Contents

1EmStat development board features ................................................................................................. 2

Circuit protection ...................................................................................................................... 2

Power options .......................................................................................................................... 2

Communication options............................................................................................................ 3

Potentiostat interfaces .............................................................................................................. 3

Arduino Integration ................................................................................................................... 3

Other ........................................................................................................................................ 3

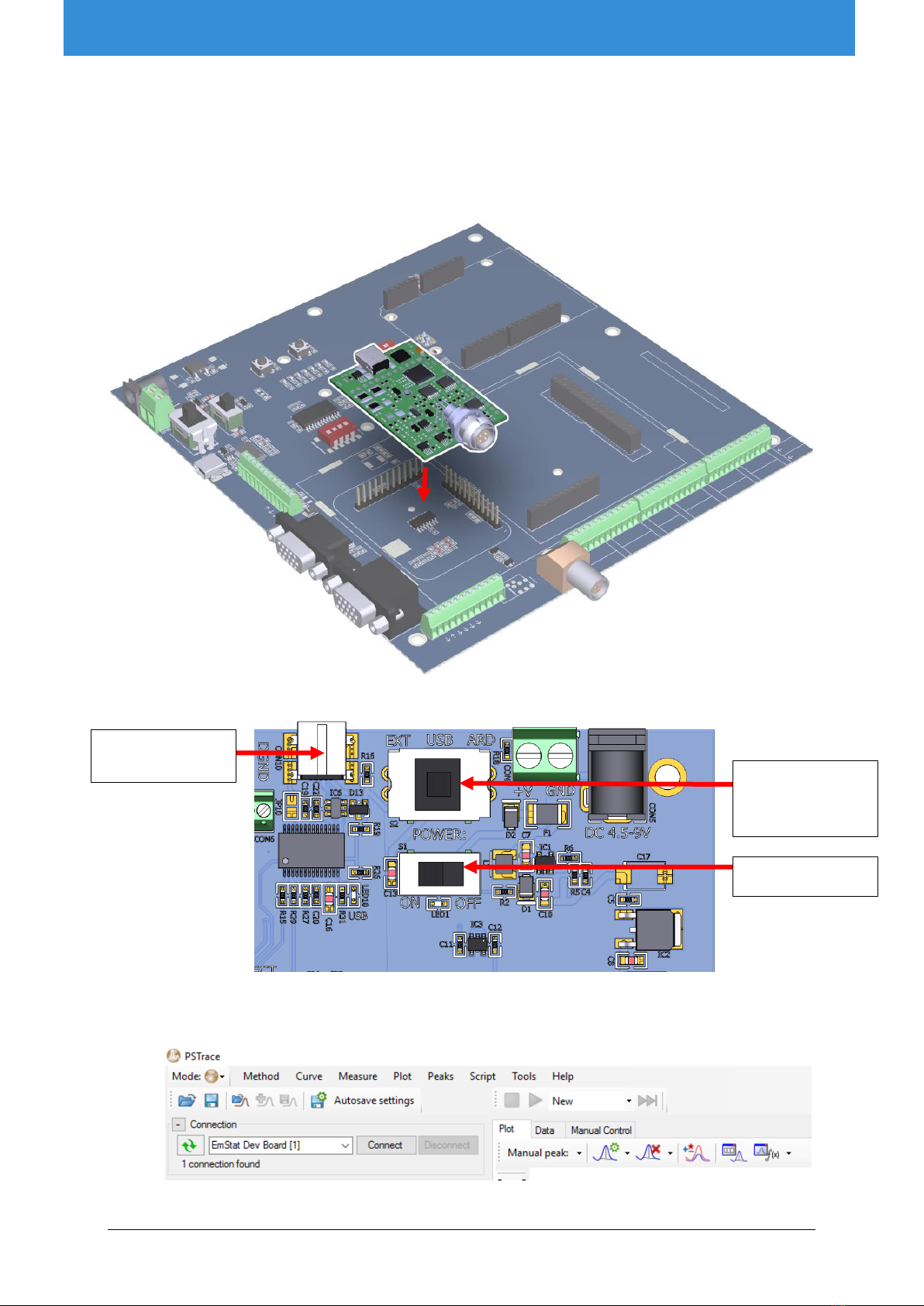

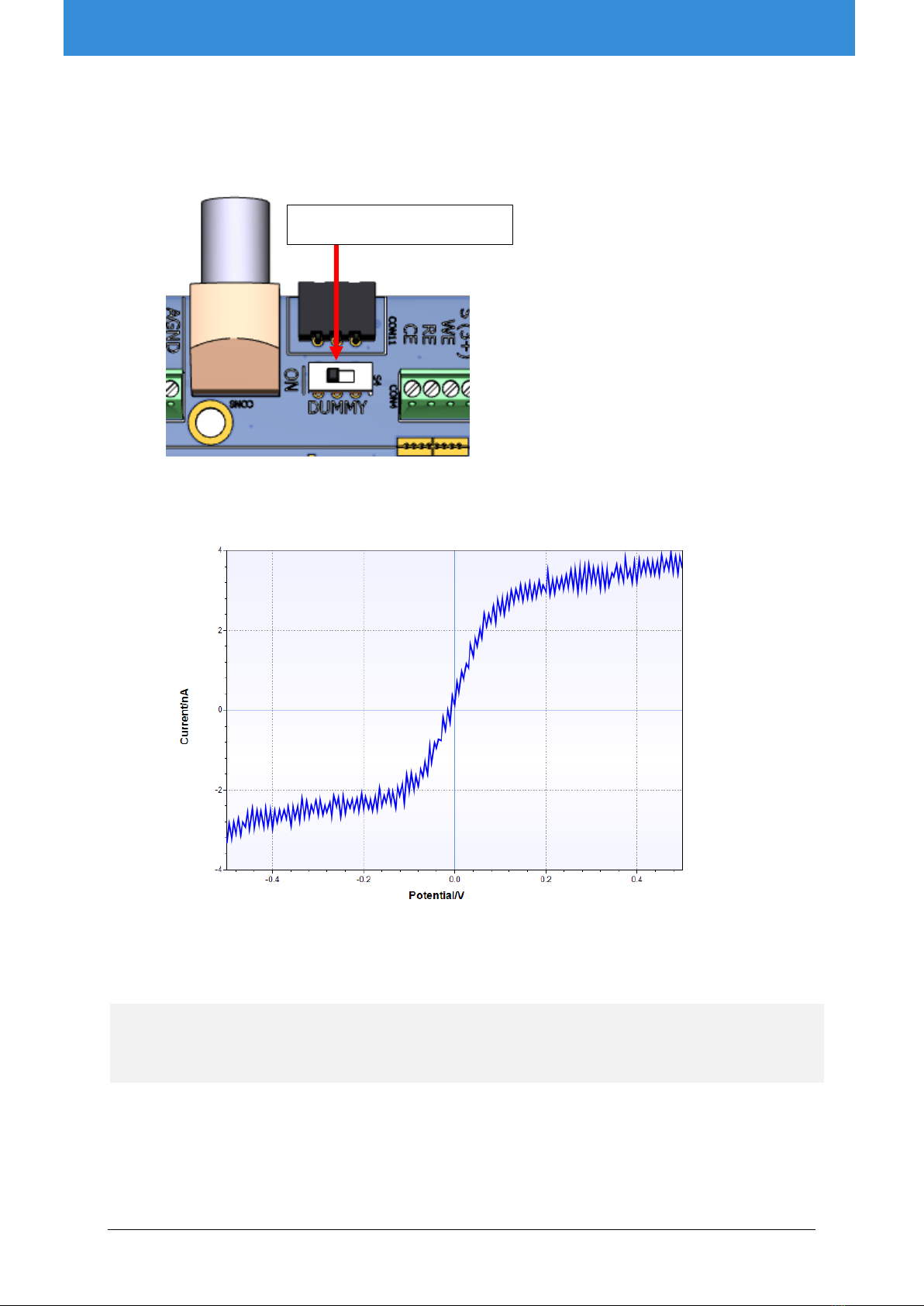

2First measurement using PSTrace ..................................................................................................... 4

3Getting started with the PalmSens Embedded SDK libraries ............................................................. 6

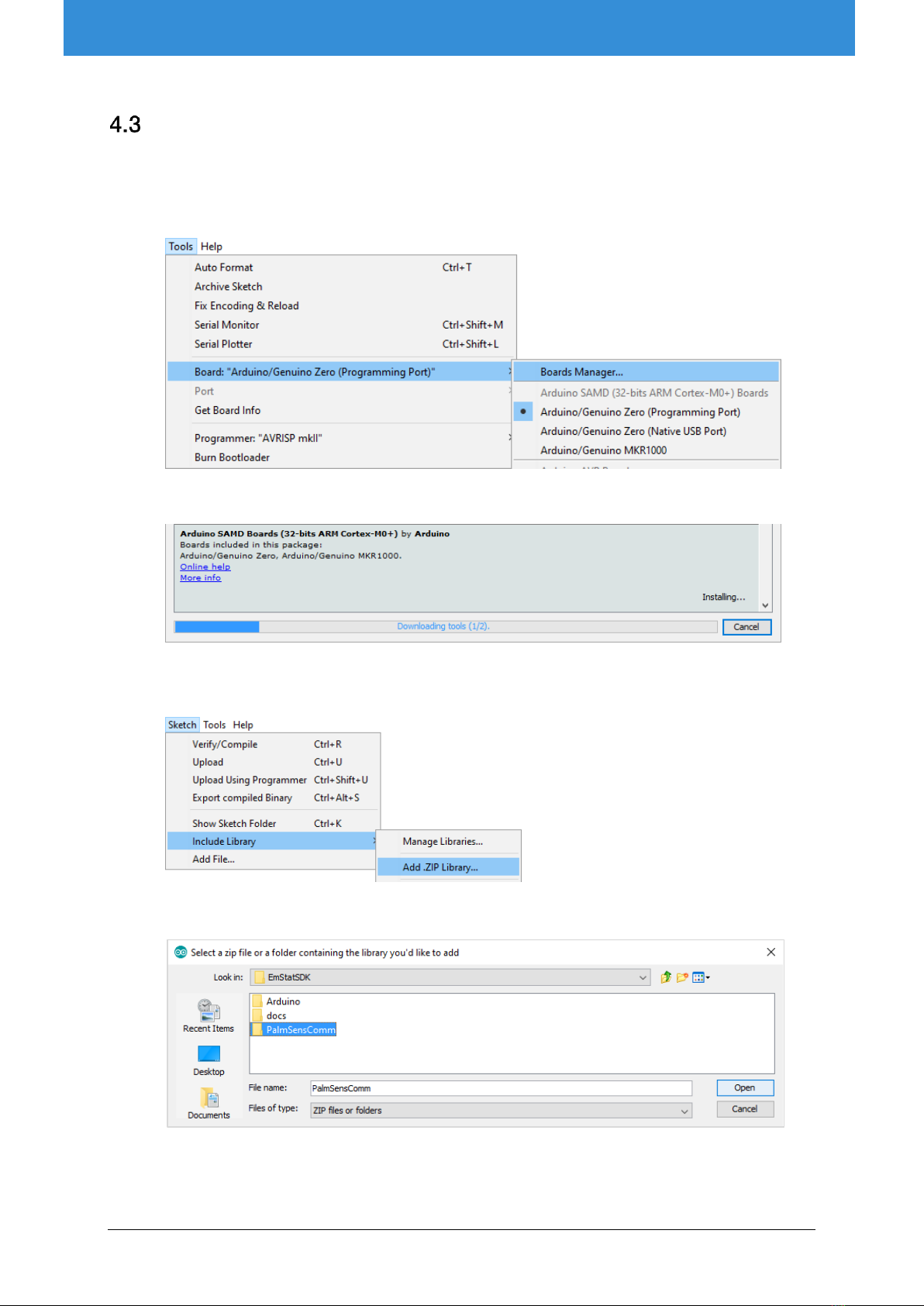

4Getting started with Arduino/Genuino................................................................................................ 7

Requirements ........................................................................................................................... 7

Preparing the EmStat dev. board for use with Arduino ............................................................. 7

Running the EmStat SDK Example for Arduino......................................................................... 8

4.3.1 Controlling the Arduino via terminal....................................................................................... 9

5Power supply options...................................................................................................................... 11

6Communication options .................................................................................................................. 11

PalmSens AUX pinout............................................................................................................. 12

RS232 communications ......................................................................................................... 12

Serial communication at TTL level........................................................................................... 12

7Pin descriptions............................................................................................................................... 13

Pinout of LEMO sensor socket (CON8)................................................................................... 13

Pinout of SPE connector (CON11) .......................................................................................... 13

CON4 pinout .......................................................................................................................... 13

CON5 pinout .......................................................................................................................... 14

8Adding a multiplexer........................................................................................................................ 15

9Noise considerations ....................................................................................................................... 16

Shielding can .......................................................................................................................... 16

10 Changing EmStat baudrate settings ............................................................................................ 17

11 Updating EmStat firmware........................................................................................................... 17

Programming the EmStat with custom firmware ..................................................................... 17

Updating the EmStat’s firmware via serial connection............................................................. 18

12 EmStat3 and EmStat3+ module specifications ............................................................................ 19

Appendix A: Change EmStat USB connection to virtual COM port ......................................................... 20