1

TABLE OF CONTENTS

I. Safety Information....................................................................................................................................................3

II. Installation & Startup...............................................................................................................................................5

2.1 Receiving Inspection................................................................................................................................5

2.2 Pre-installation Preparation.....................................................................................................................5

2.2.1 Elevator Foundation.............................................................................................................................5

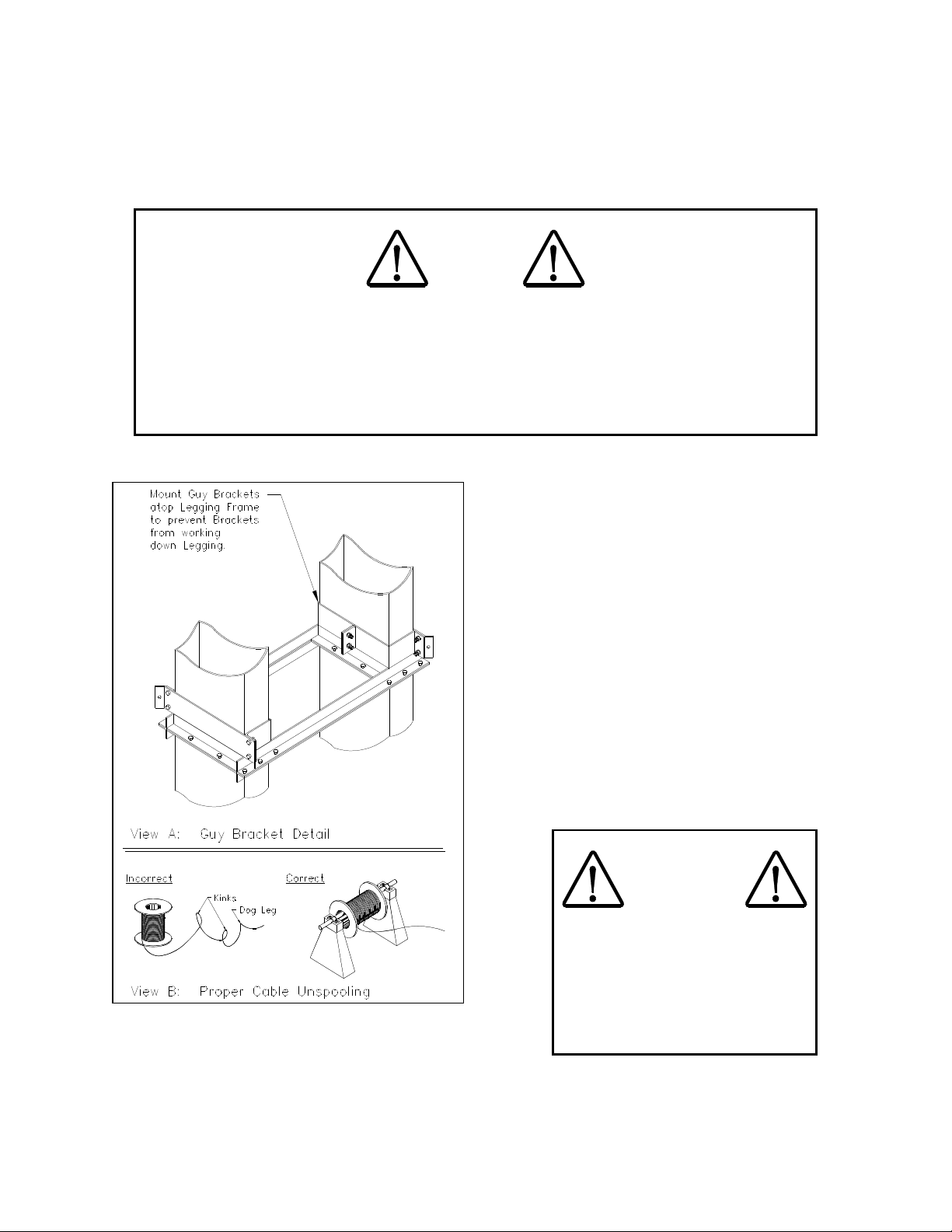

2.2.2 Elevator Guying Or Bracing .................................................................................................................6

2.2.3 Elevator Intake.....................................................................................................................................7

2.2.4 Elevator Discharge ..............................................................................................................................8

2.2.5 Positioning Trunk Sections For Ladder................................................................................................8

2.2.6 Elevator Belt Selection.........................................................................................................................8

2.3 Elevator Erection (Assembly) .................................................................................................................9

2.3.1 Vertical Assembly ................................................................................................................................9

2.3.2 Belt And Bucket Installation ...............................................................................................................17

2.3.3.1 Belt/Bucket Installation ...................................................................................................................19

2.3.3.1.1 Method 1; Simultaneous Belt And Bucket Installation;(Less than 100 Ft)...................................21

2.3.3.1.2 Method 2; Belt Only With Buckets Attached After Splicing Belt...................................................22

2.3.4 Belt Splicing .......................................................................................................................................23

2.3.5 Hood Installation .................................................................................................................................23

2.3.6 Drive Installation ................................................................................................................................23

2.3.7 Initial Belt Tracking (See Figure 2.15) ................................................................................................24

2.3.8 Rubber Throat Slide Adjustment........................................................................................................28

2.3.9 In-Service Belt Tension......................................................................................................................28

2.3.10 Elevator Bucket Filling .....................................................................................................................29

III. Maintenance ......................................................................................................................................................32

3.1 General Maintenance ...........................................................................................................................32

3.2 General Housekeepingand Periodic Inspection....................................................................................32

3.3 Lubrication ............................................................................................................................................34

3.3.1 Reducer .............................................................................................................................................34

3.3.2 Motor..................................................................................................................................................34

3.3.3 Head & Boot Shaft Bearings..............................................................................................................34

3.3.4 Roller Chain Drive..............................................................................................................................34

3.3.5 Sleeve Guides And Shafts.................................................................................................................34

3.4 Adjustment and Repair Procedure........................................................................................................34

3.4.1 Elevator Belt Tension.........................................................................................................................34

3.4.1.1 Boot Takeup (Belt Tension) Adjustment.........................................................................................34

3.4.1.2 Drive V-Belt (If Installed).................................................................................................................35

3.4.2 Belt Tracking......................................................................................................................................35

3.4.3 Belt Splicing .......................................................................................................................................35

3.4.4 Throat Slide Adjustment ....................................................................................................................35

3.4.5 Roller Chain Tension .........................................................................................................................35

IV. Spare Parts.........................................................................................................................................................36

4.1 Scope....................................................................................................................................................36

4.2 Ordering Parts ......................................................................................................................................36

V. Warranty..............................................................................................................................................................36