The

factory settings are shown in grey colour

.

M

ODE.1 (

Smart

Cell System

)

:

MODE

.

2 (

XPS.2

2 (XPS.22 (

Brushless Power Profiles

XPS.2 Brushless Power ProfilesXPS.2

)

:

only with connected Brushless motor

Higher value means more overall power and more

aggressive

throttle

response

.

T

ea

m

T

i

p

s

:

The following XPS.2

(Brushless)

settings are the preferences from our teamdrivers:

•

Tou

ring Car

: Bonded: 4-7 Sintered: 3-5

•

Off-Road 2

WD

+

Truck:

Bonded: 1-2 S

intere

d:

1

•

1

/12: Bonded: 3-5

S

intered:

2-4

•

Off-Road 4

WD

: Bonded:

1

-4 Sintered:

1

-3

MO

DE

.

2

(

2 (2

PMS.2

Brushed Power Profiles

PMS.2 Brushed Power ProfilesPMS.2

)

:

only with connected Brushed motor

Higher value means more overall power and more

aggressive

throttle

response

.

T

ea

m

T

i

p

s

:

The following PMS.2

(Br

ushed)

settings are the preferences from our teamdrivers:

•

Tou

ring Car

:

Brushed

:

3-5

•

Off-Road 2

WD

+

Truck:

Brushed

:

1-2

•

1

/12:

Brushed:

2-3

•

Off-Road 4

WD

:

Brushed

: 1-4

•

19/27T motors:

Brushed: 5-

6

M

OD

E.3

(

I

nitial Br

ake

):

A

llows you to set a certain level of „hand-brake-effect“

.

T

eam

T

ips

:

A

good starting po

int for the

brake

setting on your radio

is 80% (bonded) and 70% (sintered)

for all classes.

M

ake sure you do the radio-setup with all setting

s on the radio on 100%.

MODE.4 (

Automatic Brake

MODE.4 (Automatic BrakeMODE.4 (

):

A

llows you to set a slight braking action in neutral range

.

Team

t

ips:

For brushl

ess motors y

ou achieve

the same

natural

slowdown as a brushed motor with no autob-

rake when you

set value 2

/3

(

for

bonded

magnets

)

or 0/1 (

for

sintered

magnets

)

.

MODE LED

Value

1

Value

2

Yellow

LiPo/NiMH

Automatic

4-

6

cell NiMH

Racing Mode

•

How to get into „programming the modes

“

Press

MODE button for 3 or more seconds.

•

How to check the stored values

C

ount the number of flashe

s of the blue SET-LED

(

1

x

= value 1, 2

x

= value 2, etc.

)

.

•

How to change the value

Press SET button to increase v

alue by one step.

•

How to get to the next Mode

P

ress M

ODE button

o

nce.

•

How to leave the programming mode

If you are in MODE.4, press the MODE button

one more time

•

Table of settings

,

values and modes: see below (grey-shaded values show

„works default set

tings“).

Smart-Temp-Readout

-

System:

A

s a world-exclusive the NOSRAM MATRIX EVOLUTION ISTC

allows

you to read-out the maximum

internal

temperature that the speedo reached. To save it to the memory you

have to briefly apply brakes after the run before you turn the switch off. You

can convienently read-out the

temperature back in the pits since it remains

stored until you turn it on the next time regularly (which will

reset the memory).

This new feature allows you to accurately check if all is running well or if you‘re close to

shutdown already

.

How to read-out the temperature:

Swit

ch

at

„OFF“ position.

Keep MODE button pressed while you turn swit

ch to „ON“ (then release button)

SET LED will start to flash blue (MODE LED is off)

, now

count the number of flashes.

•

T

hermal shutdown of the speedo would occur

at 5 flashes.

•

The higher the number

o

f

flash

es

, the cooler the speedo ran

(e.g. the

better it is!).

•

E

very flash

over

5

equals

to

~

8

°C

lower internal temp.

(

e.g. 10

flashes is

40°C below shutd

own)

Launch Control

:

Well known

and famous

from our brushed speedos!

No

w

also available for brushless

, the

launch control

allows

„rocket like“ starts

.

After activation it gives you more power

one time for the start

(this

feature is only recommended to be used with touring cars on

high traction surfaces

!).

How to activate launch control

:

Hold tr

igger of transmitter at full brake

for 5sec before start.

Ready

and active

!!!

Smart

Ce

ll S

ystem

:

Ready

for th

e next battery technology – LiPo batteries! NOSRAM’s exclusive and

smart SmartCell System ensures that LiPo batteries can be used safely without

accidentially

deep-discharging

of

the cells.

T

he motor function will be shut-off and the SET LED will flash

if

the system recognises very low

if the system recognises very low if

battery voltage

.

T

ip

:

We recommend using value 2 for 4-6 cells NiMH racing purposes, which disengages the LiPo protection.

XPS.2

Brush

less - Power Profiles:

A

n all new brushless technology which results in more power

and better driveability. Depending on the status of the car (start, acceleration and full speed) the software

calculates the perfect motor management. Higher value means more overall power and

aggressive response

.

Caution

:

Do not

advance

mechanical timing on the

motor

.

L

eave the motor timing on

minimum timing, which

e

q

uals to

2mm

on the

sticker.

PMS.2 Brushed

- Power Profiles

PMS.2 Brushed - Power ProfilesPMS.2 Brushed

:

T

he known and world‘s winning PMS.2

Brushed

power programs

have been implemented

into the NOSRAM MATRIX EVOLUTION ISTC aswell.

Higher value means more overall

power and

aggressive respons

e.

A

utomatic Br

ushless / Brushed Adaption

:

The NOSRAM exclusive Automatic Brushless/

Brushed Adapt

at

ion

detects the connected motor type

during

turn-on

/

initialisation

and adjusts the correct

brushless or brushed

operation

automatically

.

No

adjustment

s

required by yourself, apart from the correct

connection of each motor type (don‘t forget the hall-sensor-wire for brushless!).

Caution

:

Keep in mind, when swopping between brushless and brushed motors, that the chosen mode values

will be identical!

Changing Mode settings without the transmitter

:

At race events you usually do not have

access to your transmitter

, but never mind since you can

simply

disconnect the receiver lead from the receiver

and

c

hange the MODE settings as described in section 7 „Mode Programming“.

8. SPECIAL FEATURES

MODE LED

Value

1

Value

2

Value

3

Value

4

Value

5

Value

6

Value

7

Value

8

R

ed

s

mooth

Power

:

1X

s

mooth

Power:

2X

s

mooth

Power:

3X

s

mooth

Power:

4X

l

inear

Power:

4X

l

inear

Power:

5

X

pr

ogressive

Power: 5X

a

ggressive

Power: 6X

MODE LED

Value

1

Value

2

Value

3

Value

4

Value

5

Value

6

R

ed

smooth

,

low traction

very

l

inear

l

inear,

p

un

ch

increasing

a

ggressive

p

rofil

e

very

aggressi-

very aggressi-very

ve

p

rofil

e

s

uper aggres-

siv

e

p

rofil

e

MODE LED

Value

0

Value

1

Value

2

Value

3

Value

4

Value

5

Value

6

Yellow

/

Yellow/Yellow

R

ed

(alternate)

No

Initial

Brake

Going from lowest to highest inital

brake setting

(value 1 = minimum / value 6 = maximum)

MODE LED

Value

0

Value

1

Value

2

Value

3

Value

4

Value

5

Value

6

Yellow

/Red (same

Yellow/Red (same Yellow

time)

No

Automatic

Brake

Going from lowest to highest automatic brake setting

(value 1 = minimum / value 6 = maximum)

Wor

ks-Default-Settings

:

A

ll N

OSRAM speed-controls

come

factory-adjusted

(de

faults are grey-

shaded

above

)

. If you loose track of the modes, you can res

tore

the

works default settings

.

With the transmit-

ter switched on, hold the SET button pressed while you switch on the speed-control. This

simple

action returns

the unit to the NOSRAM works default settings.

P

ower Capacitor

:

Never disconnect the power-capacitor!

It offers

increased

punch

an

d

additional pro-

tection

.

Freeze

Drive D

esig

n

:

NOSRAM’s secret FreezeDrive Design results in lower speedo temperature under

all racing conditions

and for b

oth brushless + brushed

. Sorry, no further details to be disclosed. Simply a step

ahead of the competition!

Forward/Brake

:

U

ncompromising and outstanding performance

for

top level competition

was the target!

Therefore the

NOSRAM engineering team

develop

ed

a pure forward/brake

co

mpetition

speed

-

control without

reverse function.

Sensored Brushless Technology

:

Enhanced Digital allows the perfect knowledge of the brushless

motor’s magnet position. This

results in

perfect motor control at high and low RPM‘s, as well as perfect brake

control.

M

ulti-Protection System, 3-way protection

:

T

he perfect protection against short-circuits

(motor), overload and overheating. If your speed-control faces overload, the motor function will be shut-off for

protection and the SET LED will flash, although the steering function is maintained. Let the speed-control cool

down for a few minutes. If you experience frequent shutdowns, check for the following:

•

Correct gear ratio (refer to motor manual for gearing recommendations)

• XPS.2 setting too high (higher

• XPS.2 setting too high (higher

val

ue will heat up motor a

ue will heat up motor a

nd

speed

speed

-control excessively)

-control excessively)

• Motor is too strong or motor is damaged.

• Motor is too strong or motor is damaged.

!

9. WARNING NOTES

No toy. Not suitable for children under 14 years.

Keep the product out of the reach of children.

Pay close attention to the following points, as they can de-

stroy the product and void your warranty. Non-observance

of these points can lead to property damage, personal and

severe injuries!

•

Never leave the product unsupervised while it is switched on,

in use or connected with a power source. If a defect occurs,

it could set fire to the product or the surroundings.

•

Never wrap your product in plastic film, metal foil or similar.

In fact, make sure it gets enough fresh air.

•

Avoid incorrect connections or connections with reversed

polarity of the product.

•

All wires and connections have to be well insulated. Short-

circuits can possibly destroy the product.

•

Never allow this product or other electronic components to

come in contact with water, oil or fuels or other electrocon-

ductive liquids, as these could contain minerals, which are

harmful for electronic circuits. If this happens, stop the use

of your product immediately and let it dry carefully.

•

Never cut off or modify the original plugs and original wires.

•

Never open the product and never solder on the PCB or other

components.

•

Never use this product when the case is open, damaged or

missing or when the product is wrapped in a shrink-fit tube.

This will reduce protection, may cause short circuits and da-

mage the product.

•

Always remove the battery from your product or disconnect

REPAIR PROCEDURES / LIMITED WARRANTY

the product from the power source, if the product is not in use.

Always remove the battery from your product or disconnect

the product from the power source, if the product is not in use.

Always remove the battery from your product or disconnect

•

Always switch on your transmitter first before you switch on the receiver or the speed control. The

receiver could receive interference signals, start full acceleration and damage your model. When you

switch off, make sure you do so in the reverse sequence. First switch off the receiver and speed control,

then switch off the transmitter.

•

Never solder a Schottky diode to the motor when you are using this speed-control.

•

If the speed-control is connected to the motor, never run the motor directly with a separate battery or

run-in device.

•

Never change the polarity of the receiver connector.

•

Always wire up all the parts of the equipment carefully. If any of the connections come loose as a result

of vibration, you could loose control over your model.

•

Avoid soldering longer then 5 seconds per soldering joint when replacing the power wires to prevent pos-

sible damage to the product due to overheating of the components. Use a high power soldering station

for soldering.

•

Never apply full throttle if the motor is not installed. Due to the extremely high RPMs without load, the

motor can get damaged.

10. TROUBLESHOOTING GUIDE

E

XPLANATION

:

If no remark, cause can be either

with

brushles

s or brushed m

otor

.

If „

B

M

“

is indi

cated

,

cause

on

ly

relating to

brushed motor.

All products from NOSRAM are manufactured according to the highest quality standards. NOSRAM guarantees

this product to be free from defects in materials or workmanship for 90 days (non-european countris only) from

the original date of purchase verified by sales receipt. This limited warranty doesn’t cover defects, which are a

result of normal wear, misuse or improper maintenance.

This applies among other things on:

•

Cut off original power plug or not using reverse polarity protected plugs

•

Receiver wire and/or switch wire damaged

•

Mechanical damage of the case

•

Humidity/Water inside the speed control

•

Mechanical damage of electronical components/PCB

•

Soldered on the PCB (except on external solder-tabs)

•

Connected speed-control with reversed polarity

To eliminate all other possibilities or improper handling, first check all other components and the trouble shoo-

ting guide, if available, before you send in this product for repair or warranty. Products sent in for repair, that

operate perfect have to be charged with a service fee.

By sending in this product, you assign NOSRAM to repair the product, if it is no warranty or Limited Lifetime

Warranty case. The original sales receipt including date of purchase needs to be included. Otherwise, no war-

ranty can be granted. For quick repair- and return service, add your address and detailed description of the

malfunction.

Because we don’t have control over the installation or use of this product, we can‘t accept any liability for any

damages resulting from using this product. Therefore using this product is at owner‘s risk. Our limited warranty

liability shall be limited to repairing the unit to our original specifications. In no case shall our liability exceed the

original cost of the unit. By installing or operating this product, the user accepts all resulting liability.

The specifications like weight, size and others should be seen as guide values. Due to ongoing technical im-

provements, which are done in the interest of the product, NOSRAM does not take any responsibility for the

accuracy of these specs.

With Limited Lifetime Warranty products, the warranty terms on the Limited Lifetime Warranty card do also

apply.

NOSRAM

-Distributor-Service:

• Package your product carefully and include sales receipt and detailed description of malfunction.

• Send parcel to your national NOSRAM distributor.

• Distributor repairs or exchanges the product.

• Shipment back to you usually by COD (cash on delivery), but this is subject to your national NOSRAM

distributor‘s general policy.

The crossed-out wheeled bin means that within the European Union the product must be taken

to seperate collection at the product end-of-life. Do not dispose of these products as unsorted

municipal waste.

SYMPTOM

CAUSE

REMEDY

Servo is working, no motor function.

Speed-control plugged in incorrectly

Plug speed-control in Ch 2

Overload protection activated

Allow speed-control to cool down

Wiring problem

Check wires and plugs

Motor defective

Replace motor

BM

- Motor brushes stuck

BM - Motor brushes stuckBM

Check that brushes are moving freely

Speed-control defective

Send in product for repair

No servo and no motor function.

Speed-control plugged in incorrectly

Plug speed-control in with correct polarity

Crystal defective

Replace components one by one.

Receiver defective

Transmitter defective

Speed-control defective

Send in product for repair

Motor runs in reverse when accelera-

ting forward on the transmitter.

BM

- Motor connected incorrectly

BM - Motor connected incorrectlyBM

Connect motor correctly

Insufficient performance.

E.g. poor brake power, topspeed or

acceleration..

Motor pinion too big or gear ratio too long.

Use smaller motor pinion/shorter gear ratio

Transmitter settings changed af ter set-up

Repeat set-up procedure

BM

- Motor worn out

BM - Motor worn outBM

Maintain motor

Motor defective

Replace motor

Speed-control defective.

Send in product for repair

Speed-control overheats or switches

off frequently.

Motor stronger than motorlimit or input voltage

too high

Use only motors and batteries which are within the

specifications of the speed-control

Motor pinion too big or gear ratio too long.

Use smaller motor pinion/shorter gear ratio

Drive train or bearing problems.

Check or replace components.

Model used too often without cool-down periods

Let speed-control cool down after every run

Motor never stops, runs at constant

slow speed

Transmitter settings changed af ter set-up

Repeat set-up procedure

Humidity/water in speed-control

Immediately unplug and dry speed-control

Speed-control defective

Send in product for repair

Radio interference

BM

- Motor suppressors not sufficient

BM - Motor suppressors not sufficientBM

Solder capacitors to motor

Receiver or antenna too close to power wires,

motor, battery or speed-control.

Receiver aerial too short or coiled up

See „Installation Tips“ and „Installation“

Receiver defective, too sensitive;

Transmitter defective, transmitter output power

too low, servo problem

Replace components one by one

Only use original manufacturers crystals

Poor battery connection

Check plugs and connecting wires

Transmitter batteries empty

Replace / recharge transmitter batteries

Transmitter antenna too short

Pull out antenna to full length

This manual suits for next models

1