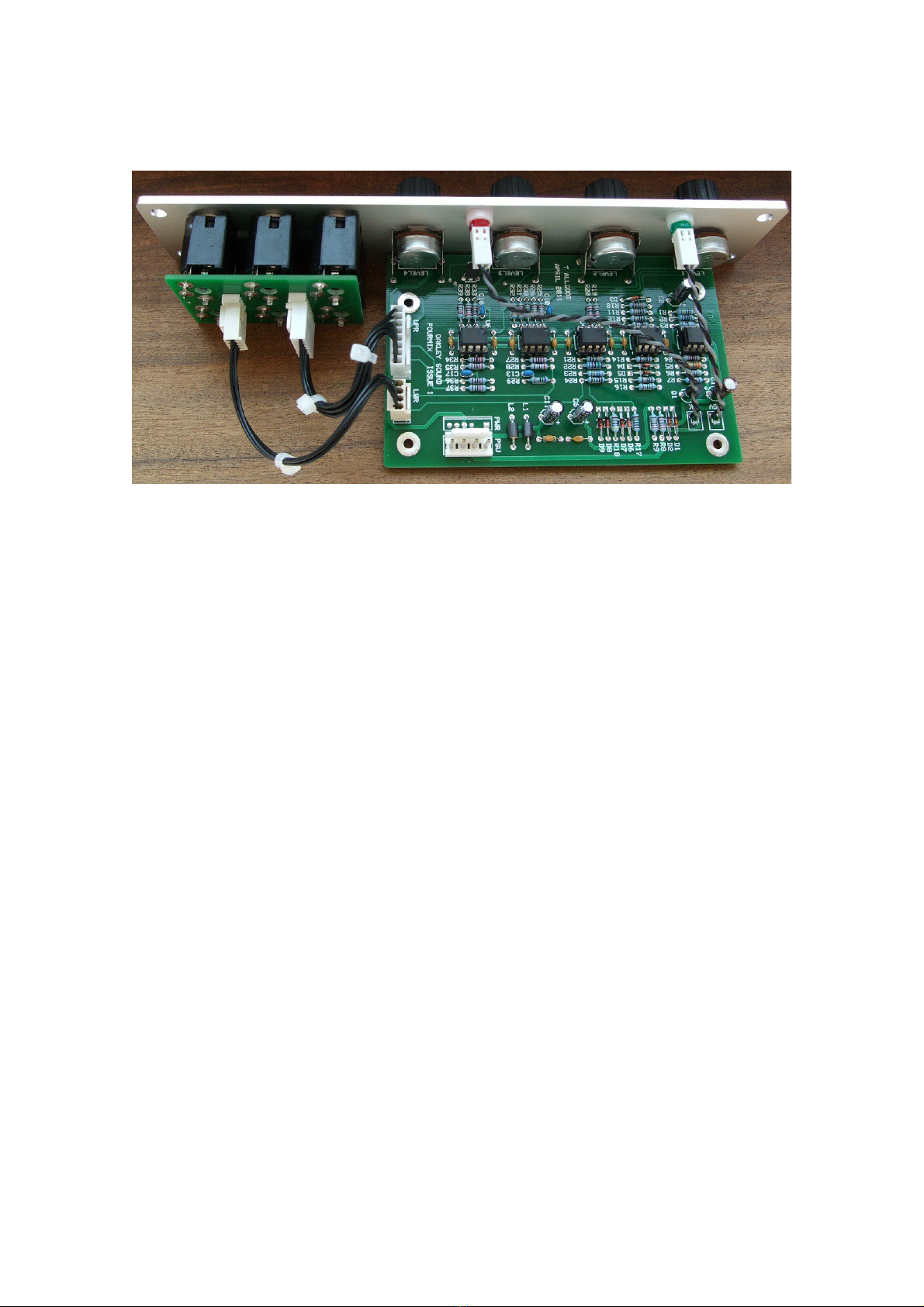

Parts Lists

There are two types of Fourmix boards, issue 1 and issue 2, please ensure that you use the

right parts list for the board you have.

For general information regarding where to get parts and suggested part numbers please see

our useful Parts Guide at the project web page or http://www.oakleysound.com/parts.pdf.

The components are grouped into values, the order of the component names is of no particular

consequence.

A quick note on European part descriptions. R is shorthand for ohm. K is shorthand for kilo-

ohm. R is shorthand for ohm. So 22R is 22 ohm, 1K5 is 1,500 ohms or 1.5 kilohms. For

capacitors: 1uF = one microfarad = 1000nF = one thousand nanofarad.

To prevent loss of the small ‘.’ as the decimal point, a convention of inserting the unit in its

place is used. eg. 4R7 is a 4.7 ohm, 4K7 is a 4700 ohm resistor, 6n8 is a 6.8 nF capacitor.

Issue 1 Fourmix Parts List

Resistors

1% 0.25W metal film types are to be recommended simply because they are better quality and

lower noise components. However, 5% ones can be substituted in any of the places if you

wish. R5 will probably have to be a 5% type since getting hold of a 1% metal film resistor in

this value may be difficult.

22R R9

75R R29

120R R7, R18

470R R6

1K R17, R24

2K2 R36, R39, R37

3K R2

3K3 R21, R10

3K9 R3

11K R4, R23, R33

22K R8, R19, R20, R22, R27, R28, R35, R34, R38

33K R25, R32, R31, R30, R26

100K R12, R15, R14, R11, R13

150K R16

1M R1

3M3 R5

4