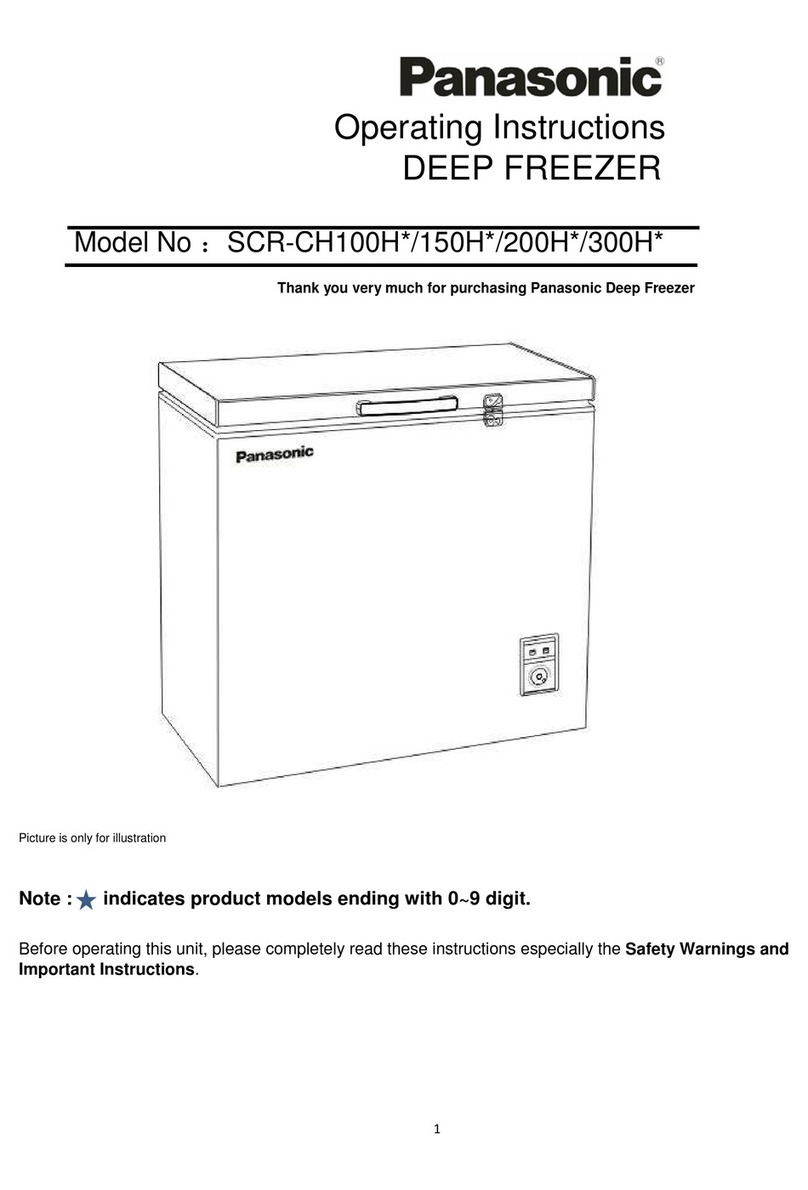

Panasonic SCR-CH100H User manual

Other Panasonic Freezer manuals

Panasonic

Panasonic MDF-U7586SC User manual

Panasonic

Panasonic MDF-DU702VH User manual

Panasonic

Panasonic MDF-U4186S Series User manual

Panasonic

Panasonic MDF-C8V1 Series User manual

Panasonic

Panasonic MDF-U7386S User manual

Panasonic

Panasonic MDF-237 User manual

Panasonic

Panasonic SCR-CH150H User manual

Panasonic

Panasonic MDF-U54V Series User manual

Panasonic

Panasonic MDF-U700VX-PB User manual

Panasonic

Panasonic MDF-136 Series User manual

Panasonic

Panasonic SCR-CH500H User manual

Panasonic

Panasonic MDF-U334 Series User manual

Panasonic

Panasonic MDF-137 Series User manual

Panasonic

Panasonic MDF-DU900V User manual

Panasonic

Panasonic MDF-U33V User manual

Panasonic

Panasonic MDF-DC700VX Series User manual

Panasonic

Panasonic MDF-U76VA User manual

Panasonic

Panasonic MDF-594C User manual

Panasonic

Panasonic MDF-U74V User manual

Panasonic

Panasonic MDF-U731 Series User manual