FOCUS HE SLIMLINE Users Instructions

SECTION ONE Important Information Continued

INTRODUCTION

The FOCUS HE SLIMLINE incorporates a single gas control, which selects ignition pilot, and main

burner low and high settings.

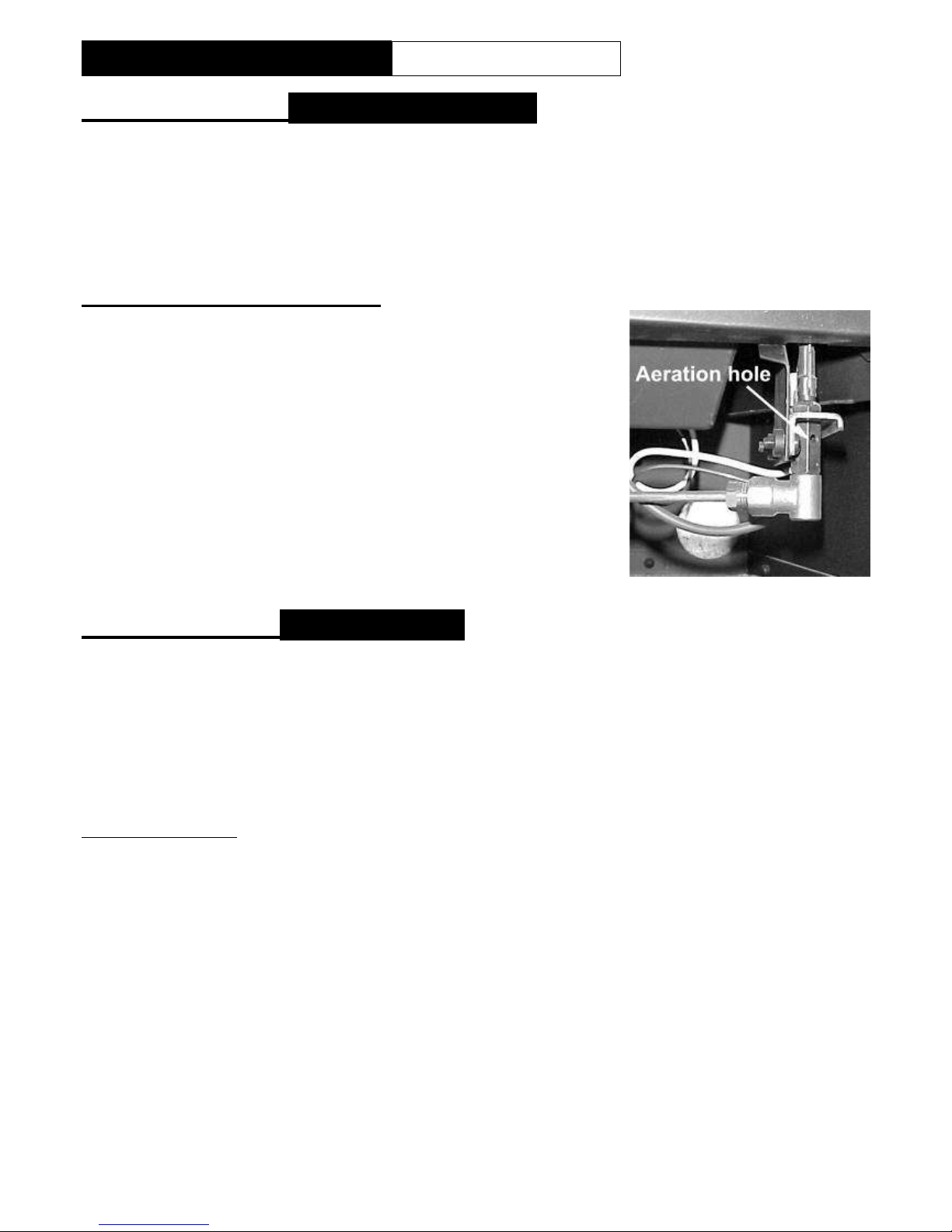

The appliance incorporates a safety device in the form of an Oxygen Depletion System, which

constantly monitors the oxygen in the room and will cause the fire to switch off if the oxygen level

reduces, for instance due to insufficient ventilation or a blocked flue.

If this regularly occurs do not attempt to relight the appliance until a qualified engineer has checked it,

the problem may not be due to lack of air or a defective flue.

A fire front (fret) must be used with this appliance.

In GB, the appliance must be installed by a competent person i.e. CORGI-registered, in accordance

with the GAS SAFETY (INSTALLATION AND USE) REGULATIONS, The Building Regulations (or

The Building Regulations (Scotland) or The Building Regulations (Northern Ireland)) and The Current

I.E.E. Wiring Regulations, if appropriate.

In IE, the appliance must be installed by a competent person and installed in accordance with the

current edition of I.S.813 Domestic Gas Installation, the current Building Regulations and the current

ETCI rules for electrical installation, if appropriate.

The pilot can be left on or the pilot can be extinguished and relit each time the fire is used.

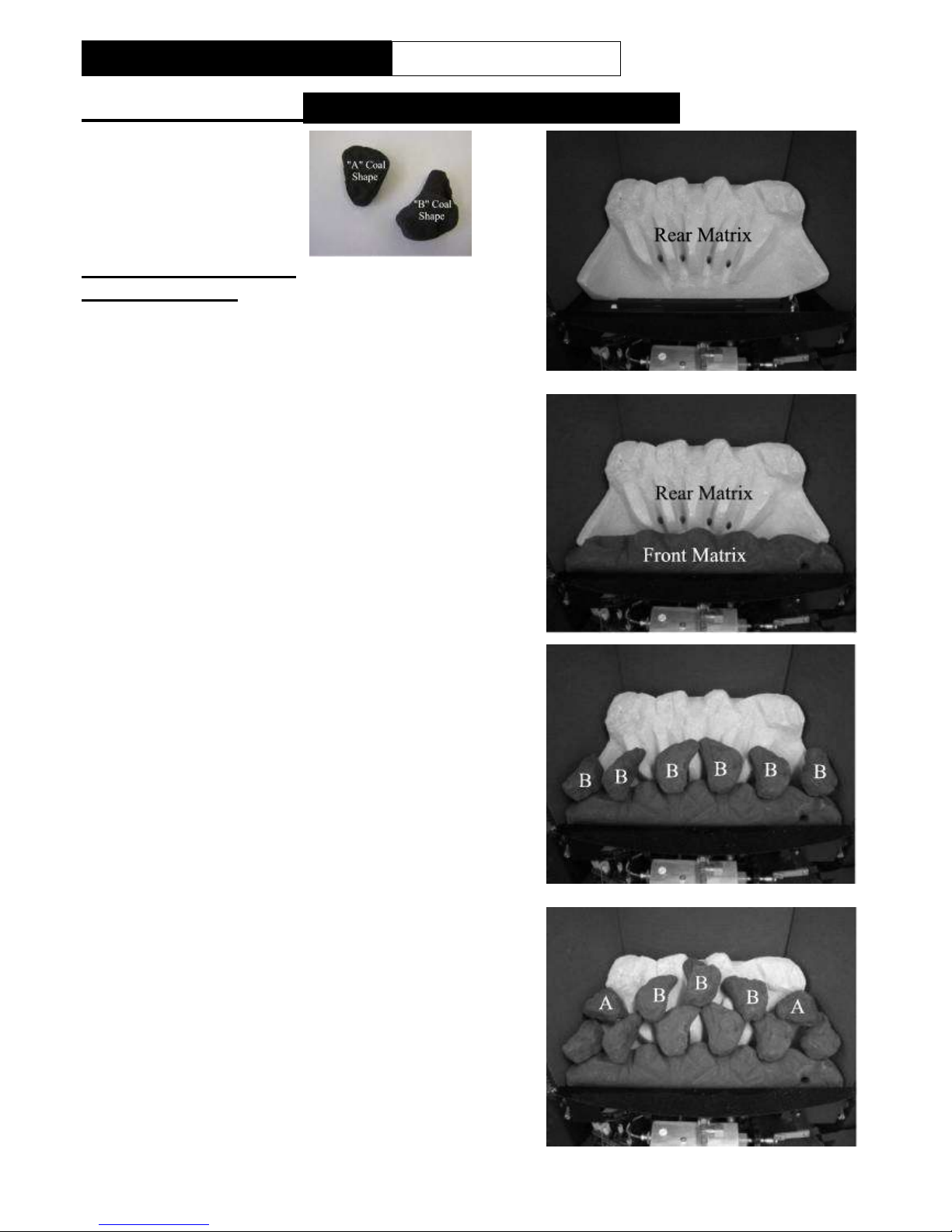

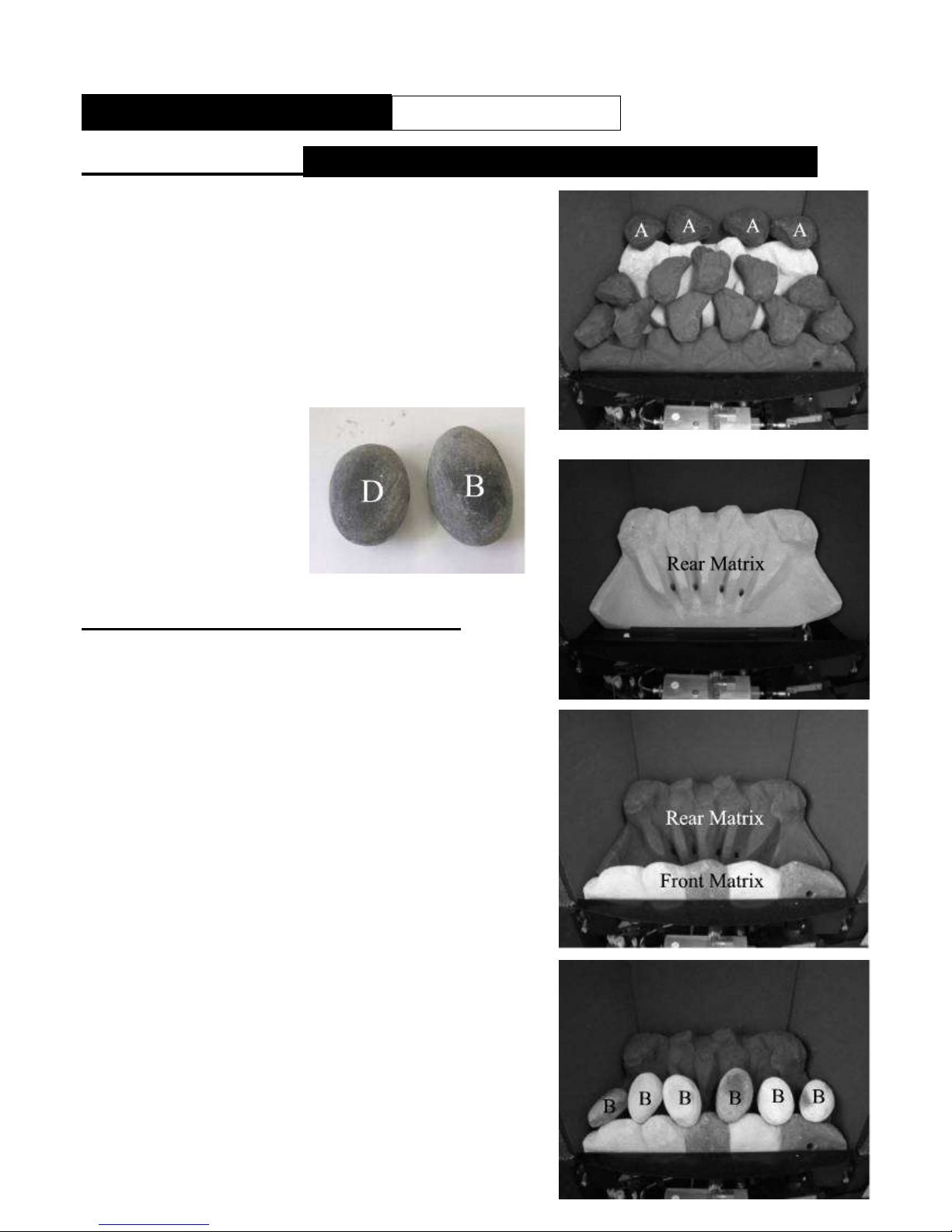

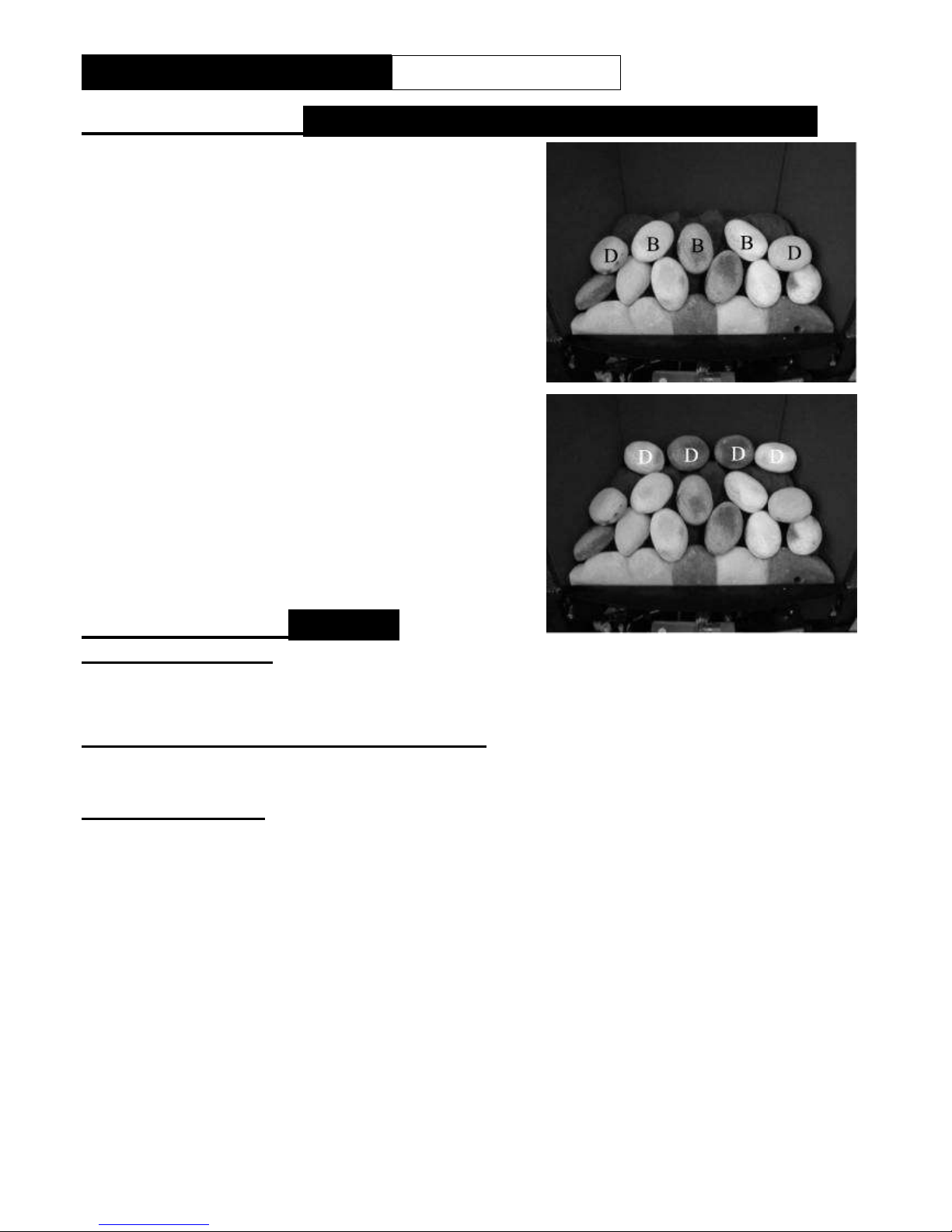

During the normal operation of the fire some black staining may appear on some parts of the fuel

bed. This is quite normal and adds to the appearance of the appliance. However, if excessive black

staining does occur it may be due to the fuel bed being incorrectly laid. This should be checked prior

to contacting a service engineer.

SECTION TWO Operation

Do not use the fire with the glass safety screen removed, or if the glass is cracked.

Do not use the fire with the canopy removed.

The pilot can be left on or the pilot can be extinguished and relit each time the fire is used.

The appliance Control Knob is positioned behind the fret.

The full lighting procedure is as follows: -

a. Push knob in as far as possible on gas control.

b. Turn knob anti-clockwise until a click is heard. The knob will stop at the position marked ' '

and a spark should be seen at the tip of the ignition probe. At the same time the pilot flame

should light. KEEP THE KNOB PRESSED IN FOR 20 SECONDS. Should the pilot fail to

light, turn the control knob clockwise to the ' ' position, wait 3 minutes and repeat the

procedure.

c. After lighting the pilot flame the control knob should be allowed to spring out slightly. This will

allow you to turn the knob further anti-clockwise to the position marked ' '. The pilot flame

should then ignite the main fire.

d. It is possible to adjust the height of the flames by turning the control knob between the

positions marked ' ' and ' '. Note that the knob 'latches' in position at either end of this

movement and must be pushed in slightly before it can be turned.

e. To turn the fire off, depress the knob slightly and turn it to the ' ' position.

f. To completely extinguish the fire, depress the knob slightly and turn to ' ' the position.

Note: -If the ignition fails the pilot can be lit with a taper or a match held at the pilot head.