Outdoor living today 8x8 Gardener's Shed User manual

Other Outdoor living today Garden House manuals

Outdoor living today

Outdoor living today 8x15 SpaceMaker Garden Shed User manual

Outdoor living today

Outdoor living today 6x9 Sunflower Playhouse User manual

Outdoor living today

Outdoor living today Little Squirt Playhouse User manual

Outdoor living today

Outdoor living today CB128-METAL User manual

Outdoor living today

Outdoor living today 8x15 Santa Rosa User manual

Outdoor living today

Outdoor living today 9x6 Cabana User manual

Outdoor living today

Outdoor living today SS84S-Metal User manual

Outdoor living today

Outdoor living today 8x4 SpaceSaver Garden Shed User manual

Outdoor living today

Outdoor living today 8x12 SpaceMaker User manual

Outdoor living today

Outdoor living today SS84S-METAL-FJ User manual

Popular Garden House manuals by other brands

Yardmaster

Yardmaster 66 ZGEY Assembly instructions

Mercia Garden Products

Mercia Garden Products 0628LOG181-V4 manual

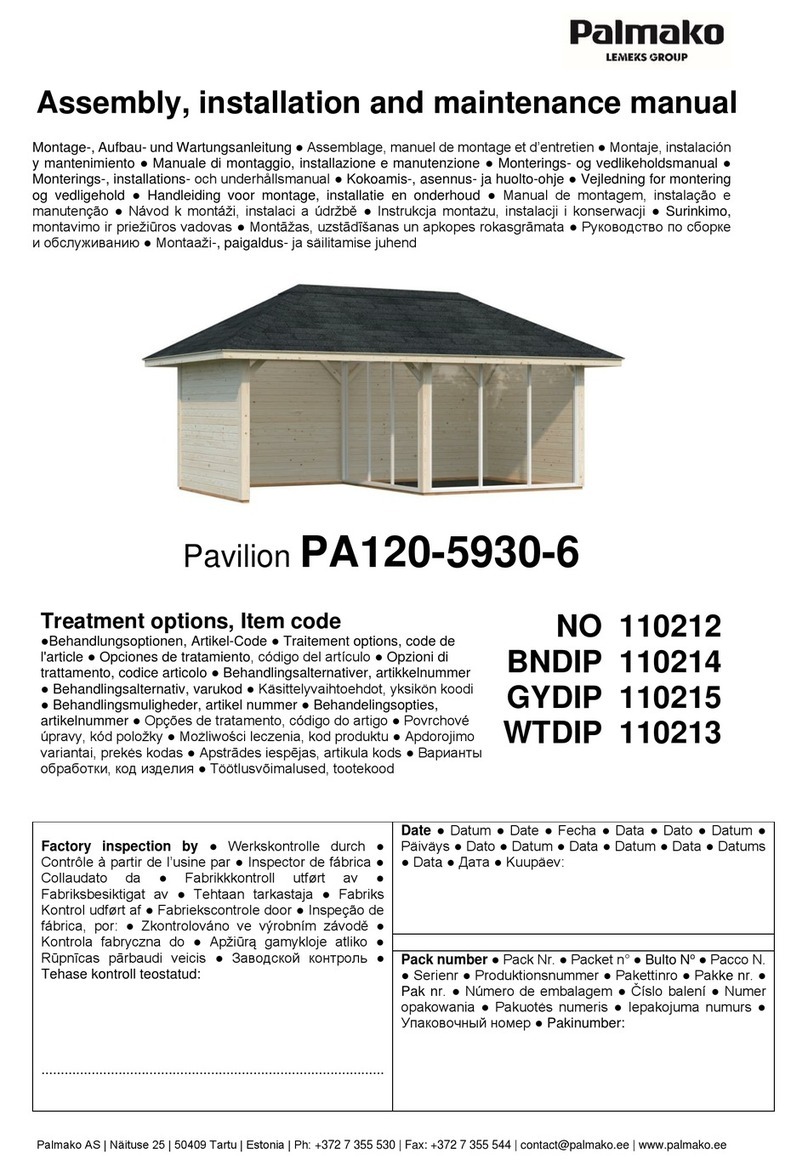

Lemeks

Lemeks Palmako PA120-5930-6 Assembly, installation and maintenance manual

Rion

Rion Hobby Gardener Assembly instructions

Select

Select ISAAC E9682 Assembly manual

Palmako

Palmako Saale installation manual

Palmako

Palmako Roger FR44-5953-2 installation manual

Lemeks

Lemeks Palmako Grace PM56-4529 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 03WES0808-V1 General instructions

Mercia Garden Products

Mercia Garden Products 03DTSHHP1206HGD4MW-V1 General instructions

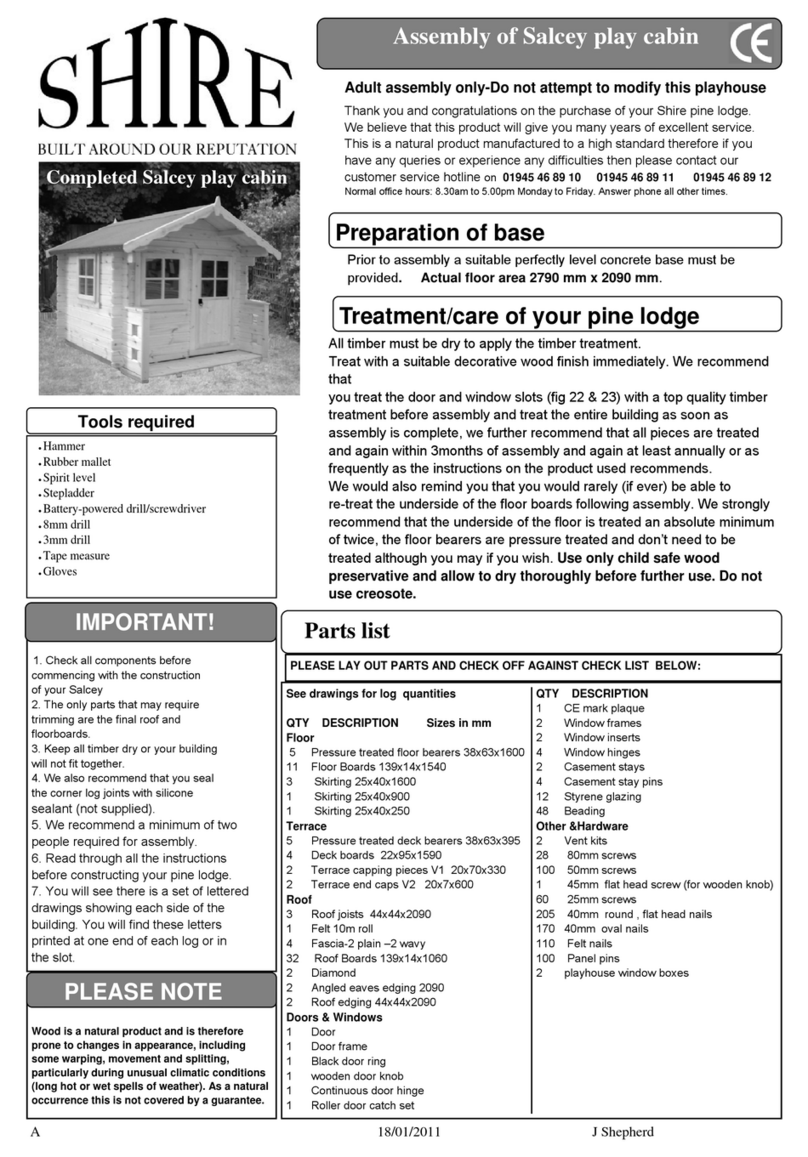

Shire

Shire Salcey Assembly

Pergola kits USA

Pergola kits USA PREMIUM VINYL PAVILION Assembly manual

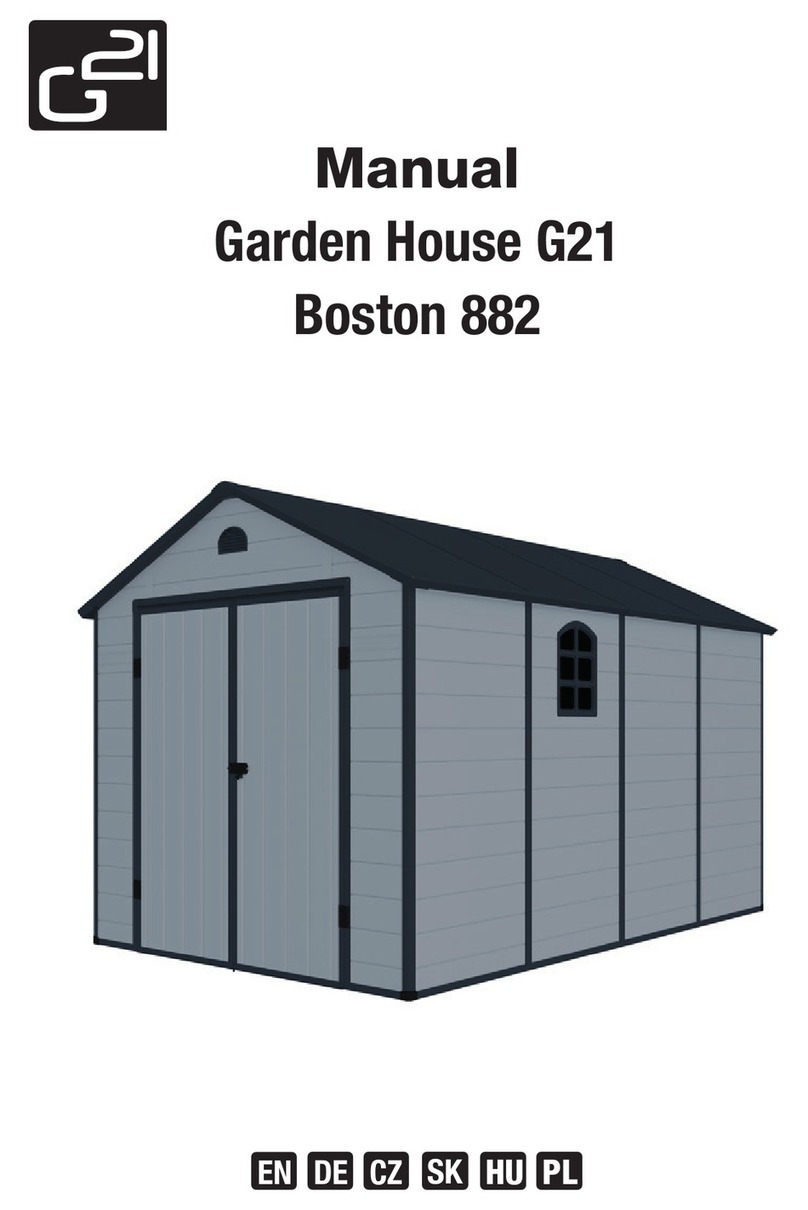

G21

G21 Boston 882 manual

Mercia Garden Products

Mercia Garden Products 05DTMBPN0503DD-V1 Assembly instructions

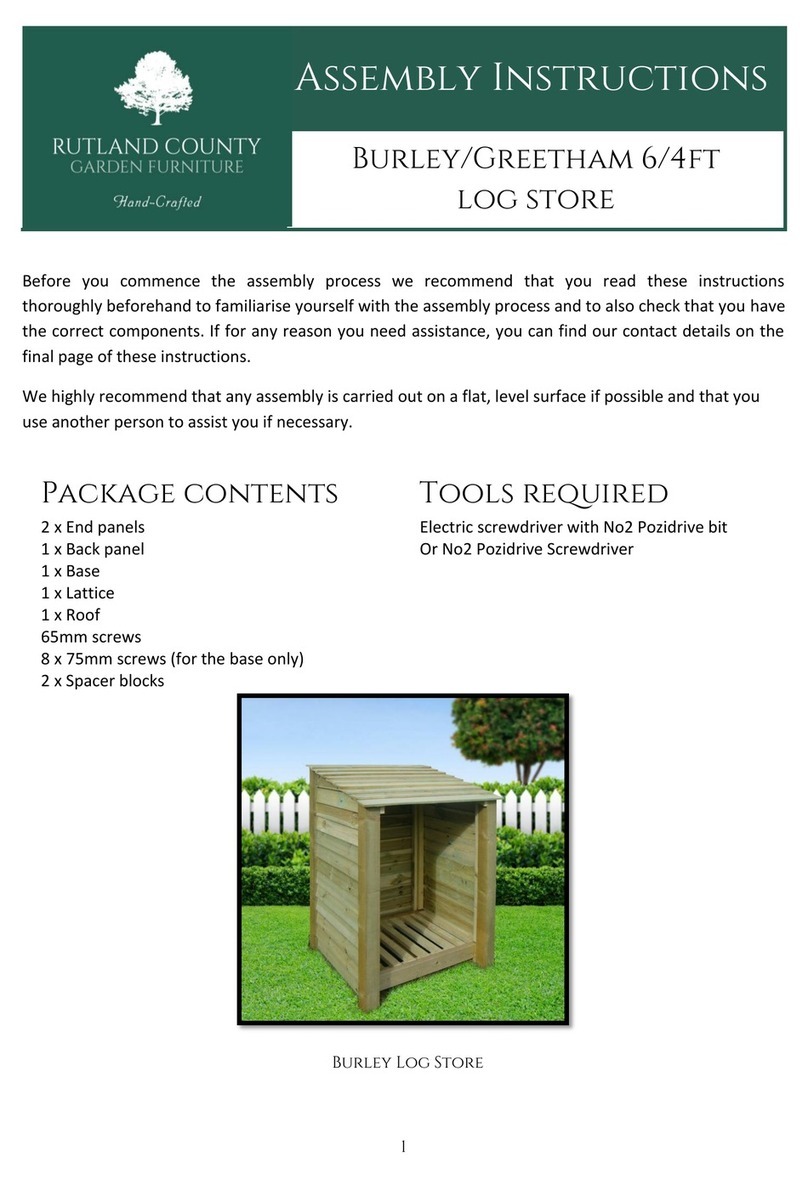

Rutland County

Rutland County Burley 6ft Assembly instructions

Palmako

Palmako Roger 27,7 installation manual

Mercia Garden Products

Mercia Garden Products 01PTOSBA0306DDNW-V1 General instructions

Gartenhaus-King

Gartenhaus-King Valery manual