2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

2 Warning --------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

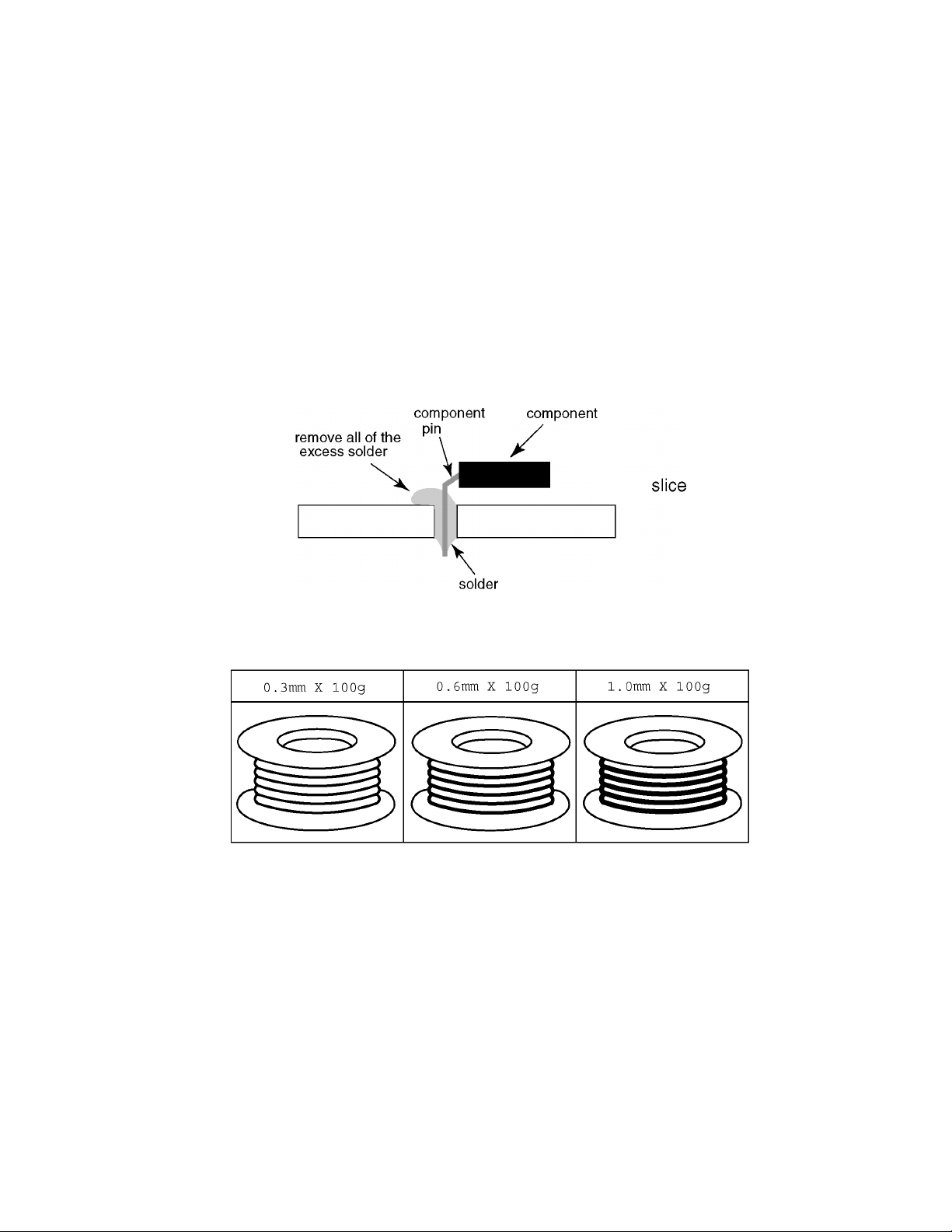

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

3.1. Service Hint--------------------------------------------------6

3.2. Applicable signals ------------------------------------------7

4 Specifications ------------------------------------------------------8

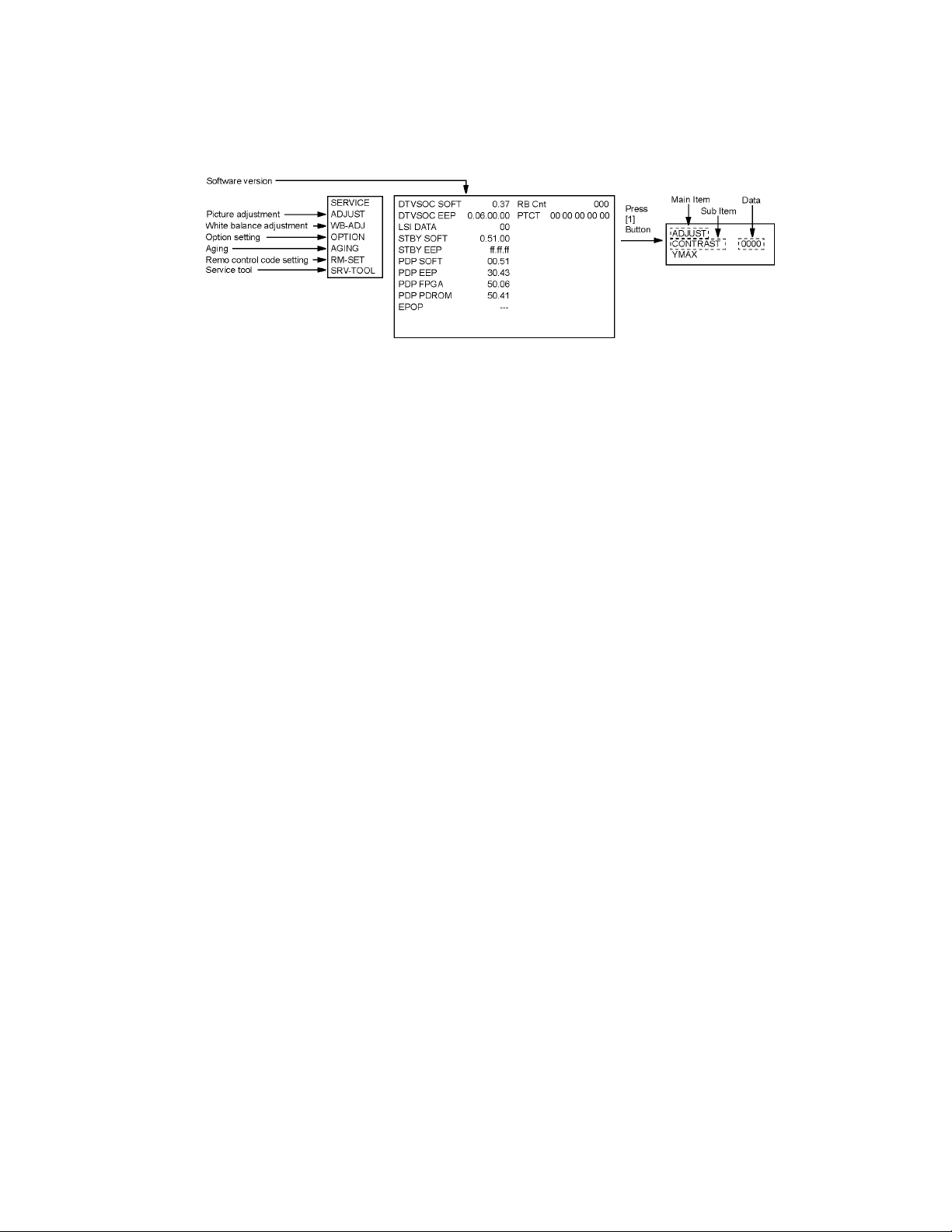

5 Service Mode -------------------------------------------------------9

5.1. How to enter into Service Mode ------------------------9

5.2. Service tool mode ---------------------------------------- 11

5.3. Hotel mode------------------------------------------------- 12

6 Troubleshooting Guide---------------------------------------- 13

6.1. Check of the IIC bus lines------------------------------ 13

6.2. Power LED Blinking timing chart --------------------- 14

6.3. No Power--------------------------------------------------- 15

6.4. No Picture -------------------------------------------------- 16

6.5. Local screen failure -------------------------------------- 17

7 Service Fixture & Tools --------------------------------------- 18

7.1. SC jig -------------------------------------------------------- 18

8 Disassembly and Assembly Instructions --------------- 19

8.1. Remove the Rear cover -------------------------------- 19

8.2. Remove the Fan------------------------------------------ 19

8.3. Remove the P-Board ------------------------------------ 19

8.4. Remove the Side terminal cover and Rear

terminal cover --------------------------------------------- 20

8.5. Remove the Tuner unit --------------------------------- 20

8.6. Remove the A-Board ------------------------------------ 20

8.7. Remove the Speakers ---------------------------------- 21

8.8. Remove the Control button unit ---------------------- 21

8.9. Remove the GK-Board --------------------------------- 21

8.10. Remove the SU-Board---------------------------------- 21

8.11. Remove the SD-Board---------------------------------- 22

8.12. Remove the SC-Board---------------------------------- 22

8.13. Remove the SS2-Board -------------------------------- 22

8.14. Remove the SS3-Board -------------------------------- 23

8.15. Remove the SS-Board ---------------------------------- 23

8.16. Remove the Support metal (C) ----------------------- 23

8.17. Remove the Support metals (L, R) ------------------ 23

8.18. Remove the Vertical bar-down assy----------------- 24

8.19. Remove the C1-Board ---------------------------------- 24

8.20. Remove the C2-Board ---------------------------------- 24

8.21. Remove the C3-Board ---------------------------------- 25

8.22. Remove the Plasma panel section from the

Cabinet assy (glass)------------------------------------- 25

8.23. Remove the Glass holders ---------------------------- 25

8.24. Remove the Rear cover fix holders------------------ 26

8.25. Remove the S-Board ------------------------------------ 26

8.26. Remove the K-Board ------------------------------------ 27

8.27. Replace the plasma panel ----------------------------- 27

9 Measurements and Adjustments -------------------------- 28

9.1. Adjustment Procedure ---------------------------------- 28

9.2. Adjustment ------------------------------------------------- 31

10 Block Diagram --------------------------------------------------- 33

10.1. Main Block Diagram ------------------------------------- 33

10.2. Block (1/4) Diagram ------------------------------------- 34

10.3. Block (2/4) Diagram ------------------------------------- 35

10.4. Block (3/4) Diagram ------------------------------------- 36

10.5. Block (4/4) Diagram ------------------------------------- 37

11 Wiring Connection Diagram -------------------------------- 39

11.1. Caution statement. -------------------------------------- 39

11.2. Wiring (1) -------------------------------------------------- 39

11.3. Wiring (2) -------------------------------------------------- 40

11.4. Wiring (3) -------------------------------------------------- 41

11.5. Wiring (4) -------------------------------------------------- 42

12 Schematic Diagram -------------------------------------------- 43

12.1. Schematic Diagram Note ------------------------------ 43

12.2. P(MULTI)-Board Schematic Diagram--------------- 44

12.3. P(SUS)-Board Schematic Diagram ----------------- 45

12.4. GK, K and S-Board Schematic Diagram----------- 46

12.5. A-Board (1/15) Schematic Diagram----------------- 47

12.6. A-Board (2/15) Schematic Diagram----------------- 48

12.7. A-Board (3/15) Schematic Diagram----------------- 49

12.8. A-Board (4/15) Schematic Diagram----------------- 50

12.9. A-Board (5/15) SchematicDiagram----------------- 51

12.10. A-Board (6/15) Schematic Diagram----------------- 52

12.11. A-Board (7/15) Schematic Diagram----------------- 53

12.12. A-Board (8/15) Schematic Diagram----------------- 54

12.13. A-Board (9/15) Schematic Diagram----------------- 55

12.14. A-Board (10/15) Schematic Diagram --------------- 56

12.15. A-Board (11/15) Schematic Diagram --------------- 57

12.16. A-Board (12/15) Schematic Diagram --------------- 58

12.17. A-Board (13/15) Schematic Diagram --------------- 59

12.18. A-Board (14/15) Schematic Diagram --------------- 60

12.19. A-Board (15/15) Schematic Diagram --------------- 61

12.20. C1-Board (1/2) Schematic Diagram ---------------- 62

12.21. C1-Board (2/2) Schematic Diagram ---------------- 63

12.22. C2-Board (1/2) Schematic Diagram ---------------- 64

12.23. C2-Board (2/2) Schematic Diagram ---------------- 65

12.24. C3-Board (1/2) Schematic Diagram ---------------- 66

12.25. C3-Board (2/2) Schematic Diagram ---------------- 67

12.26. SC-Board (1/4) Schematic Diagram ---------------- 68

12.27. SC-Board (2/4) Schematic Diagram ---------------- 69

12.28. SC-Board (3/4) Schematic Diagram ---------------- 70

12.29. SC-Board (4/4) Schematic Diagram ---------------- 71

12.30. SS-Board (1/2) Schematic Diagram ---------------- 72

12.31. SS-Board (2/2), SS2-Board and SS3-Board

Schematic Diagram ------------------------------------- 73

13 Printed Circuit Board------------------------------------------ 74

13.1. P(MULTI)-Board------------------------------------------ 74

13.2. P(SUS)-Board -------------------------------------------- 77

13.3. GK, K and S-Board-------------------------------------- 79

13.4. A-Board ---------------------------------------------------- 80

13.5. C1-Board--------------------------------------------------- 82

13.6. C2-Board--------------------------------------------------- 83

13.7. C3-Board--------------------------------------------------- 84

13.8. SC-Board -------------------------------------------------- 85

13.9. SS-Board -------------------------------------------------- 87

13.10. SS2 and SS3-Board ------------------------------------ 89

14 Exploded View and Replacement Parts List----------- 91

14.1. Exploded View and Mechanical Replacement

Parts List --------------------------------------------------- 91

14.2. Electrical Replacement Parts List ------------------- 97