10 Pacic Ventilation

Connection to power mains

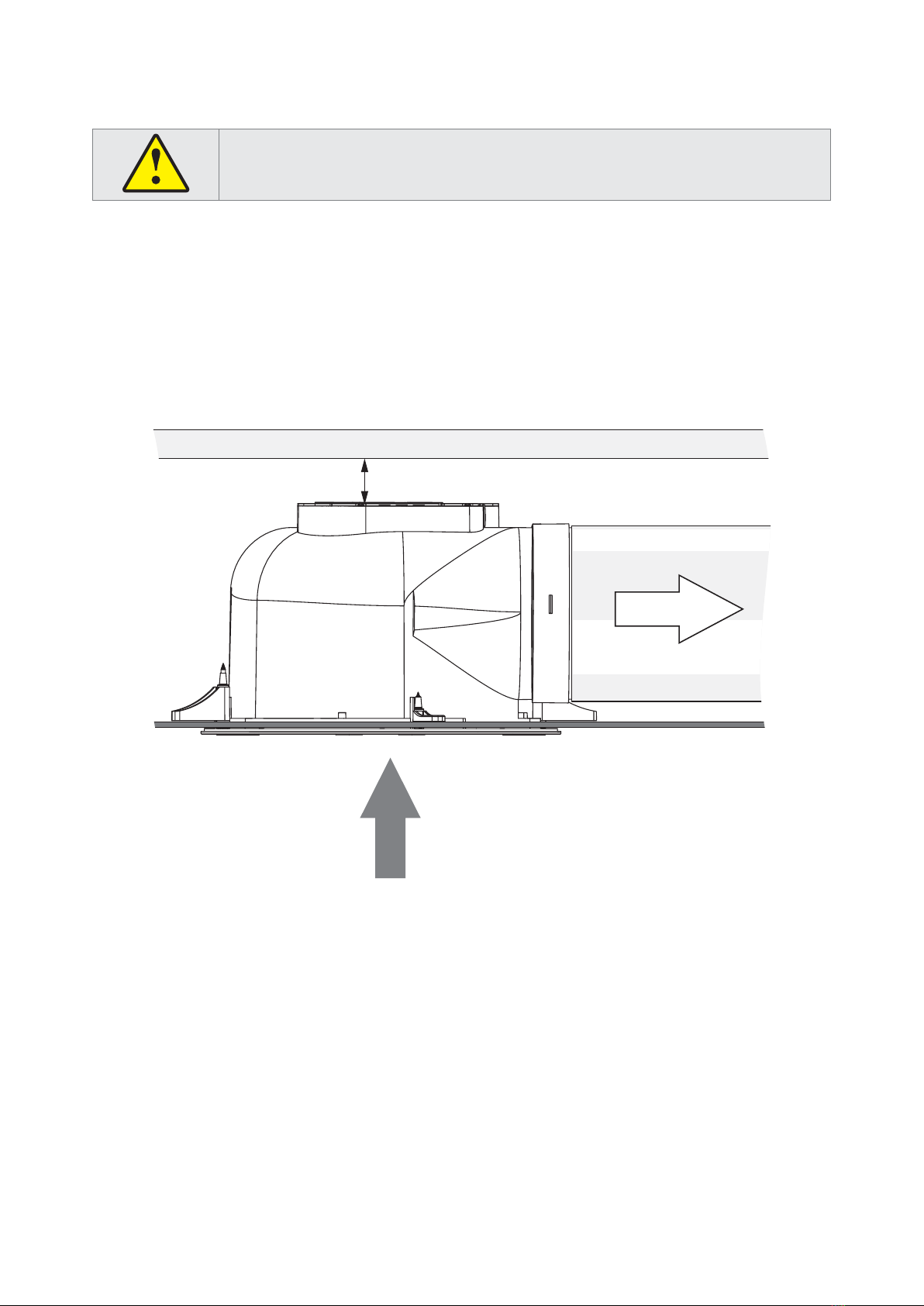

Power off the power supply prior to any operations with the unit.

The unit must be connected to power supply by a qualied electrician.

The rated electrical parameters of the unit are given on the Manufacturer’s label.

Any tampering with the internal connections is prohibited and will void the warranty

The fan is rated for connection to single-phase AC 220-240 V/50 (60) Hz.

The fan is connected to power mains with an electric plug through a QF circuit breaker with a magnetic trip integrated

into the xed wiring system.

The position of the automatic circuit breaker must ensure free access for quick power-off of the unit.

Wiring diagram of the fan

L

QF

L

N

N

S

N

QF

L

N

L

S1

S

N

QF

L

N

L

S1

Terminal designations on the wiring diagram: L – phase; N – neutral; S1 — switch; QF – automatic circuit breaker.

Electronics operation algorithm

Timer (T)

After turning on an external switch, such as a light switch, the fan turns on.

After the switch is turned off the fan keeps operating for a set turn-off delay time period, adjustable

from 0 to 30 minutes.

Humidity sensor (TH)

If the set humidity level in the room is exceeded from 60 % to 90 %, the fan turns on.

As the indoor humidity level drops down the fan keeps operating for a set turn-off delay time period, adjustable

from 0 to 30 minutes, and then turns off.

The fan delivery set includes a specially designed

plastic screwdriver for fan settings adjustments.

Use it to change the turn-on and turn-off delay time

and the humidity set point. H

60% 90%

T

2 min 30 min

— To adjust the fan turn-on delay time, turn the control knob Ton clockwise to increase and counter-clockwise

to decrease the turn-on delay time respectively, adjustable from 0 up to 2 minutes.

— To adjust the humidity set point, turn the control knob H clockwise to increase and counter-clockwise to decrease

the humidity sensor set point, adjustable from 60% up to 90%.

Do not use a metal screwdriver, knife, etc.

For adjustment operations not to damage the circuit board.