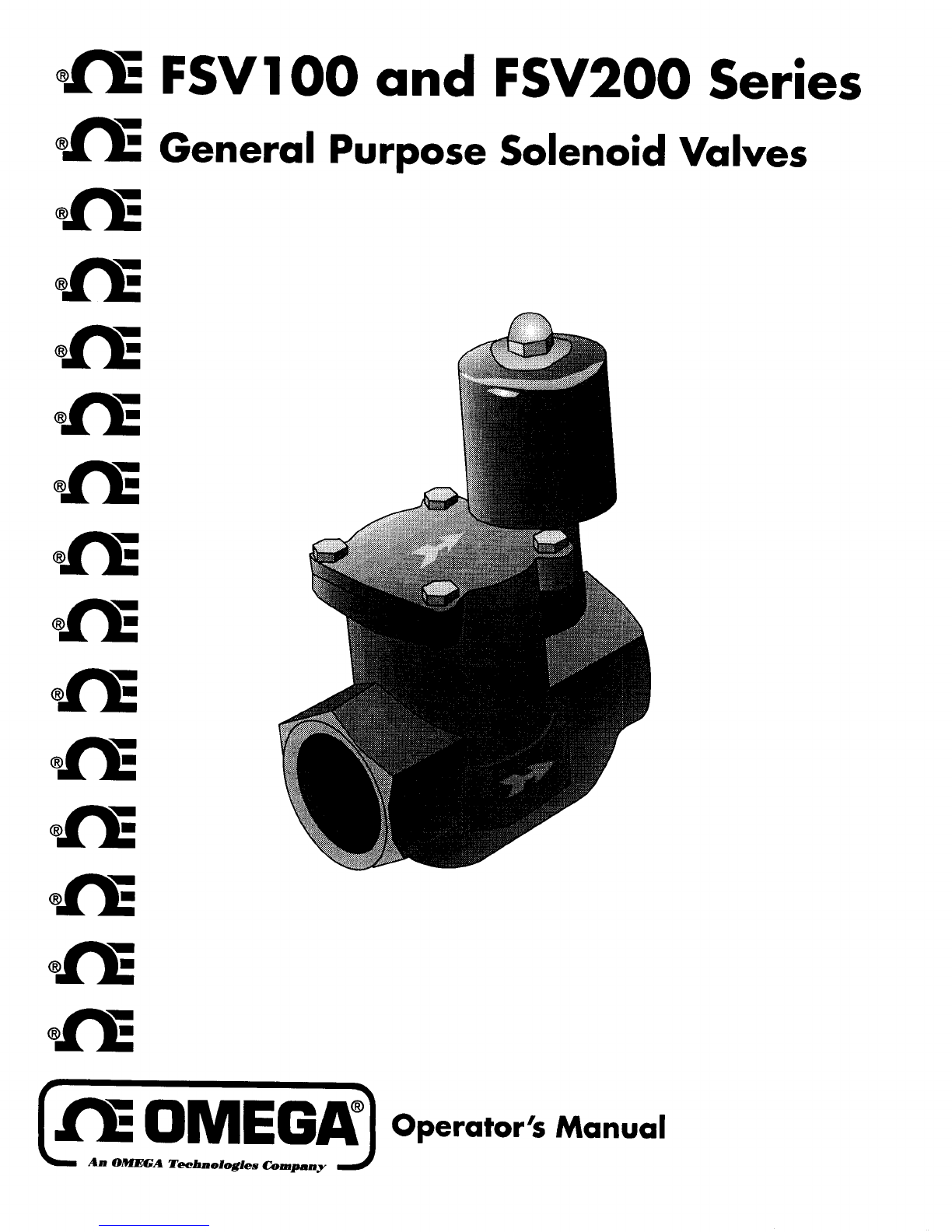

Piston-

TypeSolenoidValvescovermostindustrialapplications.Atwo-wayvalvecontrolstheflowof

fluidthroughasinglepassage. Ithastwoports,aninletandanoutlet.Anormallyclosedvalve

doesnotpassfluidunlessitisenergized.Thereisfailsafepositivevalveclosingintheevent

ofpowerfailurethatpreventsfloodingoroverfilling.

Thesevalvescoverawiderangeofoperatingpressuresandtemperatures.5PSIto150PSI

pressureandtemperaturesto195°Faffordsbroadapplicationandtremendousflexibility. The

longlifebronzecastingsandwaterproofcoilsinsureperformanceconsistencyforalonglife.

Sincethevalvesareveryrugged,theyprovidelowincidenceofdowntimeandmaintenance.

Minimumpressuredropinternaldesignofthisvalveassuresexceptionalflowperformance.

FSV200

SeriesTwo-WayNormallyClosedPilotOperated

FSVIOO

and

(1)

Operator’sManual(1)

Ifyouhaveanyquestionsabouttheshipment,pleasecallOMEGACustomerServiceDepart-

ment.Whenyoureceivetheshipment,inspectthecontainerandequipmentforsignsofdam-

age.Noteanyevidenceofroughhandlingintransit.Immediatelyreportanydamagetothe

shippingagent.

NOTE

Thecarrierwillnothonoranyclaimsunlessallshipping

materialissavedforinspection.Afterexamining

andremovingcontents,savepackingmaterialandcarton

intheeventreshipmentisnecessary.

1.2 Description

TheOMEGA@

.l

Unpacking

RemovethePackingListandverifythatyouhavereceivedallequipment,includingthefollow-

ing(quantitiesinparentheses):

GeneralPurposeSolenoidValve

Chapter 1 Introduction

1