Timeless Wings Arsenal VG-70 User manual

1

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

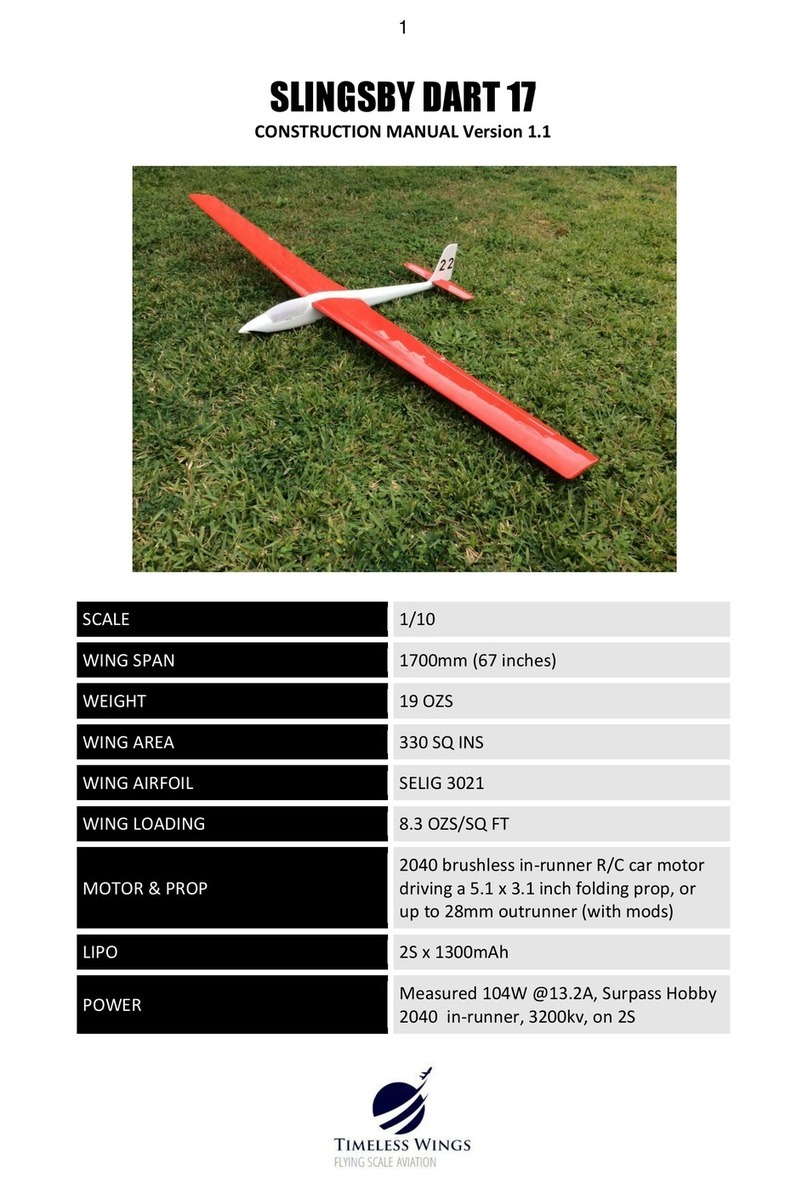

SCALE

1/13 (approximately)

WINGSPAN

687mm (27 inches)

LENGTH

797mm (31.4 inches)

FLYING WEIGHT

640g (22.5 ounces)

WING AREA

160 SQ IN

WING LOADING

20 OZS/SQ FT

EDF

X-FLY Galaxy or FMS 50mm EDF or

similar 4S unit

LIPO

4S x 1300mAh

2

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

Arsenal VG-70 –history

Shortly after the conclusion of WW2, the French Arsenal company began designing a swept-

wing research aircraft that would incorporate wind-tunnel data acquired from former

Messerschmitt engineers. The required airframe would be the smallest structure that could

fit the Junkers Jumo 004, which was the only available engine at that time.

The result was the Arsenal VG-70, with a fuselage built from metal, along with wooden

wings and tail. The nearly complete airframe was displayed at the Paris Aero Show in 1946,

and ground testing was completed by the end of 1947.

Wind tunnel testing which indicated some potential problems delayed the first flight until 23

June 1948, when it became the second French jet aircraft to fly. After a brief but successful

test-flying career, the VG-70 was retired in early 1949, as it had reached its development

potential, and the much-improved follow-on VG-90 was well under way.

3

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

NOTES ABOUT THE DESIGN PROCESS AND PRINTING OPTIONS:

The Arsenal VG-70 files include G-code files and .3MF files for all parts, sliced on the free Prusa slicer

(version 2.5.2).

In the first instance, the G-code files should be generic enough to give acceptable results when

loaded directly on a cartesian printer with at least a 200 x 200 x 200mm build volume, with direct

drive or Bowden extruder, but individual results may vary.

Alternatively, the Prusa slicer is easy to use to load the corresponding part .3MF file as a project, and

to change any applicable settings that are not working for your specific print job. These parts have

not been tested in other slicers and Prusa slicer should be used. Except for the motor mount, canopy

and auxiliary air intake which are in normal PLA, all parts are printed from LW-PLA.

The LW-PLA components were printed with 3DLabPrint PolyLight 1.0 LW-PLA which gave excellent

results. E-Sun PLA+ was used for PLA parts and can be recommended. Other filaments may require a

small adjustment to print temperatures and/or extrusion multiplier to give similar results.

Design methodology:

This model has been designed so that all components are solids and are printed with an outer skin

and internal infill. Depending on variables such as nozzle condition, extruder condition, bed

temperature sensor accuracy, filament condition etc. it may be necessary to tweak some of the print

settings to give the best results. The .3MF files when loaded as a project into Prusa slicer will

populate the Print Settings, Filament Settings and Printer Settings with the generic values generated

by the designer, as well as loading the component STL file.

The drop down “Printer Settings” menu can be used to load the default settings specific to your

printer (such as prime line G-code etc.) Additionally, any changes that you make in the Print Settings

menus or Filament Settings menus can be saved (if desired) under another name from the “Save

current….” icon option adjacent to the drop-down menu boxes at the top left of the Prusa window.

For this model, gyroid infill seems to work best on fuselage components, and cubic infill for the

wings and horizontal tail. Feel free to play around with the settings to achieve the balance of

strength vs skin support that you are comfortable with!

By default, a small amount of part cooling fan is used on all parts. If necessary, better layer adhesion

may be achieved with the fan off, if the print result is acceptable in other respects.

LW-PLA parts should be printed one at a time. Weights and times are just a guide, but should be

close to default file values, and are conservative giving strong parts. Weight saving may be achieved

at the discretion of the builder. In practice extrusion multipliers down to 0.45 and infill down to 4%

may be achieved on a good printer giving a suitable weight saving. The default setting (for most

parts) is an extrusion of 0.5 and infill 6% (Gyroid for the fuselage and Cubic for the wings and tail).

4

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

5

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART F1

•LW-PLA

•Print weight: 1.98g

•Print time: 34 mins

PART F2

•LW-PLA

•Print weight: 23.48g

•Print time: 4hr 14min

6

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART F3

•LW-PLA

•Print weight: 31.55g

•Print time: 6hr 13min

PART F4

•LW-PLA

•Print weight: 23.57g

•Print time: 4hr 23min

7

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART F5

•LW-PLA

•Print weight: 32.24g

•Print time: 5hr 59min

PART F6

•LW-PLA

•Print weight: 25.51g

•Print time: 4hr 51min

•4% gyroid infill preset in

G-code and .3MF files

8

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART hatch

•LW-PLA

•Print weight: 9.55g

•Print time: 2hr 35min

•A brim may be necessary

if print bed adhesion is

not good

PART W1L

•LW-PLA

•Print weight: 20.13g

•Print time: 3hr 49min

9

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART W1R

•LW-PLA

•Print weight: 20.13g

•Print time: 3hr 49min

PART W2L

•LW-PLA

•Print weight: 12.01g

•Print time: 2hr 21min

10

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART W2R

•LW-PLA

•Print weight: 12.01g

•Print time: 2hr 21min

PART W3L

•LW-PLA

•Print weight: 6.11g

•Print time: 1hr 32min

•A brim may be necessary

if print bed adhesion is

not good

11

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART W3R

•LW-PLA

•Print weight: 6.11g

•Print time: 1hr 32min

•A brim may be necessary

if print bed adhesion is

not good

PART L aileron

•LW-PLA

•Print weight: 3.22g

•Print time: 45mins

•8 bottom layers +

extrusion multiplier of

0.7 have been preset in

G-code and .3MF files

•A brim may be

necessary if print bed

adhesion is not good

12

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART R aileron

•LW-PLA

•Print weight: 3.22g

•Print time: 45mins

•8 bottom layers +

extrusion multiplier of

0.7 have been preset in

G-code and .3MF files

•A brim may be

necessary if print bed

adhesion is not good

PART L wing tip

•LW-PLA

•Print weight: 0.43g

•Print time: 8min

13

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART R wing tip

•LW-PLA

•Print weight: 0.43g

•Print time: 8 mins

PART L tailplane

•LW-PLA

•Print weight: 6.26g

•Print time: 1hr 20min

•A brim may be necessary

if print bed adhesion is

not good

•An extrusion multiplier

of 0.7 is preset in G-code

and .3MF files

14

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART R tailplane

•LW-PLA

•Print weight: 6.26g

•Print time: 1hr 20min

•A brim may be necessary

if print bed adhesion is

not good

•An extrusion multiplier

of 0.7 is preset in G-code

and .3MF files

PART L elevator

•LW-PLA

•Print weight: 3.36g

•Print time: 47min

•A brim may help if print

bed adhesion is not good

•8 bottom layers + an

extrusion multiplier of

0.7 is preset in G-code

and .3MF files

15

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART R elevator

•LW-PLA

•Print weight: 3.36g

•Print time: 47min

•A brim may help if print

bed adhesion is not good

•8 bottom layers + an

extrusion multiplier of

0.7 have been preset in

G-code and .3MF files

PART L tail tip

•LW-PLA

•Print weight: 0.51g

•Print time: 10m

16

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART R tail tip

•LW-PLA

•Print weight: 0.51g

•Print time: 10m

PART auxiliary

air intake

•PLA

•Print weight: 9.73g

•Print time: 1hr 2mins

•A brim may be necessary

if print bed adhesion is

not good

•Arachne perimeter

generator has been

preset in G-code and

.3MF files

17

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PART motor &

servo mount

•PLA

•Print weight: 10.43g

•Print time: 51min

•Arachne perimeter

generator has been

preset in G-code and

.3MF files

PART canopy

•Natural (clear) PLA

•Print weight: 4.28g

•Print time: 24min

18

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

PREPARING THE PARTS FOR ASSEMBLY

LW-PLA parts will need a little cleaning up in places with a sharp blade and/or sandpaper before

assembly. Note that the colour of the material changes (goes lighter) when sanding deeply and can

highlight the underlying structure. At the expense of a slight increase in weight, a coat or two of

water-based polyurethane evens out the colour and gives a significant increase in strength to the

skin.

Medium cyanoacrylate glue used with accelerator is the preferred adhesive for all parts of this

model. As an alternative, Gorilla Clear Polyurethane Glue (the non-expanding kind) has been used

interchangeably on this and several other projects with great success. The beauty of this latter glue

is that you have many minutes of positioning time as opposed to just seconds with CA. This can be

very helpful especially on wing panel alignment or even on control surface hinges. A paper towel

used dry or with isopropyl alcohol removes any residue before the glue sets.

The assembled model is in 6 parts: The forward and rear fuselage sections which are screwed

together and can be separated for fan and servo installation and removal; the hatch which is

magnetically attached for electronics access, and a detachable auxiliary air intake which gives day to

day access to the fan. Finally, two wing halves sit on a carbon spar and are held in place by screws.

FORWARD FUSELAGE ASSEMBLY

•Cut fuselage alignment pins to the lengths shown on the diagram below from 3mm dowel or

carbon rod and insert into formers as shown. Check that all parts fit together snugly. Separate

parts again then apply glue in turn to the front and rear of F2, and the front F4 where it

contacts F3. Carefully reassemble parts and clamp until dry.

•Glue 10mm diameter x 3mm thick hatch magnet into the hole in the front of F4.

19

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

REAR FUSELAGE ASSEMBLY

•Take two lengths of elevator piano wire pushrods and push through the pushrod channels in

F5 and F6 until they slide freely. The channels will take up to 1.2mm (0.047in) diameter wire

(optimum), but 0.8mm (0.031in) has been used on one prototype and works OK.

•Cut fuselage alignment pins to the lengths shown on the diagram below from 3mm dowel or

carbon rod and insert into formers as shown. Check that all parts fit together snugly. Separate

F5 and F6 again then apply glue to the front of F6, ensuring glue does not get into the pushrod

channels or on the pushrods . Carefully reassemble parts and clamp until dry.

HATCH ASSEMBLY

•Glue 10mm diameter x 3mm thick hatch magnet into the hole in the rear of the hatch.

IMPORTANT! Make sure that the polarity of the magnet is correct so it attracts the

hatch magnet in F4.

•Place the hatch on a flat surface then glue canopy in place.

20

Timelesswings.com

PRINTING AND ASSEMBLY GUIDE ARSENAL VG-70 VERSION 1.2 28 JUNE 2023

WING ASSEMBLY

•Cut wing alignment pins to the lengths shown on the diagram below from 3mm dowel or

carbon rod and insert into holes as shown. Check that all parts fit together snugly. Some light

sanding of mating surfaces with a flat block may be necessary. Note that the wing tips are not

added at this stage to make fitting the ailerons easier.

•Glue parts together and clamp until dry.

AILERON ATTACHMENT

•LEFT Wing underside shown (repeat process for RIGHT wing).

•Cut CA hinge sheet to dimensions in drawing below. Glue to wing first, then aileron.

Table of contents

Other Timeless Wings Toy manuals

Popular Toy manuals by other brands

V-tech

V-tech Soothing Songs Lovey user manual

Silvercrest

Silvercrest SKK 2 A1 quick start guide

Modeltech

Modeltech Fun Fighters P-51 ARF Assembly instructions

PLAYTIVE JUNIOR

PLAYTIVE JUNIOR MEGA BUBBLE Instructions for use

V-tech

V-tech Fix-It Buddies Toolbox Series Parents' guide

Matt:e

Matt:e Barbie FRL85 instructions