Novatech 11.569.00-B User manual

Revision: 0

Release date: 28.10.2021

OWNER’S MANUAL 1.0

ROLL TRAILER 100T 60FT

For transporting evenly distributed loads on the trailer

PROJECT NUMBER:11.569.00-B

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

2

Revision History

REVISION

DATE

DESCRIPTION

PAGE

CHANGED BY

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

3

Table of Contents

1. Product information................................................................................................................. 4

2. Terms and units ....................................................................................................................... 6

3. Safety....................................................................................................................................... 8

4. General description................................................................................................................ 13

5. Operating rules ...................................................................................................................... 15

6. Working with the trailer ........................................................................................................ 16

6.1. Before first use............................................................................................................... 16

6.2. Connecting the tugmaster............................................................................................... 16

6.3. Loading the trailer.......................................................................................................... 17

6.4. Driving with the trailer................................................................................................... 19

6.5. Driving on the ramp ....................................................................................................... 20

6.6. Disconnecting the tugmaster.......................................................................................... 20

6.7. Trailer transport and stacking storage............................................................................ 21

7. Maintenance........................................................................................................................... 24

7.1. Maintenance manual ...................................................................................................... 24

7.2. Grease points.................................................................................................................. 26

7.3. Bolts ............................................................................................................................... 27

7.4. Old tire replacement....................................................................................................... 27

7.5. Bearings replacement..................................................................................................... 27

7.6. Maintenance schedule .................................................................................................... 28

7.7. General safety................................................................................................................. 28

8. Spare parts ............................................................................................................................. 28

9. Warranty regulations ............................................................................................................. 29

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

4

1. Product information

Manufacturer:

NT Industry Sp. z o.o.

(subsidiary of Novatech Aps.)

Fabryczna 1

43-180 Orzesze /Poland

Vendor:

Novatech Aps.

Skudehavnsvej 30

9000 Aalborg / Denmark

Phone no: +45 98 16 50 09

Fax no: +45 98 16 80 97

Type: Transport equipment

Name: Roll Trailer 100t 60ft

Project number: 11.569.00-B

Production year: 2021

Weights and loads

Capacity [kN]

1000

Tare weight [kg]

12000

Axle load [kN]

820

4 x 205

5th wheel load (without gooseneck) [kN]

305

Dimensions

Total length [mm]

18500

Total width [mm]

2790

Total height [mm]

900

Rear overhang [mm]

5000

Length of the loading area (ft)

60

Running gear

Number of axle lines

2

Number of wheels

8

Tire size (solid rubber) (inch)

22x16x16

Loading platform

Steel deck

5mm checker plate

Max surface pressure 19,4kN/m2

Speed and distance

Speed max. (km/h)

6

With load

10

Without load

Distance with max. speed (m)

2000

Min. 3 hours break between driving

cycles

Accessories

D-rings

Equipped

50 pcs 50t BL

Lashing eye

Equipped

2 pcs on each longbeam

Forklift pockets

Equipped

2050 mm distance in between

Finish

Shoot blasting

Sa 2½

EN ISO 8501

Top coat

C3

EN ISO 12944-6

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

5

Road requirements

Max ramp angle (deg)

6

Max allowable transverse slope (deg)

4

Max tugmaster angle (deg)

±70

Other requirements

Ambient temperature (°C)

MIN. -20; MAKS +40

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

6

2. Terms and units

Table 1. Unit conversion table

SI / METRIC SYSTEM

US UNITS

1 mm

0.03937 in

1 m

3.281 ft

1 km

0.6214 mi

1 km/h

0.6214 mph

1 kg

2.205 Ib

1 t

2205 Ibs

1 N

0.2248 Ibf

1 Nm

0.7376 Ibf*ft

1 bar

14.5 psi

1 liter

0.264 gal

Table 2. Definitions table

Cargo deck

The area within the CTU boundaries onto which packages may be placed and

secured.

Cargo transport unit (CTU)

A freight container, swap body, vehicle, railway wagon or any other similar

unit in particular when used in intermodal transport.

Clean CTU

A CTU free from:

Any previous cargo residues;

Any securing materials used from previous consignments;

Any marks, placards or signs associated with previous

consignments;

Any detritus (waste) that may have accumulated in the CTU;

Visible pests and other living or dead organisms, including any part,

gametes, seeds, eggs or propagules of such species that may survive

and subsequently reproduce; soil; organic matter;

All other items covered by contamination, infestation and invasive

alien species that can be discovered upon visible inspection.

COG

Center of gravity

Contamination

Visible forms of animals, insects or other invertebrates (alive or dead, in any

lifecycle stage, including egg casings or rafts), or any organic material of

animal origin (including blood, bones, hair, flesh, secretions, excretions);

viable or non-viable plants or plant products (including fruit, seeds, leaves,

twigs, roots, bark); or other organic material, including fungi; or soil, or

water; where such products are not the manifested cargo within the CTU.

Overloaded

Load (kN) placed on the trailer is greater than the maximum capacity.

User

Whoever uses the Roll Trailer or has it operated by suitable trained personal

is considered to be the user (employer/company)

Trained personnel

Trained personnel are persons who have been instructed and trained in the

duties with which they are entrusted and risks which may arise from

incorrect behaviour, have been advised on the necessary protective devices,

precautions, applicable regulations, accident prevention regulations and

prevailing conditions and have proven their ability.

Qualified person

(specialist)

A qualified person is one with the necessary qualification, based on

theoretical and practical knowledge of trailers, for the required activities as

listed in the manual. Person with the authority to undertake certain

maintenance work on our products include service engineers of

manufacturer and trained fitters with the corresponding certification.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

7

SWL

Safe Working Load (SWL) is the maximum safe force that a piece of lifting

equipment, lifting device or accessory can exert to lift, suspend, or lower,

a given mass without fear of breaking.

TARE

Tare is unladen weight of a device.

Remarks

DANGER

Highest danger level

Immediate danger of death or severe injury

The action is forbidden

WARNING

High danger level

Possible danger of death or severe injury

Measures to be taken for preventing specific danger

CAUTION

Hazardous situation

Danger of injury or property damage

Measures to be taken for preventing specific danger

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

8

3. Safety

This section contains general safety instructions for supplied machine. This manual should

be reviewed very carefully by all persons working on or with supplied machine.

Conditions

REMEMBER: YOU are the best to prevent YOU from getting injured if you think about

it before you come near the machine.

You should think about your own safety first. Various errors must be corrected as soon

as possible.

Operators should think twice before they do anything with the machine not to get

injured.

Machine should not be started until the operator is satisfied that there are no persons

or unwanted things close by, in or on the machine and start-up can be done without

risk to life and injury and damage to the machine.

There are not always more persons in the immediate vicinity, so it requires that operators

are extra careful in their use since help is not in the immediate vicinity.

General safety instructions for maintenance personal.

Maintenance and service personnel must remember to disconnect the power supply

for machine, when maintenance, repair works, troubleshooting, cleaning etc are performed.

Put a sign on the machine indicating that "Do not start, work in progress" and "This energy

source is locked." The service worker writes his name on the sign, so the third party can see

who is working on the machine.

As long as the desired power is connected, it is incumbent for the service employees to make

sure that others cannot get injured by / in / on machine.

After repairs, troubleshooting etc. is completed, the service employees ensure that

all connections, guards etc. are properly installed, secured and connected before the machine

is start up again.

CAUTION

Risk of injury

Read the instructions

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

9

General safety information

CAUTION

Risk of injury

Read the instructions

CAUTION

Danger when assembling of components and risk of cuts due to sharp edges.

Use safety gloves

CAUTION

Danger of flip over components due to insufficient stability or if it falls down

during transportation

Never work under suspended components

Always use suitable, undamaged and tested cranes and load

attachment gear for the respective load

Wear safety shoes.

Use safety helmet

CAUTION

Danger from sliding, rolling or falling components due to improper use

of trailer

Ensure transport equipment has sufficient capacity

Wear safety shoes.

Use safety helmet

CAUTION

Danger of grease and oil. Risk of slipping!

Immediately remove grease and oil residues

It is recommended for operators to use non-slip footwear, safety vest

and helmet when working near machine

CAUTION

Danger due to high working areas. Risk of falling down!

Work only in safe areas.

Use safety helmet

Use safety harnesses

Entrance on gooseneck is forbidden

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

10

CAUTION

Movement/rotation of different components can result in the danger

of injury.

Never reach between moving parts with your hands or other body

parts

Use safety gloves and helmet

NOTICE

Before starting, ensure that all devices are in place and functional.

Take into account the capacity limits (especially lifting capacity).

Use appropriate safety equipment when working under special

temperature conditions.

You should not use medicines that affect reaction and perception,

when working with it.

It is the user and NOT Novatech ApS, which is responsible for all

personal and property damages, arising due to non-proper use.

Safe operation is not guaranteed if the machine is not used according

to specifications.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

11

Use protective equipment appropriate for the work when you operate or maintain

machine.

The following safety equipment must be available:

Safety Gloves

Shoes according to DIN EN ISO 2045, category S3 or in accordance with local

regulations.

Safety helmet.

Safety glasses.

Hearing protection.

Safety Vest

Mask

Always obey the local laws and regulations regarding safety.

All safety equipment must be visually inspected prior to use by the user.

The user is responsible for:

The use of the necessary personal safety equipment.

Regular cleaning and care of equipment.

Timely replacement of damaged or defective equipment or components.

DANGER

It is forbidden to use trailer with construction defects or damages without

service personnel permission, except emergency drive for repairs.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

12

CAUTION

Noise Impacts during machine operation.

Wear ear protection

Exhaust gases from TUGMASTER. Danger of suffocation!

See TUGMASTER manual for indoor use

Danger at the start of the machine while people are in the danger zone.

Visual inspection before starting that no person is in the danger area

Use safety vest for better visual contact

NOTICE

Operators should be trained in usage of machine.

Ensure that there are no unwanted components or the like on / in

or around the machine before start-up.

Only use approved and tested lifting equipment and accessories

which are CE marked.

The Tugmaster operator must have a valid certificate.

Avoid exceeding max gooseneck angle (±70°) to increase service life

of tyres.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

13

4. General description

Roll Trailer is designed as steel structure with running gears (Fig. 1). It is designed to work

with tugmaster for transporting general cargo.

Fig. 1 Roll trailar ready to work

Frame

The Roll Trailer is constructed as a skeletal frame steel S355J2 acc. To EN 10025 with

following features:

Longitudinal IPE main beams and between these cross members made of either IPE

or U-profiles;

Wheel beam made as box profile above running gear;

Forklift pockets made of bended C-shape profile with reinforcement;

Reinforced gooseneck tunnel;

Rear crossbeam square profile;

Special arrangement of crossbars above running gear.

Platform

Platform is constructed from checker plate resting on IPE cross members;

Steel checker plate above wheels and support in front for empty stacking;

Running Gear

2 rocker arms, box construction, type: straight;

4 axles, EN 10025 Steel S355 J2, dimension 140x140 mm;

Axle bolt in steel C45;

8 steelband reinforced solid rubber tires 22x16x16;

Bronze bushings for axle and rocker arm;

Novatech standard bearings;

Cover of bearing house made by pressed steel cover;

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

14

Lubrication nipple placed in wheel and bolts for service;

Additional

40 pcs of D-rings 50t BL (6 at front end, 4 at rear end, 15 at each main beam);

Lashing eyes (2 at the end of each main beam)

All screws, nuts and washers are galvanized;

Stacking support.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

15

5. Operating rules

General remarks

The Roll trailer is intended for internal use only.

The Roll trailer is not equipped in braking system. Required braking force should be

generated by the tugmaster.

Prohibited activities

Do not step under the trailer when it is not empty.

Do not drive with forklift on the deck.

Do not pull/push the load on the deck.

Do not smoke, eat or drink during packing, securing or unpacking.

Do not concentrate heavy cargo on small areas of the floor.

Do not load with eccentric load distribution.

Do not use securing or protection equipment which is incompatible with the cargo.

Do not secure the cargo with devices overstressing the structure of the trailer/cargo.

Do not overstress securing devices.

Do not over tighten securing devices so that the packaging or goods are damaged.

Do not fasten web lashings by means of knots.

Required activities

Do use blocking or lashing or a combination of these methods to prevent the cargo

from sliding and tipping in any direction.

Do secure the cargo in a way that forces are distributed over an appropriate area

of a unit.

Do secure each single loaded item independently where necessary.

Do use non-slip surface material to refrain packages from sliding where appropriate.

Do use hooks or shackles to fasten lashings where applicable.

Do check that the CTU and any cargo securing equipment are in good condition.

Do select the securing methods best adapted to the characteristics of the cargo, the

mode of transport and the properties of the CTU.

Do load with the center of gravity correctly located in the CTU.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

16

6. Working with the trailer

6.1. Before first use

Due to the fact that after production the roll trailer was stored and transported, which means

that it was out of use for a long time. Before the first use, service activities should be

performed, including:

visual inspection whether the product has not been damaged during its transport;

check that trailer is complete, there are no loose parts and all bolts are properly

tightened (due to transport, the trailer may be delivered with disconnected elements

that should be installed after delivery);

lubrication of all greasing points (for complete description of lubrication, see section

7.2 "Greasing points").

6.2. Connecting the tugmaster

Lower/raise 5th wheel approximately to the coupling height of the trailer.

Drive tugmaster (equipped with gooseneck) into mid line of the trailer, adjust 5th wheel

height, drive until gooseneck is locked in the tunnel of the trailer. Slowly lift the trailer to see

if the connection is rigid.

Perform daily inspections (daily inspection is limited to a check for visual damage).

NOTICE

During coupling and uncoupling operation all personnel have to wear

safety equipment.

DANGER

When coupling the Roll Trailer to the Tractor, ensure that no other

persons are near. Roll Trailer do not have EMERGENCY STOP.

HIGH DANGER of crushing.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

17

6.3. Loading the trailer

Trailer is made for transport of general cargo evenly distributed over the length of the trailer.

For special load cases please contact Novatech.

Other types of cargo has to be placed on the trailer and secured by suitable securing

equipment like lashings so no danger can appear.

The COG of the load should be placed as close to the COG of the trailer as possibly.

Loading the trailer

Before loading, make sure that Roll Trailer is parked horizontally

The total load of the roll-trailer must not exceed its maximum load capacity;

All cargo needs to be secured in the way that while driving no movement can occur.

CAUTION

Trailer may not be used for anything other than specified purposes, unless

Novatech ApS has given written permission.

Consequences:

Loss of warranty;

Exclusions of liability claims.

NOTICE

The user and not Novatech ApS. is responsible for all personal injury

and property damage that occurs due to non-proper use.

Safe operation is not guaranteed if the machine is not used according

to specifications.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

18

Uniformly Distributed Load

UDL as shown in the diagram below (Fig. 2) so that the centre of gravity of the load

is in the appropriate areas of the diagram;

Other loading methods may result in overloading and damaging the trailer;

Fig. 2 Load diagram for evenly distributed load

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

19

6.4. Driving with the trailer

When transport driving, you can either pull or push the Roll Trailer along a pre-planned

route. We recommend pulling the Roll Trailer. When backing up the Roll Trailer, you must

have unimpeded rear visibility.

The driver must always carefully observe the driving route and drive at the speed required

by the situation.

Drive with load only on previously checked driving route.

Never exceed the recommended driving speed. According to technical specification of solid

rubber tyre 22x16x16 speed limit is 6km/h with load and 10km/h with empty trailer. Do

not exceed max distance limit 2000m due to the risk of overheating tires and bearings and

respect required standstill time at least three hours between driving cycles.

Keep COG of cargo as low as possible. Avoid exceeding max gooseneck angle (±70°) to

increase service life of tyres. When performing turns always observe outer turning circle

of tugmaster and inner turning circle or trailers rear part.

Cross bumps and another uneven terrain drive very slowly.

Sharp turns drive very slowly.

The issues listed below may have a detrimental effect on the manoeuvrability of the Roll

Trailer and require that you lower your speed:

• load weight

• the location of the centre of gravity in the vertical direction

• the location of the centre of gravity in the horizontal direction

• aisle widths

• road inclinations

• speed bumps, railroads and other uneven spots

• underpasses

• lighting and visibility

• other traffic

• road condition

• slipperiness of road surface

• bends.

NOVATECH ApS - Skudehavnsvej 30 - DK 9000 Aalborg. P.O.Box 540

Tel. +45 98 16 50 09 Fax +45 98 16 80 97 mail@novatech.dk

20

6.5. Driving on the ramp

Do not approach ramp sideways. Trailer is capable of going on ramps up to 6 deg.

Fig. 3 Info graphic for ramp angle

Keep in mind that height of the Roll Trailer body must be adjusted accordingly, using

the terminal tractor’s fifth wheel.

when driving the rear end of the trailer onto the ramp, the tractor saddle should be

lowered as much as possible to achieve about 30-50 mm distance between front foot

and ground in order to obtain the maximum clearance at the rear;

when the trailer suspension is on the upper edge of the ramp, raise the tractor's

saddle as much as possible to obtain the maximum clearance between the ground and

bottom surface of the longbeams.

6.6. Disconnecting the tugmaster

Adjust 5th wheel height, until gooseneck is unlocked from the tunnel of the trailer. Slowly

lower the gooseneck to see if the connection has been released. Make sure that gooseneck

is disconnected with trailer, then drive out the tugmaster straight forward. Perform daily

inspections by checking for visual damage.

Table of contents

Popular Utility Vehicle manuals by other brands

Toro

Toro 07213TC Operator's manual

Chironex

Chironex SPARTAN XT 600 EFI owner's manual

Equinox Systems

Equinox Systems nomad Assembly instructions and operation manual

MULTIQUIP

MULTIQUIP Whiteman series Operation and parts manual

Polaris

Polaris Ranger RZR SW Service manual

Peco

Peco X20 Convertible Trailer Vac Operator's manual

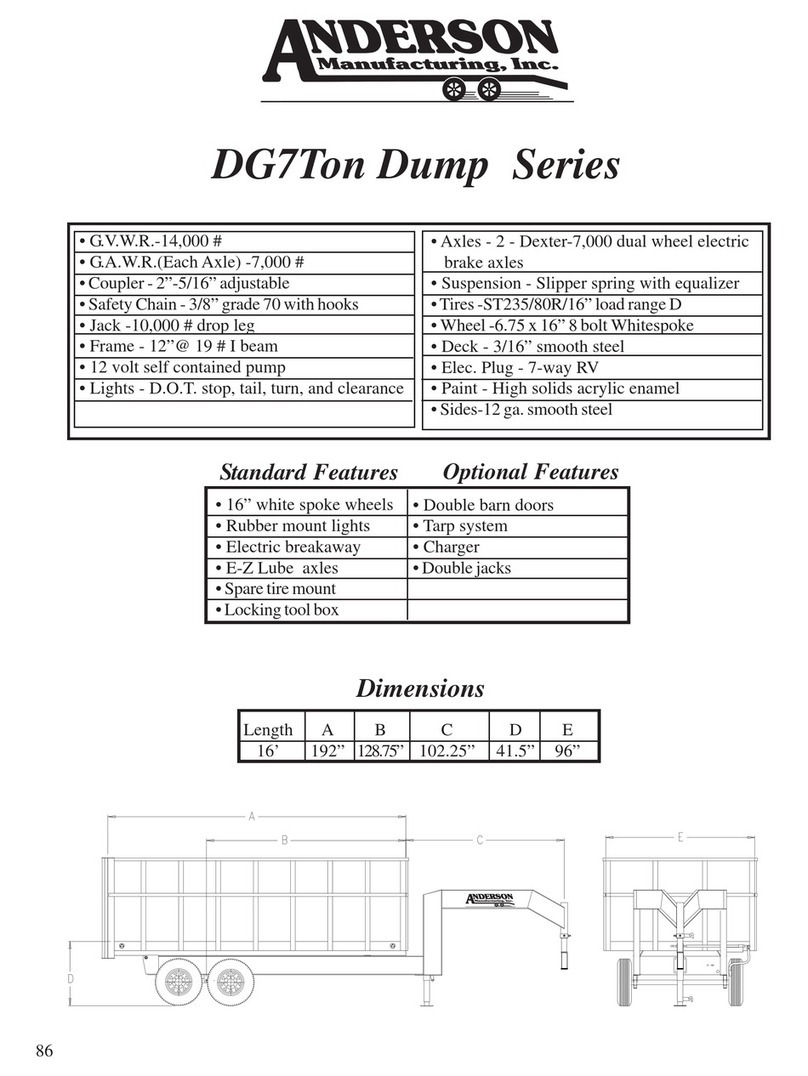

Anderson Manufacturing

Anderson Manufacturing Dump Series DG7Ton Specification sheet

Polaris

Polaris 2015 RZR XP 1000 EPS owner's manual

Crown

Crown CR-48 owner's manual

Dane Technologies

Dane Technologies QuicKART 2000 Series Service manual

Erde

Erde DAXARA 158.2 Assembly and usage instructions

Knapen Trailers

Knapen Trailers EXTREME user manual