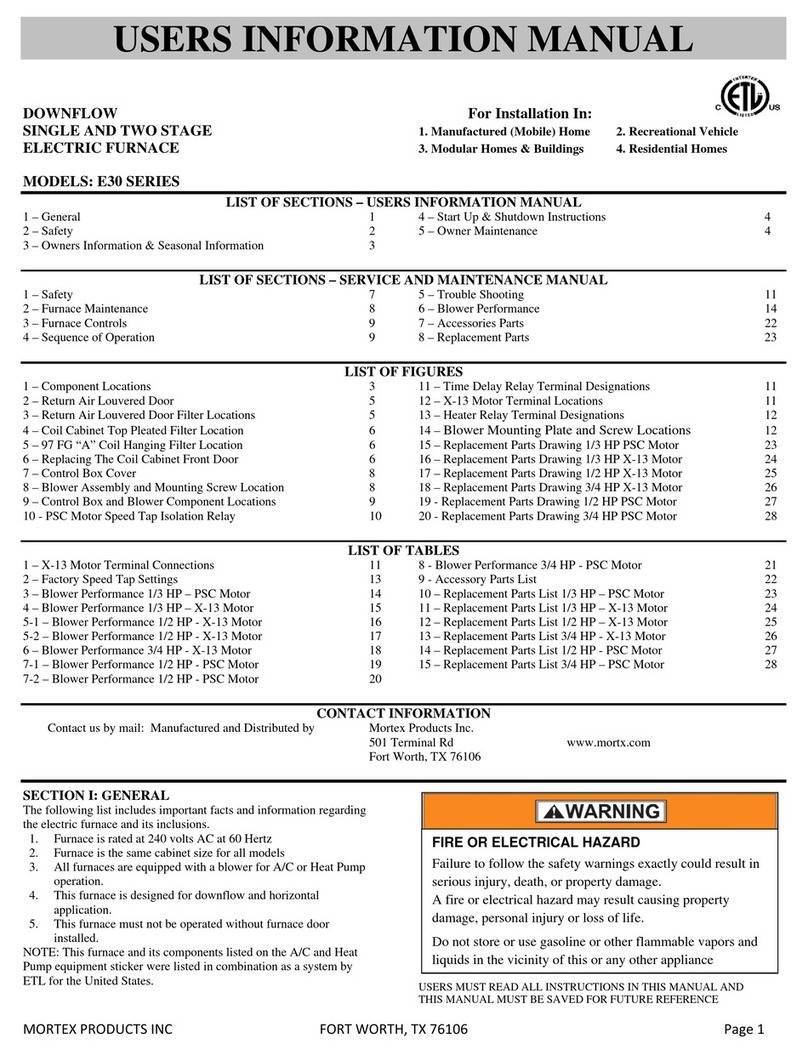

2.6 SUPPLY AIR ADJUSTMENTS

The supply air must be adjusted based on heating/air

conditioning output and the static pressure of the duct

system. For the desired airflow, refer to Table 1, as well

as Table 4 and Table 5 for the airflow based on static

pressure.

For the adjustment of the airflow on heating mode, to

obtain the temperature rise described in the technical

specification table Table 2 and Table 3), the orange wire

must be positioned on the terminal corresponding to the

LOW, MED-LOW, MED-HIGH or HIGH blower speed.

For the adjustment of the airflow on air-cooling mode,

to obtain a sufficient airflow (350 to 450 CFM per

Ton), the blue wire must be positioned on the terminal

corresponding to the LOW, MED-LOW, MED-HIGH or

HIGH blower speed.

Blower speeds are adjusted in factory for 0.5 inch W.C.

static pressure.

Table 1: Supply air adjustment on cooling mode

MOTOR

HP

COOLING

CAPACITY

(0.5 ‘’ w.c.)

BLOWER

SPEED

(Motor 120V)

BLOWER

SPEED

(Motor 240V)

1/3

1.5 LOW LOW

2.0 MED-LOW LOW

2.5 MED-HIGH MED

3.0 HIGH HIGH

1.0

2.5 LOW LOW

3.0 MED-LOW MED-LOW

3.5 MED-LOW MED-HIGH

4.0 MED-HIGH MED-HIGH

5.0 HIGH HIGH

If heating and air-cooling speeds are the same, the

orange wire and the blue wire can be connected on the

same terminal on the motor.

2.7 INSTALLATION OF

ACCESSORIES

WARNING

ELECTRICAL SHOCK HAZARD

Turn OFF electrical power at the fuse box

or service panel before making any electrical

connection and ensure that a proper ground

connection is made before connecting line

voltage.

Failure to do so can result in death or bodily injury.

2.7.1 Humidifier and electronic air cleaner

UNIQUE This unit is equipped with a 120 VAC terminal

for the connection of accessories up to a maximum of

2 amps. A humidifier and an electronic air cleaner can

be wired to terminals L1 and N of the unit. Refer to

the wiring diagrams in this manual (Figure 12 and Figure

13). A field supplied 24 VAC transformer can be installed

for accessories using 24 VAC. A separate power source

must be used if the accessories draw more than 2 amps.

Some accessories require control relays. A location has

been set aside in the unit for the installation of relays:

a 24 VAC (part number OFE-L01H009 ). In addition, a

24 VAC relay can be wired between terminals W1 and C

to be activated during a call for heat. Refer to the wiring

diagrams for the location of the relay RACC on the control

panel and in accessory instructions.

2.7.2 Use of a heat pump

When using a heat pump, a thermostat with dual fuel

option or a fossil fuel kit is required that prevents the

operation of the electric elements and the heat pump at

the same time. Refer to the instructions provided with the

thermostat or the “Fossil Fuel” kit for the proper wiring

of the furnace and the heat pump. The simultaneous

operation of the electric elements and the heat pump will

cause overheating of either unit. The safety controls of

the appliances will shut down the elements or heat pump,

since they are not designed to function in this fashion.

3 OPERATION

3.1 START-UP

Before starting up the unit, be sure to check that the

following items are in compliance:

1. The electrical installation and ventilation are

conform;

2. The blower access door is in place and the blower

rail locking screws are well tightened;

3. The blower speed adjustments for heating and air

conditioning are appropriate and in accordance

with to the specifications in this manual;

4. The thermostat of the room is in heating mode and

is set higher than the ambient temperature;

5. The breakers on front panel are set on the “ON”

position.

To start the unit, turn the main electrical switch on.

3.2 USE OF MANUAL FURNACE

CONTROLS ON ADVANTAGE

FURNACE

When there is a demand for heat, the pilot light (L-1)

comes on. Refer to the wiring diagram.

When the “HI/LO” switch is put into the “LO” position, it

will shut down approximately half the elements.

However, it is important to put the switch back to

6