Thank You!

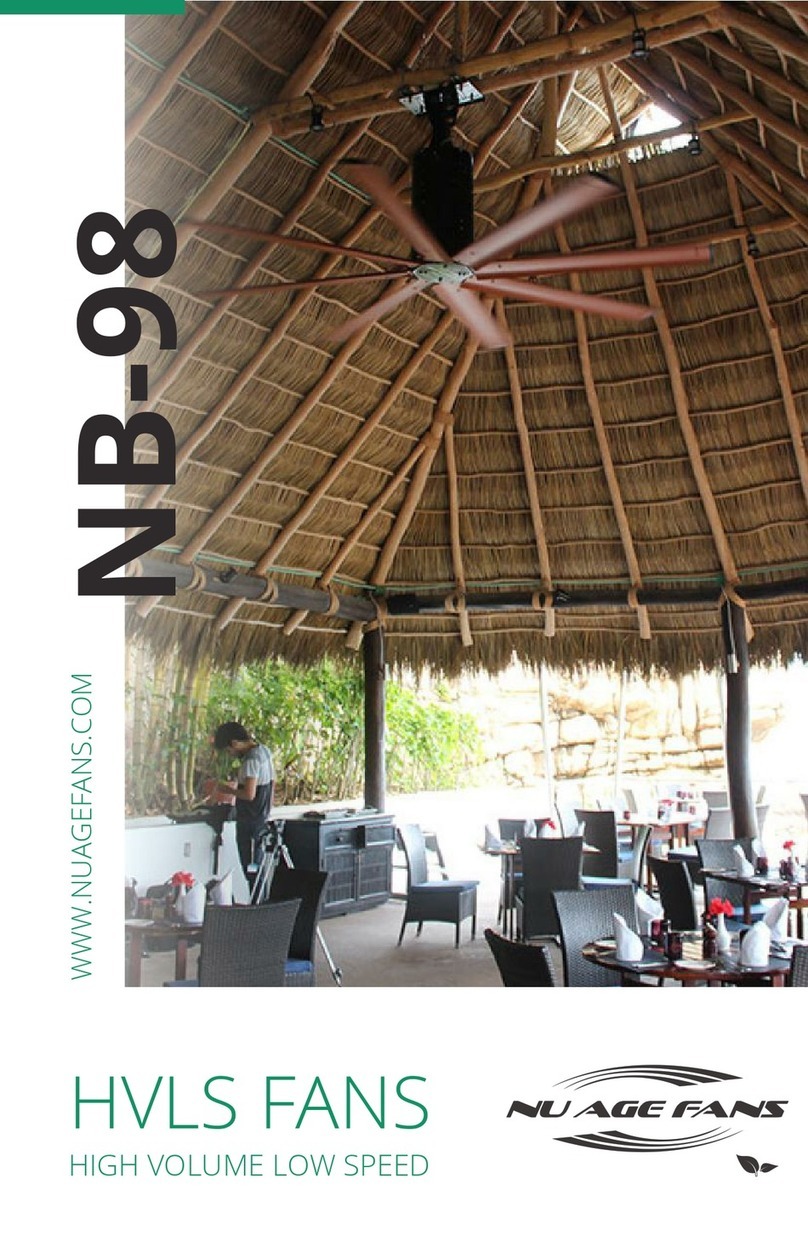

You have just acquired the most ecient and robust industrial ceiling

fan. We appreciate your condence in our products; our quality

management system focuses on your satisfaction; this is why we

manufacture every part of our fans with the highest quality materials,

controls, and techniques, including unique safety features.

Nu Age Fans brand represents the commitment made by our entire

team to guarantee our product is the best choice in safety, durability,

price, operating cost, and eciency.

All of our fans have been rigorously tested before shipment to ensure

mechanical and electrical compliance.

VMG Ventilation Services S.A. de C.V.’s fan, parts and trademarks are

covered the following patents and marks:

35552, 36328, 35653, 37260, 39566, 38886, 39150, 38723, 1340093,

3087, 47497, 40670, 38723, 1340093, 46431, 1594230, 1596295,

1594688, 1692098, 1690006 and others in process.

Failure to follow the required installation procedures specied in

this installation guide will constitute a breach of and will void all

warranties. Due to continuous process improvement, this user’s guide

specications and information are subject to change, cancelation, or

modication without prior notice.

All rights reserved. No part of these pages, either text or image, may

be used for any purpose other than personal use. Reproduction,

modication, storage in a retrieval system or retransmission, in any

form or by any means, electronic, mechanical or otherwise, for reasons

other than personal use, is strictly prohibited without prior written

permission from the owners of this material.

Nu Age Fans