2

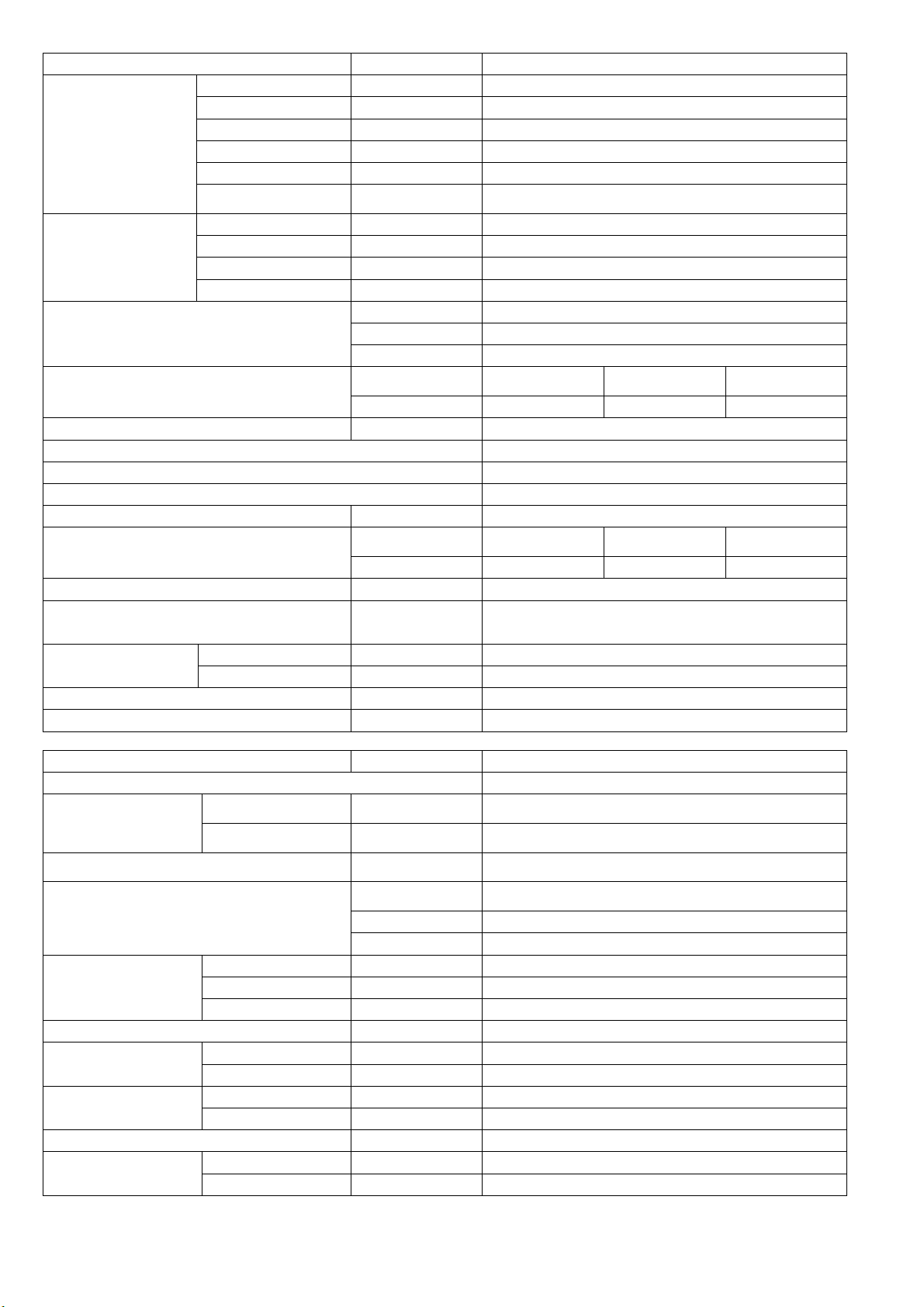

TABLE OF CONTENTS

PAGE PAGE

1.Safety Precautions ............................................. 4

2.Specifications ..................................................... 7

2.1WH-SDC03H3E5 WH-UD03HE5 ................... 7

2.2WH-SDC05H3E5 WH-UD05HE5 ................. 10

3.Features ............................................................. 13

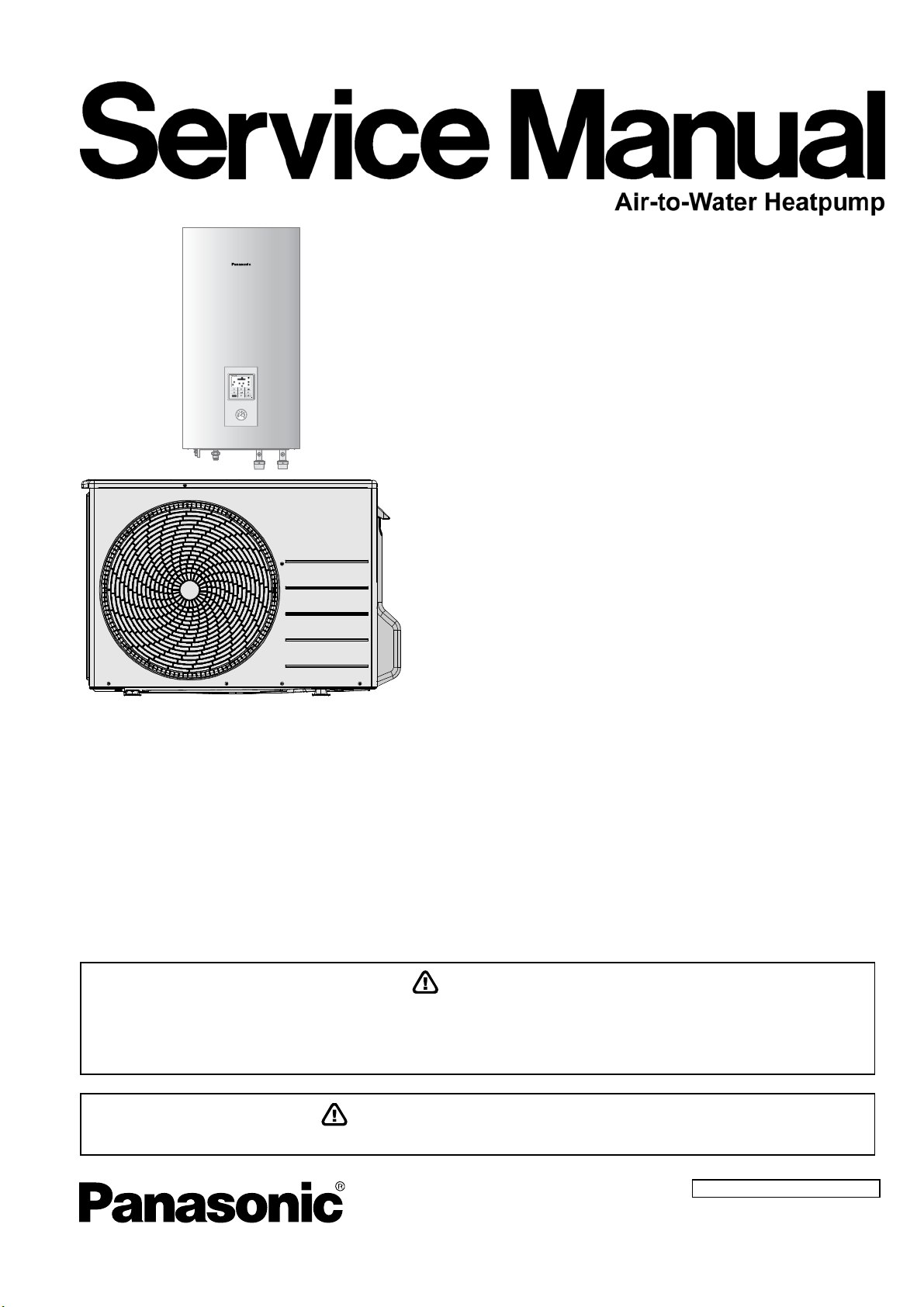

4.Location of Controls and Components .......... 14

4.1Indoor Unit ................................................... 14

4.2Outdoor Unit ................................................. 37

5.Dimensions ....................................................... 38

5.1Indoor Unit ................................................... 38

5.2Outdoor Unit ................................................. 39

6.Refrigeration and Water Cycle Diagram ........ 40

6.1Standard System (Optional PCB not

connected) ................................................... 41

6.2Advance System (Optional PCB connected) ...

.................................................................... 41

7.Block Diagram .................................................. 42

8.Wiring Connection Diagram ............................ 43

8.1Indoor Unit ................................................... 43

8.2Outdoor Unit ................................................. 44

9.Electronic Circuit Diagram .............................. 45

9.1Indoor Unit ................................................... 45

9.2Outdoor Unit ................................................. 46

10.Printed Circuit Board ....................................... 47

10.1Indoor Unit ................................................... 47

10.2Outdoor Unit ................................................. 49

11.Installation Instruction ..................................... 50

11.1Indoor Unit ................................................... 50

11.2Variation of system ...................................... 56

11.3System Installation ....................................... 67

11.4Outdoor Unit ................................................. 78

12.Operation and Control ..................................... 83

12.1Basic Function ............................................. 83

12.2Water Pump ................................................. 96

12.3Indoor Unit Safety ......................................100

12.4Auto Restart Control ..................................100

12.5Indication Panel .........................................100

12.6Indoor Back-Up Heater Control .................101

12.7Tank Heater Control ...................................103

12.8Base Pan Heater Control (Optional) ..........105

12.9Heater Turn ON/OFF priority Control .........105

12.10Force Heater Mode ....................................106

12.11Powerful Operation ....................................107

12.12Quiet Operation ..........................................107

12.13Sterilization Mode ......................................108

12.14Outdoor Ambient Thermo OFF Control .....109

12.15Alternative Outdoor Ambient Sensor Control ..

..................................................................110

12.16Force DHW mode ......................................110

12.17Anti Freeze Control ................................... 111

12.18Solar Operation (Optional) ........................ 112

12.19Boiler Bivalent Control .............................. 114

12.20External Room Thermostat Control (Optional)

................................................................. 116

12.21Three Ways Valve Control ........................ 117

12.22Two Ways Valve Control........................... 117

12.23External OFF/ON Control ......................... 118

12.24External Compressor Switch (Optional PCB) ..

................................................................. 119

12.25Heat/Cool Switch (Optional PCB) ............. 120

12.26SG Ready Control (Optional PCB) ........... 121

12.27Demand Control (Optional PCB) .............. 123

12.28Holiday Mode ............................................ 124

12.29Dry Concrete ............................................. 124

12.30Flow Sensor .............................................. 124

13.Protection Control ......................................... 125

13.1Protection Control for All Operations ........ 125

13.2Protection Control for Heating Operation.. 127

13.3Protection Control for Cooling Operation .. 128

14.Servicing Mode .............................................. 129

14.1How to Take Out Front Plate .................... 129

14.2Test Run ................................................... 129

14.3Expansion Vessel Pre Pressure Checking 129

14.4Pump Down Procedures ........................... 130

14.5How To Adjust Pump Speed ..................... 131

14.6How To Adjust Pump Speed ..................... 132

14.7How To Unlock Cool Mode ....................... 133

14.8EEPROM Factory Default Data Setup

Procedure ................................................. 134

14.9Dry Concrete Setup .................................. 135

15.Maintenance Guide........................................ 137

15.1Maintenance for Water Filter Set .............. 138

16.Troubleshooting Guide ................................. 140

16.1Refrigeration Cycle System ...................... 140

16.2Relationship between the Condition of the Air-

to-Water Heatpump Indoor and Outdoor Units

and Pressure and Electric Current ............ 141

16.3Breakdown Self Diagnosis Function ......... 142

16.4Error Codes Table ..................................... 144

16.5Self-diagnosis Method .............................. 146

17.Disassembly and Assembly Instructions ... 192

17.1To Remove Front Plate ............................. 192

17.2To Remove Pressure Gauge .................... 192

17.3To Open Control Board Cover .................. 193

17.4To Remove Control Panel ........................ 193

17.5To Remove RCCB .................................... 194

17.6To Remove Transformer and Electronic

Controller Board ........................................ 194

17.7To Open Control Board ............................. 195

17.8To Remove Pressure Relief Valve, Air Purge

Valve and Flow Sensor ............................. 195

17.9To Remove Water Pump and Bottle Complete

................................................................. 196

17.10To Remove Filter ...................................... 197