_NE-9970,-NE-9970C

NE-9870,

NE-9870C

Act”

(NHW)

:

NE-9970C

and

NE-9870C.

exposed

to

excessive

microwave

radiation.

appropriate

address

listed

below.

(808)

682-2851

IN

PUERTO

RICO

(416)

624-5010

original

design.

DURING

SERVICING

(A)

Do

not

operate

or

allow

the

oven

to

be

operated

with

the

door

open.

(B)

Make

the

following

safety

checks

on

all

ovens

to

be

serviced

before

activating

the

magnetron

or

other

microwave

source,

and

make

repairs

as

necessary:

(1)

Interlock

operation

(2)

Proper

door

closing

(3)

Seal

and

sealing

surfaces

(arcing,

wear,

and

other

damage)

(4)

Damage

to

or

loosening

of

hinges

and

latches

(5)

Evidence

of

dropping

or

abuse

(C)

Before

turning

on

microwave

power

for

any

service

test

or

inspection

within

the

microwave

generating

WARNING

1.

This

product

should

be

serviced

only

by

trained

qualified

personnel.

2.

Though

this

product

has

been

manufactured

in

compliance

with

:

“Federal

Performance

Standard

21

CFR

Subchapter

J”

(D.H.H.S.);

NE-9970

and

NE-9870

or

“Radiation

Emitting

Devices

It

is

very

important

all

repairs

should

be

made

in

accordance

with

procedures

described

in

this

manual

to

avoid

being

3.

Check

for

radiation

leakage

after

every

servicing

according

to

the

“Procedure

for

measuring

radiation

leakage”on

page

30.

4.

Any

serviceman

who

learns

of

any

accident

pertaining

to

microwave

radiation

leakage

should

immediately

notify

the

Matsushita

Engineering

and

Service

Company

IN

U.S.A.

(MESCO)

50

Meadowland

Parkway,

Secaucus,

New

Jersey

07094

Attention

:

Engineering

Support

Division.

(201)

348-7000

IN

HAWAII

PANASONIC

HAWAII,

INC.

(PHI)

91-238

Kauhi

St.

Ewa

Beach

P.O.

Box

774

Honolulu,

Hawaii

96808-0774

PANASONIC

SALES

COMPANY,

Division

of

(PSC)

Matsushita

Electric

of

Puerto

Rico,

Inc.

Ave.

65

De

Infanteria,

KM

9.7

Victoria

Industrial

Park

Carolina,

Puerto

Rico

00630

(809)

769-4320

IN

CANADA

Matsushita

Electric

of

Canada

Limited

(MELCA)

5770

Ambler

Drive,

Mississauga,

Ontario,

L4W

2T3

5.

There

are

special

components

used

in

the

microwave

oven

which

are

important

for

safety.

These

parts

are

shaded

on

the

schematic

diagram

and

marked

with

a

A\

on

the

replacement

parts

list.

It

is

essential

that

these

critical

parts

should

be

replaced

with

manufacturer's

specified

parts

to

prevent

microwave

leakage,

shock,

fire,

or

other

hazards.

Do

not

modify

the

PRECAUTIONS

TO

BE

OBSERVE

TO

AVOID

POSSIBLE

EXPOSURE

TO

EXCESSIVE

MICROWAVE

ENERGY

D

BEFORE

AND

compartments,

check

the

magnetron,

waveguide

or

transmission

line,

and

cavity

for

proper

alignment,

integrity

and

connections.

(D)

Any

defective

or

misadjusted

components

in

the

interlock,

monitor,

door

seal,

and

microwave

gen-

eration

and

transmission

systems

shail

be

repaired,

replaced,

or

adjusted

by

procedures

described

in

this

manual

before

the

oven

is

released

to

the

owner.

(E)

A

microwave

leakage

check

to

verify

compliance

with

the

Federal

Performance

Standard

should

be

performed

on

each

oven

prior

to

release

to

the

owner.

CONTENTS

(page)

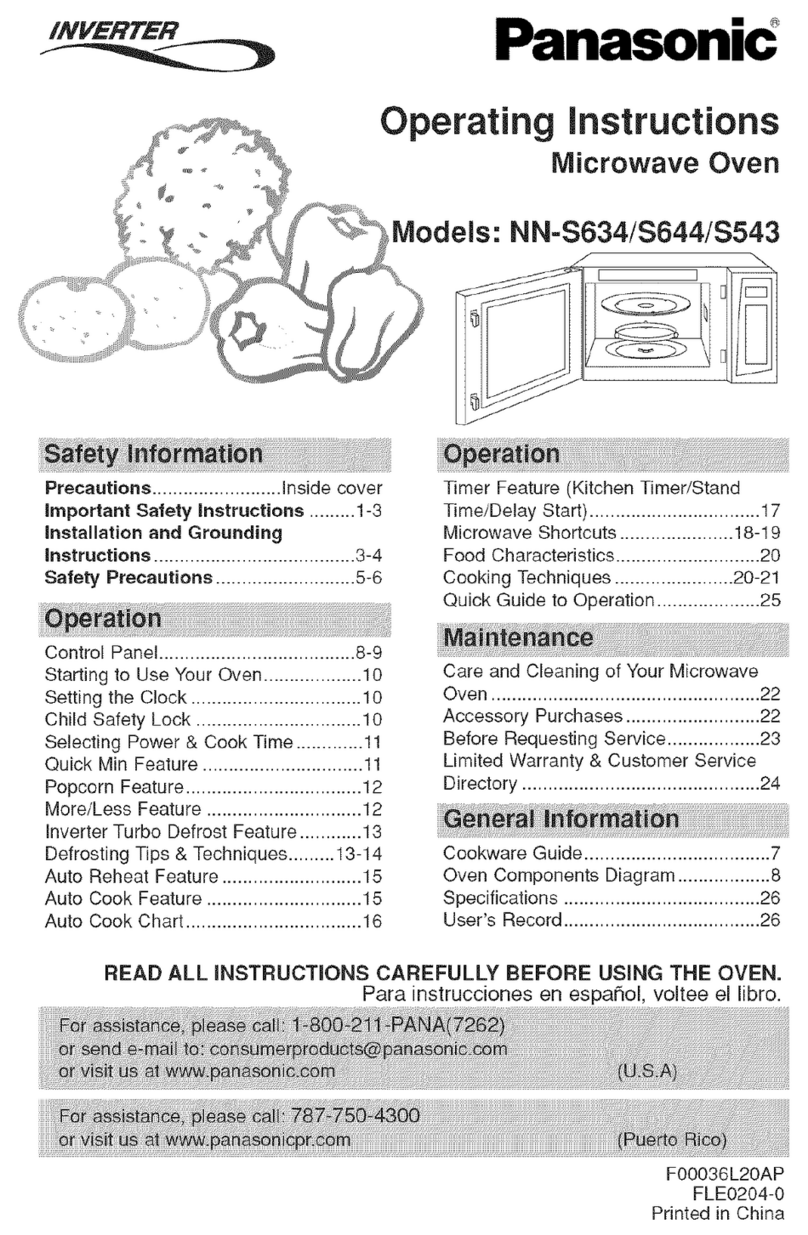

OPERATING

INSTRUCTIONS

=*-+++--1+10se+esseeessesceeeeeeseeretereeeeeneees

4

CAUTIONS

TO

BE

OBSERVED

WHEN

TROUBLESHOOTING:

«+--+

23

SCHEMATIC

DIAGRAM

(NE-9970,

NE-Q870)-+-+-+--+++-+++e-seseeeeeeeeenens

14

DISASSEMBLY

AND

PARTS

REPLACEMENT

PROCEDURE:*

««-+--=-:

24

SCHEMATIC

DIAGRAM

(NE-9970C,

NE-9870C)

so

veie

einai’

docwacsleincie

dhe

seus

15

COMPONENT

TEST

PROCEDURE

<::seeceeceeersssseectecceeveeesens

wteutenes

7

WIRING

DIAGRAM

(NE-9970,

NE-9870)

USiae

sold

asieeleieies

oeieaie

ad

ala

Sbaea

ed

es

Vese's

16

MEASUREMENTS

AND

ADJUSTMENTS:

itccceeeseseseeeeseneeees

eeteeneas

29

WIRING

DIAGRAM

(NE-9970C,

NE-Q870C)-++-++-+++++2+0+eeseseeeeeeeeetens

17

PROCEDURE

FOR

MEASURING

RADIATION

LEAKAGE

----+++<22+e+

30

DESCRIPTION

OF

OPERATING

SEQUENCE

-eseses

eee

ec

eceeeeeeeeeseteeeee

18

TROUBLESHOOTING

GUIDE

ret

ese

ecceceddiecaniisdesstececcrhedecs

(arses

Sate

31

AUTO

SENSOR

EXPLANATION,

DIGITAL

PROGRAMMER

CIRCUIT

TEST

PROCEDURE

:::::-::

genet

37

K

FACTORS

AND

POWER

LEVELS

0

revssesecereecceeetereeeeereececeneeseesees

22

EXPLODED

VIEW

AND

PARTS

LIST

«cee

cere

cere

eceeceeeenecee

teen

eee

wr

tee

eaee

43