What are the CSA and NRTL?

CSA (Canadian Standards Association also known as CSA International) was established in 1919 as

an independent testing laboratory in Canada. CSA received its recognition as an NRTL (Nationally

Recognized Testing Laboratory) in 1992 from OSHA (Occupational Safety and Health Administration) in

the United States of America (Docket No. NRTL-2-92). This was expanded and renewed in 1997, 1999,

and 2001. The specic notications were posted on OSHA’s ofcial website as follows:

Federal Register #: 59:40602 - 40609 [08/09/1994]

Federal Register #: 64:60240 - 60241 [11/04/1999]

Federal Register #: 66:35271 - 35278 [07/03/2001]

When these marks appear with the indicator “C and US” or “NRTL/C” it means that the product is

certied for both the US and Canadian markets, to the applicable US and Canadian standards. (1)

Argus rectier and power system products, bearing the aforementioned CSA marks, are

certied to CSA C22.2 No. 950 and UL 1950, or CSA/UL 60950.

As part of the reciprocal, US/Canada agreement regarding testing laboratories, the Standards Council

of Canada (Canada’s national accreditation body) granted Underwriters Laboratories (UL) authority to

certify products for sale in Canada. (2)

Only Underwriters Laboratories may grant a licence for the use of this mark, which indicates compliance

with both Canadian and US requirements. (3)

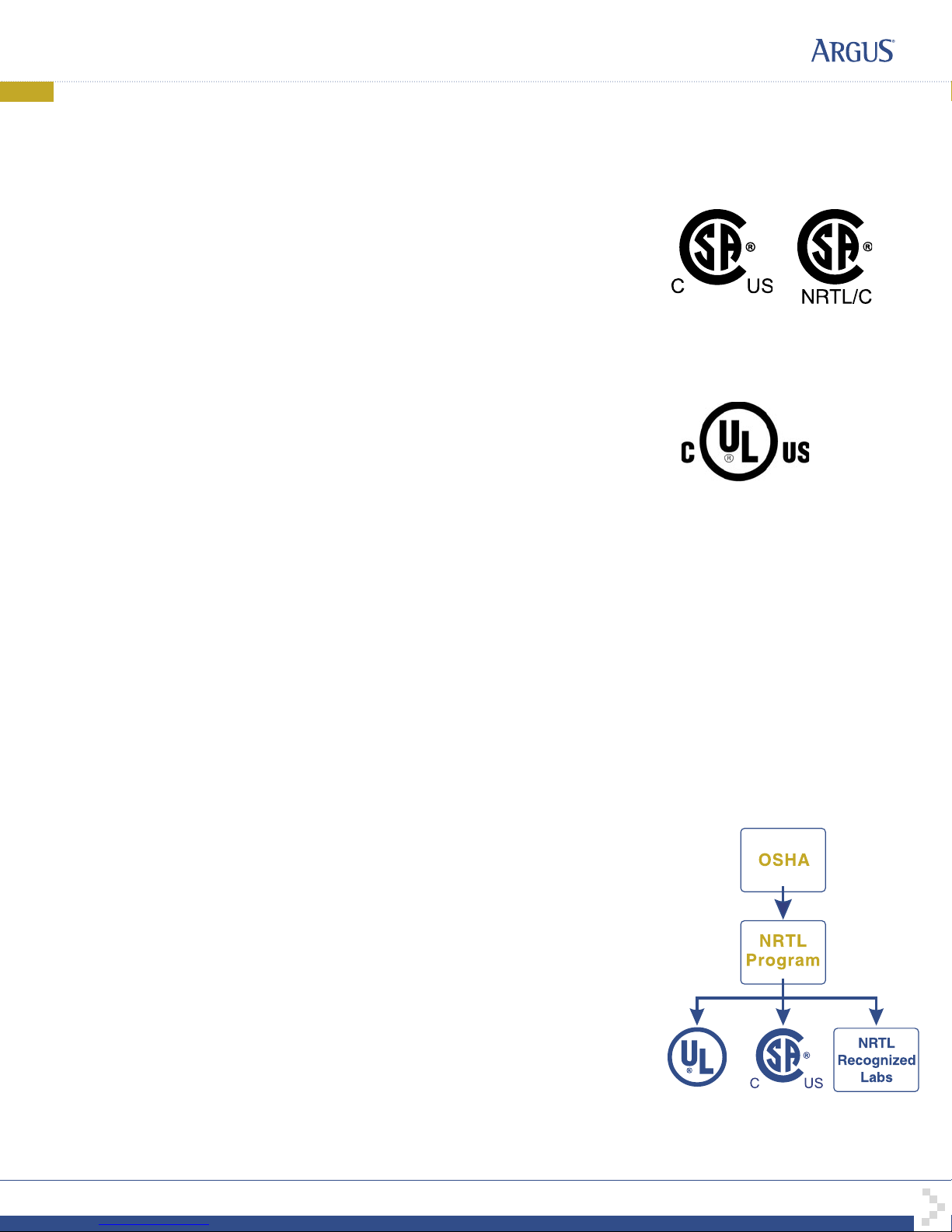

What are NRTLs and what do they do?

NRTLs are third party organizations recognized by OSHA, US Department of Labor, under the NRTL

program.

The testing and certications are based on product safety standards developed by US based standards

developing organizations and are often issued by the American National Standards Institute (ANSI). (4)

The NRTL determines that a product meets the requirements of an appropriate consensus-based

product safety standard either by successfully testing the product itself, or by verifying that a contract

laboratory has done so, and the NRTL certies that the product meets the requirements of the product

safety standard. (4)

When was the NRTL started and who governs it?

In 1983, in a suit brought on by an independent testing laboratory, OSHA was court ordered to remove

specic references to UL (Underwriters Laboratories) and FMRC (Factory Mutual Research Corporation)

from its regulations.

In 1988, OSHA revised its regulations to remove those references and the NRTL program was

established.

The NRTL Program is both national and international in scope with foreign labs permitted.

References:

Information in this document has been developed from the ofcial websites of the respective

organizations.

(1) www.csa-international.org

(2) www.scc.ca

(3) www.ulc.ca

(4) www.osha.gov

CSA/NRTL — MARKS — BACKGROUND

argusdcpower.com

048-554-10-I1 Rev C (2004/02)

The product on which either of these marks appear

has been certied by CSA as meeting applicable

Canada/US standards.

The product on which this mark

appears has been certied by UL

as meeting applicable Canada/US

standards.