Defender 500 | 9www.natvac.com | 800.253.5500

• The pump must be installed so that it is easily accessible for

inspection and maintenance�

• The vacuum pump must be installed on a rigid base or stand� The

drive can be by shaft, belts and pulley, or hydraulic motor�

• The drive shaft must be mounted so that it does not create any

axial thrust; the inclination of the shaft must not exceed 15 degrees

(seeg.2)

• When using belts and pulley, the pulley can be mounted directly on

the rotor shaft on the larger diameter inboard portion of the shaft�

The alignment between the pulley of the pump and the driving

pulley must be thoroughly checked� The tension must be adjusted

sothebeltsexforabout1/16th between pulleys�

• The direction of rotation and RPM are marked on the front of the

pump�

• The direction of rotation required by your drive system should be

determined prior to ordering the pump�

Drive System ______________________________________________________

Direction of Rotation ___________________________________________

7

4. Installation

4.1 Checking at arrival

- upon receipt check that the pump and related accessories are

not damaged.

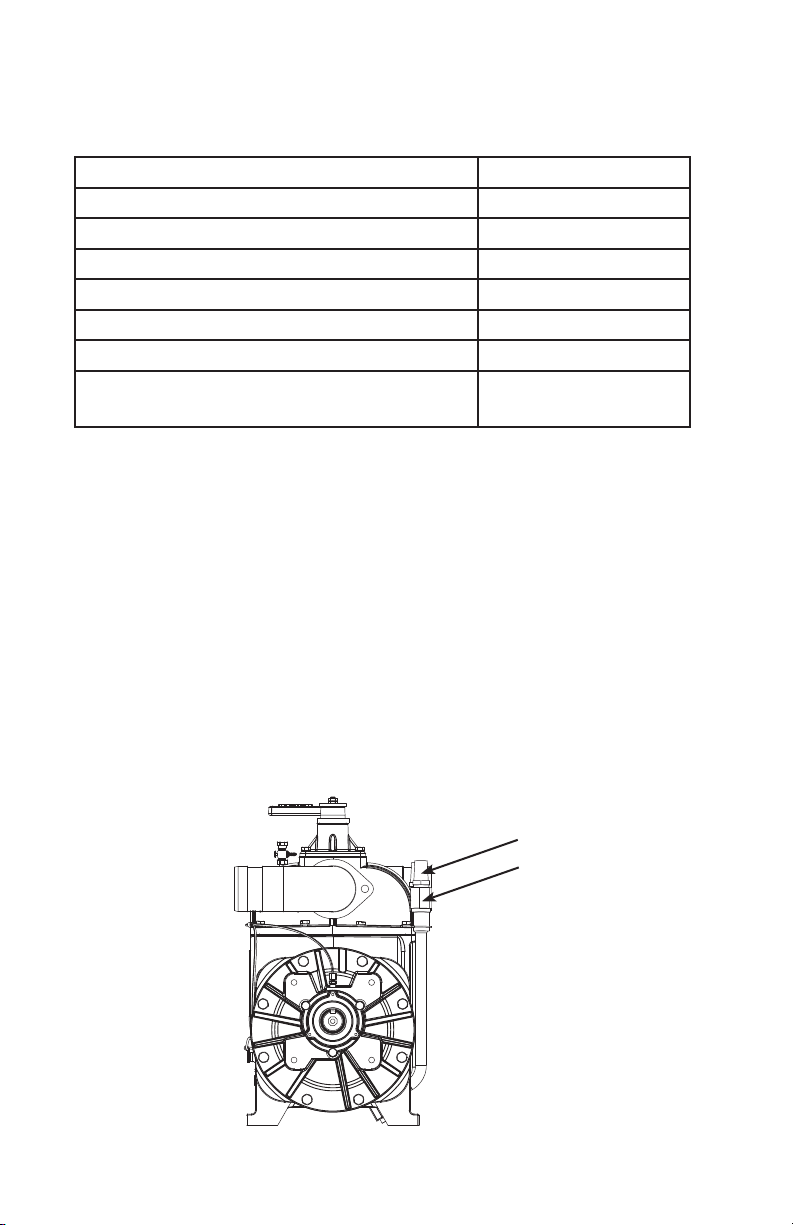

4.2 Pump mounting / Drive connection

- The pump must be installed so that it is easely accessible for

inspection and maintenance.

- The vacuum pump must be installed on a rigid base or stand.

The drive can be by cardan shaft, belts and pulley or by hydraulic

motor.

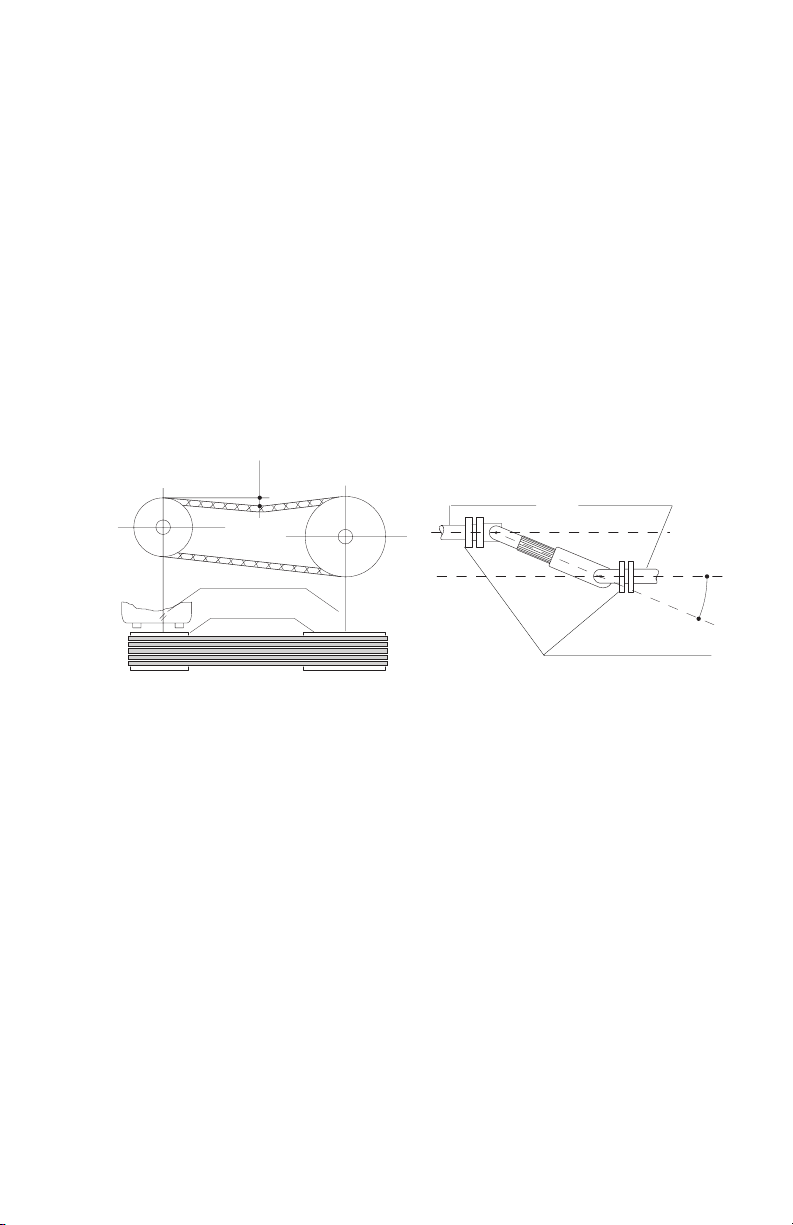

- The cardan shaft must be mounted so that it does not create any

axial thrust; the inclination of the shaft must not exceed 15°(see

fig. 2).

- When using the belts and pulley, the pulley can be mounted

directly on the rotor shaft eccept for R 430 .

For model R 430 pumps the pulley must be mounted with the

suitable support, supplied by JUROP.

The alignment between the pulley of the pump and the driving

pulley must be thoroughly checked.

The V-belts tension must be normal, that means the belts must

flex for about 2 cm. under the thumb pressure.

- With the hydraulic transmission the motor must be connected by

means of a support and a flexible joint.

The transmission must be protected according

to current safety standards (for Europe 89/

392 CEE standards).

Check that the actual shaft rotation

direction matches that of the arrow on

the label fixed on the front of the pump.

Fig. 2

15°

Transmission drive

Vacuum pump axle

axles must be parallel

16 - 20 mm

Flange must be

perfectly parallel

V-belts must be

exactly in line

- Check that the rotor/shaft is not blocked.

Figure 2