11

Operating Suggestions

Flat Plastic:

1. Preheat the oven and tray/cart to the desired cooking temperature.

2. Place the plastic in the center of the cooking tray and roll the tray/

cart into the oven.

3. Your new PDQ Oven will work best if set at 400°F or 204°C

for plastics such as Polypropylene, Copolymer and Polyethylene.

Special plastics may require a different setting.

4. Plastics less than 1/8” or 3mm cook best when utilizing a “cool

tray” or by removing the tray/cart from the oven and allowing it

to cool to room temperature before placing the plastic on the tray

and sliding it into the oven.

5. Colored plastics generally will require 2-3 minutes longer to

cook than the same thickness natural color plastics.

Bubble Forming:

1. Lower the tray/cart to the lower position.

2. Preheat the oven to the desired cooking temperature. Normally

between 375°F and 440°F or 190°C and 225°C

3. Select the appropriate size bubble forming frame and insert the

plastic into the frame.

4. Position the bubble forming stand in the center of the tray/cart and

place the bubble forming frame on the stand and roll into the oven.

Oven Fan/s:

1. The fan/s circulate the heated air in the oven. The fan/s do not draw

external air into the oven or exhaust heated air out of the oven.

2. The fan/s are variable speed and are controlled by the fan control

knob on the front of the oven.

3. The oven operator shall determine the fan/s usage based on cooking

requirements and preferences.

The Teflon sheeting on the tray is a durable nonstick material.

However, it is not indestructible. It is wise to exercise care when

using it. For example, avoid sliding hard objects across the sur-

face. As with other materials, the surface will degrade over time.

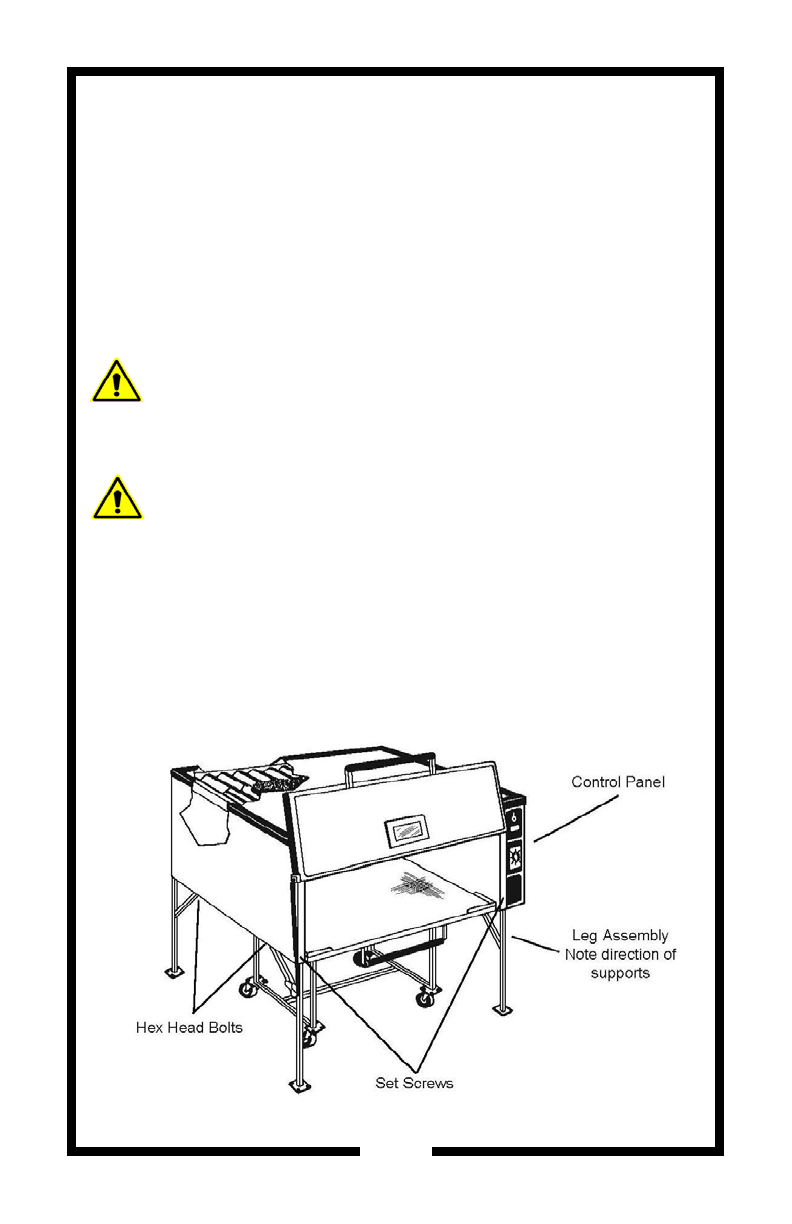

Oven Setup

4

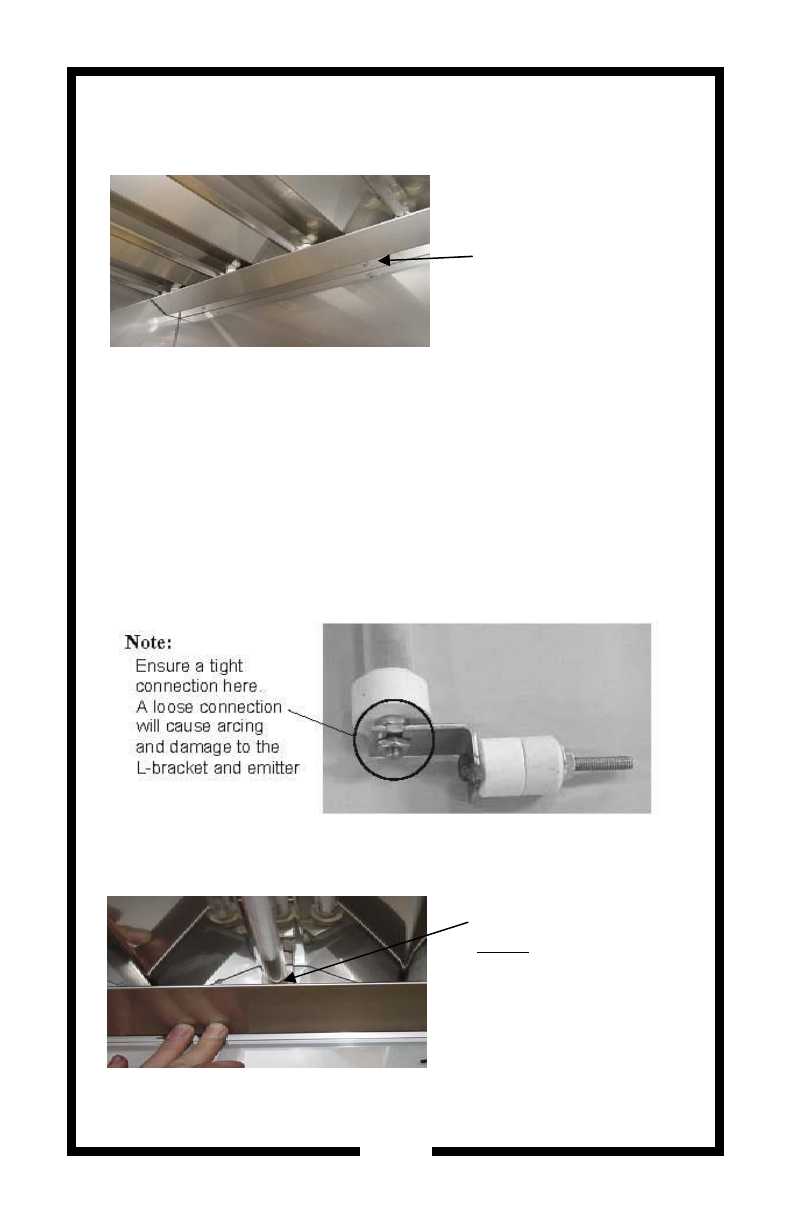

4. If you have a 5A model, install the casters on the cart using

the hardware provided.

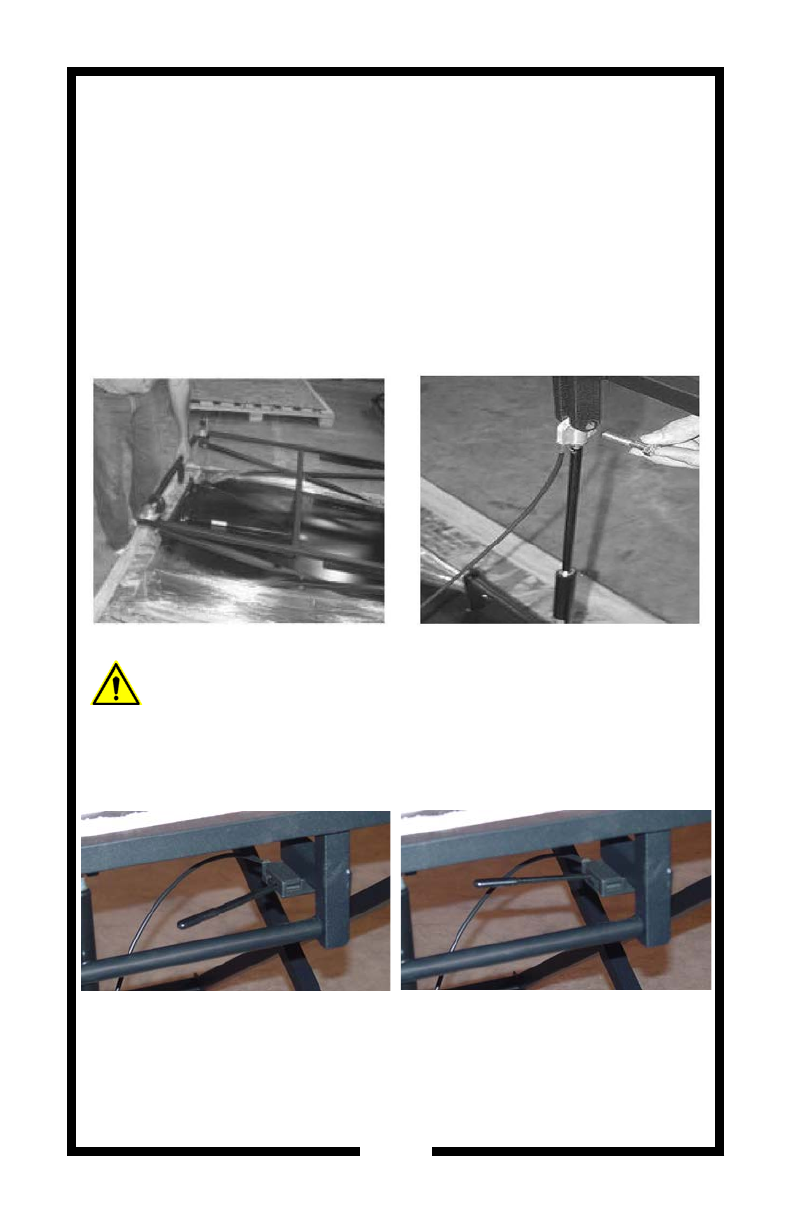

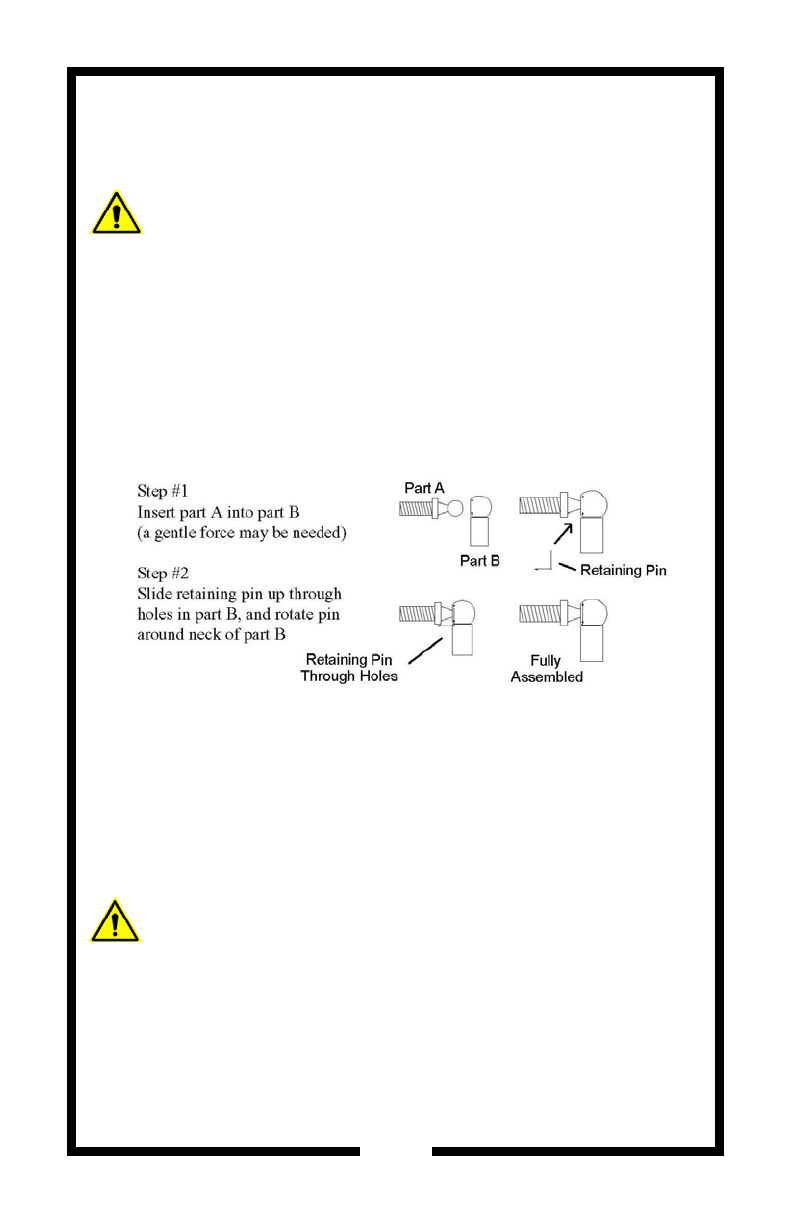

5. Lift the lower section of the cart high enough to accept the

gas spring, then rotate the gas spring upward until the male

portion fits into the female portion of the cart. Insert the bolt

and lightly tighten the lock nut against the mount. Do not

over tighten as this is a pivot point.

6. Flip the cart over onto the wheels. Then carefully remove and

unpack the Teflon sheeted tray and replace it on the cart. Ad-

just the cart height using the quick release lever. (Use the

upper level for flat plastics and the lower level for bubble

forming)

UNLOCKED

Cart may be raised or lowered

to required height

LOCKED

Cart height is now locked into

osition