INLINE MOUNT Exhaust Brakes

INSTALLATION MANUAL - L2031 PG. 5

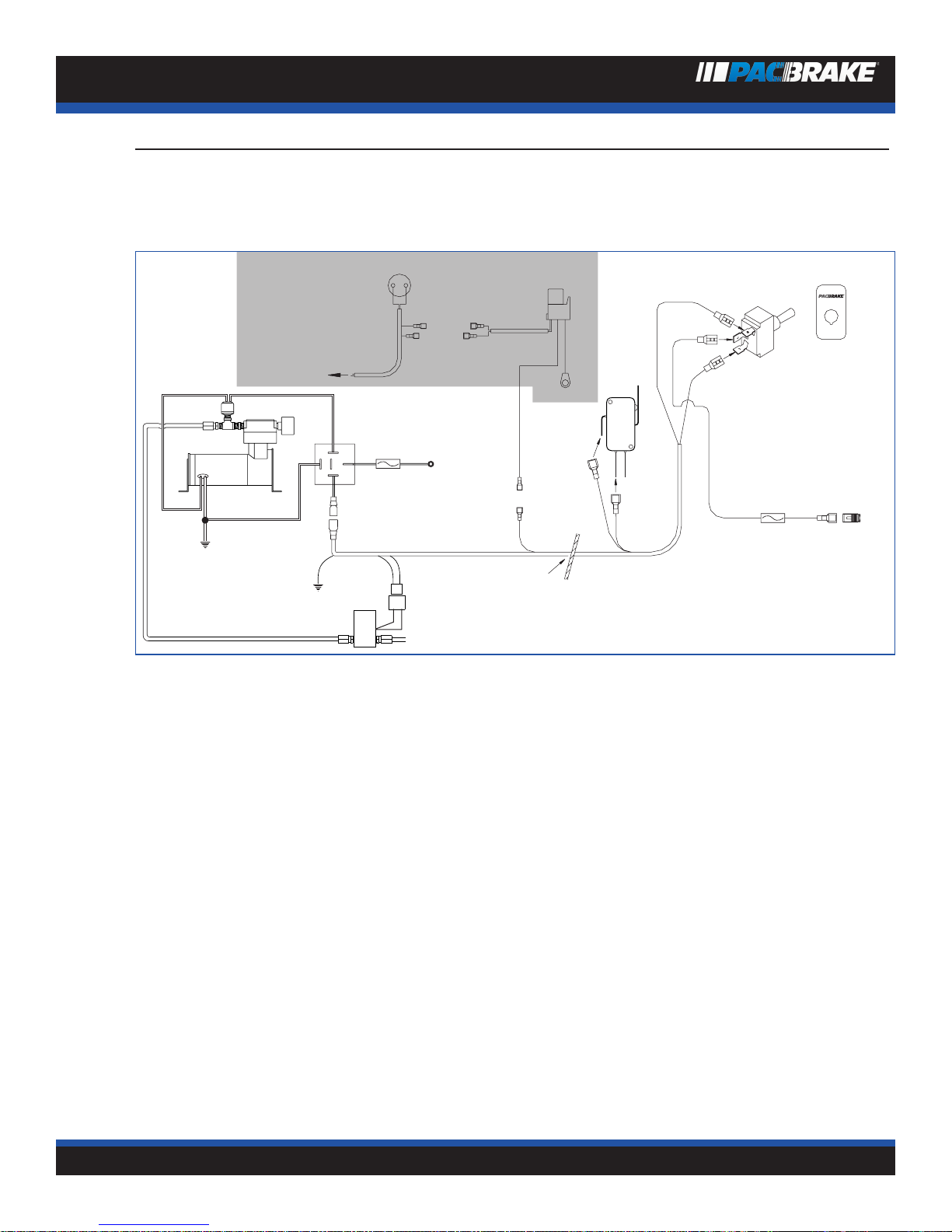

Wiring Schematic Index

* 1998-2002 Ford Econoline Vans equipped with Powerstroke, see wiring schematic on page 6

* Pre-1998 Ford Econoline Vans Equipped with Powerstroke, see wiring schematic on page 9

* Navistar vehicles equipped with 444E, see wiring schematic on Page 13

* 1999-2002 Dodge 24 Valve Electronic equipped with Cummins 5.9/ISB, see wiring schematic on page 14

* Pre 1999 Dodge 12 Valve Mechanical equipped with Cummins 5.9, see wiring schematic on page 16

Application Guide

Engine

Max.

Backpressure @RPM

Exhaust

Brake

*C10300 model is an adjustable brake

and must be set during a road test

using a backpressure gauge. Due

to upgrades and variations between

engines (i.e: different turbo chargers) it

is not possible for Pacbrake to provide

a preset brake to cover all possibilities.

Econoline or Ford Powerstroke 32 PSI 3400 C20366

Dodge Cummins 5.9L 35 PSI 3100 *C10300

Dodge Cummins 5.9L

(with heavy duty valve springs)

60 PSI 3100 *C20369

Dodge Cummins 24 valve 60 PSI 3100 *C10300

International 444E 32PSI 3400 *C20366

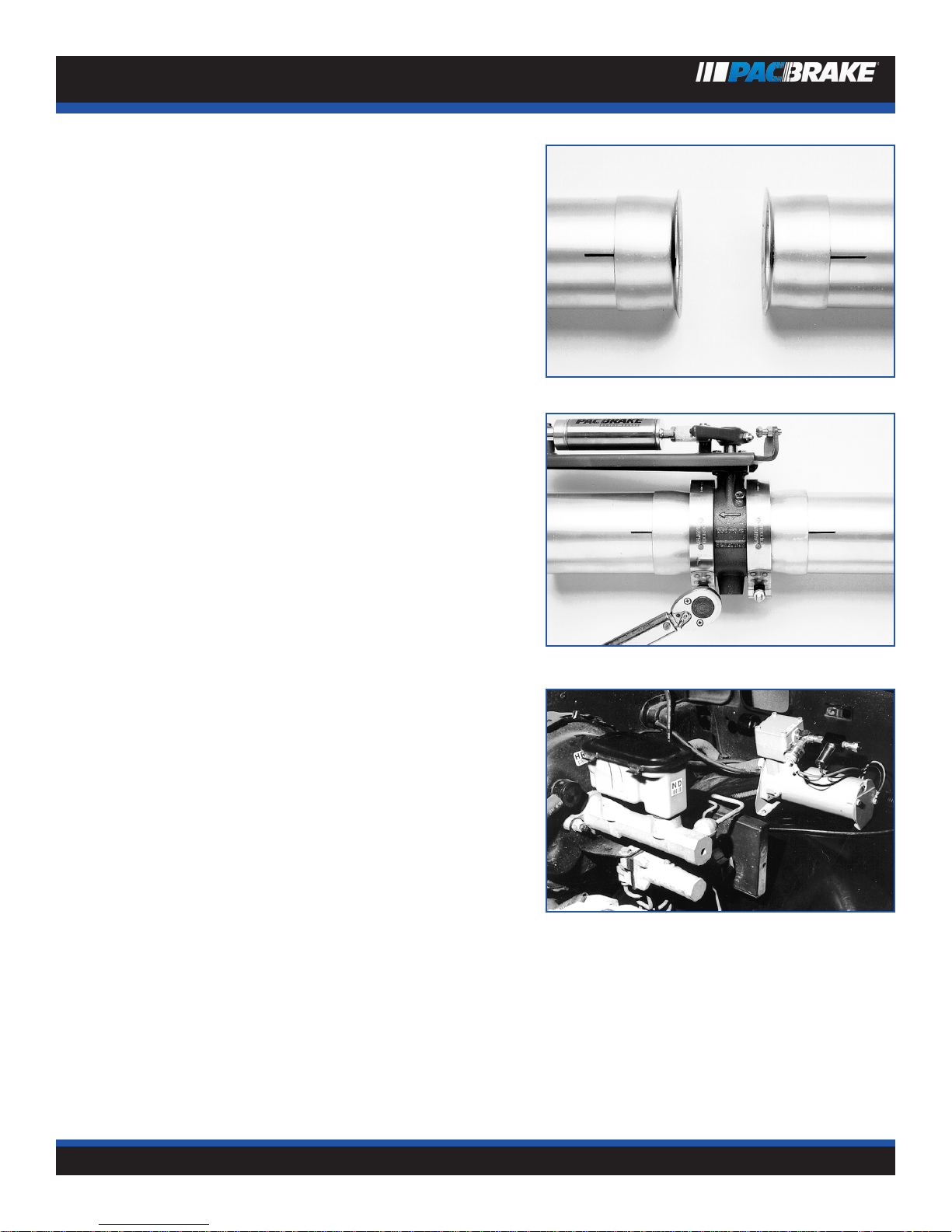

Testing Exhaust Brake Back Pressure

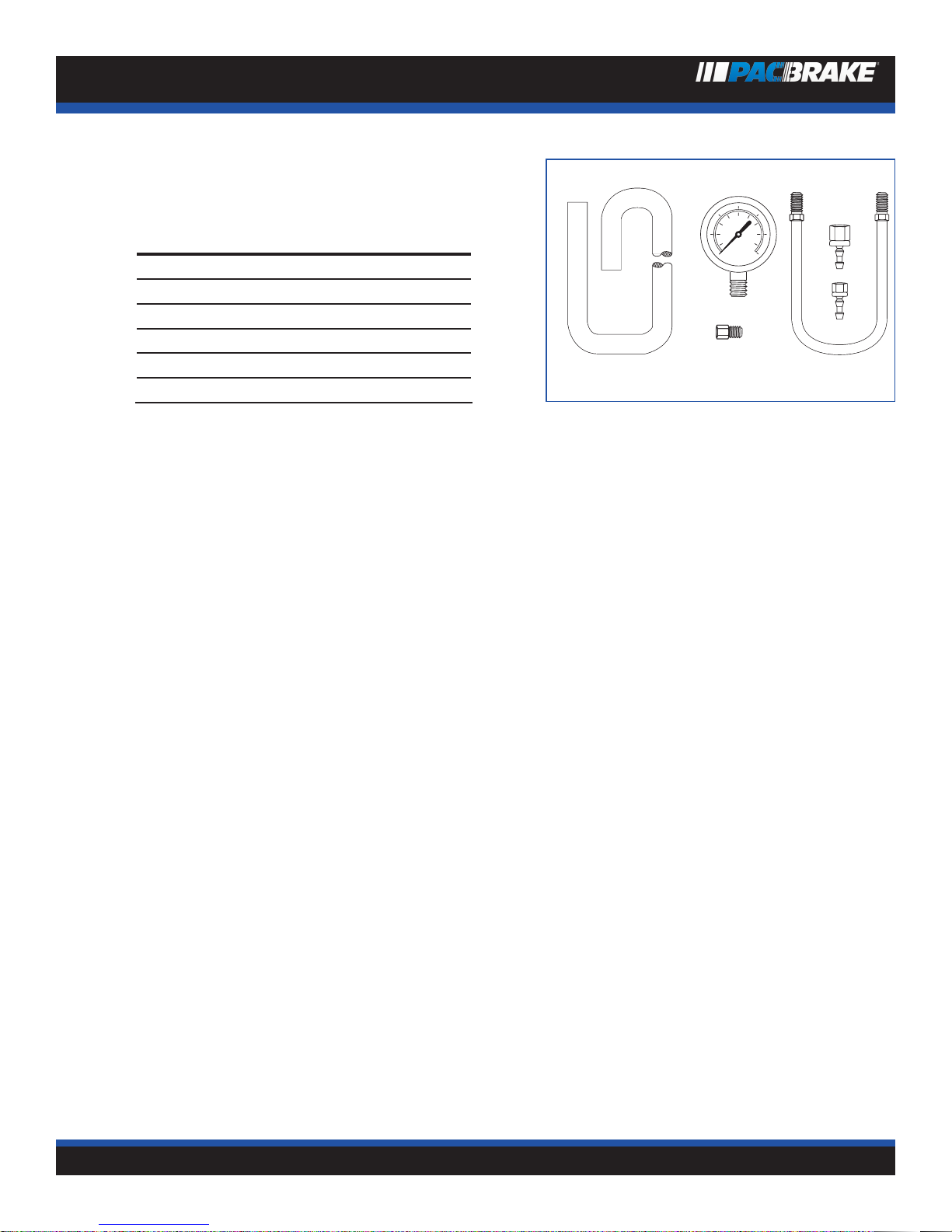

Prepare for road test check or set exhaust brake back pressure. Pacbrake test gauge kit PT# C10600, can be purchased through

the Pacbrake distribution system. This kit contains all the necessary parts to perform back pressure tests. The gauge used must be

a dampened (liquid filled) type to accurately read this pressure.

1. Remove the 1/8” NPT plug located in the exhaust brake body and install fitting #3. Install the steel tube #4 into the fitting

installed in the exhaust brake. Instert fittings #5 and #6 into the neoprene hose, moistening the fittings and firmly pushing

the hose onto the barbed end. Install one end of the hose to the steel tube and the other to the gauge. Tighten all fittings

securely. Route neoprene hose into cab.

Note: This test must be performed to ensure engine manufactures back pressure specifications are not ex-

ceeded - check the application guide for the correct maximum allowable PSI setting at governed speed.

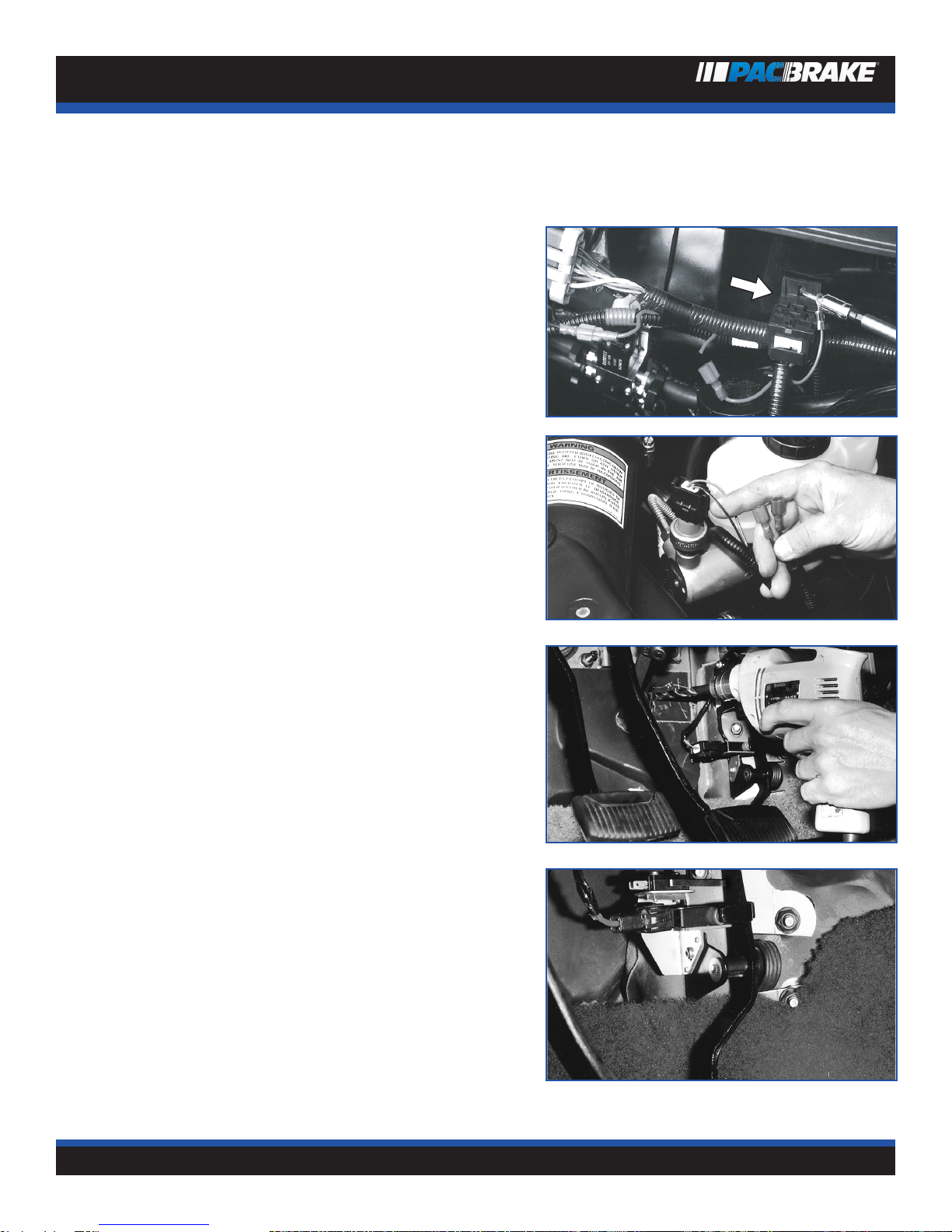

2. Warm the engine to normal operating temperature.

3. Road test the vehicle by providing long durations of maximum RPM with the exhaust brake applied. This is best achieved

with weight in the vehicle and a downhill grade.

4. .Read and record the pressure achieved on the gauge at the governed engine speed. Pacbrake inline models have an

adjustable stop bolt to adjust exhaust back pressure, This is done by the stop screw which limits the activating arm travel,

thus reducing back pressure.