HHS

Hopper Heating System Installation Instructions

DESCRIPTION

The nVent RAYCHEM Hopper Heating System (HHS) is designed for

use with Electrostatic Precipitator (ESP) hoppers, baghouse hoppers

andmaterial / dust-collector hoppers.

It is highly recommended for all HHS heaters to be used in conjunction

with a temperature control device. These instructions describe the

procedure for installation, storage and handling of HHS heaters.

Carefully follow all directions.

ADDITIONAL / OPTIONAL MATERIALS REQUIRED

The HHS heater must be installed

correctly to ensure proper operation

and to prevent shock or fire. Read these

important warnings and carefully follow

all the installation instructions.

• All electrical wiring must follow

local electrical codes. Ground fault

equipment protection must be used on

each heater branch circuit to minimize

the danger of re if the heater is

damaged or improperly installed

and to comply with nVent design

requirements, agency certications

and national electrical codes.

• Damaged heaters and connections

must be replaced. Do not attempt to

repair or energize if damaged. Only

qualied personnel are allowed to

connect electrical wiring. Disconnect

all supply power at the source before

making any power connections. It is

highly recommended to never operate

heaters without a temperature control

device.

• The end-user is responsible for

providing a suitable disconnecting

device.

• The end-user is responsible for providing

a suitable electrical protection device.

• Final installation / wiring is to be

inspected by the authority who has

jurisdiction in the area that the heater

is installed.

• Approvals and performance are based

on the use of specied parts only.

Do not use vinyl electrical tape or

substitute parts.

• Read and understand this entire manual

before operating this electric heater.

Leave these installation instructions

with the user for future reference.

• Failure to observe these warnings may

result in personal injury or damage to

the heater.

Read and understand this entire manual before operating or servicing these heaters. Failure to understand how to safely operate these

heaters could result in an accident causing serious injury or death. These heaters should only be operated by qualified personnel and any

individual who has not read and understood all installation instructions is not qualified to install this product. Additional copies of this

manual are available upon request.

WARNING:

WARNING: CAUTION:

Approvals valid only when installed in accordance with

all applicable instructions,codes, and regulations.

Ordinary Locations

• Never handle the heater while it is in operation; always

disconnect the heater from the power source and allow for

proper cooling prior to handling.

• Inspect heater before use.

• If spillage of foreign matter onto the heater occurs,

disconnect from the power source and clean after the heater

is allowed to cool.

• Never operate a heater without an appropriate heat sink.

(Device being heated is considered a heat sink).

• Do not operate the heater above the rated temperature value.

• Fasten the heater to the heated surface using approved

methods only.

• Do not repair damaged or faulty heaters.

• Do not crush or apply severe physical stress on the heater or

lead wire assembly.

• Avoid hazards or unsafe practices which could result in

personal injury or property damage.

LIMITED WARRANTY

nVent offers 1 year limited standard warranty for the RAYCHEM HHS.

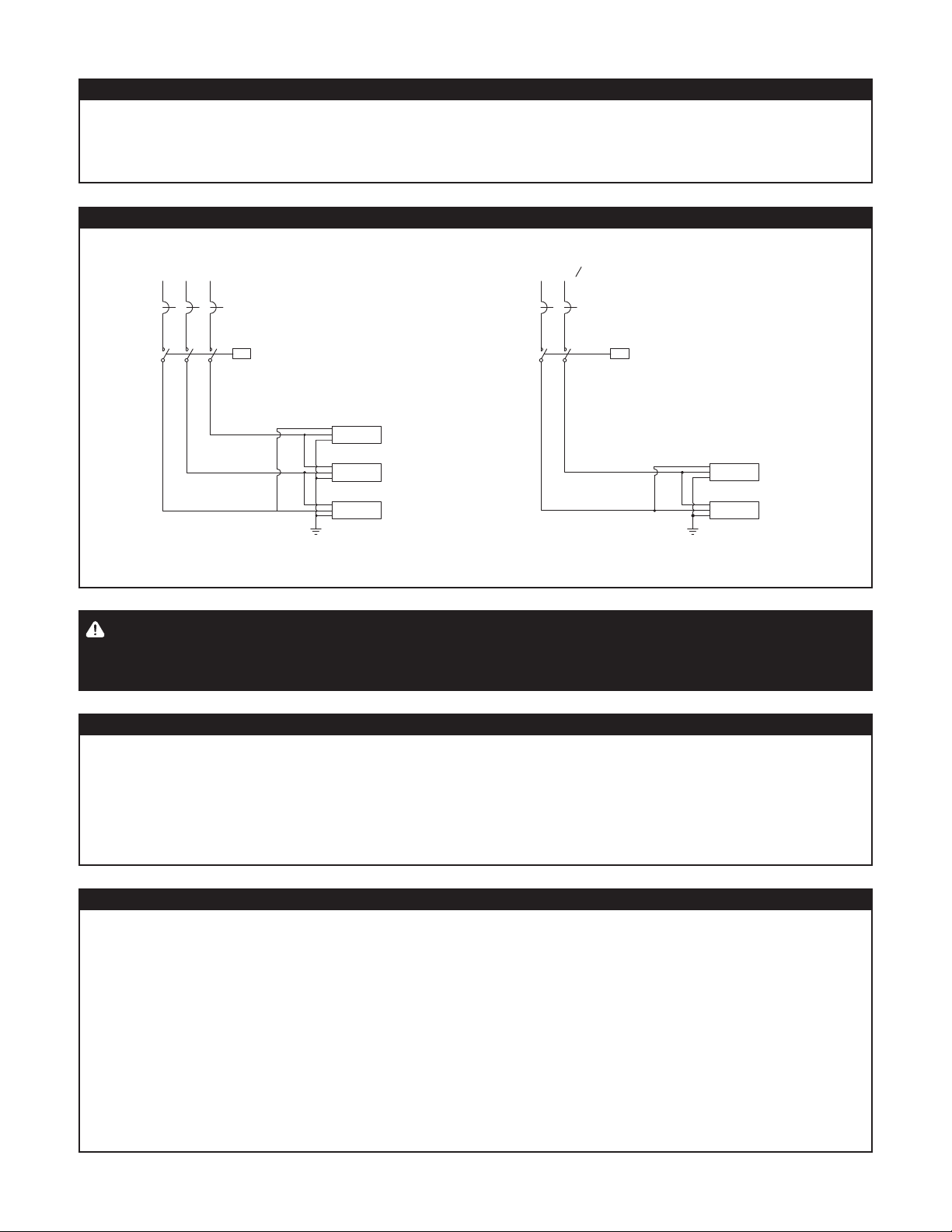

SAFETY ALERT SYMBOL

The symbol above is used to call your attention to instructions

concerning your personal safety. It points out important safety

precautions. It means “ATTENTION! Become Alert! Your Personal

Safety is involved!” Read the message that follows and be alert to

the possibility of personal injury.

• Wire strippers

• Cleaning / prep supplies

• Wire ties

• Mounting hardware

• Junction box

• Temperature controller

and sensor

• Silicone RTV

• High-temperature

adhesive tape

• Wrap Wound Heater

(HHS-WWH) for the

Conical Throat

• Insulating material

APPROVALS

HHS PRODUCT SPECIFICATIONS

Power density

Standard wattages up to 4650 W/m²

(3.0 W/in²)

Voltage range (nominal)

120 to 600 VAC

Maximum continuous

exposure / maintenance

temperature

260ºC (500ºF)

Maximum intermittent

exposure temperature

(power off)

538ºC (1000ºF)

Minimum installation

temperature

–20ºC (–4ºF)

Dielectric strength

Up to 2,200 VAC

Power leads 5.0m (16 ft.) long, moisture resistant, high-

temperature stainless steel overbraid with

a standard heater ground wire