1 Application area / device features

1.1 Application area

The REGTRONIC PE controllers are high-performance microprocessor-controlled

units for controlling the functions of solar thermal systems. The REGTRONIC PE is

the ideal controller for systems with one collector and one storage tank.

The controllers are designed for use in dry areas and for residential, business and

commercial applications. If you want to use the unit for other purposes, check ap-

plicable statutory regulations before use.

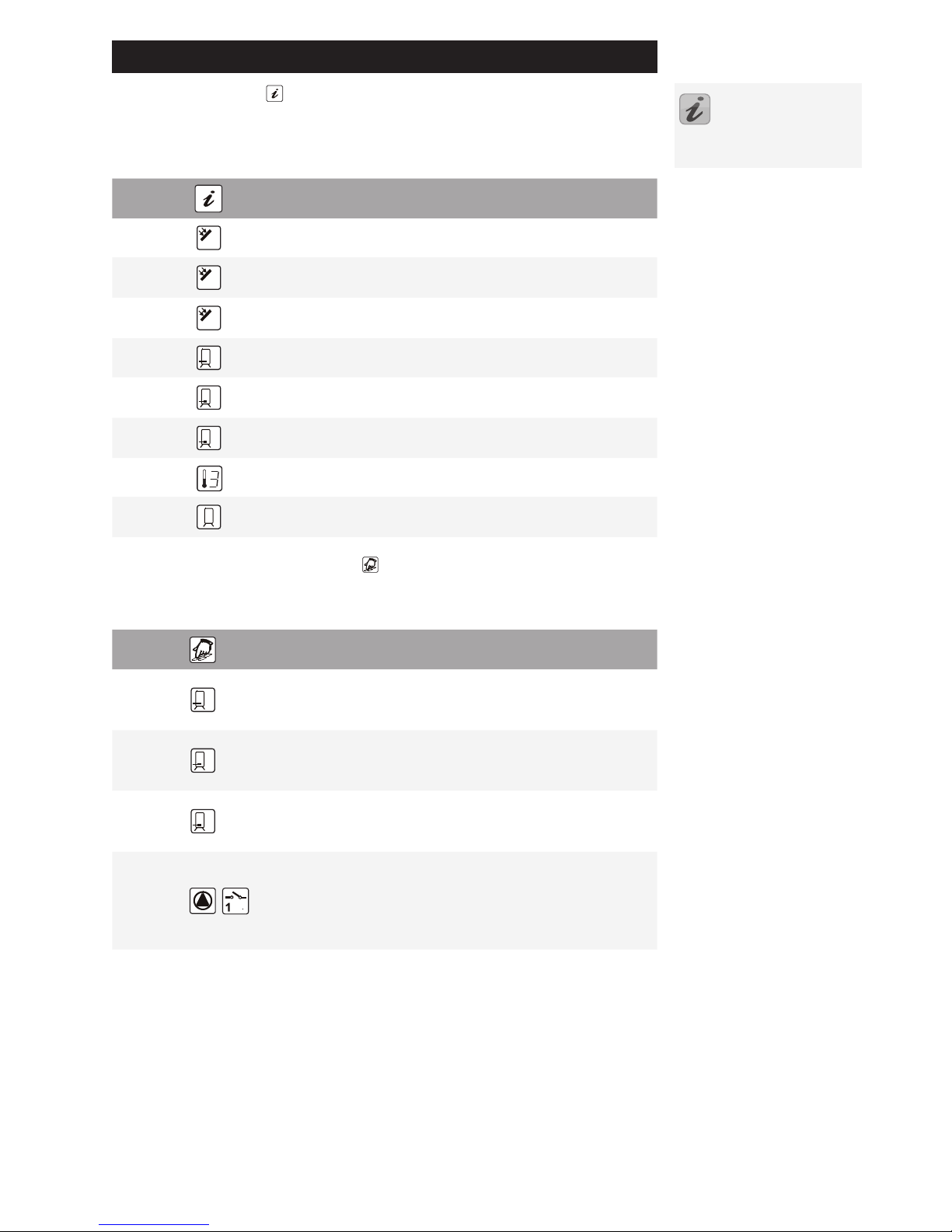

1.2 Device features

The REGTRONIC PE generation of controllers is equipped with the following fea-

tures:

Intuitive user menus with icons and four control buttons◼

Adjustable control values◼

RPM control of the solar circuit pump via block modulation or switching controll◼

Extensive functions for system monitoring, using symbols to indicate errors and◼

faults

Storage of all values, even during prolonged mains power supply outage◼

Various protective functions: system and collector protection, recooling and◼

ow monitoring

Generous wiring space◼

Available accessories:

Temperature sensor PT1000◼

Sensor connection box◼

Immersion sleeves◼

2 Safety instructions

Always ensure that you isolate the device from the mains power supply before◼

starting installation or wiring work on its electrical components. Make sure that

you never confuse the SELV (safety extra low voltage) connectors (sensor, ow

transmitter) with the 230 V connectors: this will destroy the device. Life-threat-

ening voltages may be present in both the device and the connected sensors.

Solar power systems can generate high temperatures. There is therefore a risk of◼

burn injuries! Exercise caution when installing the temperature sensors!

Mount the REGTRONIC PE in a location where it will not be subjected to exces-◼

sive operating temperatures (>50 °C) by any external heat sources.

For safety reasons, the system should only be operated manually during testing.

In this operating mode, the system does not monitor maximum temperatures or

sensor functions. Do not operate the system if there is recognisable damage to

the controller, cables or the connected pumps and valves.

You must isolate the

control unit from mains

power before carrying out any

assembly or wiring work.

The connection and start-up of

the REGTRONIC PE should only be

carried out by qualified technical

personnel. All work must comply

with the applicable safety

regulations.