Manual HC Acoustic Housing Page 2

Version: 01/2018

Table of content

1. General information................................................................3

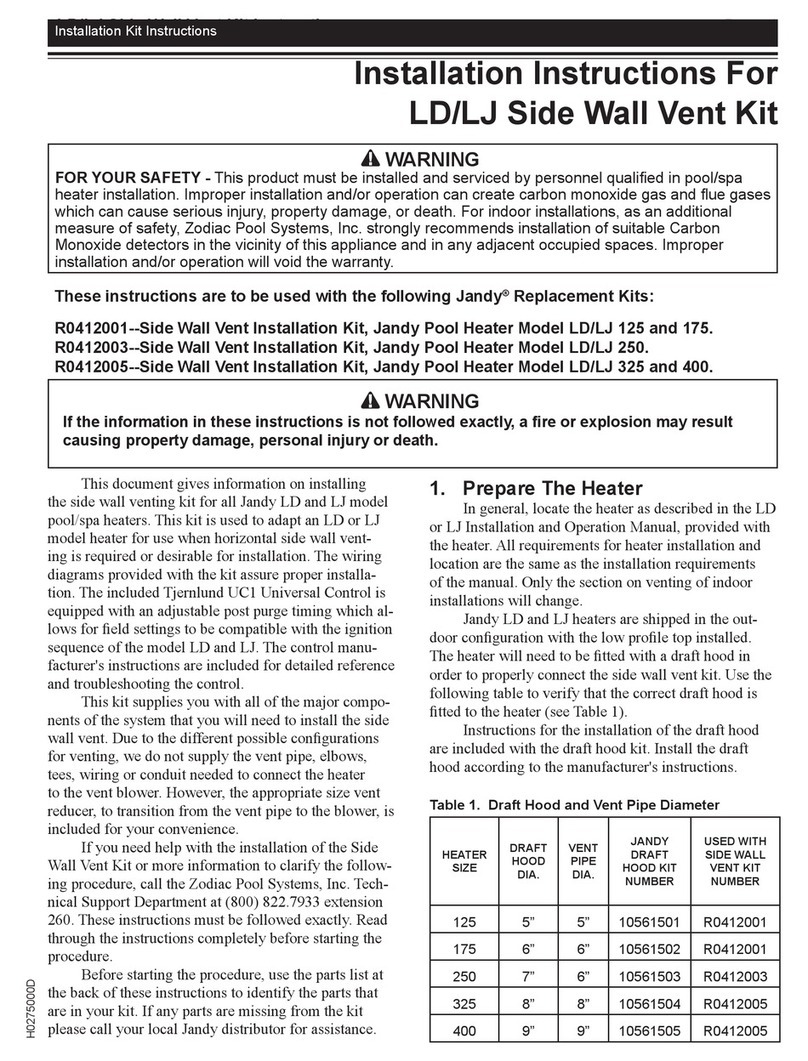

2. Technical Data.......................................................................3

3. Performance sound insulation..................................................5

4. Warranty ..............................................................................7

5. Safety ..................................................................................7

5.1 Intended use .........................................................................7

5.2 Safety instructions .................................................................7

5.2.1 Risks during unloading and transportation................................. 7

5.2.2 Risks from electric power ........................................................ 7

5.2.3 Risk of damage to property and the environment ....................... 7

5.3 Emergency procedures............................................................7

5.3.1 Fire fighting........................................................................... 7

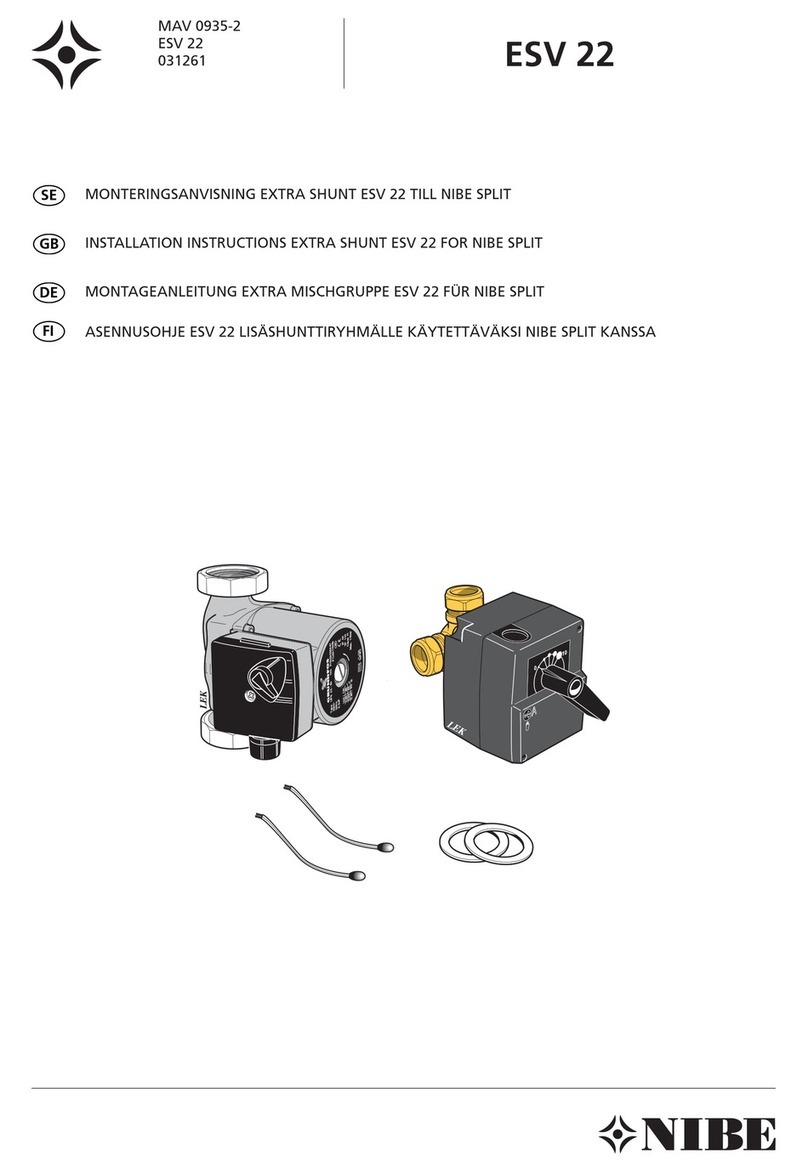

6. Product delivery.....................................................................8

6.1 Unloading / transport to location of installation..........................8

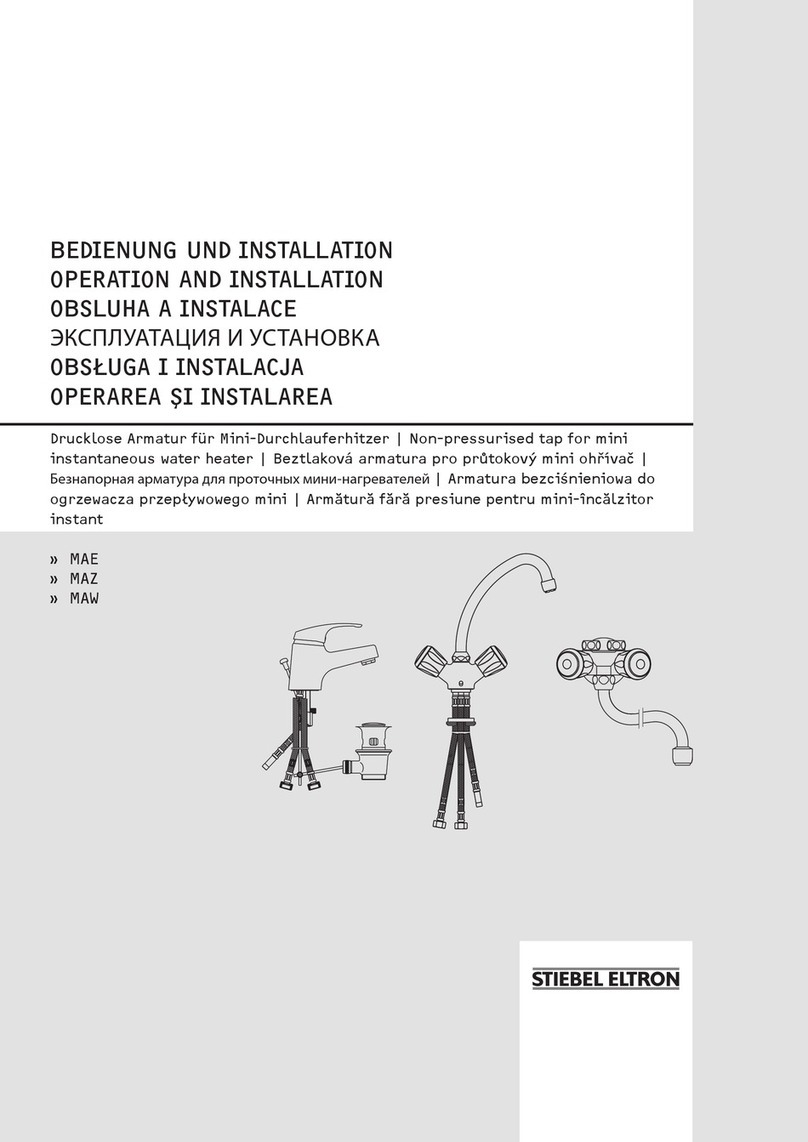

7. Installation of unit..................................................................9

7.1 Installation HC100NP/HC200NP.............................................. 10

7.2 Installation HC100NP SA ........................................................12

7.3 Montage HC200NP_SA...........................................................14

7.4 Montage HC Drain Pan ...........................................................16

7.5 Wall mounting .....................................................................17

7.6 Retrofit Fix Beam.................................................................18

7.7 Foundation / Wall................................................................. 19

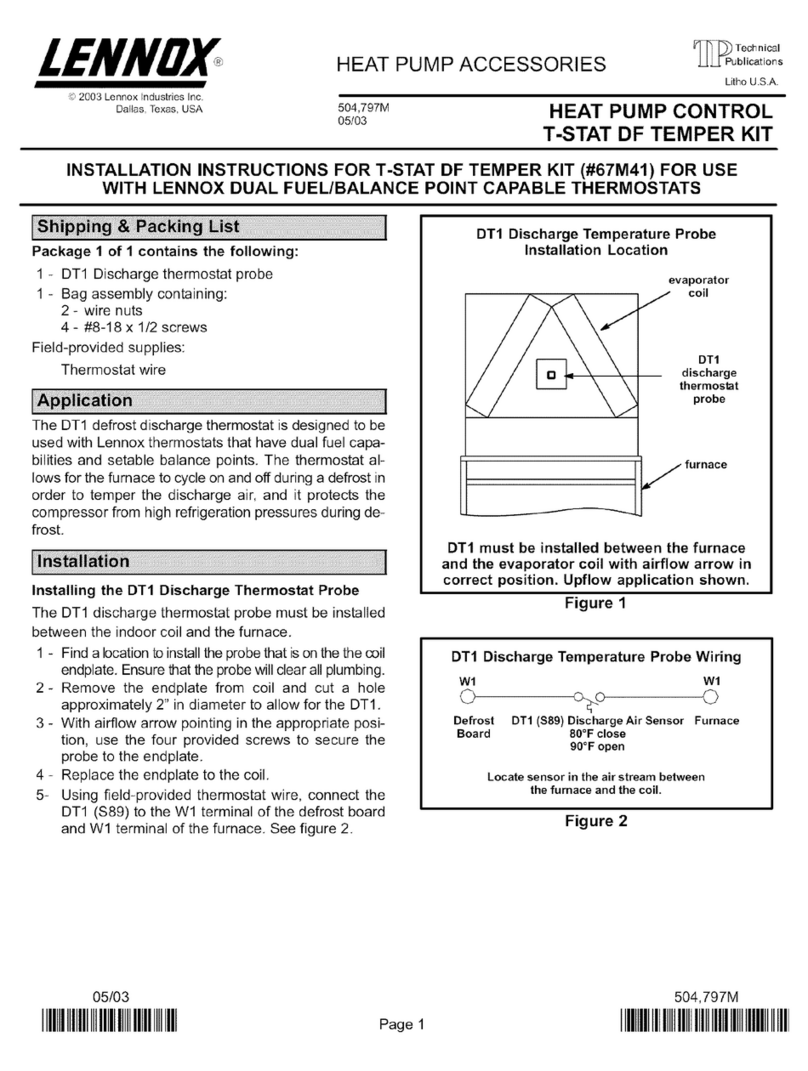

7.8 Installation of Heat Pump, Air Conditioning.............................. 19

8. Maintenance and Service ...................................................... 19

8.1 General............................................................................... 19

8.2 Silencers............................................................................. 19

8.3 Grounding........................................................................... 20

8.4 Test run.............................................................................. 20

8.5 Removal and disposal ........................................................... 20