Congratulations!! You have just invested in the world’s greatest component

system-period. When properly installed and tuned, your Oz Audio Matrix com-

ponents will transform your car audio system into a concert experience. You

will be pleased to know that the engineers at Oz Audio are committed to provid-

ing you the highest level of performance and quality in the industry. Oz Audio

speaker systems are the product of countless hours of research, development,

and engineering. These efforts are necessary to continue our development of

new technologies and materials that make it possible for Oz audio to maintain

its reputation as the best sounding speakers on the planet.

The audio system you have invested in today is a testament to our “No Com-

promise” approach to the pursuit of the most accurate and natural sounding

musical reproduction possible. We began with the development of a mid-bass

driver capable of delivering tight accurate bass down to 36 Hz (easy for us, hard

for them), transition swiftly enough to provide faultless midrange, and do it all

without an enclosure. We accomplished this through the use of our flat progres-

sive-roll spider, computer optimized suspension compliance, oversized voice

coil, and a proprietary 3-layer cone. This honeycomb matrix of woven glass

fiber and Nomex has proven itself the perfect medium to accomplish these

amazing feats. All of these technologies are fastened to our proprietary cast

aluminum basket. For the treble range we commissioned our newly developed

silk soft dome tweeter. This tweeter exemplifies the next step in the evolution

of our original silk soft dome tweeter which set industry standard 15 years ago.

This breakthrough in engineering uses a new silk cotton blend to distribute

crisp clear high’s that exceed the limits of human hearing and the performance

of metal dome tweeters. When the capabilities of these two independents are

coupled through our audiophile crossovers, the results must to be heard to be

believed.

Through years of Research & Development and competition we have unlocked

a combination of speakers and electronics that have set a new industry stan-

dard for excellence. This became evident when our original design of compo-

nents set the first and only perfect score ever recorded in sound quality history.

We have succeeded where others have failed; our systems provide endless

hours of musical enjoyment with the lowest amounts of distortion or ear fatigue

at any and all volume levels. Through our use of innovative materials and

technology, coupled with the strictest quality and performance standards in the

industry, you have bought front row center tickets for every CD you own. Every

time this system played it will be remembered as an experience.

Congratulations, you are taking the firsts steps on your newest journey through

sound.

Features:

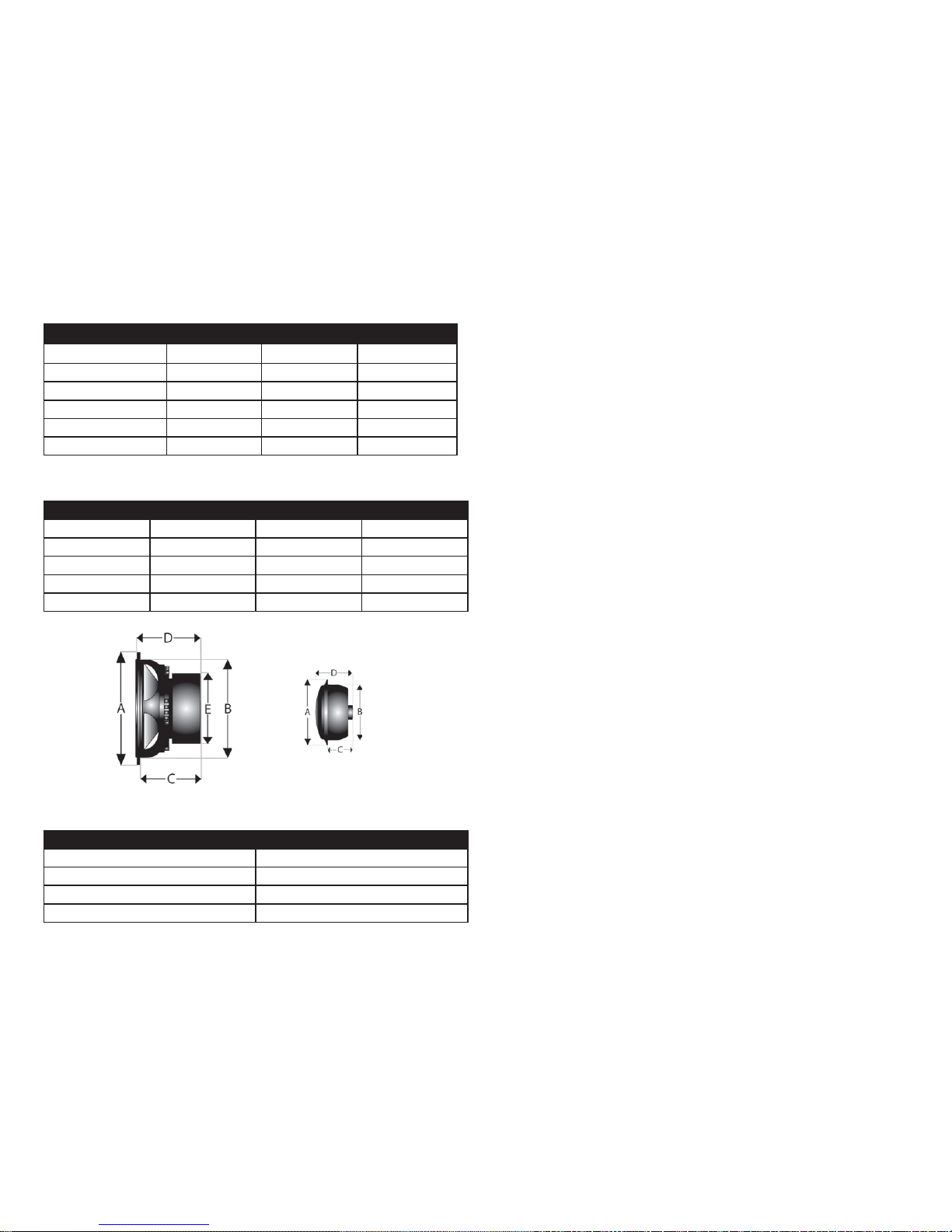

Mid-bass:

• 3-layer glass fiber and Nomex cone woven in a honeycomb matrix

• High quality Butyl Rubber surround

• Flat progressive roll spider

• Thermoset Four layer copper voice coil

• Aluminum voice coil former for improved heat dissipation

• Custom embossed, protective magnet boot

Tweeter:

• 1” silk soft dome tweeter

• Neodymium iron-boron motor structure

• Ferrofluid cooled motor for advanced heat dissipation

Crossover:

• New proprietary design and cosmetics

• 12 dB per octave, 2-way crossover

• Three position tweeter attenuation switch 0, -1.5 dB, -3 dB

• Tweeter polarity switch 0/-180

• Heavy duty gold plated terminals