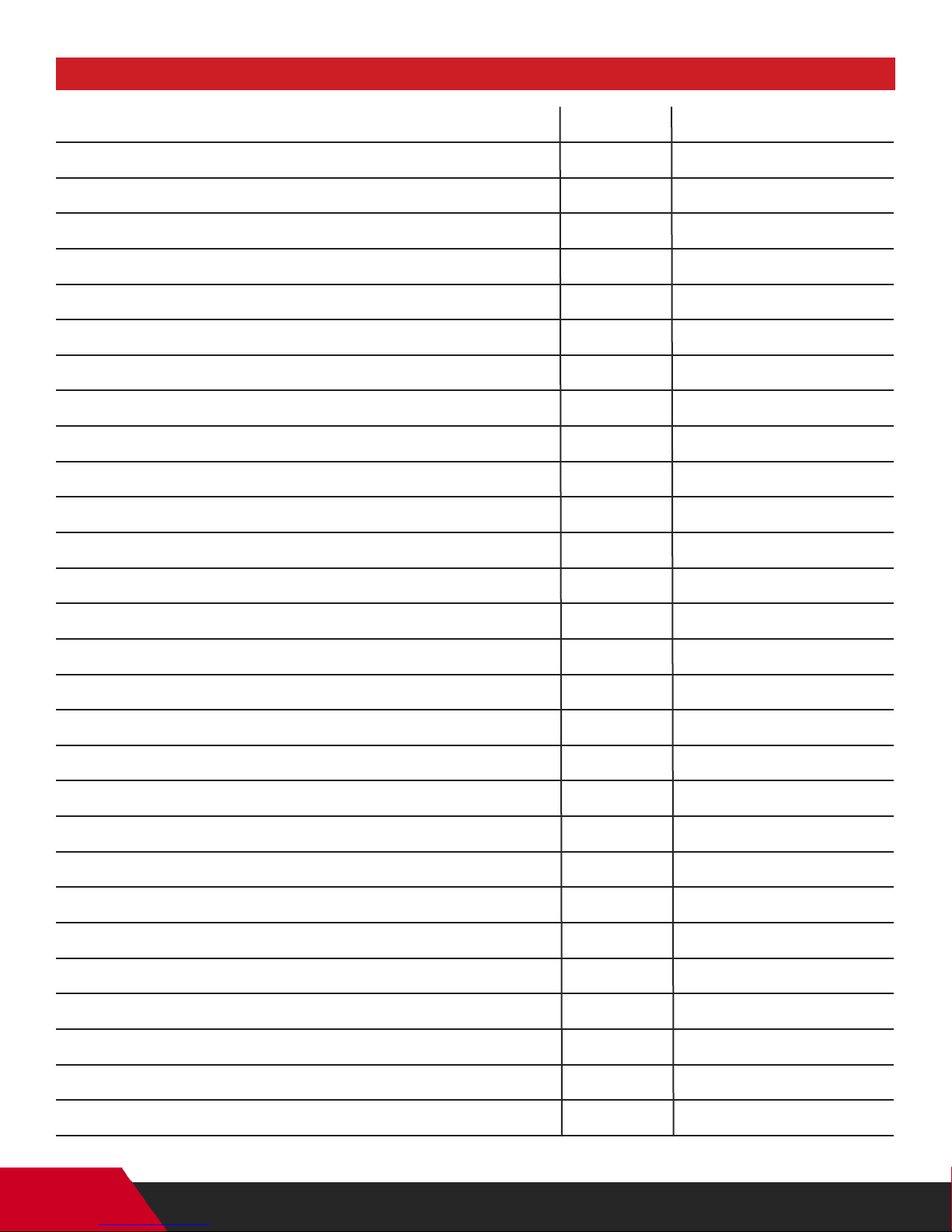

Table of Contents

Safety Guidelines....................................................................................................................................................................................................... 1

Precautions.................................................................................................................................................................................................................. 1

Electrical Grounding................................................................................................................................................................................................. 1

Your Kiln........................................................................................................................................................................................................................ 2

How your Dehumidication Kiln Works ............................................................................................................................................................ 2

Floors ............................................................................................................................................................................................................................. 2

Ceilings.......................................................................................................................................................................................................................... 2

Doors.............................................................................................................................................................................................................................. 2

Construction Guidelines......................................................................................................................................................................................... 3

Equipment Installation............................................................................................................................................................................................ 4

Figure 1-1 Chamber Plan........................................................................................................................................................................................ 5

Figure 1-2 Kiln Chamber Section C ..................................................................................................................................................................... 6

Figure 1-3 Kiln Chamber Section D..................................................................................................................................................................... 7

Figure 1-4 Kiln Chamber Recommended Dimensions ................................................................................................................................ 8

Figure 1-5 Kiln Chamber Wall Details................................................................................................................................................................. 9

Figure 1-6 Kiln Chamber Front Elevation........................................................................................................................................................10

Figure 1-7 Kiln Chamber Door Framing ..........................................................................................................................................................11

Figure 1-8 Kiln Chamber Door Section E ........................................................................................................................................................12

Figure 1-9 Kiln Chamber Door Section F ........................................................................................................................................................13

Figure 1-10 Deectors and Baes ....................................................................................................................................................................14

Figure 1-11 Equipment Front..............................................................................................................................................................................15

Figure 1-12 Equipment Back ...............................................................................................................................................................................16

Figure 1-13 Fan Diagram ......................................................................................................................................................................................17

Wet and Dry Bulb, Controller Installation and Use......................................................................................................................................18

Sensor Technology..................................................................................................................................................................................................18

Dry Bulb Sensor .......................................................................................................................................................................................................18

Wet Bulb Sensor.......................................................................................................................................................................................................18

L200S Kiln Controller..............................................................................................................................................................................................19

Figure 2-1 L200S Controller.................................................................................................................................................................................19

How L200S Control Works....................................................................................................................................................................................19

Wet Bulb Installation..............................................................................................................................................................................................19

Figure 2-2 Wet Bulb ................................................................................................................................................................................................19

Using L200S...............................................................................................................................................................................................................20

Figure 2-3 Controller Display...............................................................................................................................................................................20

Parameters.................................................................................................................................................................................................................20

Settable Parameters ...............................................................................................................................................................................................20

Serial Interface..........................................................................................................................................................................................................20

Alarm Conditions / Messages .............................................................................................................................................................................21

Figure 2-4 Wiring .....................................................................................................................................................................................................22

Technical Specications........................................................................................................................................................................................23

L200M Kiln Controller............................................................................................................................................................................................24

Figure 2-5 L200M Controller................................................................................................................................................................................24

How L200M Works ..................................................................................................................................................................................................24

Figure 2-6 Wet Bulb ................................................................................................................................................................................................24

Wet Bulb .....................................................................................................................................................................................................................24

Timber Probes...........................................................................................................................................................................................................25

Probe Placement .....................................................................................................................................................................................................25

Figure 2-7 Correct Probe Placement ................................................................................................................................................................25

Figure 2-8 Incorrect Probe Placement .............................................................................................................................................................25

Power On....................................................................................................................................................................................................................26

Figure 2-9 L200M Display.....................................................................................................................................................................................26