INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE. OWNER: RETAIN THE MANUAL FOR FUTURE REFERENCE.

WARNING: FOR OUTDOOR USE ONLY

Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

DANGER: FIRE OR EXPLOSION HAZARD

If you smell gas:

DANGER: FLAMMABLE GAS UNDER PRESSURE.

Leaking LP-GAS may cause a fire or explosion if ignited causing serious bodily injury or death. Contact LP

Gas supplier for repairs, or disposal of this cylinder or unused LP-GAS.

»Know the odor of LP-gas, if you hear, see or smell leaking

LP-GAS, immediately get everyone away from the cylinder and

call the Fire Department, Do Not Attempt repairs.

»LP-GAS is heavier than air and may settle in low places while

dissipating.

» Contact with the liquid contents of the cylinder will cause freeze burns

to the skin.

» Do not allow children to tamper or play with the cylinder.

»When not connected for use, keep the cylinder valve turned o.

Self-contained appliances shall be limited to a cylinder of 30lbs.

capacity of less.

»Do not use, store, or transport a cylinder where it would be

exposed to high temperatures. The relief valve may open,

allowing a large amount of flammable gas to escape.

»When transporting, keep the cylinder secured in an upright

position with the cylinder valve turned o.

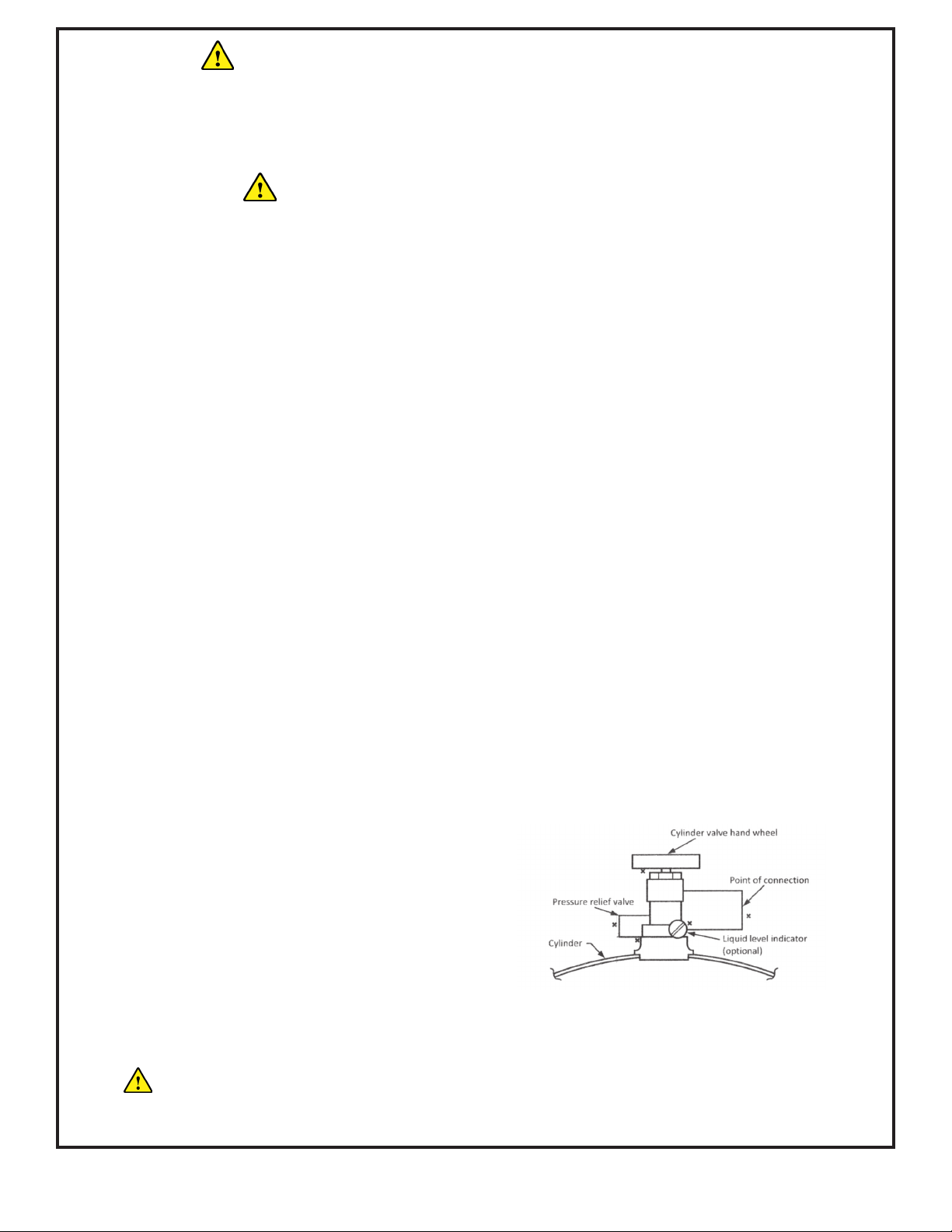

When Connecting for use:

» Use only compliance with applicable codes.

» Read and follow the manufactuer’s instructions.

» Consult the manufacturer’s instructions concerning the

cylinder connection provided with your appliance

» Be sure the regulator vent is not pointing up.

» Turn o all valves on the appliance.

» Do not check for gas leaks with a match or open flame. Apply

soapy water at areas marked “X”. Open the cylinder valve if bub-

bles appear, close the valve, and have the LP-gas service person

make needed repairs. Also, check the appliance valve and con-

nections to ensure they do not leak before lighting the appliance.

» Light appliance following manufacturer’s instructions

» When the appliance is not used, keep the cylinder valve closed.

CALIFORNIA PROPOSITION 65 WARNING

This product can expose you to Carbon Monoxide, which is known

to the state of California to cause cancer and birth defects or other

reproductive harm. (For more information, go to: www.p65warnings.ca.gov)

» Do not store or use gasoline or other flammable vapors and liquids, In the vicinity of this or

any other appliance.

» An LP-Cylinder not connected for use shall not be stored in the vicinity of this or any other

appliance.

» For use with Natural or Propane gas only.

» If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

» Shut o gas to appliance.

» Extinguish any open flame.

» If odor continues, leave the area immediately.

» Aer leaving the area, call your gas supplier or Fire department.

Failure to follow these instructions could result in fire or explosion, which could cause

property damage, personal injury, or death.

WARNINGS

THIS SECTION OUTLINES WARNING ASSOCIATED WITH INSTALLATION, USE, AND OPERATION.