CONTENTS

SERVICING

NOTICES

ON

CHECKING.

.............ssescscsscsseesessesseneessenneseesseersesanenseneeneess

Al-1

HOW

TO

ORDER

PARTS

.................05

Al-1

CONTENTS...

ceeeseeteeeeeeee

wee

AQ-1

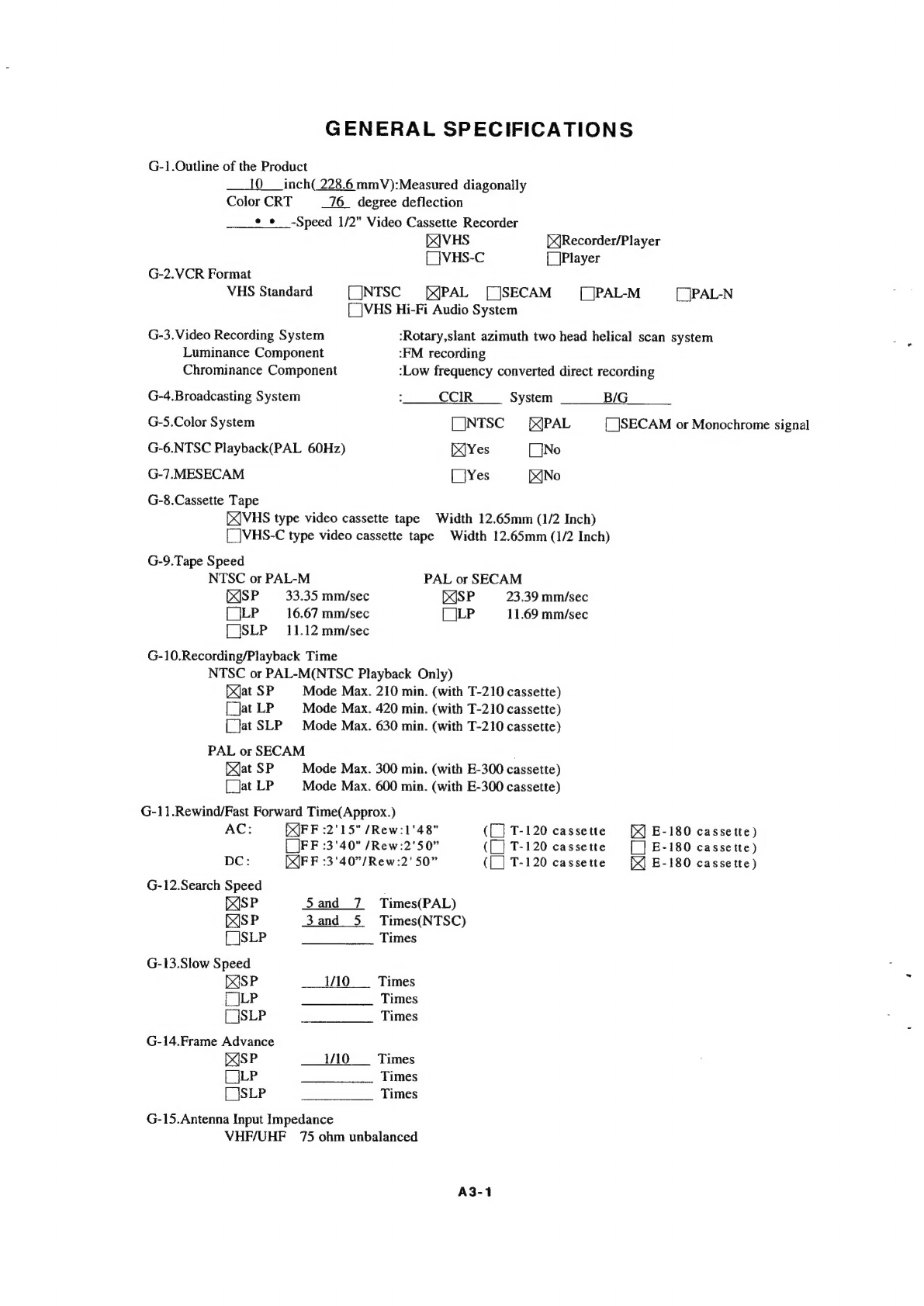

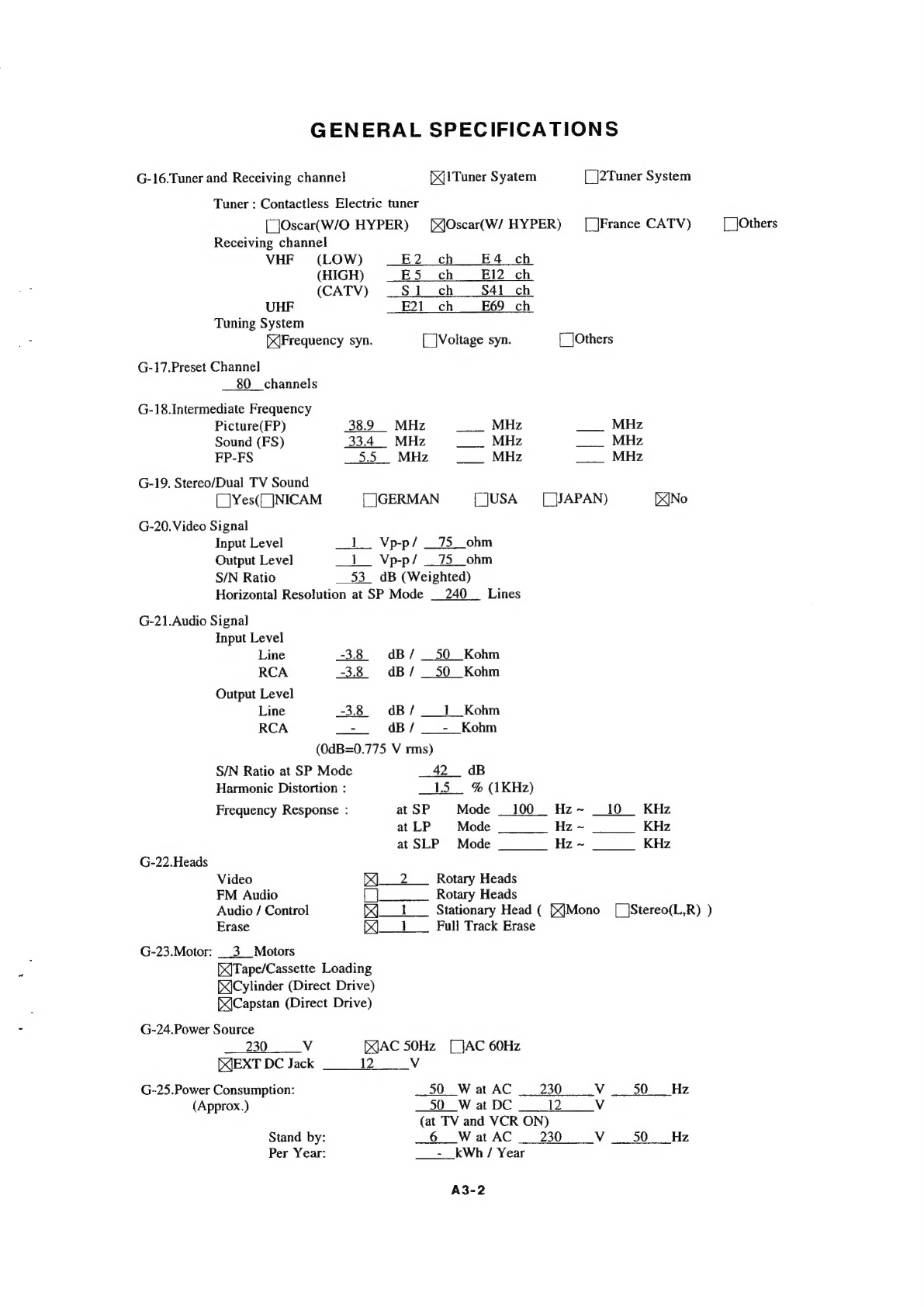

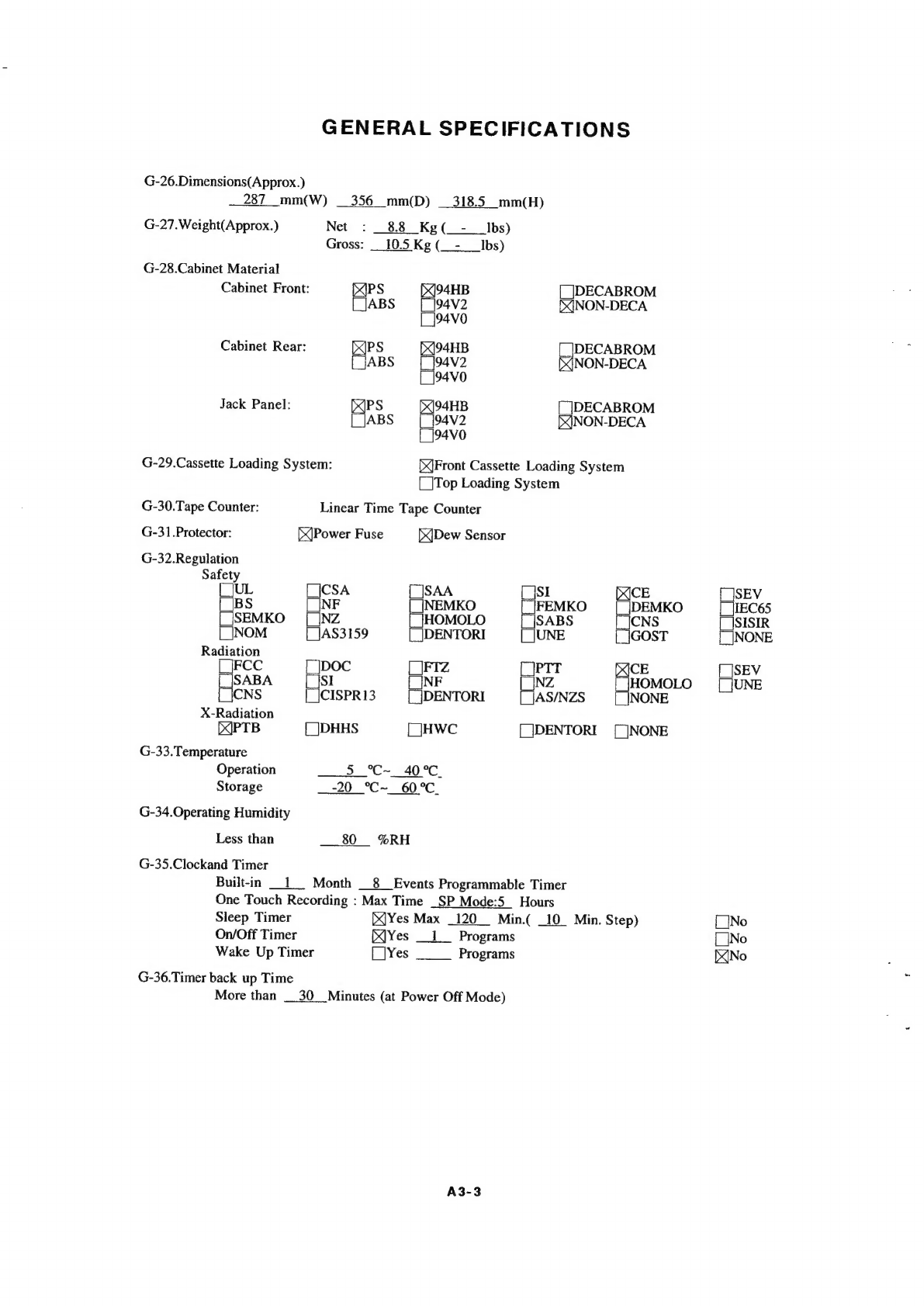

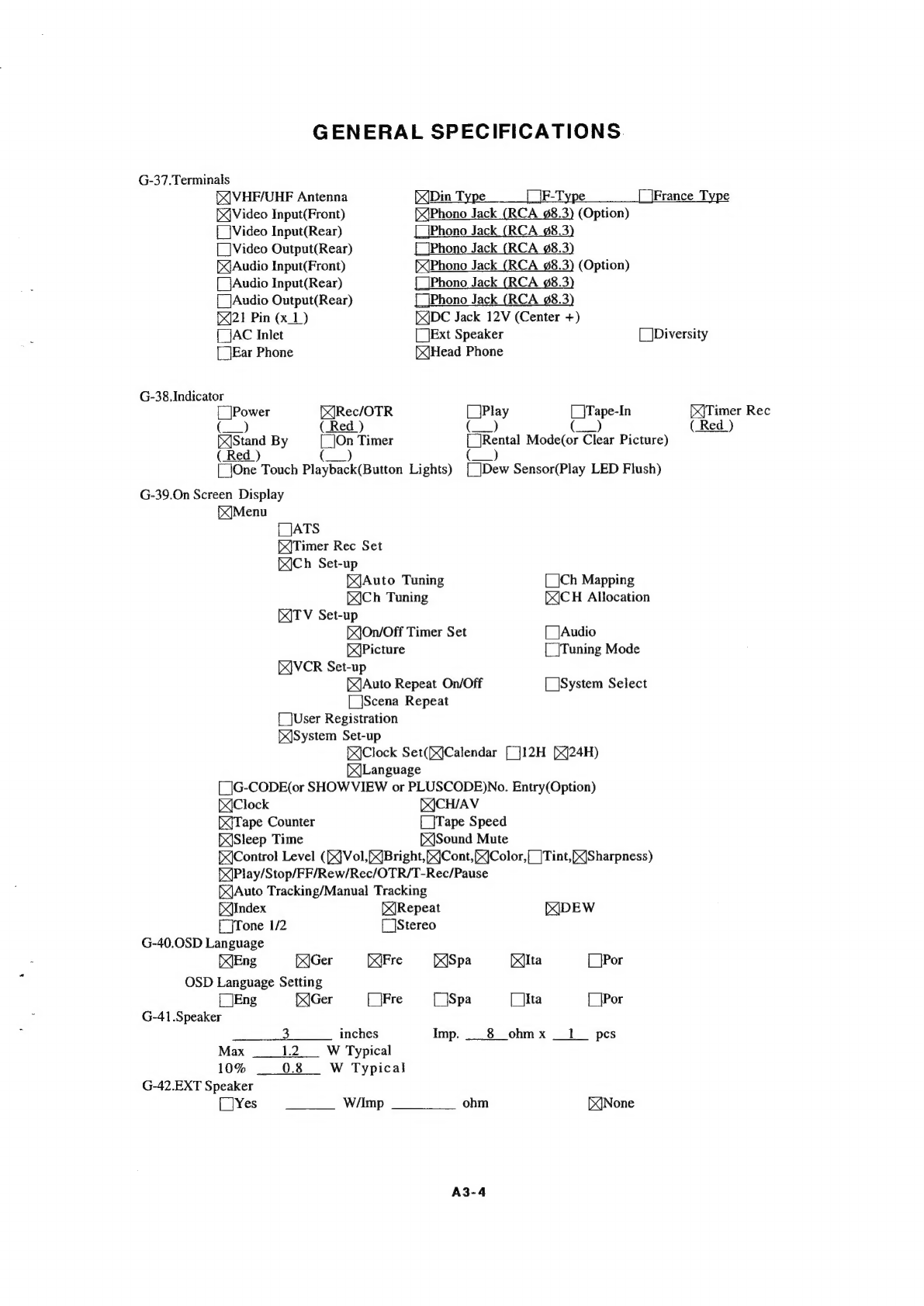

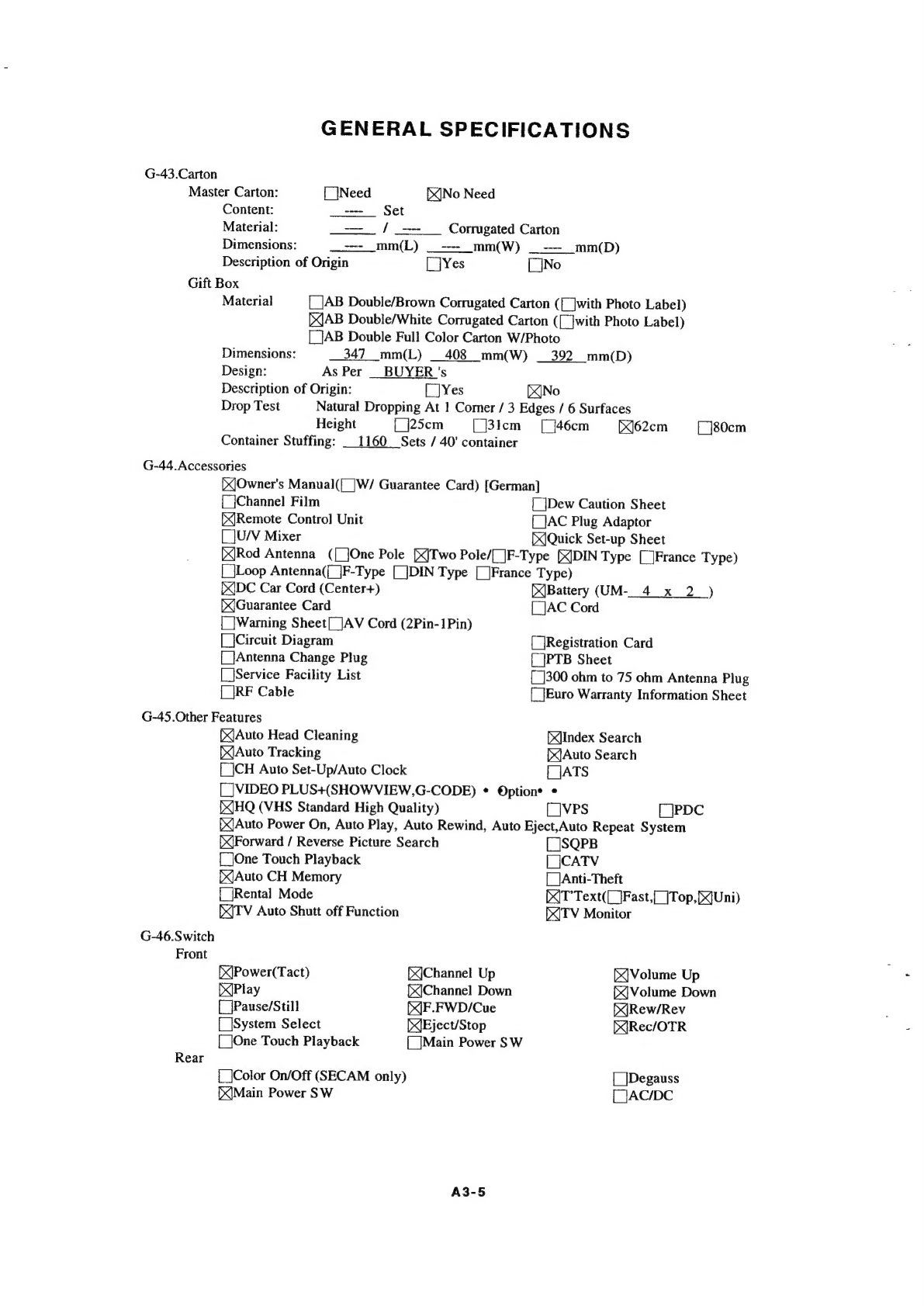

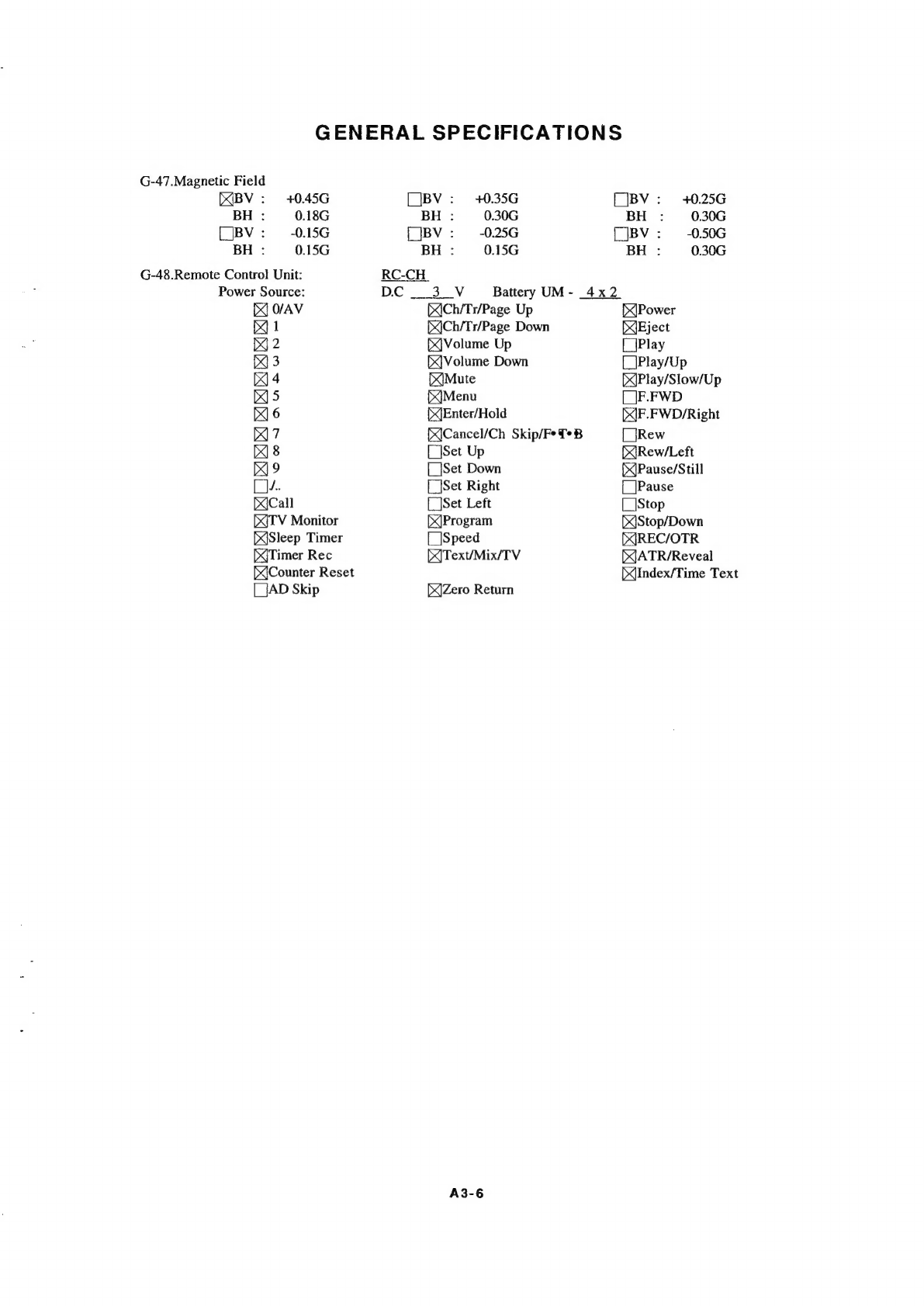

GENERAL

SPECIFICATIONS

A3-1~A3-6

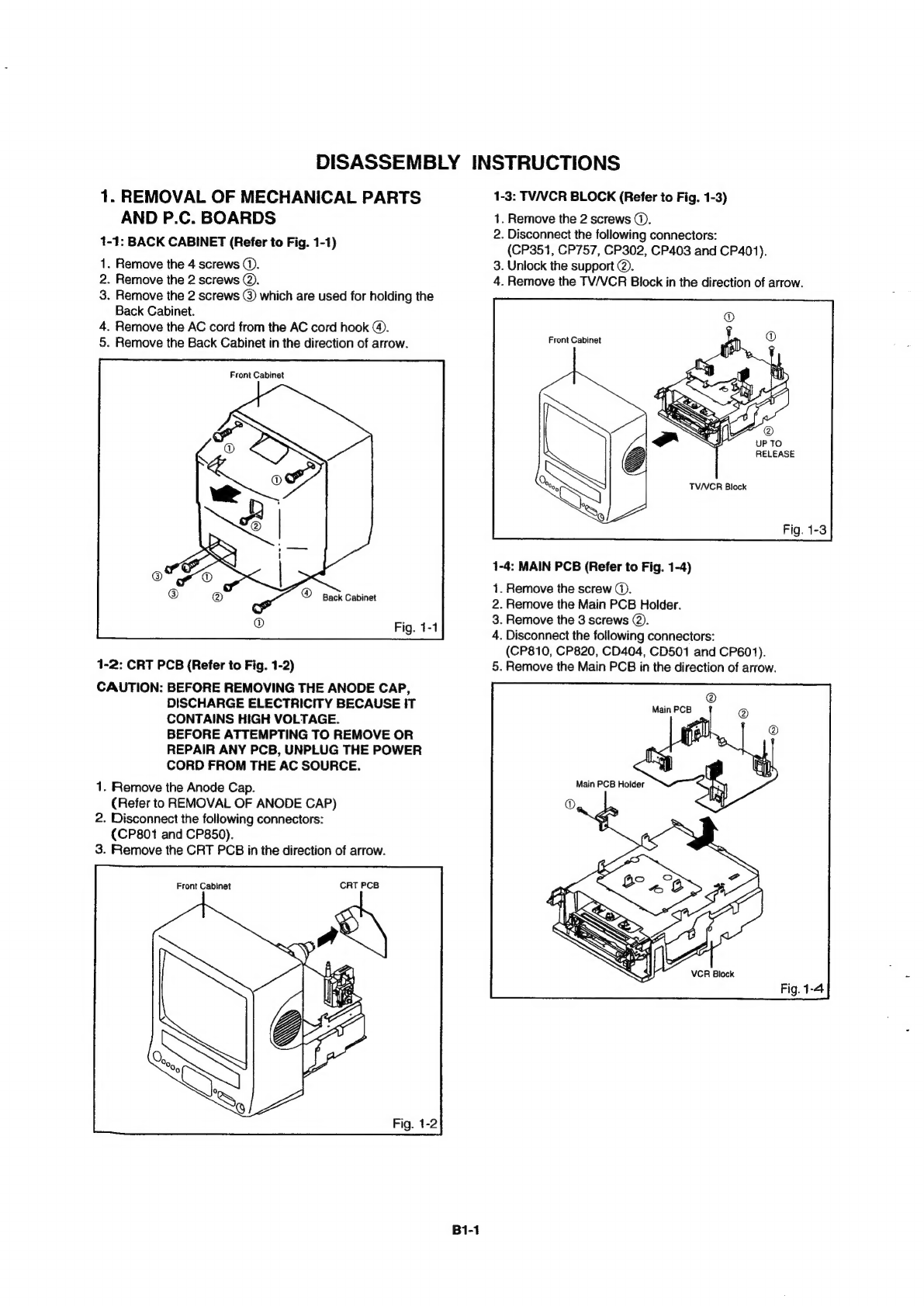

DISASSEMBLY

INSTRUCTIONS

1.REMOVAL

OF

MECHANICAL

PARTS

AND

P.C.

BOARDS

...........s.c:csccereseeeeeee

B1-1,

B1-2

2.REMOVAL

OF

DECK

PARTS

.......ecccessssssseesescnseseeeeseesenseesssseesseessseeeeaacenanseeseanace

B2-1~B2-5

3.REMOVAL

OF

ANODE

CAP

ou...

cescceseessessssesssseseessensessessenseseessseeasassanansesanesec®

B3-1,

B3-2

KEY

TO

ABBREVIATIONS

......

..

Ct-1,

C1-2

SERVICE

MODE

LIST

............cccscscesssscessessseeeeseeeees

..

C2-4

PREVENTIVE

CHECKS

AND

SERVICE

INTERVALS

NOTE

FOR

THE

REPLACING

OF

MEMORYIC

..

SERVICING

FIXTURES

AND

TOOLS

................

PREPARATION

FOR

SERVICING

..

.

C5-2

MECHANICAL

ADJUSTMENTS

..

..

D1-1~D1-4

ELECTRICAL

ADJUSTMENTS.

ote

eeeeececeesanecsenseseassenseeseserseseseneeeesnenteenenene

D2-1~D2-6

BLOCK

DIAGRAMS

PV

BE

OG

sich.

cocscescceatctesscccbsetsncudsesersuccascnecsectns

suede

rovend

soesrsoseotsctauy

acbesesstessdducesbecsoaehs

E-1,

E-2

Y/C/AUDIO/HEAD

AMP/21PIN/AIN/OUT

..

.

E-3,

E-4

MICON/POWER/OPERATION

..

..

E-5,

E-6

PMB,

Siscsetivcccsctsesecsnedcsdntirasessuuetcnswdusdcpsveussccscavestrsedeetpnendesbivoesvsoiecuesdeatustzcviecddseue

E-7,

E-8

PRINTED

CIRCUIT

BOARDS

MAINIGRID

sssesecesopsdccesssceconssnscsssnoscsceceaccecacabeccadarteassetsesesbnanedeisaceussoeonSuccsenetscteosbvesbetps

F-1,

F-2

SYSCON....

.

F-3~F-6

OPERATIONIDEGK.

4

sveshssiscceceseccscesncecedensecesesaesstocvsteseesenssinssed

susie

sausucedecsthassensseczcnns

F-7,

F-8

SCHEMATIC

DIAGRAMS

Y/CIAUDIO/HEAD

AMP.

............sssscsssesssssessssscscersssessssssssessescesseceseeecessseresseuonsensacasans

G-1,

G-2

MICON

ou.

cee

ccceseetseeeeeeseeseoes

aoe

.

G-3,

G-4

POWER

ue

scscseseseeescsssessssenenaseenens

vee

.

G-5,

G-6

21PINAN/OUT

.

G-7,

G-8

CHROMAIIF

......

.

G-9,

G-10

SOUND

AMP

1...

ccccsssnesesnsssssssesesesenesessesseeesessesceneeeenesessseseaesaeseaeatsnssessanesseesenasenenes

G-11,

G-12

TTEXT

.......

wee

G-13,

G-14

TV

POWER...

.

G-15,

G-16

DEFLECTION

G-17,

G-18

CRT

....sseeeeeeee

G-19,

G-20

OPERATION

..

.

G-21,

G-22

DECK

oo

sctscssiceitensticicmetedetiecss

.

G-23,

G-24

INTERCONNECTION

DIAGRAM

.

.

G-25,

G-26

WAVEFORMS

.............:.ccseccsseseeeeeneee

MECHANICAL

EXPLODED

VIEWS

.

.

11,

1-2

CHASSIS

EXPLODED

VIEWS.

...............:0:00

.

1-3,

1-4

MECHANICAL

REPLACEMENT

PARTS

LIST

.

.

J1-1

CHASSIS

REPLACEMENT

PARTS

LIST

.........

J2-1

ELECTRICAL

REPLACEMENT

PARTS

LIST

ow...

eee

ccceeneteeeeee

tenes

..

J3-1~J3-3