OSHIMA OP-450GS User manual

1

欢迎使用“欧西玛”迷你式粘合机

THANK YOU FOR USING “OSHIMA”MINI COMPACT PRESS MACHINE

使用前,请详阅

BEFORE YOU BEGIN,PLEASE READ CAREFULLY

OP-450GS

OP-520GS

使用说明书

OPERATING MANUAL

2

3

操作面板

操作面板

Mini Press Machine

C O LD LA M P

SEC

S P E E D

C O N T R O L

TH E R M O S TA T

温度控制 速度调节

P O W E R

电源开关 冷却指示灯

3

4

一、開機

1、接上使用電源,(請特別注意;1P220V 電源線採用三線,即紅接火線,

黑接零線,黃接地。切勿接錯。)將機器總電源開關撥向“ON”位置。

2、按下電源開關。調整使用速度(壓著時間以 10-34 秒之間為正常使用),

設定溫度以及壓力(速度、溫度、壓力之調整視燙件之布的特性而定);

本機最高使用溫度 180℃。

3、冷卻時按電源開關,該重定機器會自動運行,當皮帶溫度冷卻到 60ºC以

下,機器自動停機。

二、溫度檢修部分

A不加溫:1、檢視電源開關有無打開;

2、檢視溫度控制器有無設定;

3、溫度控制器不動作,更換“溫度控制器”;

4、保護器跳脫或內部短路;

5、“溫度感應線”(SENSER)成開路狀態;

B加溫過高:1、溫度控制器輸出無法斷開,造成 SSR 加熱;

2、SSR 固態繼電器觸點短路,更換 SSR。

三、皮帶運轉檢修部分

A運轉指示燈有動作:

1、馬達控制器故障(包括皮帶全速運轉無法控制);

2、馬達或傳動部分卡死;

3、皮帶表面有粘膠,使上下皮帶粘合,因而馬達無法轉動皮

帶請先將溫度開關打開,將溫度設定在 120ºC;當溫度到 120ºC

時,請開啟馬達使皮帶轉動後,清潔皮帶表面;

B運轉指示燈無動作

1、檢視電源有無輸入;

2、皮帶偏離,依照“皮帶偏離調整說明”調整:

5

3、檢視控制之保險絲有無斷毀。

C皮帶調整說明

①450GB028 皮帶張力滾筒

②450GB029 下傳動滾筒

③450GA002 滾筒座

④450GB026 波浪滾筒

⑤450GB027 矽膠滾筒

注意:

1、當更換皮帶時,請確認④、⑤長的一邊靠邊皮帶黃色繩邊位置。

矽膠滾筒

长短

2、在皮帶安裝好時,保證皮帶黃色在①、②靠近滾筒邊緣的位置一樣寬(約

1-2MM)

黃色線

下传动滚筒 皮带张力滚筒

3、如果寬度不同,請調整③左右移動然後確認黃色邊緣一樣寬。如注示(2)

(上面箭頭只代表參考值)

附:如果皮帶繩邊嚴重磨損,則無法調整。

6

四、注意事項

1. 工作臺面,請勿放置硬物(如:剪刀、筆、固定針……),以防止隨著燙件

捲入機器內,而造成皮帶損壞及斷裂;

2. 出料口,上下撥片/刮片、皮帶接觸之面,若附有髒物,必須隨時清除,以

保持皮帶表面之清潔;

3. 不能在皮帶的內裏作清潔,只能清潔皮帶表面;每日下班前應用壓縮空氣槍

徹底清潔機台內部。

4. 如有粘膠或附著其他髒物,也須隨時以“清潔劑”清除。

5.務必用隨機附送到水平儀將機器調整水準後再開機運行。

6.當遇到較厚布料時,請適當減輕或放掉壓力,以防皮帶卡死。

7.機器溫控器各內部參數,出廠前已設定好,切務隨意調節,否則會影響機

器的正常運行。用戶只需設定所需的溫度即可。

8.請不定期給面器各傳動部份加注潤滑油(高溫黃油)。

請根據工用時間反工作量,適時更換清潔布。(清潔布請使用純棉布,一般

包裹 3-4 層為宜,不可太厚。)

9.本機器屬開邊式粘合機,最大使用寬度不得超過 450MM(OP-450)或

520MM(OP-520)或只需單邊粘合之大片襯布。

10.如果貴公司要使用開邊式工作,請把上機架與下機架的連接固定板拆卸下

來。

11.具體操作前,請詳閱使用說明書。

7

一、Switch On

1.Connect to the power,( please notice the power specification 1P/220V or 3P/220V.

Please do not connect wrongly.)

2.Switch the power switch on. Adjust the speed( time setting in the range of 10-34

seconds as the normal using), then set up temperature and top pressures;( the

adjustment of the speed, temperature, pressure depend on the characteristics of fabrics.

the maximum service temperature of 180℃

3.Switch the power button to Off status. The machine will be cooled down

automatically. When belt temperature lower below 60ºC, the machine will stop

automatically.

二、Temperature Trouble Shooting

A、Temperature doesn’t work:

1、Exam the power switch whether turn on.

2、Does the thermostat be set?

3、Replace the thermostat if did not work.

4、Protective jumps whether off or inner electric part short circuit;

5、The temperature probe responds the line"( SENSER) been non-working.

B、Temperature is overheated.

1、The temperature controller can't control, resulting in the SSR keeps heating.

2. The SSR gets short circuit, Please replace the SSR.

8

三、Belt Transmission Trouble Shooting

A、Working Indicator light is on:

1、Motor controller was break-down, or belts keep on full speed,

can not be controlled.

2、Motor or transmission system was stuck.

3、There are some glue adhered to the belt surface causing belts

stuck. Please turn thermostat and set. the temperature at

120ºC. When reach to 120ºC, turn on the motor and then clean

the belt surface.

B、Indicator lamp is off:

1、Does the power switch turn to “ON”position?

2、Do the belts go warping? Please adjust the belts accordingly.

3、Whether the fuse of controller is breakdown.

C、ADJUSTMENT FOR BELT

①450GB028 Belt Tension Roller

②450GB029 Lower driving Roller

③450GA002 Roller Set

④450GB026 Wave Roller

⑤450GB027 Silicon Roller

Attention:

1、When replace belt, please confirm④、⑤longer side close to belt

yellow linear guide edge.

Silicon roller

longer short

9

2、Once belt mounted, pls confirm the width of the yellow linear

guide edge is the same (about1-2mm)between①、② .

Yellow linear guide

Lower driving roller belt tension roller

3、If the width is different, please adjust③towards right &left to

align the yellow linear guide edge with the same width as point

(2)(The arrow headed on machine is for reference)

P.S. If the yellow guide linear edge is worn seriously ,it could mot be

adjusted. Please replace a new belt.

四、Attentions

1、Do not put any hard objects (such as scissors, ball pen, needle……)

to the entrance of the belt.

2、Please keep the exit, the strip off device / scraper clean, if any dirty

on those parts, please clear on time.

3、Please clean the belts after work.

4、Please use OSHIMA cleaning solvent to remove the dirt or glue

attached on the surface of the belts.

5、Please use the attached horizon kit to adjust the machine in

horizontal for working.

6、For any heavier fabrics, please release the pressure to prevent the

machine stuck.

10

7、All the parameters of thermostat are all set. Please do not adjust the

parameters.

8、Please oil the machine regularly. And please replace the cleaning

rod’s fabric regularly to keep the machine clean.

9、The fusing piece width can not exceeds the width of machine.

Please operate according to the machine size ( 45cm or either

52cm )

10、If your company wants to use to open the side type works, please

dismantle the machine unload with bottom mold conjunction pole.

11、Please read the manual before using.

11

12

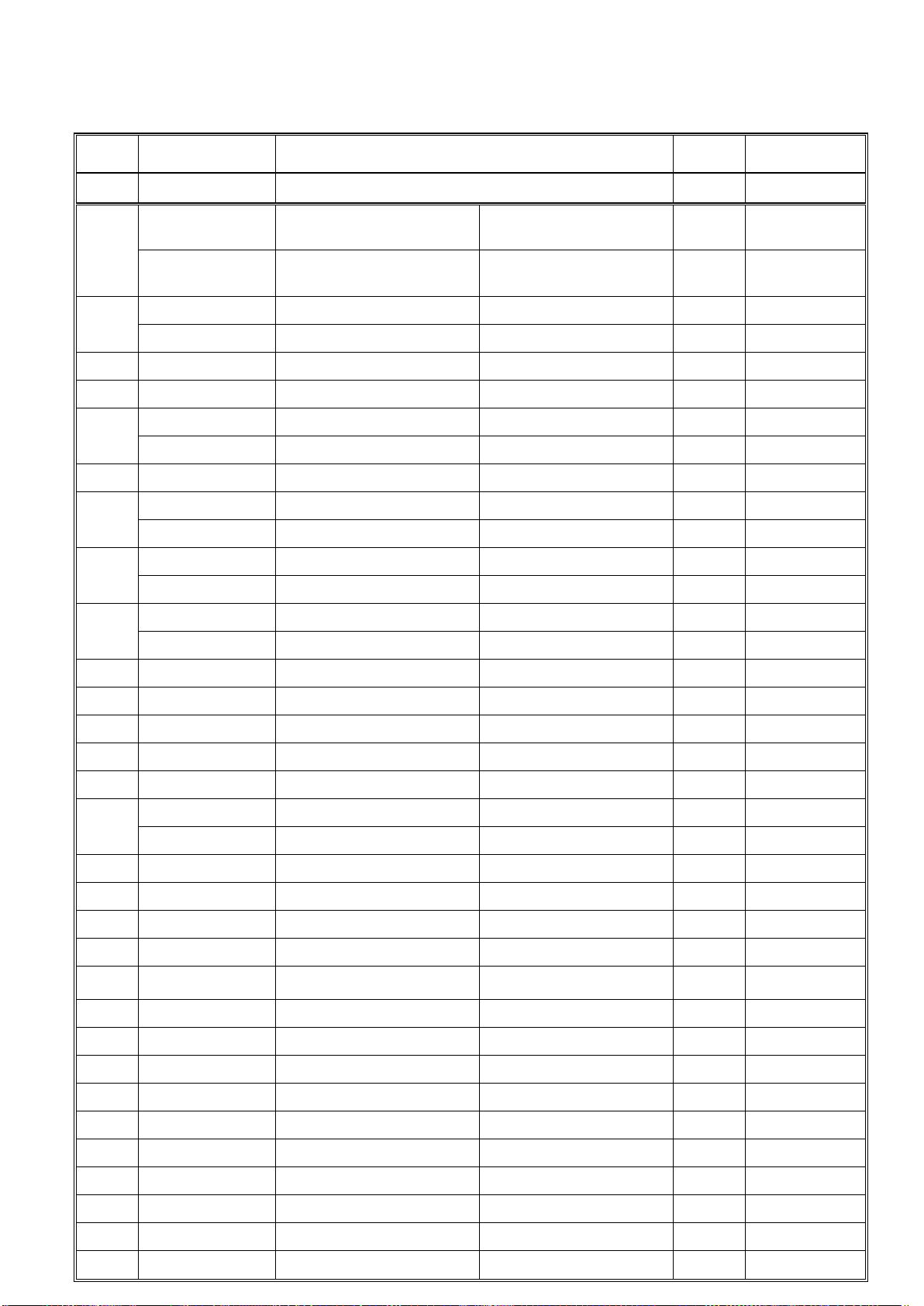

机械零件目录 Part list

NO.1

序号

部件编号

部件名称规格

数量

备注

No.

Part no.

Part description/spec.

q'ty

Remark

1

450GA001

機架主體

Main body of

machine

1

450G/GS 用

520GA001

機架主體

Main body of

machine

1

520G/GS 用

2

450GA015

前護罩

front protecting

cover

1

450G/GS 用

520GA015

前護罩

front protecting

cover

1

520G/GS 用

3

450GA003

右護罩

right protecting

cover

1

4

450GA033

後蓋板

rear cover

1

5

450GA017

前桌板

front board

1

450GA044

前桌板

front board

1

450GSL

6

450GA026

前桌板支持板

underprop of the

front board

2

7

450GA010

托座

holding seat

1

450G/GS 用

520GA010

托座

holding seat

1

520G/GS 用

8

520GA016

右桌板

right table board

1

520G/GS 用

450GA016

右桌板

right table board

1

450G/GS 用

9

520GA011

支座

supporting base

1

520G/GS 用

450GA011

支座

supporting base

1

450G/GS 用

10

450GB012

軸套

bearing jacket

4

11

450GA034

下壓力調節座

bottom adjust

pressure base

1

12

450GA023

調壓片

adjust pressure

piece

1

13

450GA031

下壓力調節塊

bottom pressure

piece

1

14

JD8306

下壓力調節杆 M10*180

bottom pressure

rod

1

15

450GA012

活動壓板

Active board

1

450G/GS 用

520GA012

活動壓板

Active board

1

520G/GS 用

16

450GA036

配電盒

electric box

1

17

DK0401

小型斷路器 2P-C20

breaker

1

18

450GA037

配電盒蓋

electric box cover

1

19

JH1060

下壓力壓簧φ2.5* φ

20*46L*6 圈

under pressure

spring

1

20

JH1045

下壓力壓簧φ2*φ15.5*55L

under pressure

spring

1

21

450GB020

活動壓板止環

active board stop

ring

1

22

450GA035

配電板

electric plate

1

23

DF0101

端子台 6P 25A

terminal bedplate

1

24

DF0309

RT14-20 20A 保險管

fused tube

2

25

DZ0401-3

LSS-32B/220V

motor controller

1

26

DB0201-1

變壓器 220V/210V,

150VA

transformer

1

27

DM0405

2.5UF 電容

capacitance

1

28

DJ0217-1

SSR-25DA 固態繼電器

solid state relay

2

29

DD0212

橙色指示燈

orange indicator

lamp

1

30

DA0102

綠色方型(帶鎖,帶燈)

green square

switch

1

13

機械零件目錄Part list

NO.1-1

序號

部件編號

部件名稱規格

數量

備註

No.

Part no.

Part description/spec.

q'ty

Remark

31

DZ0702

電位器 B20K

(B203)

potentiometer

1

32

DZ0235

溫度控制器

thermostat

1

33

450GA004

上座

upper seat

1

450G/GS 用

520GA004

上座

upper seat

1

520G/GS 用

34

450GSA002

撥片器蓋

cover of rotary

strip-off device

1

450GS/520GS 用

35

450GA009

調壓杆

adjust pressure rod

1

450G/GS 用

520GA009

調壓杆

adjust pressure rod

1

520G/GS 用

36

450GA021

調壓片(中)

Adjust pressure piece

piece(middle)

1

37

450GA022

調壓片(左)

adjust pressure

piece(left)

1

38

450GB018

導塊

block

2

39

450GA024

導塊固定座

block fixed base

2

40

450GA025

指示杆

indicator rod

1

41

JH1067

上壓力彈簧φ

3*17*12*65

spring

1

42

ZW0055

梅花手柄 M10

handle

1

43

DJ0119-1

交流接觸器

SP-16

contactor

1

44

DF0304

RT14-20

4A

fuse tube

1

45

450GA045

加長型連接座

(後面)

Lengthen

concatenation(back)

1

450GSL 專用

46

450GA046

加長型連接座

(前面)

Lengthen

concatenation(front)

1

450GSL 專用

47

450GA054

支撐座

support base

1

48

450GA007

清潔杆

clean pole

1

49

450GA008

清潔杆

clean pole

1

50

JB2009

培林 1000086

bearing

2

51

450GB013

軸銷

Bearing pin

1

52

450GB014

軸套

bearing jacket

1

53

450GB031

滑輪固定座

The pulley fixed

1

54

DF0102

端子台

TB1512

terminal bedplate

2

14

15

机械零件目录 Part list

NO.2

序號

部件編號

部件名稱規格

數量

備註

No.

Part no.

part description/spec.

q'ty

remark

1

450GA006

滾筒座(上前)

roller seat

1

2

450GA005

滾筒座(上後)

roller seat

1

3

JD1049

外六角螺釘 M8*110

hexagon screw

4

4

450GB012

滾筒軸承座

roller bearing base

4

5

JH1044

皮帶張力彈簧φ2*φ12*7*28

belt tension spring

4

6

450GA030

調整塊

adjust block

4

7

JB2073

軸承 6202ZC4

bearing 6202ZC4

14

8

450GA002

滾筒座(下前)

roller seat

1

9

450GB030

上傳動滾筒

upper transfer roller

1

450G/GS 用

520GB030

上傳動滾筒

upper transfer roller

1

520G/GS 用

10

450GB026

波浪滾筒

wave roller

2

450G/GS 用

520GB026

波浪滾筒

wave roller

2

520G/GS 用

11

450GB028

皮帶張力滾筒

belt tension roller

2

450G/GS 用

520GB028

皮帶張力滾筒

belt tension roller

2

520G/GS 用

12

JP2022

上皮帶 460*1530

upper belt

1

450G/GS 用

JP2032

上皮帶 520*1530

upper belt

1

520G/GS 用

13

450GB032

電熱器本體

Electro thermal machine body

4

450G/GS 用

520GB032

電熱器本體

Electro thermal machine body

4

520G/GS 用

14

450GA027

電熱槽固定板

fixed board for electro thermal

trough

8

15

450GB022

襯套(1)

sleeve (1)

4

450GS

HEATER

電熱片(0.8KW,1.0KW)

各2

heater

4

450G/GS 用

520GS

HEATER

電熱片(0.7KW,1.4KW)各 2

heater

4

520G/GS 用

17

450GA014

壓板

pressing board

4

450G/GS 用

520GA014

壓板

pressing board

4

520G/GS 用

18

ZA3113

保溫棉 130*90*30

heat preservation cotton

4

19

450GA013

內槽

inner trough

4

450G/GS 用

520GA013

內槽

inner trough

4

520G/GS 用

20

DX0303

高溫線 2.5mm2*60

high temperature lead

8

21

DF0813

絕緣高溫矽膠套φ10*100

silica gel jacket

8

22

JP2024

下皮帶 460*1840

lower belt

1

450G/GS 用

JP2033

下皮帶 520*1840

lower belt

1

520G/GS 用

JP2072

下皮帶 460*2440

lower belt

1

450GSL 用

23

450GB027

矽膠滾筒

silica gel roller

1

450G/GS 用

520GB027

矽膠滾筒

silica gel roller

1

520G/GS 用

24

450GB029

下傳動滾筒

lower transfer roller

1

450G/GS 用

520GB029

下傳動滾筒

lower transfer roller

1

520G/GS 用

16

25

450GA029

皮帶支持片(短)

belt holding board (short)

4

26

450GA028

皮帶支撐片(長)

belt holding board (long)

4

17

18

机械零件目录 Part list

NO.3

序号

部件编号

部件名称规格

数量

备注

No

part no.

part description/spec.

q'ty

remark

1

DM0346-3

YN90-40/90JB50G12

MOTOR + GEAR

1

1 +24 = one set

2

450GA019

馬達座

motor base

1

3

450GA018

支座

holding seat

1

4

JH2029

鏈條張力彈簧

chain tensioning

spring

1

5

450GA020

臂

arm

1

6

450GB011

輪軸

axle

1

7

450GB010

惰輪

idler wheel

1

8

JL1001

鏈條

chain

1

9

450GB017

馬達齒輪

motor gear

1

10

450GSB005

雙排齒輪

double gear

1

450GS/520GS

用

11

450GSB001

撥片杆齒輪

gear of rotary strip-off

rod

2

450GS/520GS

用

12

450GSA004

撥片器固定座

fixed seat of rotary

strip-off

4

450GS/520GS

用

13

450GSA003

撥片器固定片

fixed patch of rotary

strip-off

4

450GS/520GS

用

14

JB2028

自潤軸承

bearing

4

450GS/520GS

用

15

450GSB002

撥片杆上環

rotary strip-off rod

upper ring

4

450GS/520GS

用

16

450GSB004

撥片器杆

rotary strip-off device

rod

2

450GS用

520GSB034

撥片器杆

rotary strip-off device

rod

2

520GS 用

17

450GSB003

撥片杆止環

rotary strip-off rod ring

4

450GS/520GS

用

18

ZA3208

撥片 490mm

rotary strip-off patch

2

450GS 用

ZA3208-1

撥片 530mm

rotary strip-off patch

2

520GS 用

19

450GA043

刮片固定座

scraper fixed seat

2

450G/520G 用

20

JH3010

刮片座彈簧

pulling spring

4

450G/520G 用

21

450GA048

刮片座

scraper seat

2

450G 用

520GA043

刮片座

scraper seat

2

520G 用

22

ZA3203

刮片 440*30MM

scraper

2

450G 用

ZA3206

刮片 498*3*3MM

scraper

2

520G 用

23

450GA047

刮片座蓋

lid for scraper seat

2

450G/520G 用

24

DM0346-3

YN90-40/90JB50G12

MOTOR + GEAR

1

450GS/520GS

25

JL1002

鏈條 25×31 目(含接目)

chain

2

450GS 用

19

20

This manual suits for next models

1

Popular Power Tools manuals by other brands

Ingersoll-Rand

Ingersoll-Rand IQV20 W7002 Series user manual

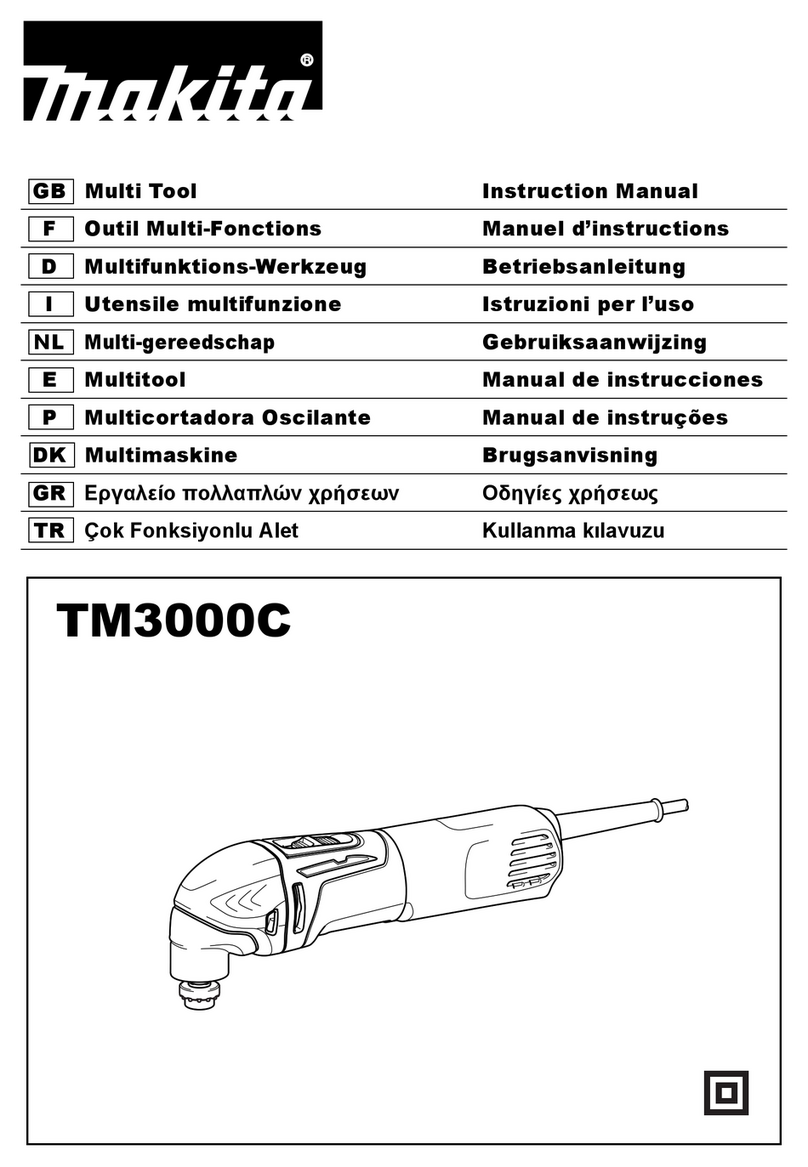

Makita

Makita TM3000C instruction manual

Black & Decker

Black & Decker BD200MT instruction manual

Hiker

Hiker H-901 instructions

Bosch

Bosch POF 1200 AE operating instructions

Ametek

Ametek Solartron Metrology Wigauge WHT User and installation manual