9

1. To open the cover, turn the actuator knob clockwise 90o until it clicks in the open position. This retracts the latches

into the handle and the cover is free to roll open into the canister. A tug on the pull strap will release the latch and

allow the cover to lock into the rails.

2. To latch the cover in one of the mid-range positions, pull it back just beyond the position desired and allow the

cover to retract until it latches into place. Latching positions are located every 12 inches along the rails. The

clicking sound is the spring-loaded latches mounted inside the handle. The latches are designed to bypass the

latching positions as the cover is being closed and to stop the cover as it is being retracted.

3. To close the cover, pull on the

strap to draw it back toward the

tailgate. When it is within easy

reach, grasp the handle by the

hand grip and pull the cover to the

latching position against the

tailgate.

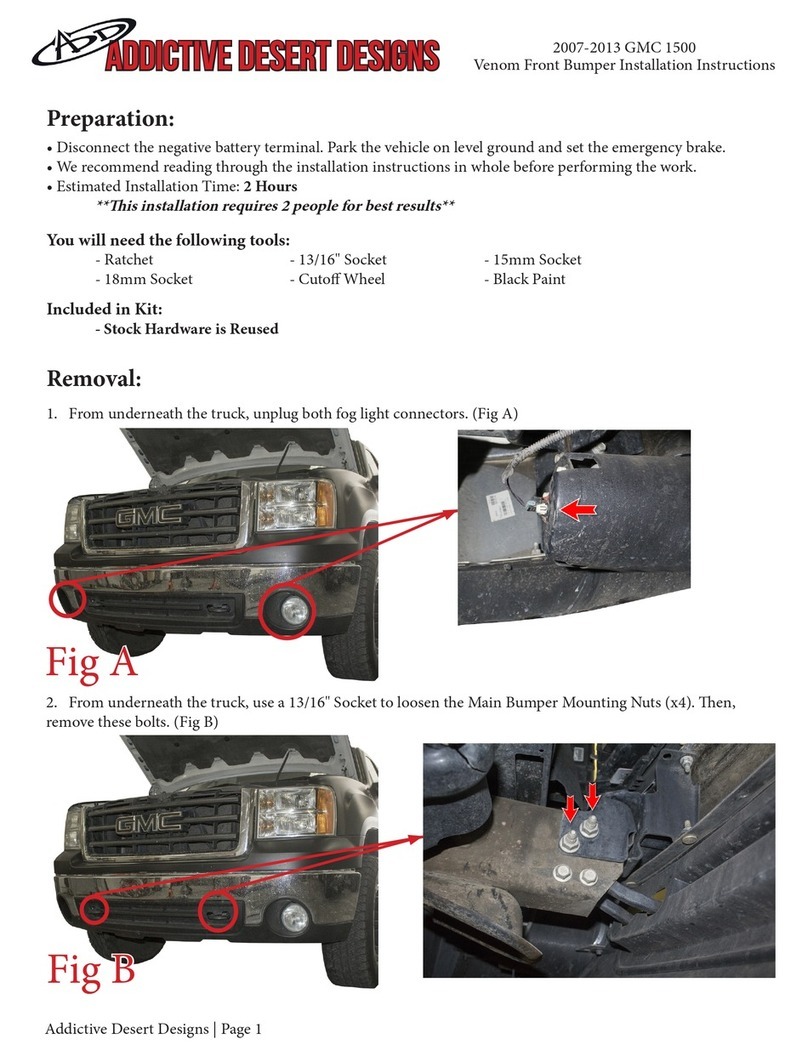

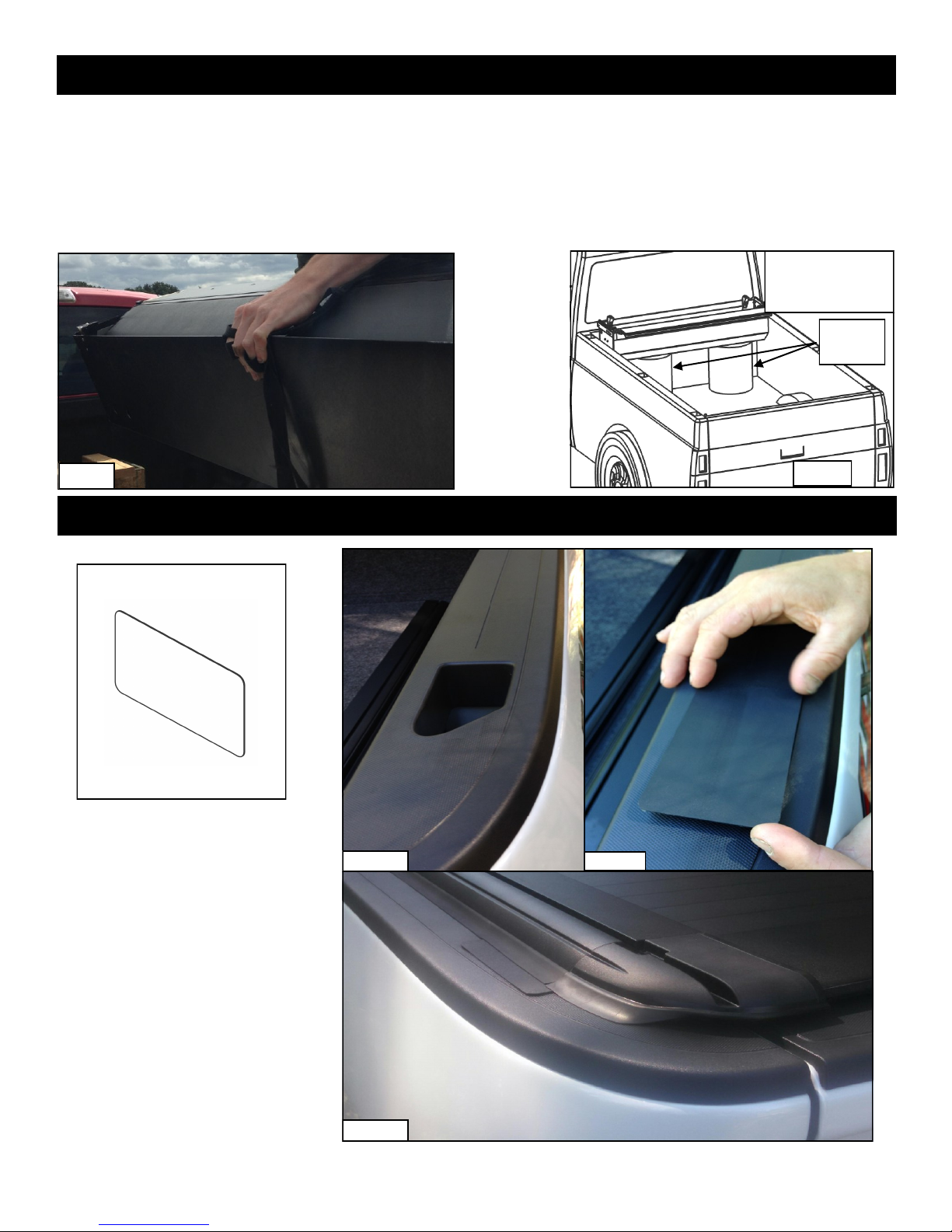

OPERATING INSTRUCTIONS

ACTUATOR KNOB PULL

STRAP

FIG 13A

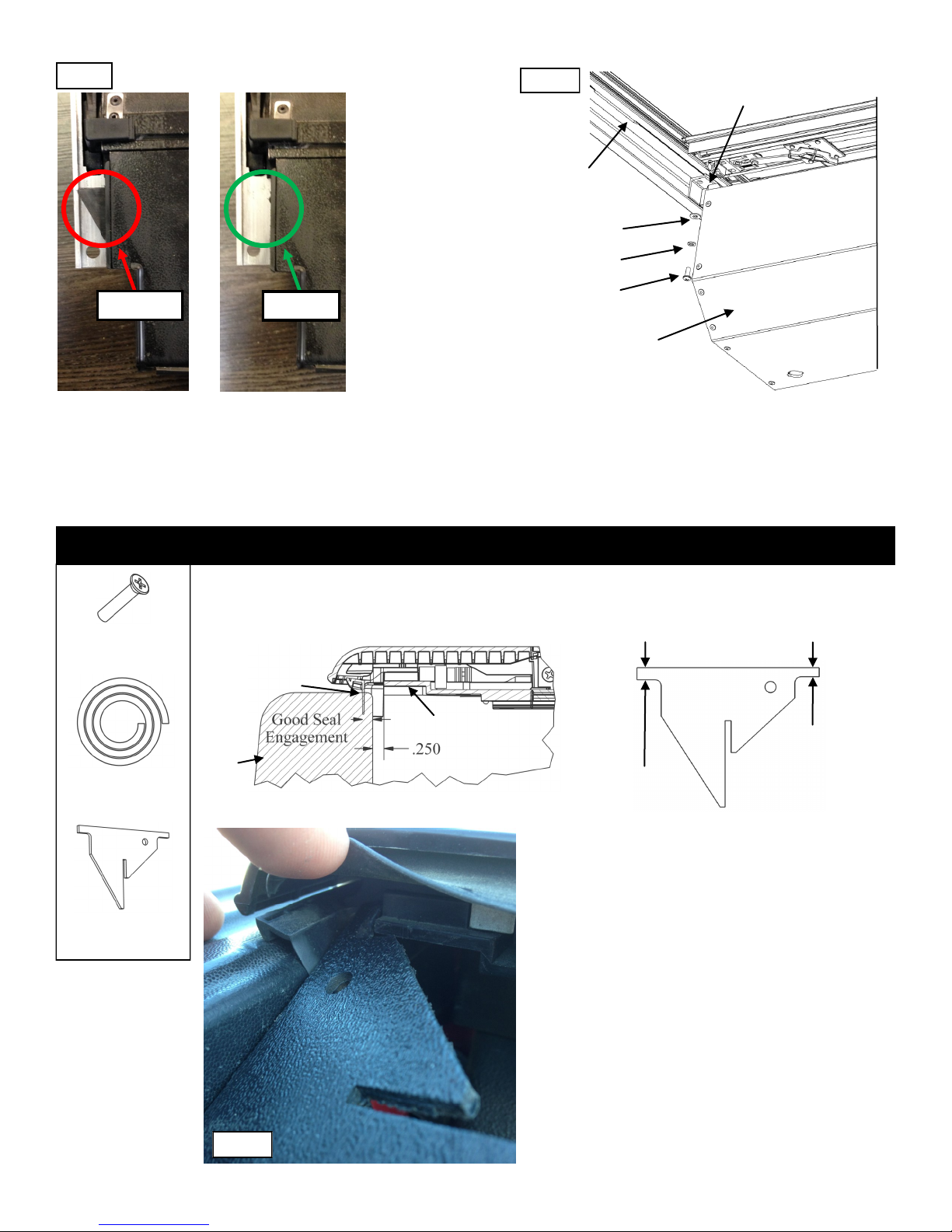

First, ensure that the Foam Washer is in place on the Drain Fitting as this

washer will help prevent water leakage. Next, test fit the drain tube to

determine the length you want to trim it. Always caution on the long side. Trim

the end that will be inserted through the truck bed using the wire cutters or a

utility knife.

With the cover opened, insert the drain tube fittings into the pre-drilled holes

on the underside of the canister by pushing them in place from under the

canister. Drain Fitting should click into place.

Place the other end of the drain tube through the plastic/rubber access port or

through the pre-drilled holes in the floor or the front wall of the truck bed. If

routing through the front wall, ensure that the drain tubes are inserted and

directed down so water flows out of the truck.

To remove the drain tubes reach under the canister, grab the drain tube fitting

and turn it while applying light downward pressure. When the retaining tabs

align with notches in the bottom of the canister the Drain Tube and Fitting will

drop out.

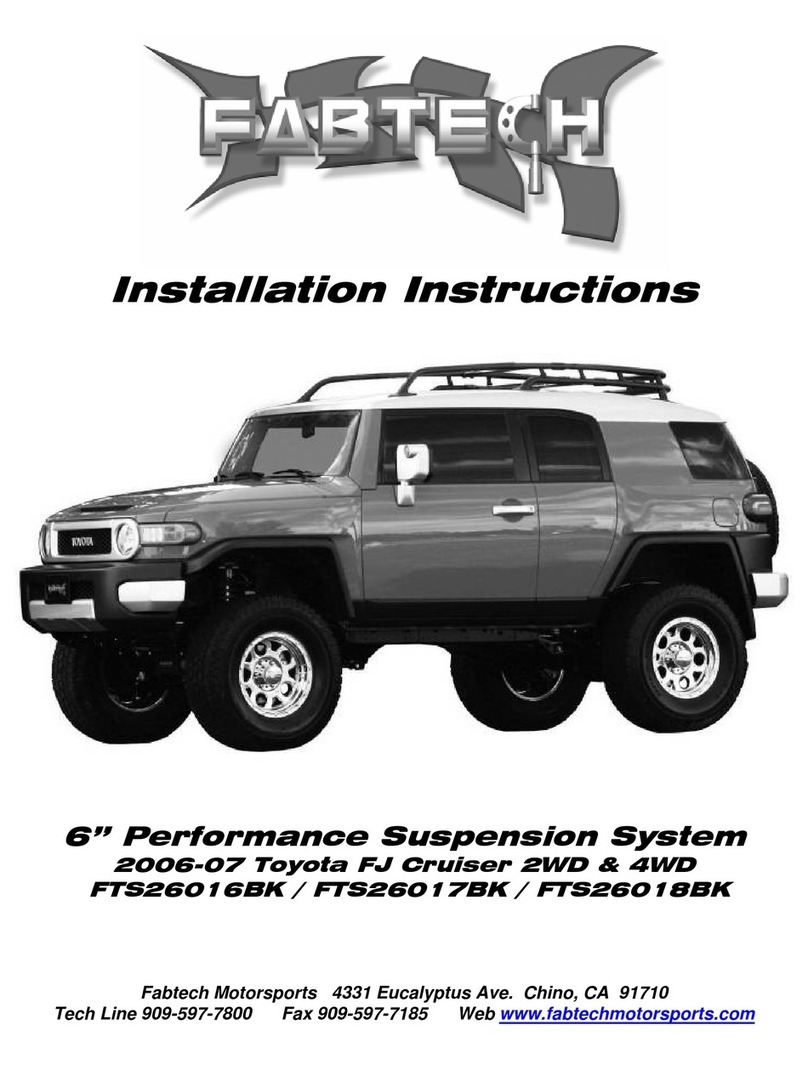

STEP 11: INSTALLING CANISTER DRAIN TUBES

Notch

Feature

Foam

Washer

Drain Fitting

Drain

Tube

FIG. 11A

Retract the cover the fully open position.

Attach the 4” Velcro strip onto the Velcro strip

already attached to the pull strap. Pull the pull

strap over to the driver’s side rail and remove

the tape from the 4” Velcro strip. Then apply the

Velcro strip onto the underside of the rail at your

desired position. This will hold the pull strap off

of the floor and out of the way when cargo is

being stored in the truck bed.

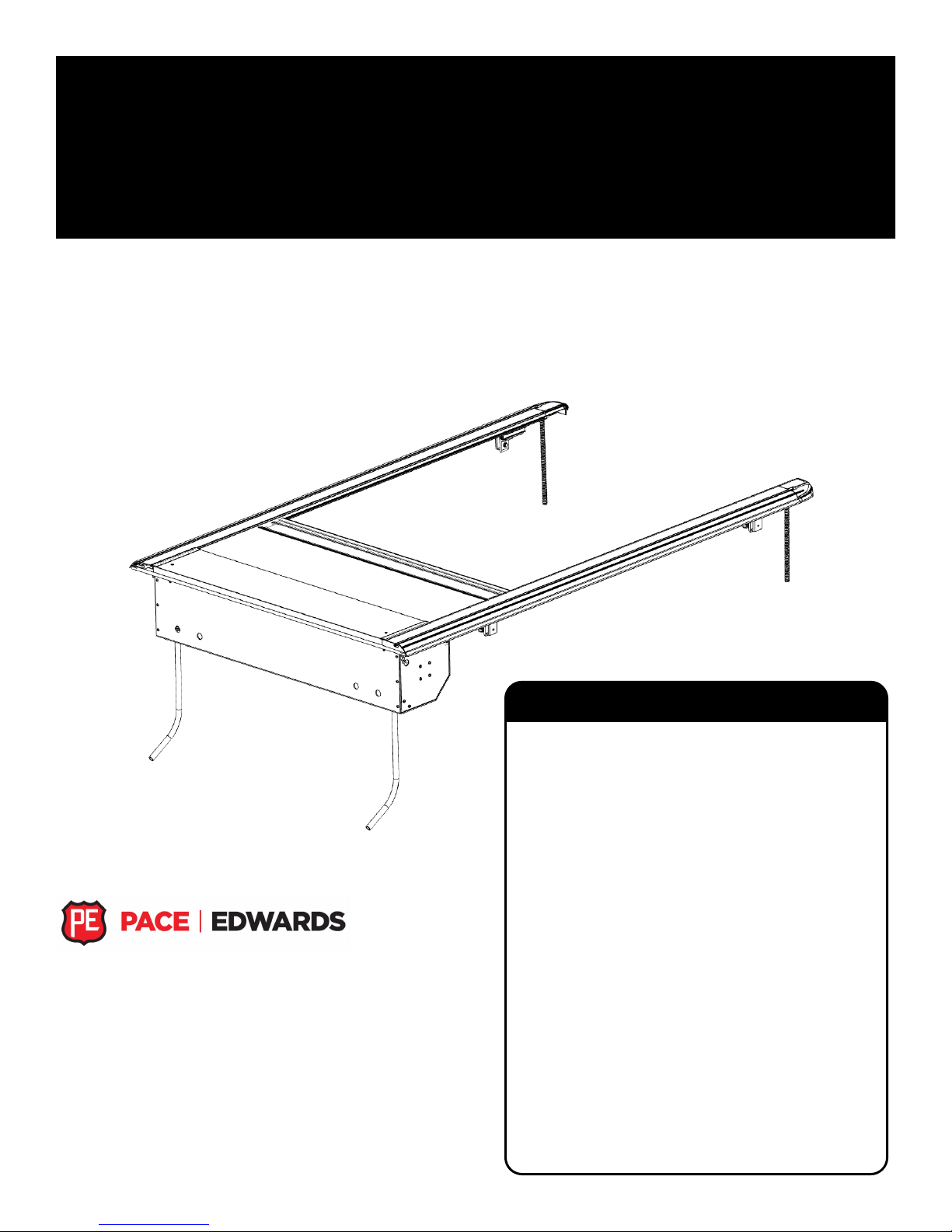

STEP 12: ATTACH THE PULL STRAP

4” VELCRO STRIP

FIG. 12A