Installation and Operation

900-0230-01-00 Rev A

7

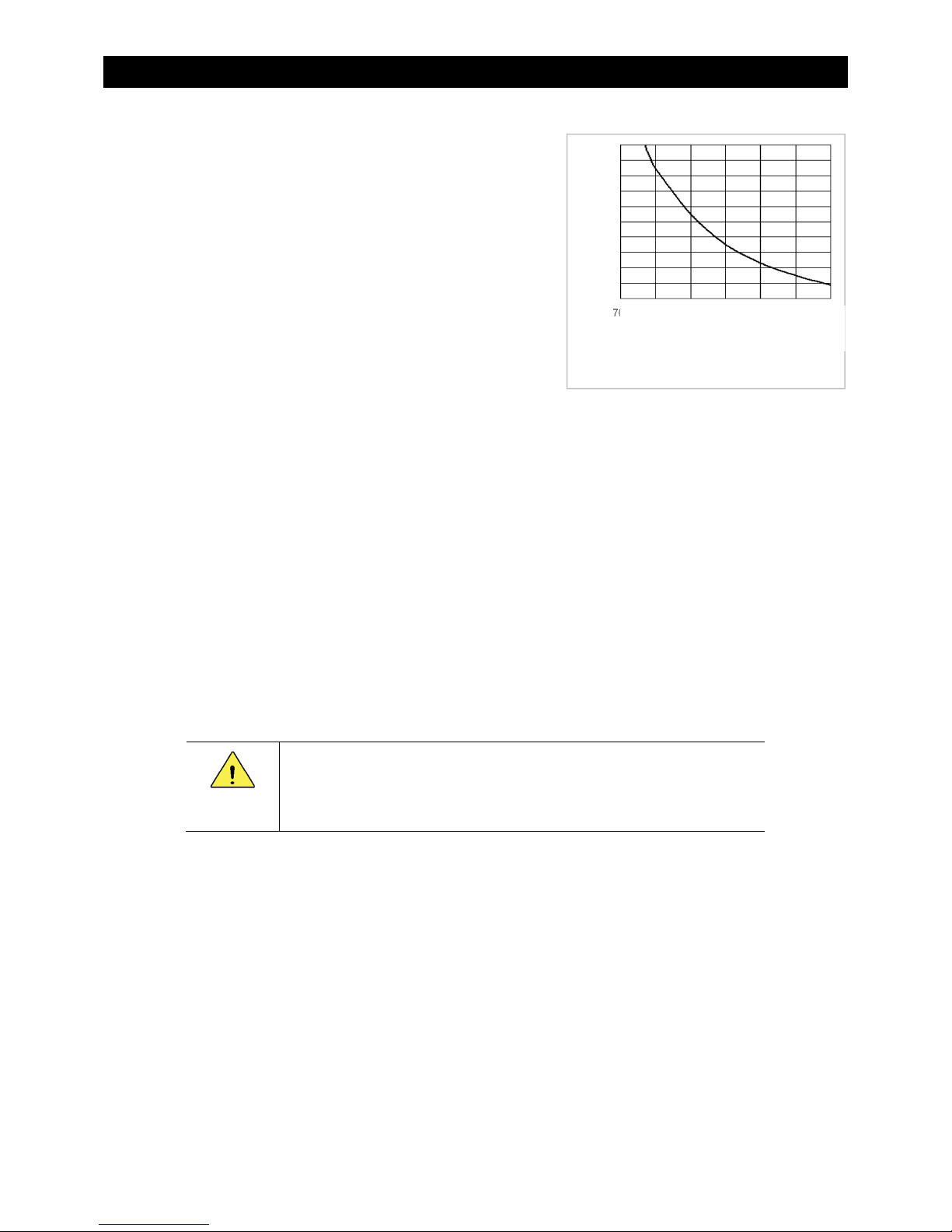

Self-Discharge

All EnergyCell batteries will discharge over time once charged, even in storage. Higher storage

temperatures increase the rate of self-discharge. The EnergyCell PLR has a longer shelf life

than other VRLA batteries. At room temperature (77°F or 25°C), the EnergyCell PLR has a

shelf life of 18 months before self-discharging to unacceptable levels. Figure 2 shows the rate

of EnergyCell PLR self-discharge at various temperatures.

Fully charged, the natural (“rest”)

voltage of all EnergyCell batteries is

approximately 12.8 Vdc. A battery

should have a freshening charge (see

page 14) if its rest voltage is below

12.5 Vdc per battery (2.08 Vdc per cell).

A battery should not be used if its rest

voltage is 12.0 Vdc or lower upon

delivery. Contact the vendor upon

receiving a battery in this state.

No EnergyCell should ever be

permitted to self-discharge below

70% state of charge (SoC). Such a

condition is highly detrimental and

will shorten battery life. (This situation is

not the same as discharging to 70% SoC

or lower under load. See page 8.)

Storing EnergyCell PLR Batteries

The EnergyCell PLR must be kept in storage no longer than the shelf life in Figure 2 for a

particular temperature. At the end of this time it must be given a freshening charge. That is, a

battery stored at 104°F (40°C) should be stored no longer than six months, while it can be

stored up to 48 months at 50°F (10°C) without a charge.

Stored batteries should be checked for open-circuit voltage at intervals. Any time the battery

voltage is less than 2.10 Vpc (volts per cell; this equates to 12.6 volts per battery), it should be

given a freshening charge regardless of the storage time.

At 104°F (40°C), the EnergyCell PLR voltage should be checked every 2 months. At 86°F

(30°C), the interval is 3 months. At 77° to 68°F (25° to 20°C) the interval is 4 months. At

temperatures lower than 59°F (15°C), the voltage only needs to be checked every 6 months.

Capacity

Battery capacity is given in ampere-hours (amp-hours). This is a current draw which is

multiplied by the duration of current flow. A draw of X amperes for Y hours equals an

accumulation of XY amp-hours.

Because the battery’s chemical reaction constantly releases energy, its level of depletion is not

always obvious. Smaller loads will deplete the batteries less than larger loads. This effectively

means that the battery has more capacity under lighter loads.

For example, if the EnergyCell 200PLR is discharged at the 20-hour rate to a voltage of 1.75

Vpc (a load expected to effectively drain 100% of its capacity in 20 hours), it will be measured to

have 203.8 amp-hours. However, at the 4-hour rate, a heavier load, only 177 amp-hours will be

measured. For discharge rates and amp-hours, see Table 4 on page 21.

Figure 2 EnergyCell PLR Shelf Life

0 6 12 18 24 30 36 42 48

Months

2.17

2.16

2.15

2.14

2.13

2.12

2.11

2.10

Rest Volts per cell (Vpc)

Approximate %

State of Charge

100

96

91

87

83

79

74

70

40°C

104°F

30°C

86°F 25°C

77°F 20°C

68°F 10°C

50°F