S-193-11-E

2

CONTENTS

1. BEFORE YOU BIGIN ............................. 3

1.1 Confirming the Nameplate ......................... 3

1.2 Transportation Considerations................... 3

1.3 Storage Considerations.............................. 3

2.OPERATING CONDITIONS ................... 4

3.GENERAL .............................................. 4

3.1 Features ...................................................... 4

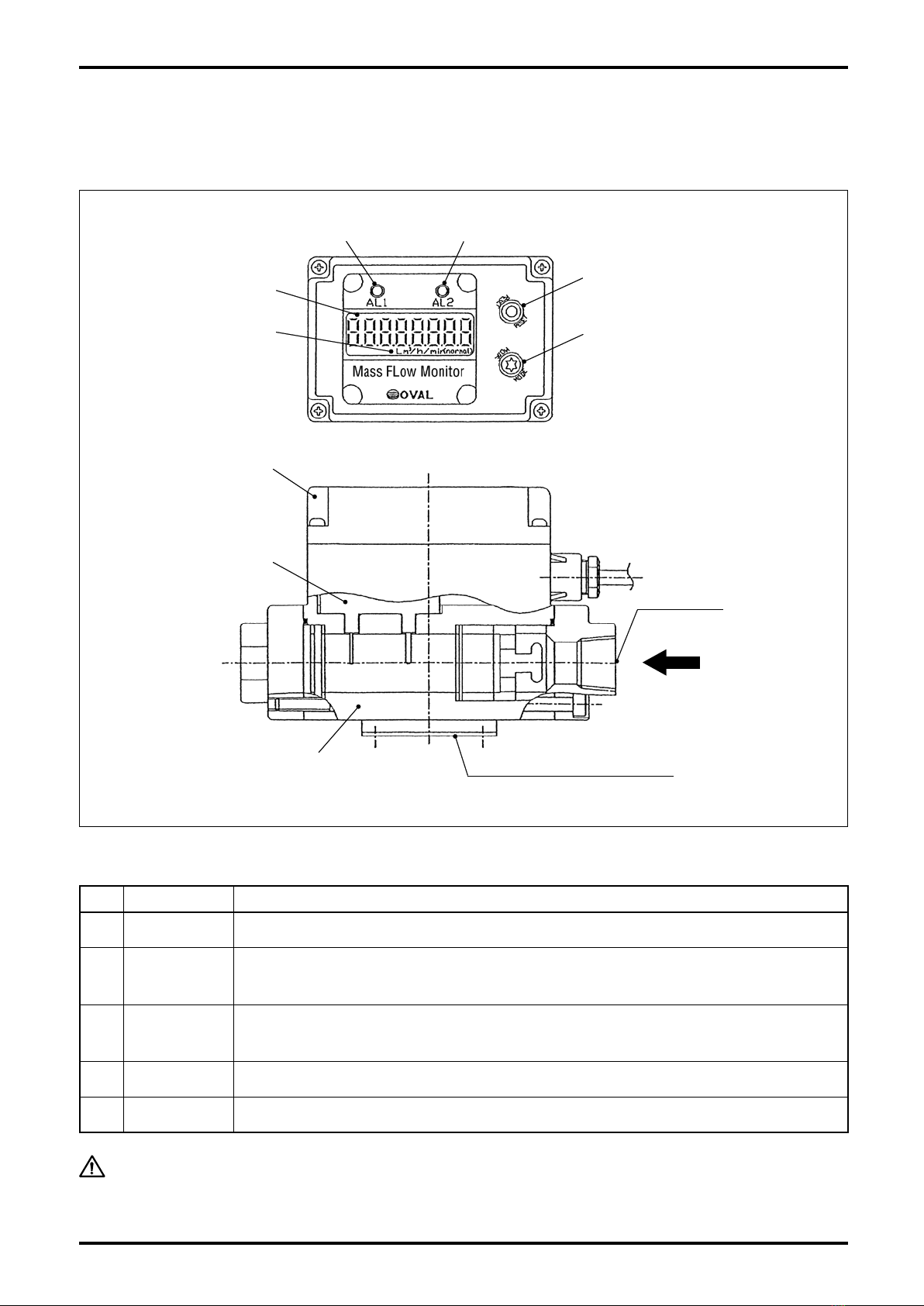

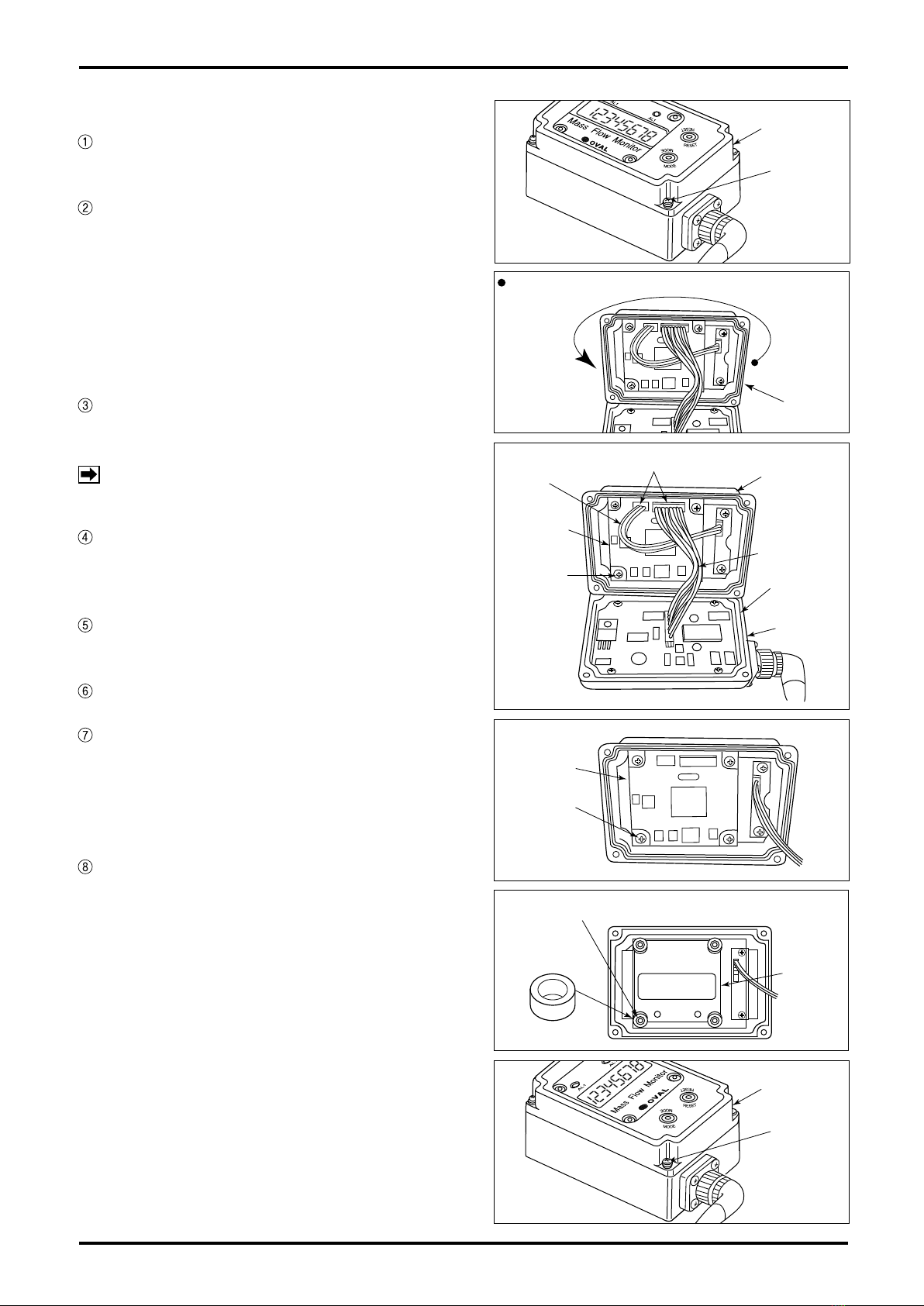

4.COMPONENT NAMES AND

FUNCTIONS .......................................... 5

4.1 Part Names................................................. 5

4.2 Individual Functions ................................... 5

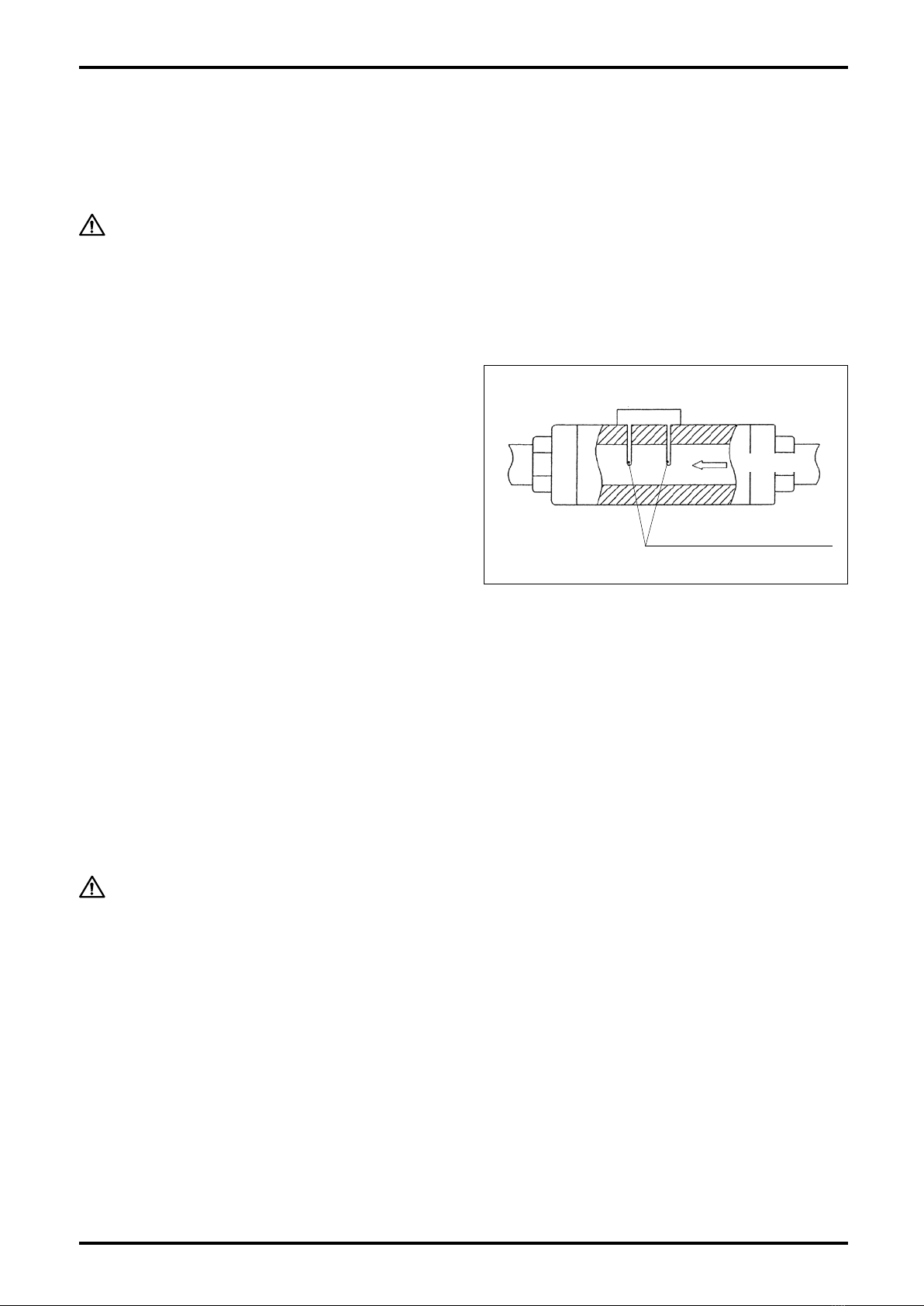

5.INSTALLATION ...................................... 6

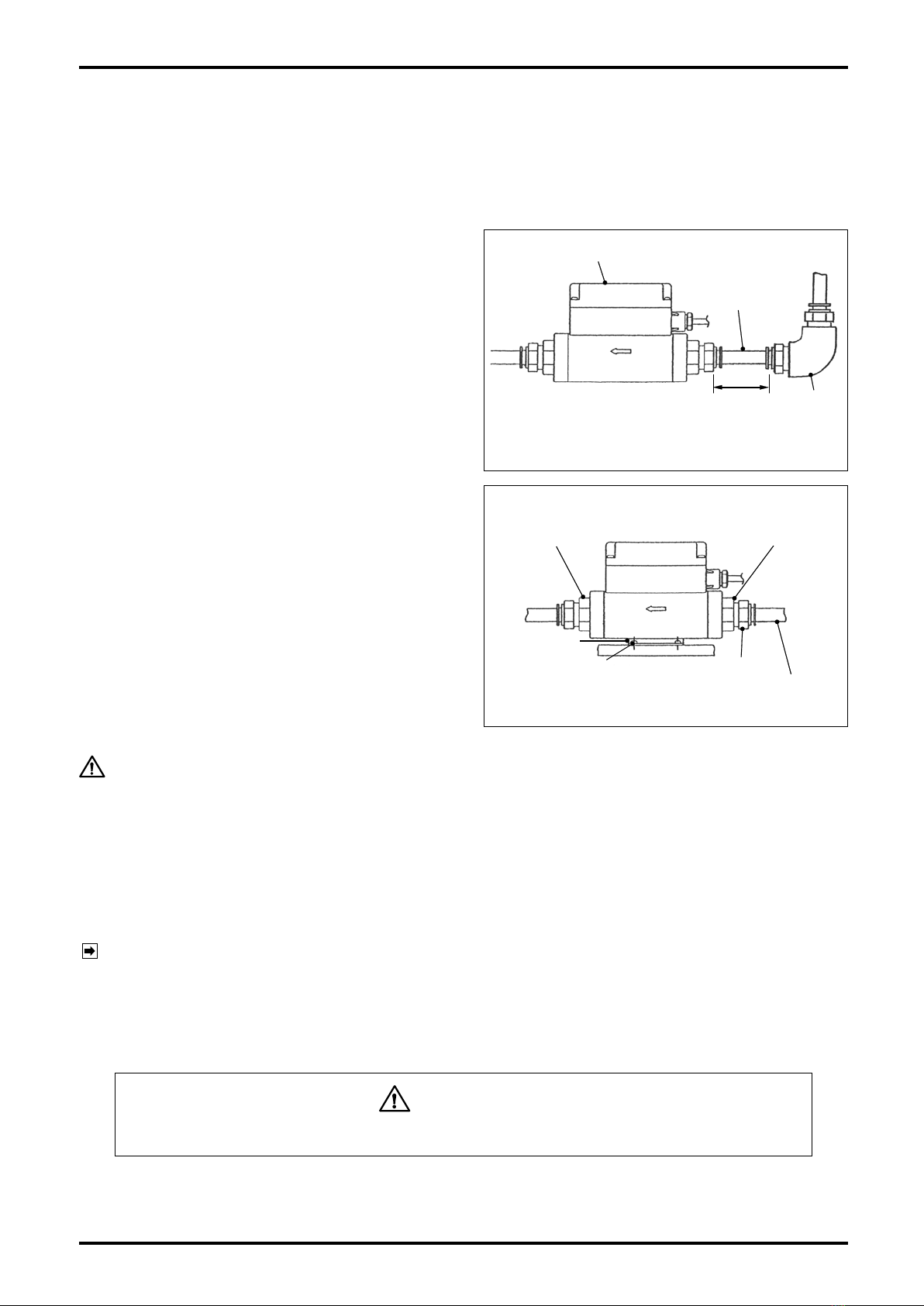

5.1 Installation Location.................................... 6

5.2 Physical Orientation ................................... 6

5.3 How to Change Display Orientation ........... 6

5.4 Conditions Required for Metered Fluid ...... 8

5.5 Tubing Guidelines....................................... 8

5.6 Maximum Service Flowrate........................ 9

6. WIRING CONNECTIONS ..................... 10

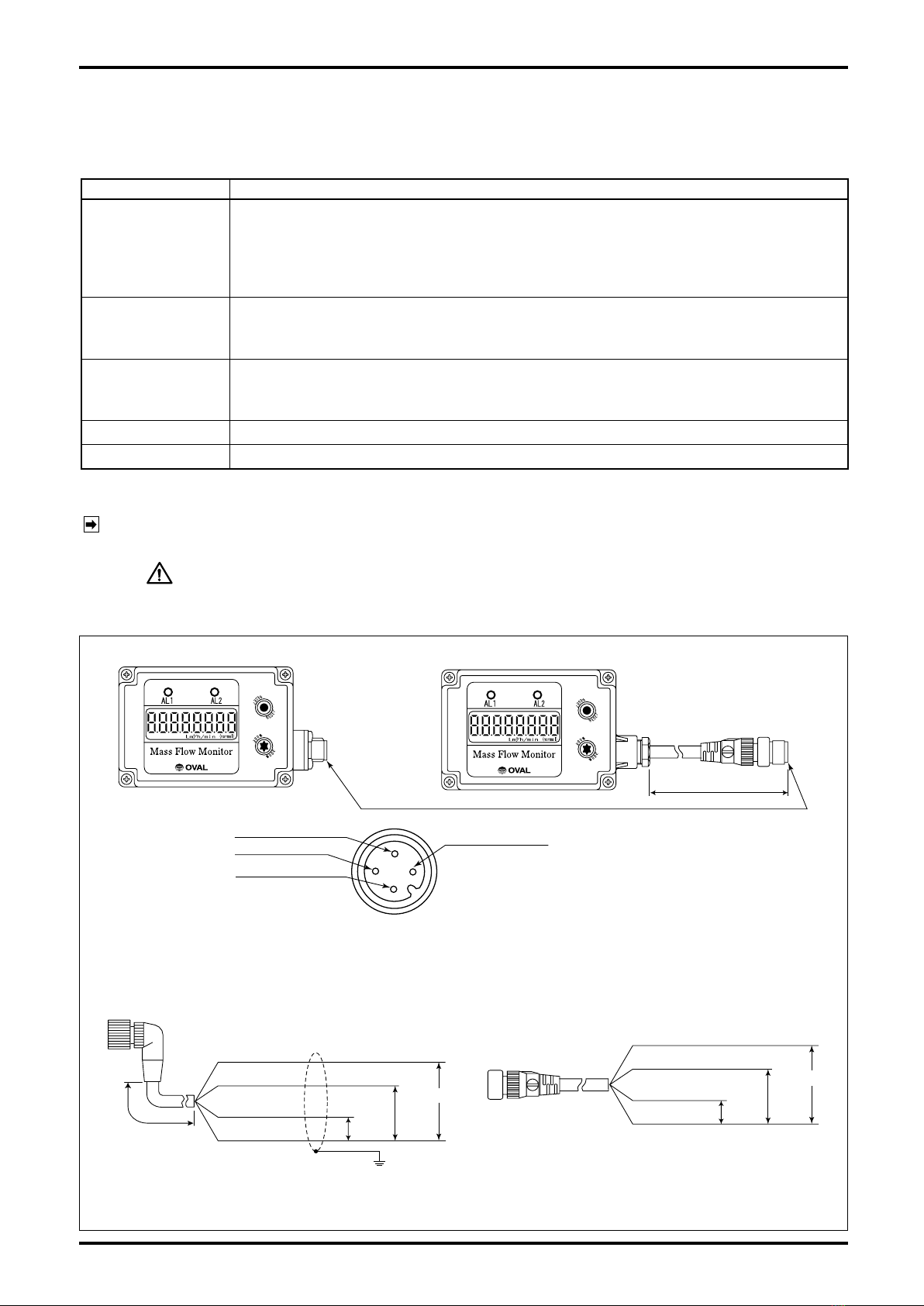

6.1 Wiring Specifications .................................10

6.2 Wiring Diagram..........................................10

6.3 Cable Specifications .................................14

7. OPERATION ........................................ 14

8.TRANSMITTER DISPLAY FUNCTIONS

AND RECONFIGURATION .................. 15

8.1 Viewing the Flow Variables ........................15

8.2 Parameter Display .....................................16

8.3 Default Parameter Settings .......................18

8.4 Parameter Reconfiguration .......................19

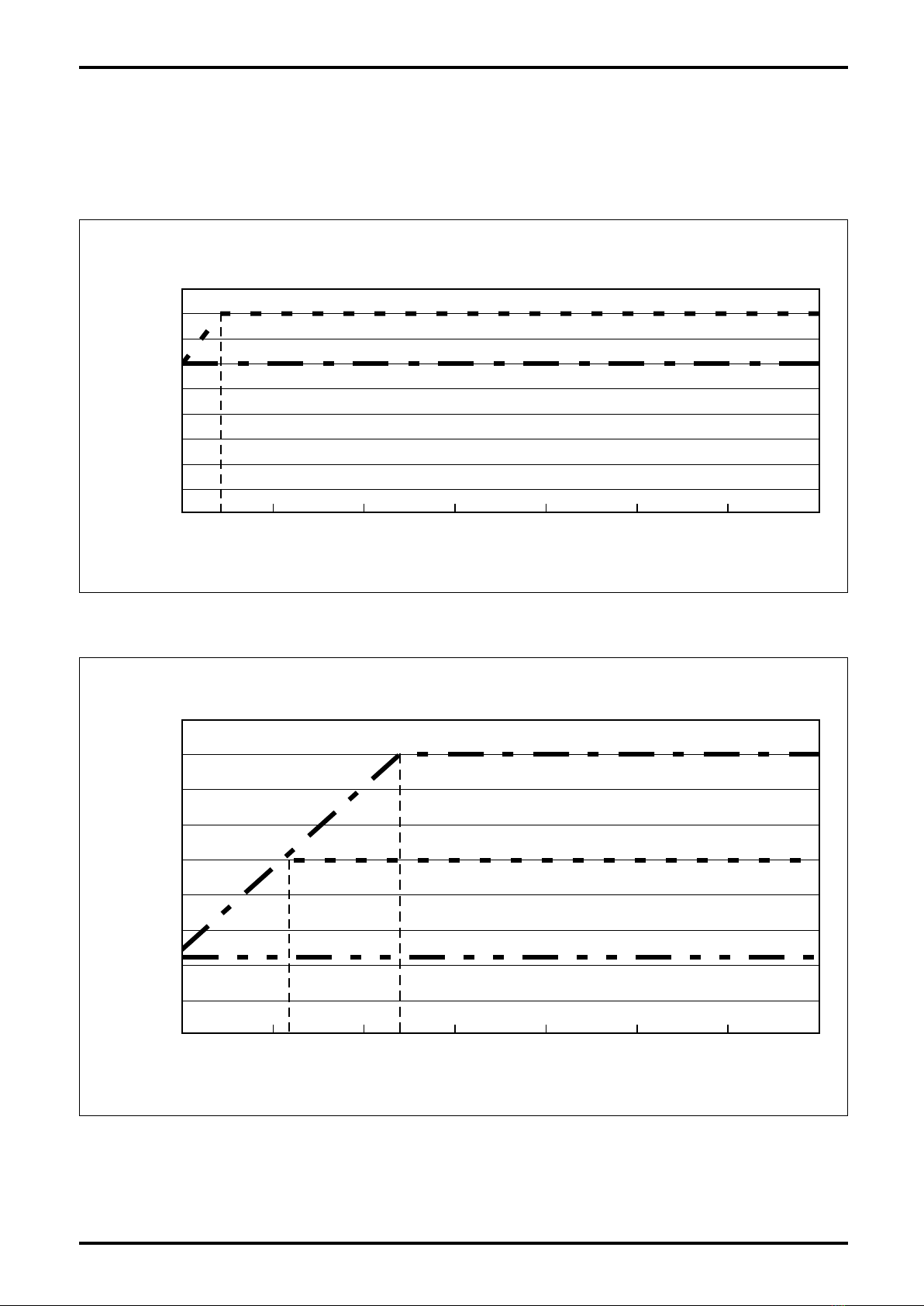

8.5 Alarm Features .........................................20

8.6 Dummy Pulse Output ................................24

8.7 Analog Output Trim ...................................25

8.7.1 Analog Trim (4mA) ....................................... 25

8.7.2 Analog Trim (20mA) ..................................... 26

8.8 Error Messages .........................................27

9. GENERAL SPECIFICATIONS ............. 28

10. APPLICABLE STANDARDS.............. 28

11. PRODUCT CODE EXPLANATION .... 29

12. OUTLINE DIMENSIONS....................30

CONVENTIONS

Shown in this manual are the signal words NOTE, CAUTION and WARNING, as

described in the examples below:

NOTE: Notes are separated from the general text to bring the user's attention

to important information.

CAUTION: Caution statements signal the user about hazards or unsafe practices

which could result in minor personal injury or product or property

damage.

WARNING: Warning statements signal the user about hazards or unsafe practices

which could result in severe personal injury or death.