Novelan Compact Station Dual User manual

Operating Manual

UK

Accessories for

Dual Air/ Water Heat Pumps

Compact Station Dual

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

283053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Please read rst

This operating manual provides important information

on the handling of the unit. It is an integral part of the

product and must be stored so that it is accessible in the

immediate vicinity of the unit. It must remain available

throughout the entire service life of the unit. It must be

handed over to subsequent owners or users of the unit.

Read the operating manual before working on or

operating the unit. This applies in particular to the

chapter on safety. Always follow all instructions

completely and without restrictions.

It is possible that this operating manual may contain

instructions that seem incomprehensible or unclear. In

the event of any questions or if any details are unclear,

contact the factory customer service department or the

manufacturer’s local partner.

As this operating manual has been written for several

unit models, always comply with the parameters for the

respective model.

This operating manual is intended only for persons

assigned to work on or with the unit. Treat all constituent

parts condentially. The information contained herein is

protected by copyright. No part of this manual may be

reproduced, transmitted, copied, stored in electronic

data systems or translated into another language, either

wholly or in part, without the express written permission

of the manufacturer.

Symbols

The following symbols are used in the operating manual.

They have the following meaning:

Information for operators.

Information or instructions for qualied

personnel.

DANGER!

Indicates a direct impending danger

resulting in severe injuries or death.

WARNING!

Indicates a potentially dangerous situation

that could result in serious injuries or death.

CAUTION!

Indicates a potentially dangerous situation

that could result in medium or slight injuries.

IMPORTANT

Indicates a potentially dangerous situation,

which could result in property damage.

NOTE.

Emphasized information.

€ENERGY SAVING TIP

Indicates suggestions that help to save energy,

raw materials and costs.

Reference to other sections of the operating

manual.

Reference to other documents of the

manufacturer.

383053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Contents

INFORMATION FOR USERS AND QUALIFIED

PERSONNEL

PLEASE READ FIRST.......................................................................2

SYMBOLS..........................................................................................2

INTENDED USE................................................................................4

DISCLAIMER.....................................................................................4

SAFETY..............................................................................................4

CUSTOMER SERVICE......................................................................5

WARRANTY / GUARANTEE...........................................................5

DISPOSAL .........................................................................................5

HEAT METERING.............................................................................5

OPERATION......................................................................................5

CARE OF THE UNIT.........................................................................6

MAINTENANCE OF THE UNIT......................................................6

MALFUNCTIONS.............................................................................6

INSTRUCTIONS FOR QUALIFIED PERSONNEL

SCOPE OF DELIVERY......................................................................7

INSTALLATION AND ASSEMBLY .................................................7

Installation location ................................................................7

Transport to installation location........................................7

Facilitating transport ..............................................................8

Installation.................................................................................8

Components of the unit.........................................................8

Installation / Hydraulic connection to heating circuit

and domestic hot water ..................................................9

Hydraulic connection of hot water tank..........................10

ELECTRICAL CONNECTIONS .....................................................10

Connect BUS cable ................................................................ 11

FLUSHING, FILLING AND VENTING THE SYSTEM ................12

Flushing, filling and venting the heating circuit ...........12

Venting the circulating pump of the heating circuit ....12

flushing, filling and venting the domestic hot water

tank.....................................................................................13

INSULATING THE HYDRAULIC CONNECTIONS....................13

SET THE OVERFLOW VALVE.......................................................13

INSTALLATION OF THE CONTROL UNIT.................................14

COMMISSIONING .........................................................................14

Safety temperature limiter..................................................15

DISMANTLING...............................................................................15

TECHNICAL DATA/ SCOPE OF DELIVERY ...............................16

PERFORMANCE CURVES

Heating capacity/COP / power consumption /

Heat pump pressure loss

FREE COMPRESSION....................................................................18

DIMENSIONED DRAWINGS........................................................19

INSTALLATION PLAN...................................................................20

HYDRAULIC INTEGRATION

Compact Station Dual / LAD...............................................22

Legend Hydraulic integration.............................................23

TERMINAL DIAGRAM...................................................................24

CIRCUIT DIAGRAMS.....................................................................25

EC DECLARATION OF CONFORMITY.......................................27

483053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Intended use

The hydraulic tower is an accessory for air/water heat

pumps intended for outdoor installation. Taking into

account its performance limits, the unit can be used in

combination with an outdoor installation air/water heat

pump in new or existing heating systems.

The unit may be used only for its intended use. This

means in combination with an LAD ... A:

•for heating.

•for domestic water heating.

The unit may be operated only within its technical

parameters.

Overview “Technical data / Scope of delivery”

and overview “Technical data /Scope of

delivery” of the operating manual for the heat

pump to which the hydraulic tower is connected.

WARNING!

Do not exceed the operating pressures

specied on the rating plate.

NOTE.

Notify the responsible power supply company

of the use of a heat pump or heat pump system.

Disclaimer

The manufacturer is not liable for losses resulting from

any use of the unit which is not its intended use.

The manufacturer’s liability also expires:

•if work is carried out on the unit and its

components contrary to the instructions in this

operating manual.

•if work is improperly carried out on the unit and

its components.

•if work is carried out on the unit which is not

described in this operating manual, and this

work has not been explicitly approved by the

manufacturer in writing.

•if the unit or components in the unit have been

altered, modied or removed without the explicit

written consent of the manufacturer.

Safety

The unit is safe to operate for its intended use. The

construction and design of the unit conform to current

state of the art, all relevant DIN/VDE regulations and all

relevant safety regulations.

Every person who performs work on the unit must

have read and understood the operating manual prior

to starting any work. This also applies if the respective

person has already worked with such a unit or a similar

unit or has been trained by the manufacturer.

Every person who performs work on the unit must

comply with the applicable accident prevention and

safety regulations. This applies in particular to the

wearing of personal protective equipment.

DANGER!

Risk of fatal electric shock!

Electrical connection work must be carried

out by qualied electricians only.

Before opening the unit, disconnect the

system from the power supply and prevent it

from being switched back on!

WARNING!

Only qualied personnel (trained heating,

cooling and electricians) may carry out work

on the unit and its components.

IMPORTANT

For safety reasons:

Never disconnect the unit from the power

supply, unless the unit is being opened.

583053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Customer service

For technical information please contact your local

heating engineer or the manufacturer’s local partner.

For a current list and additional partners of the manuf-

acturer, please visit www.novelan.com.

Warranty / Guarantee

For warranty and guarantee conditions, please refer to

the purchase documents.

NOTE.

Please contact your dealer about all matters

concerning warranties and guarantees.

Disposal

When decommissioning the unit, always comply

with applicable laws, directives and standards for

the recovery, recycling and disposal of materials and

components.

“Dismantling”.

Heat metering

In addition to proof of the unit’s eciency, the

EEWaermeG (German law on renewable energy heat)

also requires heat metering (hereafter also referred to

as HQR). Heat metering is mandatory for air/water heat

pumps. Heat metering for brine/ water and water/water

heat pumps has to be installed for ow temperatures

≥ 35°C. The heat metering must record the total thermal

energy released (heating and domestic hot water) in the

building. In the case of heat pumps with heat metering

the analysis is carried out via the regulator. It displays

the thermal energy delivered in the heating system in

kWh.

Operation

Your decision to purchase a heat pump or a heat pump

system is a long-term contribution to protecting the

environment through low emissions and reduced

primary energy use.

You can operate and control the heat pump system with

the control unit of the heating and heat pump regulator.

NOTE.

Make sure that the control settings are correct.

Operating manual of the heating and heat

pump regulator.

To ensure that your heat pump or heat pump system

operates eciently and ecologically, the following are

especially important:

€ENERGY SAVING TIP

Avoid unnecessarily high ow temperatures.

The lower the ow temperature on the heating

water side the more ecient the system.

€ENERGY SAVING TIP

Preferably use purge ventilation. Compared

to continuously open windows, it is better to

air rooms by fully opening windows for a short

period, two to three times a day (so-called

“rapid” or “purge” ventilation); this reduces

energy consumption and your heating bill.

683053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Care of the unit

You can clean the outer surfaces of the unit with a damp

cloth and proprietary household cleaning products.

Do not use cleaning or care products that contain

abrasives, acids and/or chlorine. Such products would

irreparably damage the surfaces and could also cause

technical damage to the unit.

Maintenance of the unit

The components of the heating circuit (valves,

expansion vessels, circulating pumps, lters, dirt traps)

should be inspected or cleaned as needed, at the

very least annually, by qualied personnel (heating or

cooling system engineers).

The hot water tank should be cleaned once a year

by qualied personnel (heating or cooling system

engineers). To do this, rst empty the hot water tank.

Then remove the polystyrene guard over the service

opening of the hot water tank. Unscrew the ange cover

of the service opening.

Check the safety valve (provided by customer) for the

hot water tank at regular intervals. Have the magnesium

anode checked and if necessary renewed by the

customer service for the rst time after 2 years and then

at appropriate intervals.

Renew anode if protective current lower than 0.3 mA.

After replacing anode, re-install earthing cable between

anode and storage tank jacket.

Ideally you should arrange a maintenance agreement

with a heating installation company. It will arrange for

the necessary maintenance work at regular intervals.

Malfunctions

In case of malfunctions, you can read out the cause of

the fault from the diagnostics program of the heating

and heat pump regulator.

Operating manual for the heating and heat

pump regulator.

IMPORTANT

Only customer service personnel authorised

by the manufacturer may carry out service and

repair work on the unit’s components.

Note that no fault is displayed if the safety temperature

limiter on the electric heating element has tripped.

“Commissioning”, “Safety temperature limiter”

section.

7

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

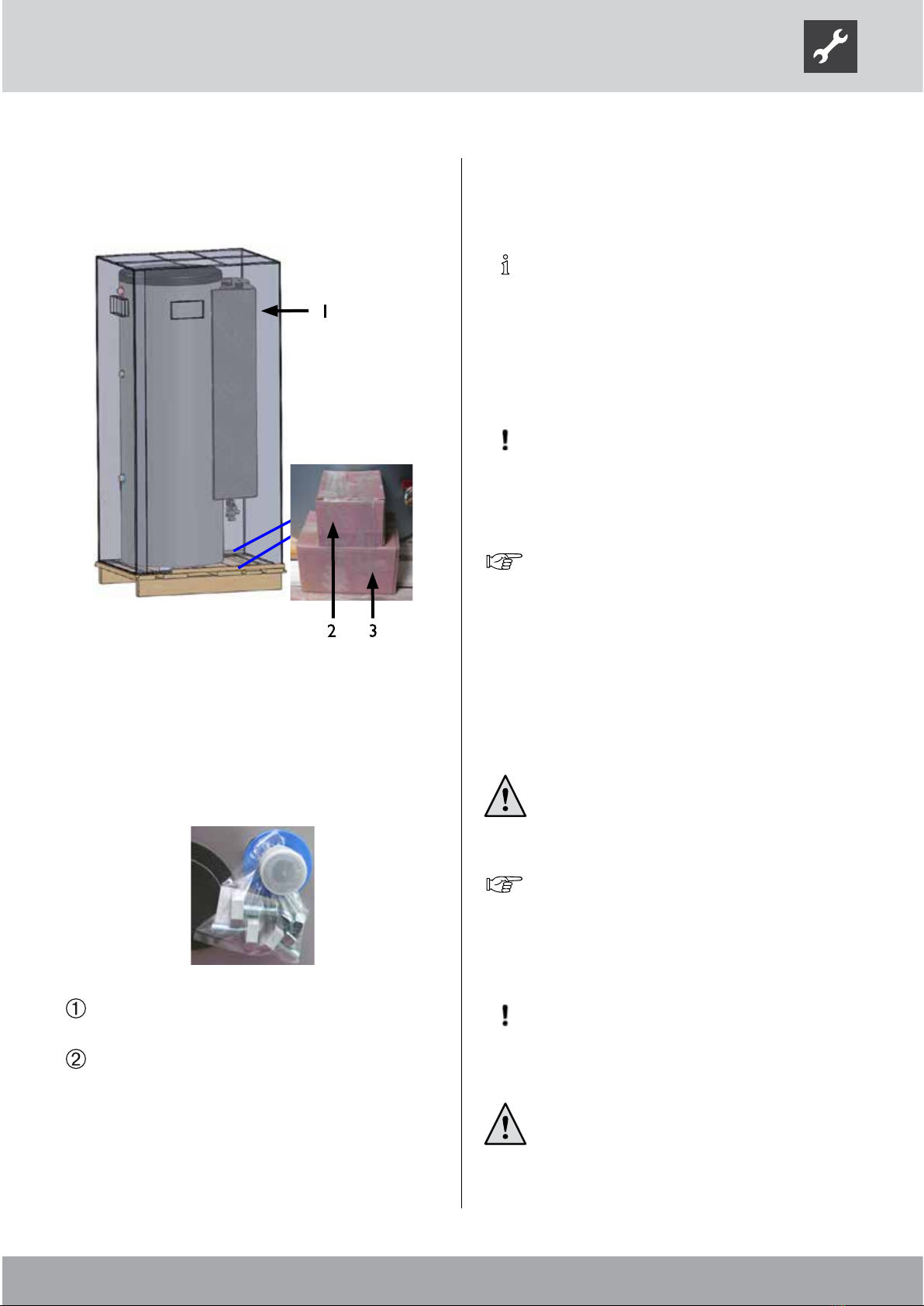

Scope of delivery

Sample layout of the scope of delivery:

Fertigungsanweisung Hydrauliktower HTD Verpackung:

Benennung:

Zeichnungsnummer:

Fertigungsanweisung Hydrauliktower

HTD Verpackung

802446

Blatt 7/8

Datum

Name

Erstellt

12.06.2012

Aepfelbach

Gepr.

Zust.

Änderungstext

Datum

Von

Norm.

600603

Schaumzuschnitte 20x10

aufkleben

607854

Karton

901x656x1792

600603

2x Schaumzuschnitte 20x10

übereinander

aufkleben

Holzleisten

aus Speicherverpackung

von SBT

Fertigungsanweisung Hydrauliktower HTD Verpackung:

Benennung:

Zeichnungsnummer:

Fertigungsanweisung Hydrauliktower

HTD Verpackung

802446

Blatt 6/8

Datum

Name

Erstellt

12.06.2012

Aepfelbach

Gepr.

Zust.

Änderungstext

Datum

Von

Norm.

AIT: 15071341, 15071441

83053800aDE Betriebsanleitung Hydrauliktower Dual

60663601 KB WP-Regelung II

60684801 BA Luxtronik II Endkunde

60684901 BA Luxtronik II Fachhandwerker

Zusätzlich beilegen nur bei

83052500aDE BA ComfortplatineII

Ergänzungs BA nur 15071441 HTD/S 230V

83063800aDE Ergänzungs-BA

Anleitungen im Minigrip 604248

Nov: 150713K0341 Compact Station

Nov 83053803aDE Betriebsanleitung Compact Station

60663601 KB WP-Regelung II

60729801 BA WPR Net Endkunde

60729901 BA WPR Net Fachhandwerker

83052500aDE BA ComfortplatineII

Brett auf Palette

befestigen

1 Compact unit (hot water tank and

buer tank, without heat pump)

2 Control unit of the heating and heat pump

regulator, outdoor temperature sensor

3 Safety subassembly, pump ball valves

Adjustable feet enclosed (on the rear):

Check the delivery for outwardly visible signs of

damage…

Check to make sure that the delivery is complete.

Any defects or incorrect deliveries

must be reported immediately.

Installation and assembly

The following applies to all work to be done:

NOTE.

Always comply with the relevant local accident

prevention regulations, statutory regulations,

ordinances, guidelines and directives.

INSTALLATION LOCATION

IMPORTANT

Install the unit inside buildings only.

The installation area must be frost-free and dry. It must

full the relevant local regulations.

Dimensioned drawing and installation plan for

the respective unit model.

TRANSPORT TO INSTALLATION LOCATION

To prevent damage during transport, always transport

the unit to the nal installation location in its original

packaging, using a lift truck.

CAUTION!

Several people are required to transport

the unit. Take into account the weight of the

unit.

Overview “Technical data /scope of delivery”,

“General unit data” section.

If it is not possible to transport the unit to the nal

installation location using a lift truck, you can also

transport the unit using a sack barrow.

IMPORTANT

Never use components and hydraulic

connections on the unit for transport purposes.

CAUTION!

Wear safety gloves.

883053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

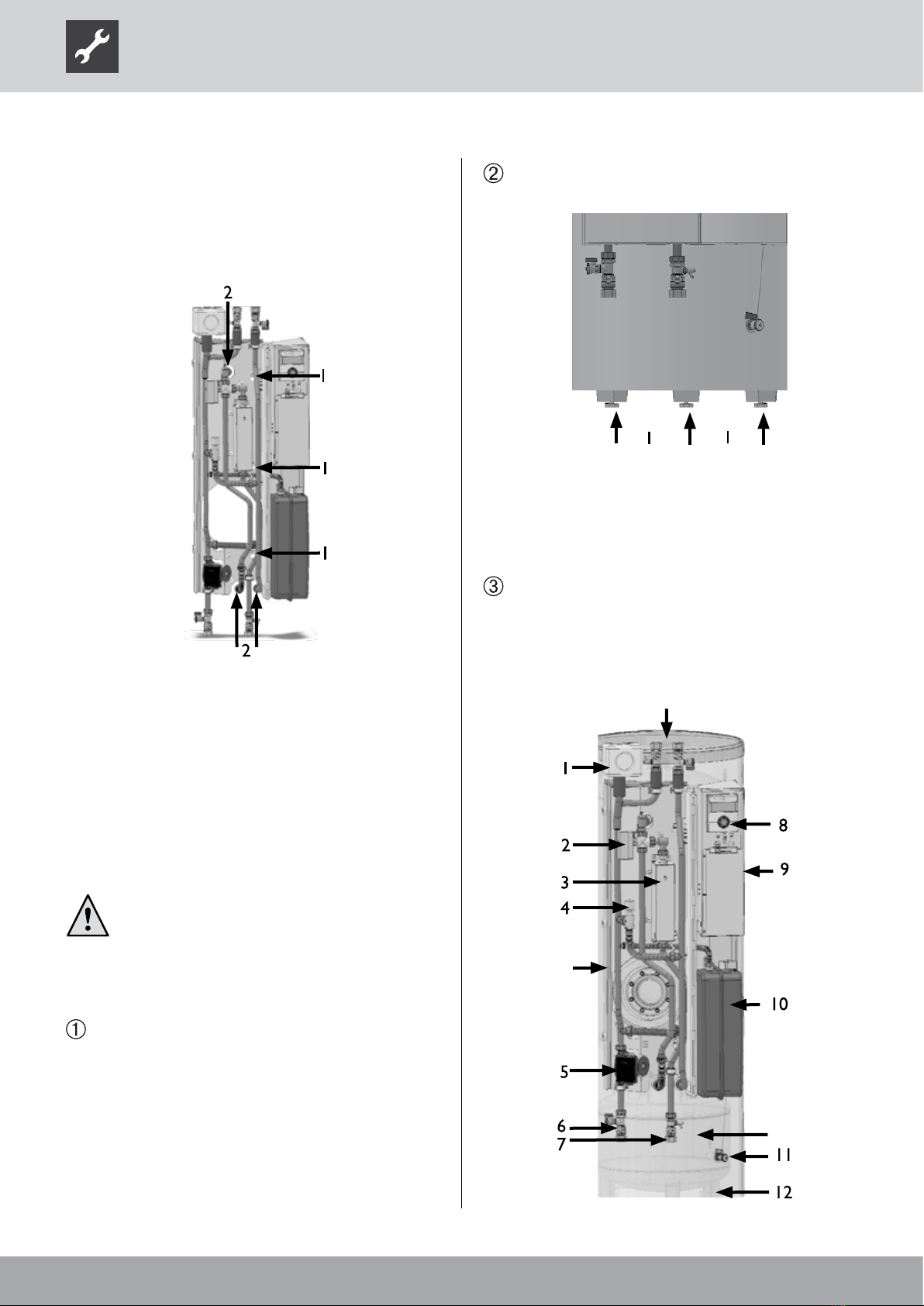

FACILITATING TRANSPORT

To make transport easier and lighter, the complete

hydraulics at the front (incl. regulator with switch

cabinet can be unscrewed.

The hydraulics are xed to the tank by 3 hexagon bolts.

1 3 hexagon bolts

2 Union nuts, which have to be

undone to unscrew them

First, undo the unit nuts on the piping to the tank,

then the 3 hexagon bolts and then remove the entire

hydraulics from the tank.

INSTALLATION

CAUTION!

Several people are required to install the

unit. Take into account the weight of the

unit.

Proceed as follows at the installation location:

Place unit on a rm and horizontal surface,

preferably insulated against structurally borne

sound…

Tilt the unit slowly and carefully to one side…

Secure unit in tilted raised position so that it cannot

accidentally tilt back into the original position.

Fit the adjusting screws onto all 3 supporting

feet…

1 Adjustable feet (for screwing in / in

the enclosed pack of small parts)

Slowly and carefully tilt the unit back into the

original position.

Adjust the three adjusting screws…

If the hydraulics were dismantled for transport

reasons, they must be screwed back onto the tank!

COMPONENTS OF THE UNIT

BWW

Galvanic anode

PSP

9

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

1 Heating circuit safety assembly (insulated)

2 Changeover valve, domestic hot water

3 Instantaneous water heater

behind heat shield

4 Overow valve

5 Circulating pump, heating circuit (HUP)

6 Shut-o ball valve with lling and drain cock

7 Shut-o ball valve with drain cock

8 Regulator

9 Switch cabinet

10 Expansion vessel

11 Drain, buer storage tank

12 Feet for adjustable screws

BWW Domestic hot water tank

PSP Buer tank

INSTALLATION / HYDRAULIC CONNECTION TO

HEATING CIRCUIT AND DOMESTIC HOT WATER

Connection positions for the heating circuit, the cold

and domestic hot water and for the circulation

see dimensioned drawings

NOTE.

Dimension heating system so that the free

compression of the circulating pumps integrated

in the unit always ensures the minimum heating

water throughput.

Always take into account the connecting lines

between the heat pump and the hydraulic

tower.

Remove the cover at the front of the Dual hydraulic

tower:

On the inside of the cover, on the left and right there are

3 grooves each, and on the tower housing the matching

3 pins on each side, which lock the cover in place:

It can therefore be taken apart and reassembled

manually.

IMPORTANT

When making the connections, always secure

the connections on the unit against twisting.

Flush heating circuit thoroughly before connecting

the unit to the heating circuit…

NOTE.

Contamination and deposits in the heating

circuit can cause malfunctions.

SAFETY COMPONENT

The safety assembly for the heating circuit is in the

enclosed pack of small parts.

Mount the safety assembly on the connection provided

on the top of the unit.

The safety drain of the safety valve must lead into

the drain via a funnel siphon in accordance with the

applicable standards and regulations!

EXPANSION VESSELS

The expansion vessel for the heating circuit is integrated.

Always check whether the size of the expansion vessel is

large enough for the system. If necessary, an additional

expansion vessel must be installed on site by the

customer according to the relevant standards.

NOTE.

The admission pressure of the expansion vessel

must be adjusted to the system (approx. 0.5 bar

less than the system lling pressure) according

to the calculation to the relevant standards (EN

12828).

10 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

NOTE.

All live wires must be stripped before they are

installed in the cable duct of the switch cabinet!

IMPORTANT

The power supply for the heat pump and the

electric heating element must be equipped with

an all-pole automatic circuit-breaker with at

least 3mm contact spacing to IEC 60947-2.

Note the level of the release current.

Overview “Technical data /scope of delivery”,

“Electrics” section..

The penetration for the electric and sensor cable is

located at the rear of the unit:

Open switch cabinet in unit.

To do this, only loosen the two upper screws of the

cover panel. Remove the remaining screws. Remove

cover panel.

Insert control and sensor wires and the wire for

the power company blocking contactor through

the bushings on the back of the unit. Guide wires

via the cable duct to the terminals in the switch

cabinet…

Make electrical connections as shown in the

terminal diagram…

“Terminal diagram” for respective unit type.

HYDRAULIC CONNECTION OF HOT WATER TANK

Connect hot water tank according to DIN 1988 and DIN

4753, Part 1 (or the local relevant standards, guidelines

and directives).

Do not exceed the operating pressures specied on the

rating plate. Install a pressure reducer, if necessary.

The sensor for the domestic water heating is already

wired up in the control cabinet.

IMPORTANT

The electrical conductivity of the domestic hot

water must be > 100µS/cm and lie within the

required drinking water quality.

DRAINING THE STORAGE TANK

IMPORTANT

Always ensure adequate ventilation when

draining the storage tank.

Electrical connections

The following applies to all work to be done:

DANGER!

Risk of fatal electric shock!

Electrical connection work must be carried

out by qualied electricians only.

Before opening the unit, disconnect the

system from the power supply and prevent it

from being switched back on!

WARNING!

During installation and while carrying out

electrical work, comply with the relevant

EN‑, VDE and/or local safety regulations.

Comply with technical connection

requirements of the responsible power

supply company (if required by the latter)!

11

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

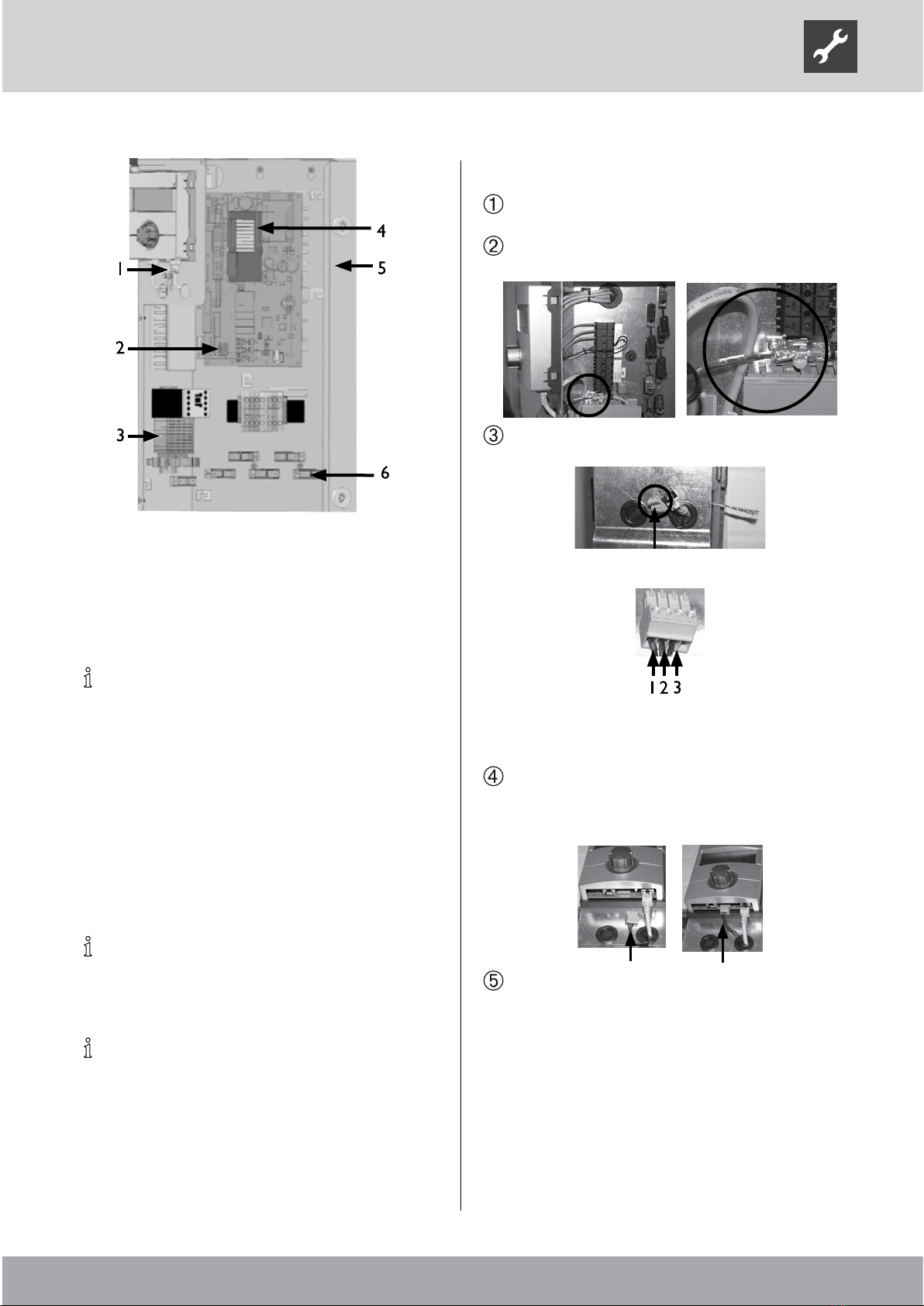

1 Bus cable connection

2 Terminal strip, external sensors

3 Control voltage connection

5 “Comfort” board

5 Electrical switch cabinet

6 Strain relief devices

NOTE.

The control unit of the heat and heat pump

regulator can be connected to a computer

or network using a suitable network cable,

enabling the heating and heat pump regulator

to be controlled remotely from there.

If such a connection is required, lay a shielded

network cable (category 6, with RJ-45

connector) through the unit during the electrical

connection work and connect it parallel to the

existing control cable of the heating and heat

pump regulator.

NOTE.

If an electric heating element is also installed in

the hot water tank, you must fuse it on site.

NOTE.

When laying the cable inside the building,

ensure that unshielded power supply cables

(outdoor unit voltage supply) and shielded

cables (LIN bus) are laid separately from each

other.

CONNECT BUS CABLE

Strip the BUS cable insulation and push the shield

back over the insulation.

Insert the end of the insulated cable with the shield

into the shield terminal.

Feed the end with the individual cores through one

of the two grommets.

Core assignment:

1 12 V

2 LIN

3 GND

Pull o the green bus connector from the bottom of

the control unit and connect the cable as shown in

the terminal diagram, then re-attach the connector

to the control unit.

After completing all electrical installation work,

lock the switch cabinet inside the unit. Close the

unit if no further installation work inside the unit is

to be carried out immediately.

12 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Flushing, lling and venting the

system

IMPORTANT

The system must be absolutely free from air

before commissioning.

Dirt and deposits in the system can cause malfunctions.

FLUSHING, FILLING AND VENTING THE HEATING

CIRCUIT

IMPORTANT

Do not exceed a pressure of 2.5 bar when

ushing the unit. The drain line of the heating

circuit safety valve must be closed before

ushing and lling.

To ush the hot water heating circuit, dismantle

the motor of the 3-way valve. To do so, remove the

U-clip on the oor of the motor and carefully pull

o the motor from above....

Turn stem through 180° and ush domestic hot

water circuit for approx. 1 minute…

Turn stem through 180° back to starting position

(rounded side of stem points to B)…

Flush heating circuit! If necessary, the heating and

hot water circuit can be ushed at the same time!

To do so, turn spindle 30°...

After completion of the ushing and lling

procedure, move spindle to starting position and

mount the motor of the 3-way valve...

NOTE.

To ensure a good seat of the motor on the valve,

make sure that the U-clip with the waist is not

pushed past the lug, because then the motor

will not be held securely on the valve!

In order to be supported securely, the U-clip must bear

with both ends against the lug.

The unit is vented automatically when the venters

(black cap) are open. If the heating circuit is lled or

drained, the venting valves open.

Vent the exchanger of the hot water tank manually.

VENTING THE CIRCULATING PUMP OF THE

HEATING CIRCUIT

Loosen the screw-on cap in the middle of the circulating

pump for the heating circuit.

13

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Set the overow valve

REMARQUE

The activities in this section are only necessary

for in-line tank integration.

Complete the worksteps quickly, otherwise the

maximum return temperature can be exceeded

and the heat pump switches to high-pressure

fault.

Turn the adjusting knob at the overow valve to

the right to increase the temperature dierence

(the temperature drop), turn it to the left to re-

duce it.

System is running in heating mode (ideally in cold

condition).

In case of low heating curve: Set the system to

“Forced heating”…

Operating manual of the heating and heat

pump controller.

Shut o valves to the heating circuit…

Ensure that the total ow is routed via the overow

valve…

Read out the ow and return temperature at the

heating and heat pump controller…

Operating manual of the heating and heat

pump controller.

Turn the adjusting knob (1) of the overow valve (2)

until the temperature drop between the ow and

return temperature is set as follows:

External temperature Recommended settings

-10 °C 4 K

0 °C 5 K

10 °C 8 K

20 °C 9 K

30 °C 10 K

Open valves to heating circuit…

Reset the heating and heat pump controller.

FLUSHING, FILLING AND VENTING THE DOMESTIC

HOT WATER TANK

IMPORTANT

Before ushing and lling the hot water

tank, the drain pipe of the safety valve must

be connected. Do not exceed the response

pressure of the safety valve.

Open domestic cold water inlet valve on domestic

hot water tank…

Open the domestic hot water valves at the taps…

Flush the domestic hot water tank until no more air

discharges from the valves at the taps…

Close hot water valves at the taps.

Insulating the hydraulic

connections

You must insulate the xed pipes of the heating circuit,

the connecting lines between the hydraulic tower and

the heat pump and the connections of the hot water

tank.

NOTE.

Insulate in accordance with relevant local

standards and directives.

14 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Installation of the control unit

Remove the cover at the front of the Dual compact

station:

1 Four cutouts in the

switchroom panel

At the rear of the control unit there are 4 hooks, on

which the control unit panel is hung:

Press down the hung control unit, until it latches

into place…

Push the control cable of the heating and heat

pump regulator into the right‑hand socket on the

underside of the control unit…

Commissioning

Follow the instructions in the section entitled

“Commissioning” in the operating manual for

your heat pump.

Ensure that…

•the water supply to the domestic hot water tank

is open.

•the domestic hot water tank is lled.

If the heat pump is switched on with an empty

tank, the control unit will display a fault.

Operating manual of the heating and heat

pump regulator.

15

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

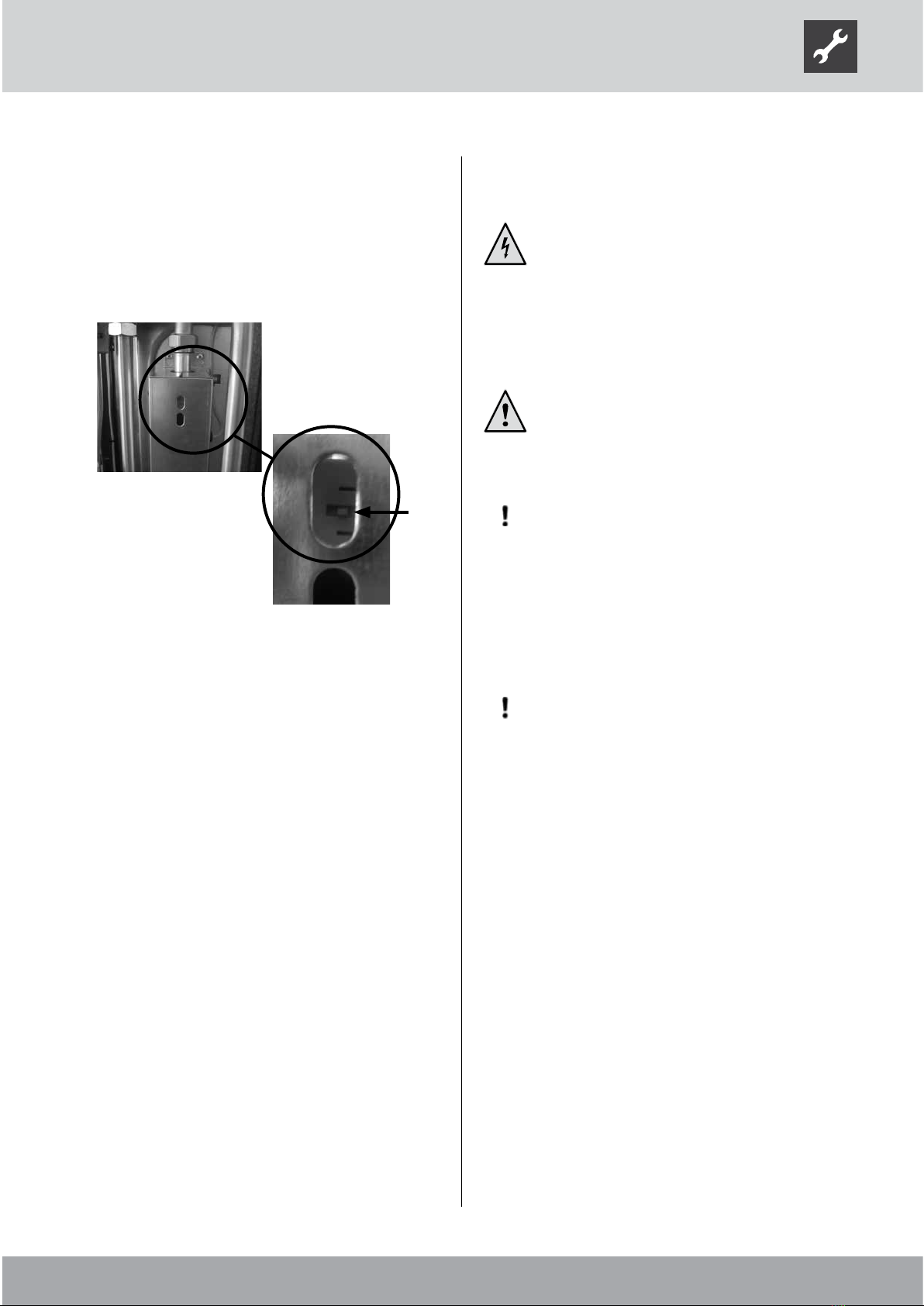

SAFETY TEMPERATURE LIMITER

A safety temperature limiter is built into the electric

heating element. In the event of a malfunction in the

heat pump or air in the system, check whether the reset

button of the safety temperature limiter has tripped. If

necessary push it in again (using an electrically insulated

screwdriver).

Safety temperature limiter and Reset button (arrow)

Dismantling

DANGER!

Risk of fatal electric shock!

Electrical connections may be installed only

by qualied electricians.

Before opening the unit, disconnect the

system from the power supply and prevent it

from being switched back on!

WARNING!

Only qualied heating or cooling system

personnel are allowed to dismantle the unit

from the system.

IMPORTANT

Recycle or ensure proper disposal of unit

components, refrigerants and oil according

to the relevant regulations, standards and

guidelines.

REMOVAL OF THE BUFFER BATTERY

IMPORTANT

Before scrapping the heating and heat pump

regulator, remove the buer battery on the

processor board. The battery can be pushed

out using a screwdriver. Dispose of battery and

electronic components in an environmentally

friendly way.

16 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

Unit designation

Accessory for heat pump

model LAD 5 - LAD 9 • applicable ı — not applicable

Functionally relevant • applicable ı — not applicable

Installation location Indoors ı Outdoors • applicable ı — not applicable

Conformity CE

Heating circuit Heating circuit efficiency pump integrated: • yes — no

Free compression heat pump ∆p ı Flow rate bar ı l/h

Flow rate: minimum throughout ı Maximum throughput l/h

max. permissible operating pressure bar

max. permissible operating temperature °C

Expansion vessel: Volume ı Normal inlet pressure l ı bar

Volume of buffer tank l

3-way valve, heating/hot water integrated: • yes — no

Heat metering integrated: • yes — no

Domestic hot water tank Net contents l

Corrosion protection: Impressed current anode ı Magnesium sacrificial anode • applicable ı — not applicable

Hot water temperature Up to °C

Output capacity at 38°C | 45 °C if removed at 10 l/min, storage temperature 60 °C l ı l

Output capacity at 38°C | 45 °C if removed at 10 l/min, storage temperature 50 °C** l ı l

Heat exchanger area, heat pump m²

max. permissible operating pressure bar

General unit data Housing dimensions (Height ı Width ı Depth) mm ı mm ı mm

Total weight kg

Connections Heating circuit ...

Heat pump

Cold water ...

Domestic hot water ...

Circulation ...

Electrics Voltage code ı all-pole circuit breaker heat pump *) ... ı A

Voltage code ı circuit breaker control voltage *) ... ı A

Voltage code ı circuit breaker electric heating element *) ... ı A

Protection type IP

Output, electric heating element 3 ı 2 ı 1 phase kW ı kW ı kW

Circulating pump, heating circuit: maximum power consumption ı current consumption kW ı A

Heating and heat pump

regulator Included in scope of delivery: • yes — no

Safety equipment Safety assembly heating circuit ı Safety assembly heat source Included in scope of delivery: • yes — no

Overflow valve integrated: • yes — no

Factory setting (adjust when commissioning the system) bar

Sound Sound pressure level in free field/sound power level dB(A) / dB(A)

* comply with local regulations ** Factory setting

Technical data/scope of delivery

17

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

CSD

•

•

• ı —

•

•

0,40 ı 1600

900 ı 2000

3

70

12 ı 1,5

62

•

•

180

— ı •

62

285 ı 230

215 ı 170

2,3

10

1800 ı 600 ı 834

150

Rp 1“ IG

Rp 1“ IG

R 1“ AG

R 1“ AG

R ¾“ AG

3~/N/PE/400V/50Hz ı C16

1~/N/PE/230V/50Hz ı B16

3~/N/PE/400V/50Hz ı B10

20

6 ı 4 ı 2

0,07 ı 0,31

•

• ı —

•

0,55

29 / 43

813309

18 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

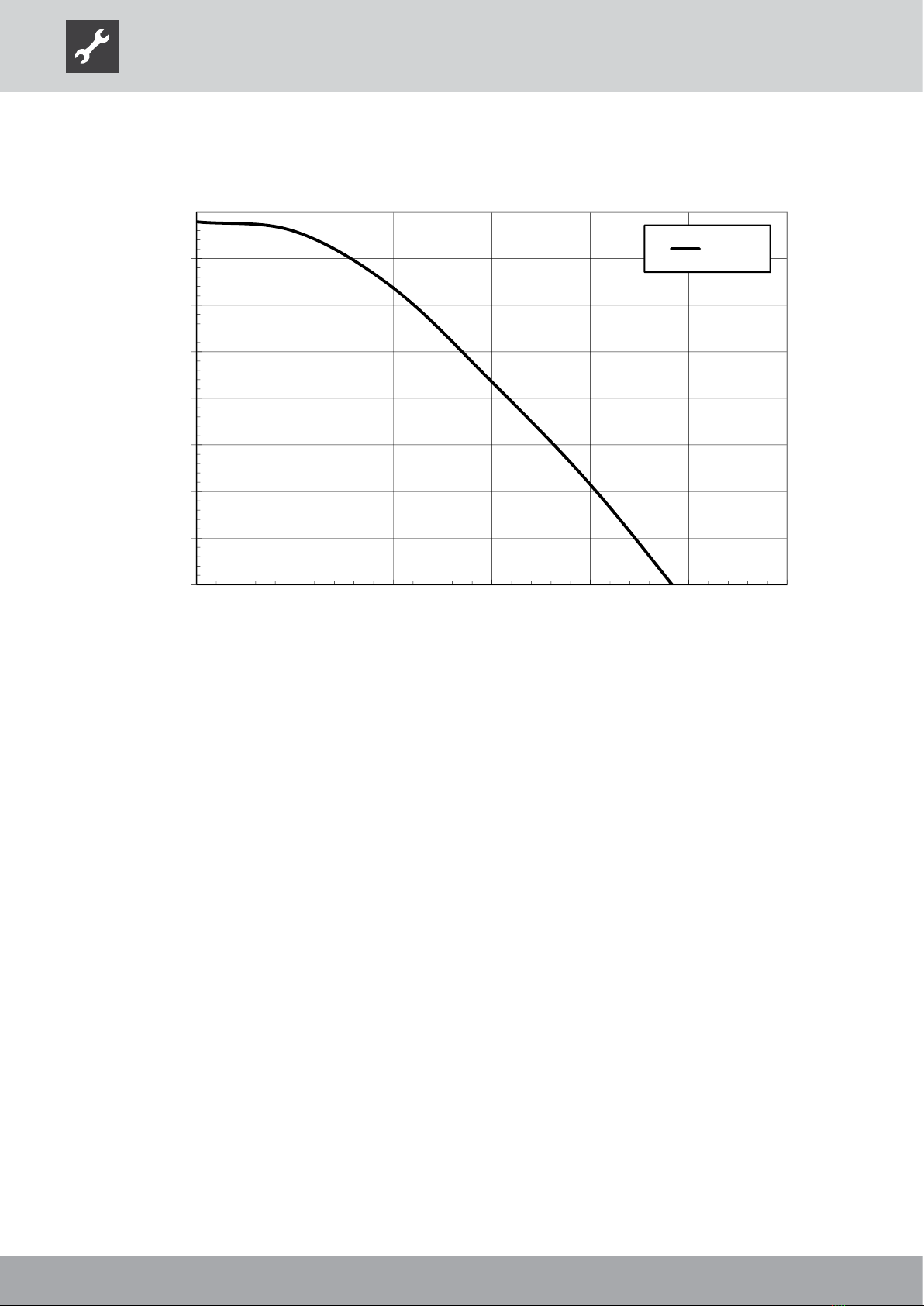

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,0 0,5 1,0 1,5 2,0 2,5 3,0

∆p (bar)

∆pmax

“ ” (m3/h)

Bezeichnung:

D t i 812032 F i P HTD(S)

812032

Seite: 1/1

Zeichnungsnummer:

Legende:

“ ” Volumenstrom Heizwasser in m3

/

h

∆pma

x

freie Pressung maximal (Werkseinstellung)

Freie Pressung HTD(S)

812032

Änd./ÄM/Ersteller/Datum

- /PEP 015-2011 / Liska / 21.06.2012

Legend: UK812022

“” Flow rate, heating water

∆p (bar) Free compression, heating circuit

Free compression Compact Station Dual

19

83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

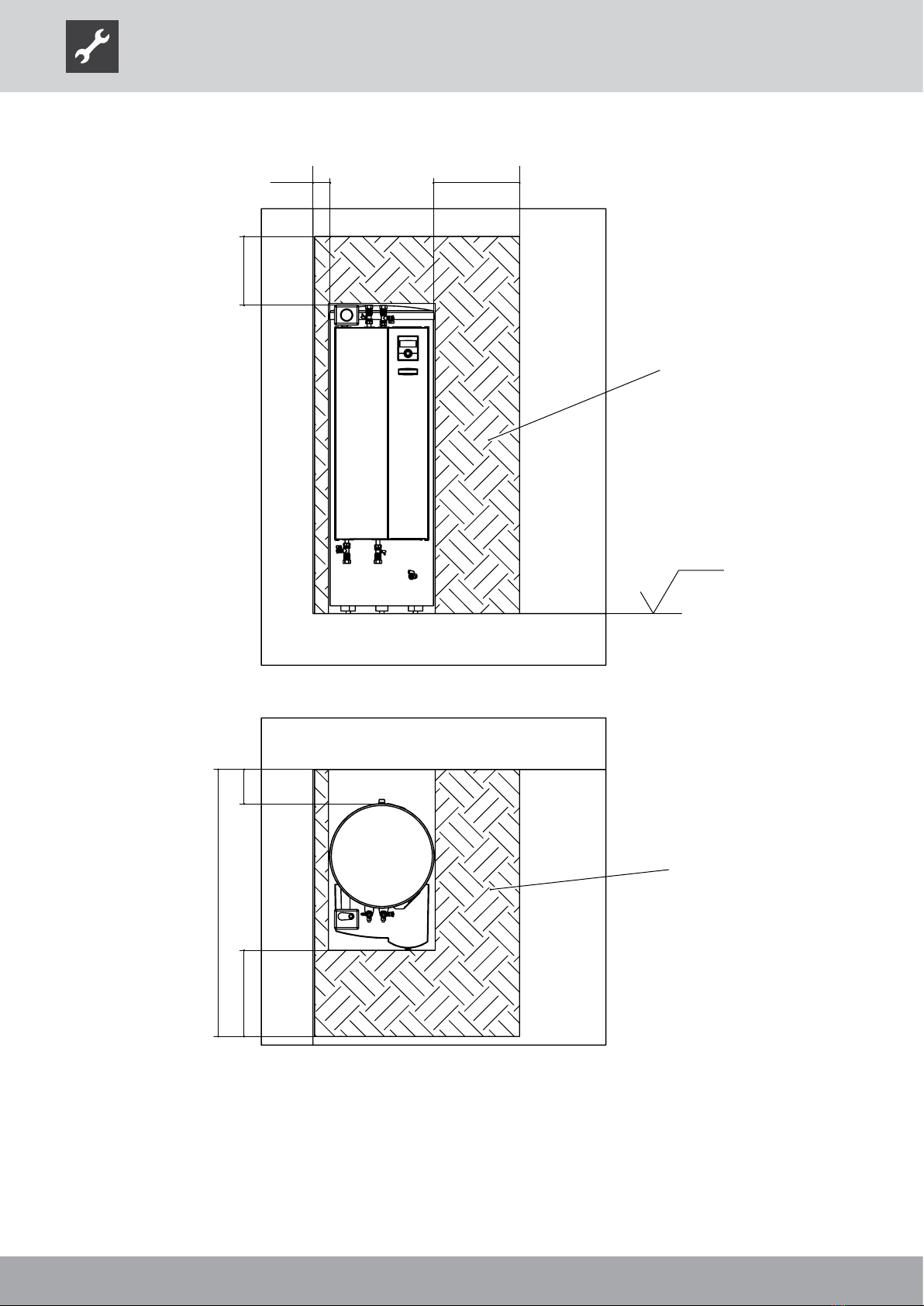

Compact Station Dual Dimensioned drawings

97

180 323

291

83

226

600

0

217

290

1547

<1800

2

3

1

5

67

4

639

0

649

599

834

30

300

0

547

1163

1651

508

216

11

8

9

10

A

E

B

8

7

6

5

4

3

2

1

www.alpha-innotec.de

D - 95359 Kasendorf

Industriestraße 3

Alpha-InnoTec GmbH

1

1

Ers. d.

Ers. f.

A

B

C

D

E

F

F

E

D

C

B

A

4

3

2

1

Benennung

Maßbild

Hydrauliktower Dual HTD 150713,-14

819417

-

Zust.

Änderungstext

PEP 015/2011

Datum

25.9.2012

RA

Von

Blatt

von

Werkstoff

Gewicht

Maßstab

1:20

Det. Maßstab

Datum

Name

Erstellt

Gepr.

Norm.

31.5.2012

Aepfelbach

25.9.2012

Aepfelbach

toleranz

Allgemein-

DIN ISO 2768 -c

Oberflächen

ArtikelNr.

Schutzvermerk ISO 16016 beachten

Legend: UK819417-

All dimensions in mm.

AFront view

BSide view from left

ERear view

Item Designation Dim.

1Safety assembly

2Heating water inflow (from heating circuit) Rp 1" IG

3Heating water outlet (in the heating circuit) Rp 1" IG

4Control unit

5Draining, buffer storage G 1/2"

6Heating water inflow (from heat pump) Rp 1" IG

7Heating water outflow (to heat pump) Rp 1" IG

8Domestic hot water R 1" AG

9Circulation R 3/4" AG

10 Cold water R 1" AG

11 Penetrations for electric/sensor cables

20 83053803dUK – Translation into English of the original German operating manual – Subject to change without notice. www.novelan.com

>100 >500

>1200

>400

FS

OKF

>1550

>500 >200

FS

Legende: 819418 -

Technische Änderungen vorbehalten.

Alle Maße in mm.

OKF Oberkante Fertigfussboden

FS Freiraum für Servicezwecke

8

7

6

5

4

3

2

1

www.alpha-innotec.de

D - 95359 Kasendorf

Industriestraße 3

Alpha-InnoTec GmbH

1

1

Ers. d.

Ers. f.

A

B

C

D

E

F

F

E

D

C

B

A

4

3

2

1

Benennung

Aufstellungsplan, Mindestabstände

Hydrauliktower Dual HTD

819418

-

Zust.

Änderungstext

PEP015/2011

Datum

14.6.2012

RA

Von

Blatt

von

Werkstoff

Gewicht

Maßstab

1:50

1:25

Det. Maßstab

Datum

Name

Erstellt

Gepr.

Norm.

5.6.2012

Aepfelbach

14.6.2012

Aepfelbach

toleranz

Allgemein-

DIN ISO 2768 -c

Oberflächen

ArtikelNr.

Schutzvermerk ISO 16016 beachten

Legend: UK819418

All dimensions in mm.

FFL Finished floor level

FS Shaded area = free space for service purposes

Installation plan Compact Station Dual

This manual suits for next models

1

Table of contents