Construction is fun but keep in mind:

●You are resposible for your own healthiness.

●almost all adhesi es contain sol ents an other olatile substances,

care for adequate entilation!

●Be carefully in the use of superglue! Fingers and eylids are glued

together faster than you do not mind!

●The processing of CFRP caused finest coal dust which must not be

inhaled or swallowed!

●Wash your hands when coal dust adheres to your fingers!

●Do not blow the coal dust from the building board, remo e the dust

with a acuum cleaner!

●Note the operating instructions by the manufacturers and suppliers.

●Handling tools can cause injury.

●Operation of an Aircraft model can cause accidents.

●Construction and operation of a flight model must be learned.

●For beginners, it is necessary that an experienced person helps.

●For damages and accidents that will arise in connection with the

construction and operating of the model, "Oli er Flugmodellbau" do

not take any resposibility.

.... and here we go with building fun!

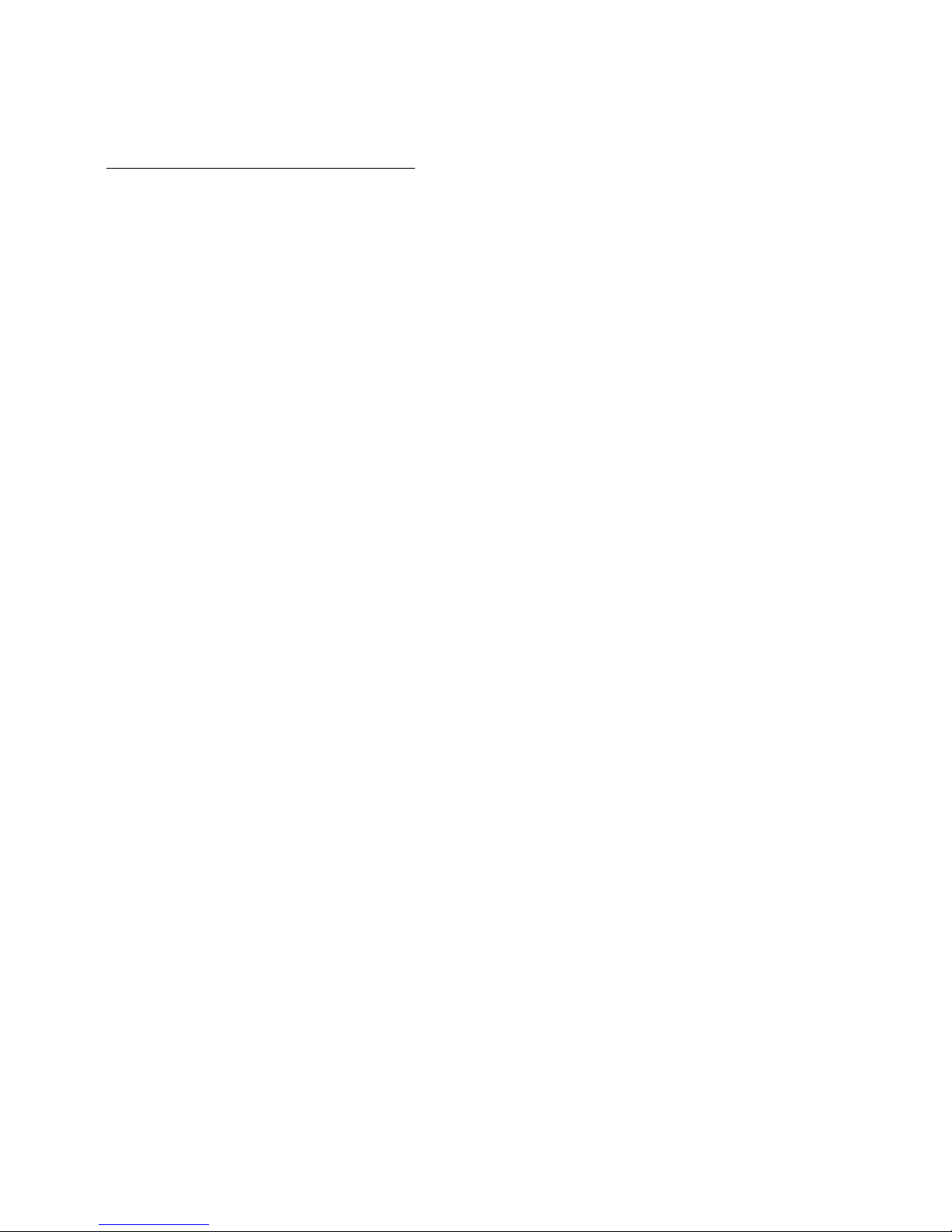

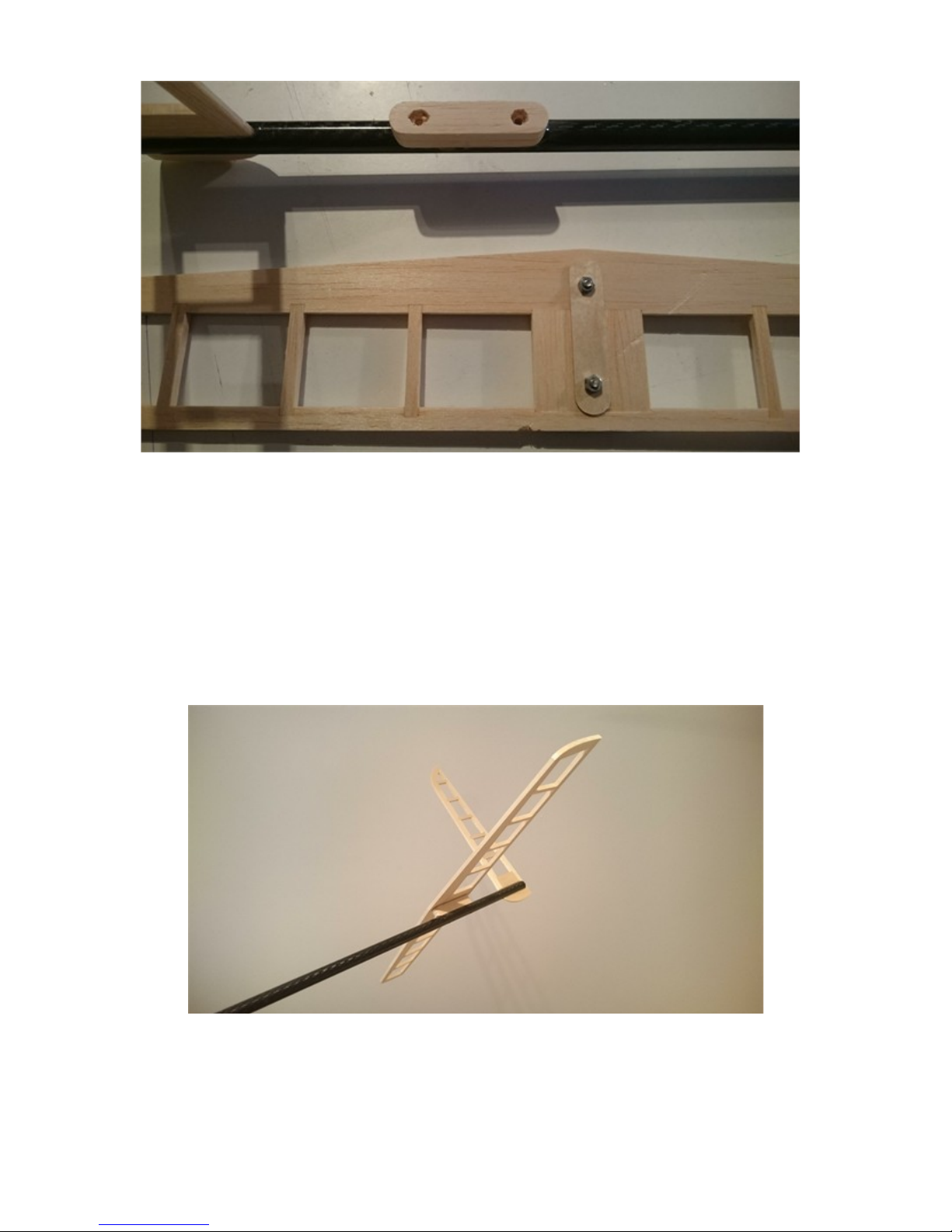

Construction of horizontal stabilizer (ele ator)

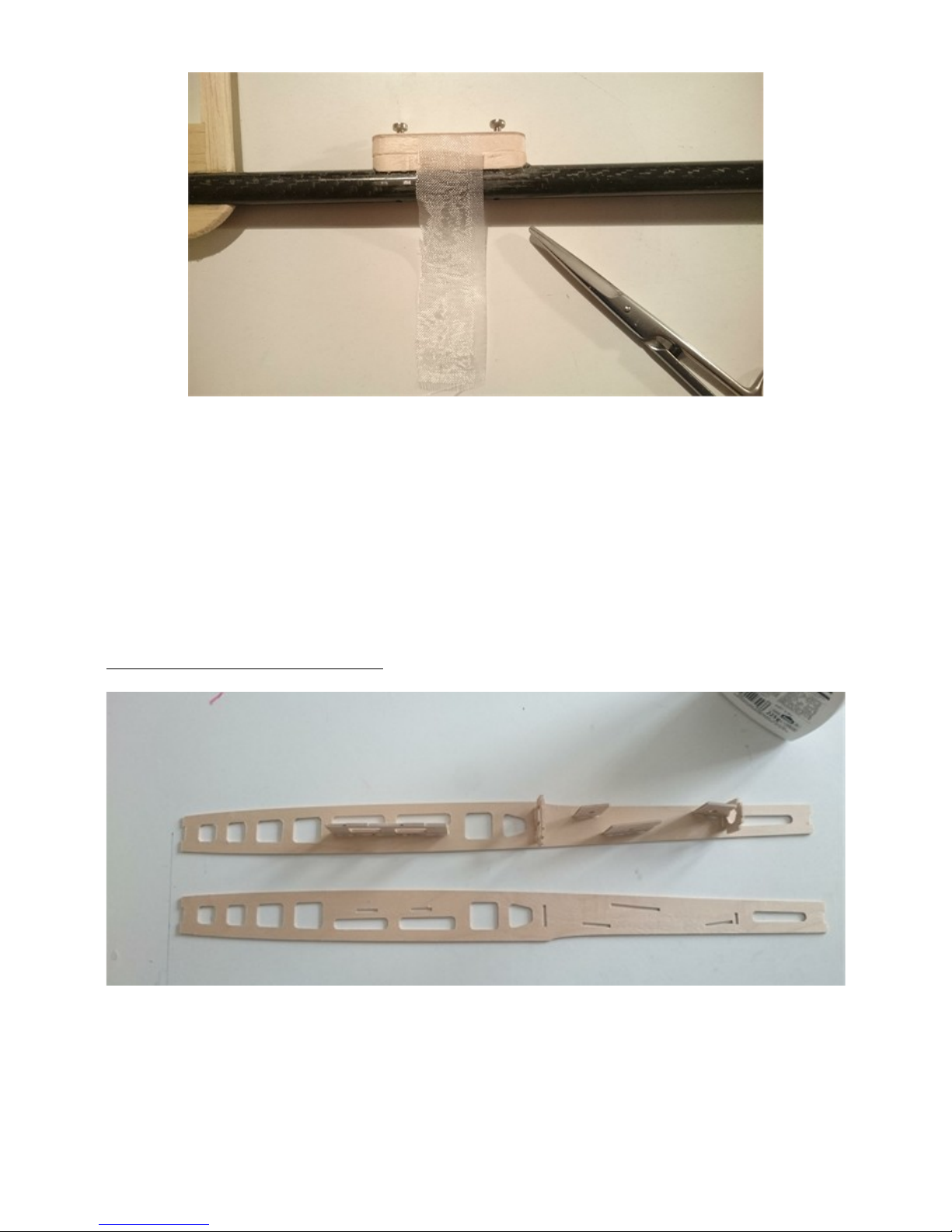

Separate components with a sharp balsa knife from balsa and connection webs

remove from the components (little grinding).

Stuck together and stick together. Use superglue in order to save weight.

Leading edge and tip grind around. Tail edge grind tapered.

Planing in the hinge region with the balsa plane at 45 degree.

The control horn is glued with superglue after ironing the covering film.

3