iv

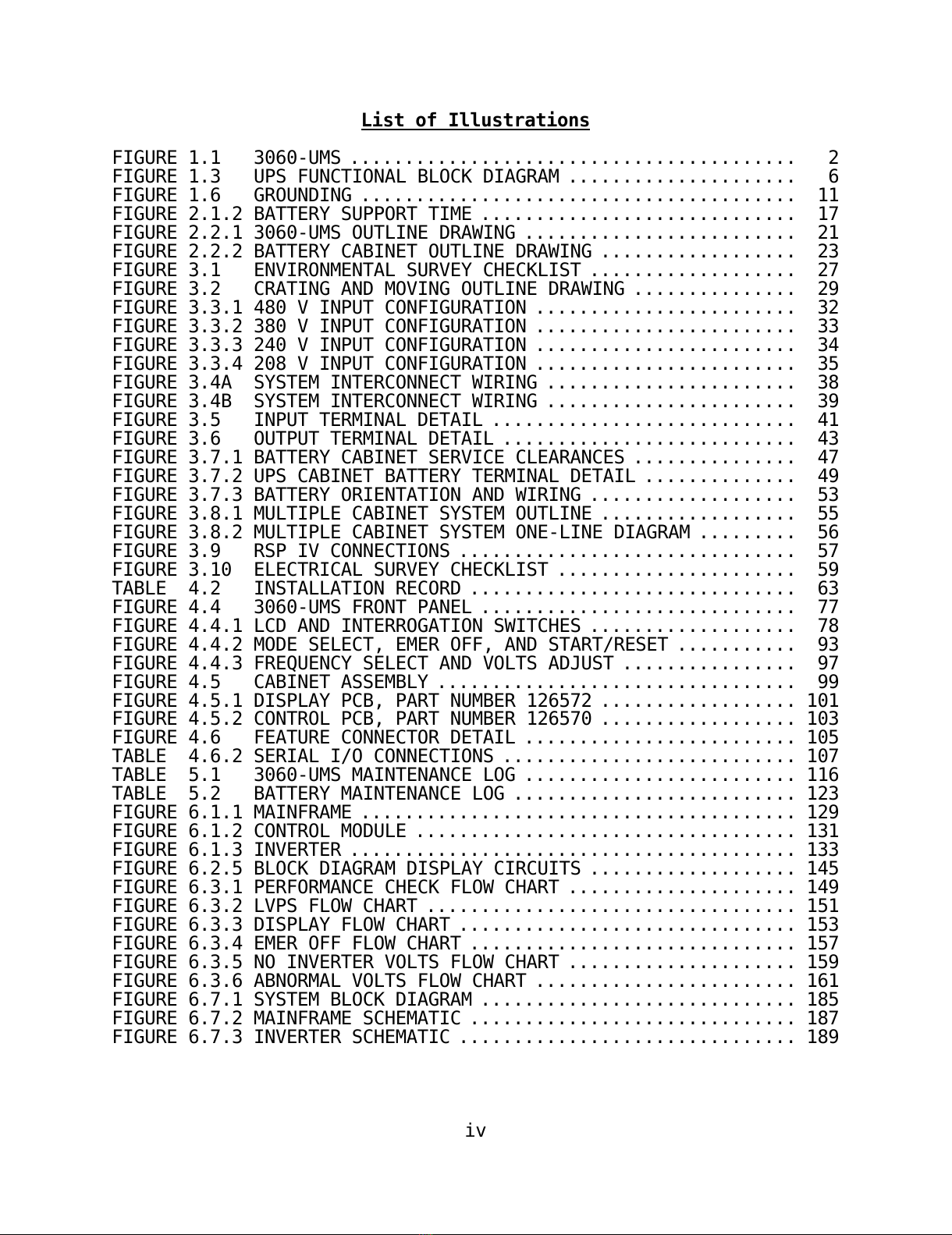

List of Illustrations

FIGURE 1.1 3060-UMS ......................................... 2

FIGURE 1.3 UPS FUNCTIONAL BLOCK DIAGRAM ..................... 6

FIGURE 1.6 GROUNDING ........................................ 11

FIGURE 2.1.2 BATTERY SUPPORT TIME ............................. 17

FIGURE 2.2.1 3060-UMS OUTLINE DRAWING ......................... 21

FIGURE 2.2.2 BATTERY CABINET OUTLINE DRAWING .................. 23

FIGURE 3.1 ENVIRONMENTAL SURVEY CHECKLIST ................... 27

FIGURE 3.2 CRATING AND MOVING OUTLINE DRAWING ............... 29

FIGURE 3.3.1 480 V INPUT CONFIGURATION ........................ 32

FIGURE 3.3.2 380 V INPUT CONFIGURATION ........................ 33

FIGURE 3.3.3 240 V INPUT CONFIGURATION ........................ 34

FIGURE 3.3.4 208 V INPUT CONFIGURATION ........................ 35

FIGURE 3.4A SYSTEM INTERCONNECT WIRING ....................... 38

FIGURE 3.4B SYSTEM INTERCONNECT WIRING ....................... 39

FIGURE 3.5 INPUT TERMINAL DETAIL ............................ 41

FIGURE 3.6 OUTPUT TERMINAL DETAIL ........................... 43

FIGURE 3.7.1 BATTERY CABINET SERVICE CLEARANCES ............... 47

FIGURE 3.7.2 UPS CABINET BATTERY TERMINAL DETAIL .............. 49

FIGURE 3.7.3 BATTERY ORIENTATION AND WIRING ................... 53

FIGURE 3.8.1 MULTIPLE CABINET SYSTEM OUTLINE .................. 55

FIGURE 3.8.2 MULTIPLE CABINET SYSTEM ONE-LINE DIAGRAM ......... 56

FIGURE 3.9 RSP IV CONNECTIONS ............................... 57

FIGURE 3.10 ELECTRICAL SURVEY CHECKLIST ...................... 59

TABLE 4.2 INSTALLATION RECORD .............................. 63

FIGURE 4.4 3060-UMS FRONT PANEL ............................. 77

FIGURE 4.4.1 LCD AND INTERROGATION SWITCHES ................... 78

FIGURE 4.4.2 MODE SELECT, EMER OFF, AND START/RESET ........... 93

FIGURE 4.4.3 FREQUENCY SELECT AND VOLTS ADJUST ................ 97

FIGURE 4.5 CABINET ASSEMBLY ................................. 99

FIGURE 4.5.1 DISPLAY PCB, PART NUMBER 126572 .................. 101

FIGURE 4.5.2 CONTROL PCB, PART NUMBER 126570 .................. 103

FIGURE 4.6 FEATURE CONNECTOR DETAIL ......................... 105

TABLE 4.6.2 SERIAL I/O CONNECTIONS ........................... 107

TABLE 5.1 3060-UMS MAINTENANCE LOG ......................... 116

TABLE 5.2 BATTERY MAINTENANCE LOG .......................... 123

FIGURE 6.1.1 MAINFRAME ........................................ 129

FIGURE 6.1.2 CONTROL MODULE ................................... 131

FIGURE 6.1.3 INVERTER ......................................... 133

FIGURE 6.2.5 BLOCK DIAGRAM DISPLAY CIRCUITS ................... 145

FIGURE 6.3.1 PERFORMANCE CHECK FLOW CHART ..................... 149

FIGURE 6.3.2 LVPS FLOW CHART .................................. 151

FIGURE 6.3.3 DISPLAY FLOW CHART ............................... 153

FIGURE 6.3.4 EMER OFF FLOW CHART .............................. 157

FIGURE 6.3.5 NO INVERTER VOLTS FLOW CHART ..................... 159

FIGURE 6.3.6 ABNORMAL VOLTS FLOW CHART ........................ 161

FIGURE 6.7.1 SYSTEM BLOCK DIAGRAM ............................. 185

FIGURE 6.7.2 MAINFRAME SCHEMATIC .............................. 187

FIGURE 6.7.3 INVERTER SCHEMATIC ............................... 189