MEK-1001 TS07004

2

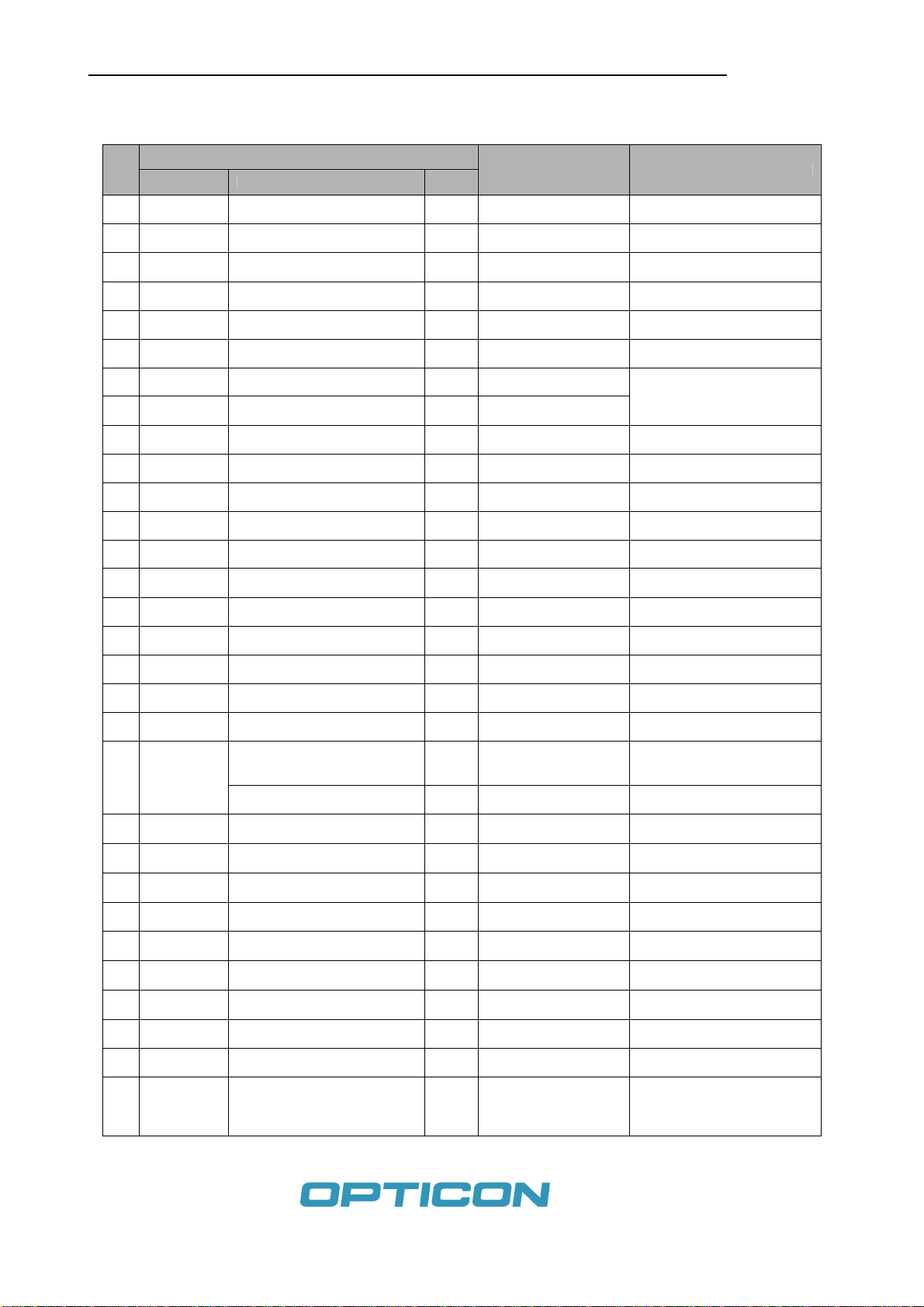

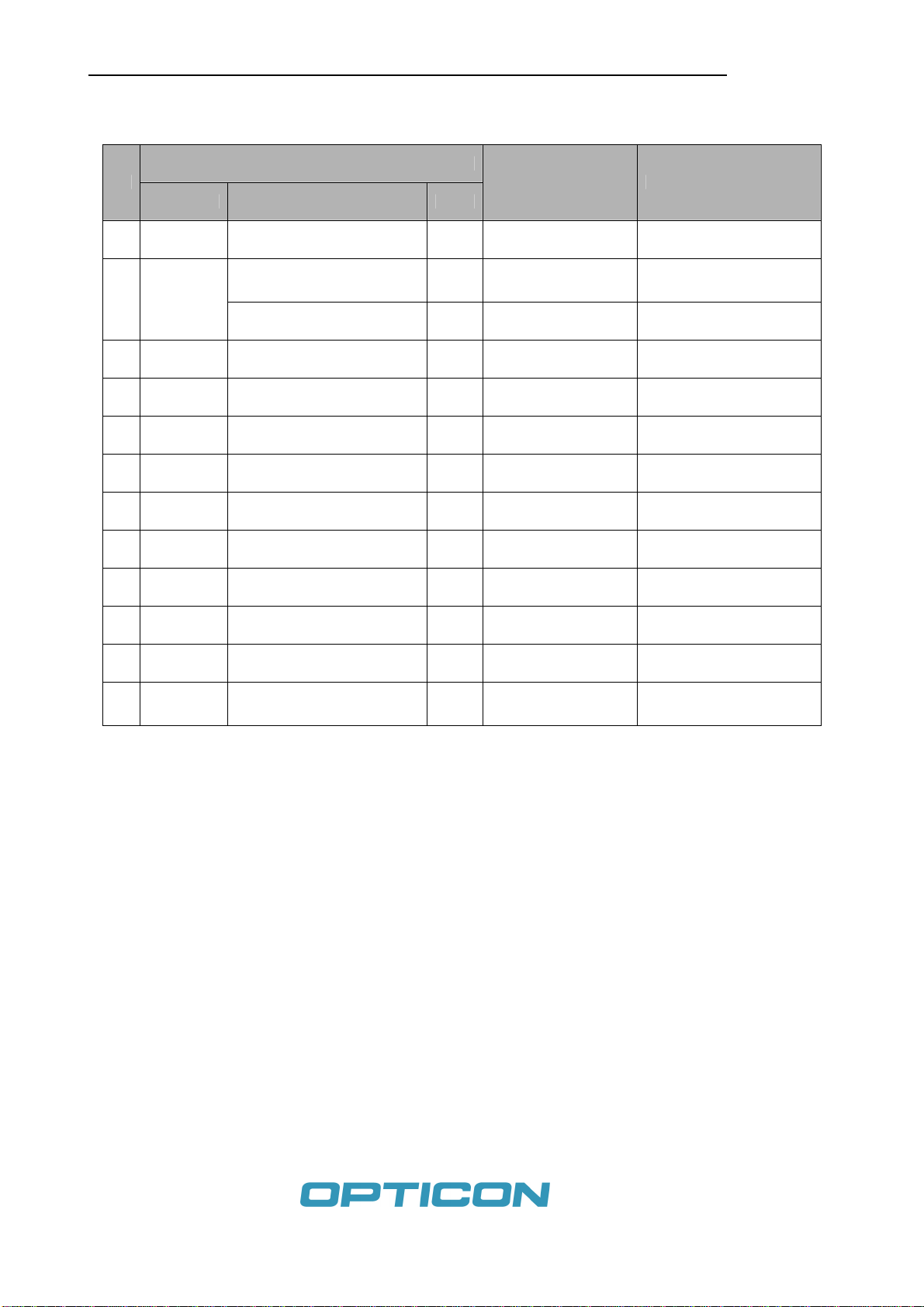

Table 2: CN_1 30-pin Connector Signals for MDI-1000 series

(Opposite pin assignments from the ones of scan engines.)

Signal

No. Name Function I/O Control Notes

1 Reserved Out Not connected

2 Reserved Out Not connected

3 EX_ILLUMn EX LED signal In L: External light ON

H: External light OFF Controls the external light

source.

4 USB_V

CC

5 USB power output Out USB bus power monitor

5 Reserved Out

6 GND System ground

7 USB- In/Out

8 USB+ In/Out USB 1.1

9 GND System ground

10 Reserved In Not connected

11 Reserved Out Not connected

12 Reserved In Not connected

13 V

CC

3.3V-power supply output Out Not connected

14 Reserved Out Not connected

15 GND System ground

16 Reserved Out Not connected

17 GND System ground

18 Reserved In Not connected

19 TRIGn Start operation signal Out L: Start operation

H: No action Command to start capturing

images or to start decoding

(When in power down mode)

Recovery signal from the power

down state Out L: Recovery from the

power down state

H: No action

20 AIM/WUPn (When not in power down mode)

Aiming control signal Out L: Aiming LED ON

H: Aiming LED OFF

21 GR_LEDn Notifies successful scanning In L: LED ON

H: LED OFF

22 BUZZER Buzzer sounding signal In L: Buzzer OFF

PWM: Buzzer ON PWM signal controls the tone

and the loudness of buzzer

23 POWER

DOWN Notifies power down state of the

scan engine In L: Normal state

H: Power down state

24 RTS Comm. Control signal to the host In Data output request from the

scan engine

25 CTS Comm. Control signal from the

host Out Data output request to the scan

engine

26 TD Data reception signal In Asynchronous data

transmission to the host.

27 RD Data transmission signal Out Asynchronous data

transmission from the host.

28 GND System ground

29 V

CC

3.3V-power supply output Out

30 DWNLDn Maintenance mode control

signal Out L: Maintenance mode

H: Non-operating status

Check the signal upon the

power supply and enable to

re-write on the software.

Note: Signal names are the same with the signal names of MDI scan engines.