9

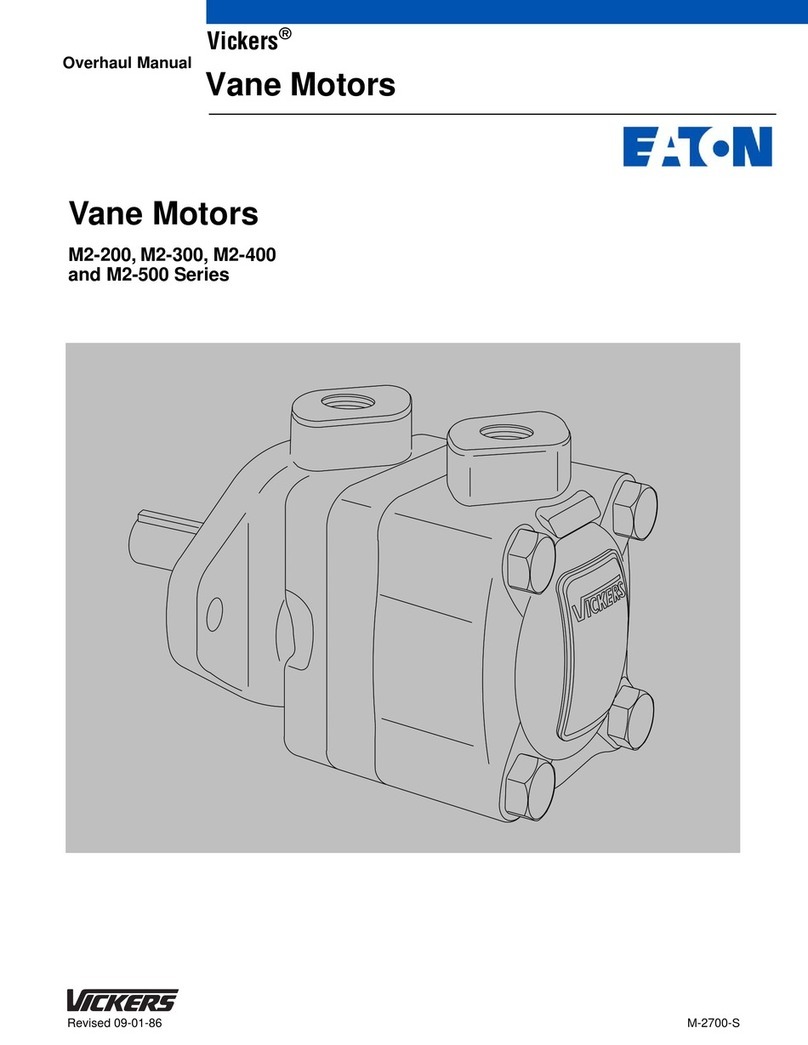

EATON Vane Motors M-2740-S June 2011

Piping and Tubing

1. All pipes fittings, hose and tubing must be thoroughly

cleaned before installation. Recommended methods of

cleaning are sandblasting, wirebrushing and pickling.

NOTE: For instructions on pickling, refer to instruction sheet

1221-S.

2. To minimize flow resistance and the possibility of leakage,

use only as many fittings and connections as necessary

for proper installation.

3. The number of bends in hydraulic lines should be kept to

a minimum to prevent excessive turbulence and friction

of oil flow and to minimize pressure drop in the lines.

Tubing must not be bent too sharply. The recommended

radius for bends is three times the inside diameter of the

tube.

Hydraulic Fluid Recommendations

General Data

Oil in a hydraulic system performs the dual function of

lubrication and transmission of power. It constitutes a vital

factor in a hydraulic system and careful selection of it should

be made with the assistance of a reputable supplier. Proper

selection of oil assures satisfactory life and operation of

system components with particular emphasis on hydraulic

motors. Any oil selected for use with motors is acceptable

for use with valves or pumps.

Data sheets for oil selection are available from Vickers

Technical Publications, Troy, Michigan. Order data sheet

M-2950-S for mobile applications.

The oil recommendations noted in the data sheet are based

on our experience in industry as a hydraulic component

manufacturer.

Where special considerations indicate a need to depart from

the recommended oils or operating conditions, see your

Vickers representative.

Cleanliness

Clean fluid is the best insurance for long service life. To

insure your hydraulic system is clean, perform the following

steps.

1. Clean (flush) entire new system to remove paint, metal

chips, welding shot, etc.

2. Filter each change of oil to prevent introduction of

contaminants into the system.

3. Provide continuous oil filtration to remove sludge and

products of wear and corrosion generated during the life

of the system.

4. Provide continuous protection of system from entry of

airborne contamination, by sealing the system and/or by

proper filtration of the air.

5. Proper oil filling and servicing of filters, breathers,

reservoirs, etc., cannot be overemphasized.

6. Good system and reservoir design will insure that aeration

of the oil is kept to a minimum.

Sound Level

Noise is indirectly affected by the fluid selection, but the

condition of the fluid is of paramount importance in obtaining

optimum reduction of system sound levels.

Some of the major factors affecting fluid conditions that

cause the loudest noises in a hydraulic system are:

1. Very high viscosities at start-up temperatures can cause

motor noises due to cavitation.

2. Running with a moderately high viscosity fluid will slow

the release of entrained air. The fluid will not be

completely purged of such air in the time it remains in the

reservoir and air will be recycled through the system.

3. Aerated fluid can also be caused by ingestion of air

through the pipe joints of inlet lines, high velocity

discharge lines, cylinder rod packings, or by fluid

discharging above the fluid level in the reservoir. Air in the

fluid causes a noise similar to cavitation.

4. Contaminated fluids can cause excessive wear of internal

motor parts, which may result in increased sound levels.

Overload Protection

A relief valve must be installed in the system to limit

pressure to a prescribed maximum. This protects the

system components from excessive pressure. The setting

of the relief valve depends on the work requirements of the

system and the maximum pressure ratings of the system

components. The relief protection must be designed to

prevent any hydraulic surge pressure, whether applied to

or generated by the motor, from exceeding the maximum

pressure rating of the motor.

In the event of an overrunning load, the motor may be driven

as a pump. If such a condition occurs, provision must be

made in the circuit to supply the motor enough hydraulic fluid

to prevent cavitation.

Drain Connection

Drain passages are provided in the motor to carry internal

leakage to a drain port in the cover. Never operate the motor

unless the drain port is connected to the reservoir. Pressure

in the drain line must not be more than 30 psi to avoid

internal damage.