MB339 – Mounting instruction

Materials / items required for assembly:

- Bonding/glue: Cyanoacrylate medium, activator for cyanoacrylate and cyan spouts dispensers;

- Finishing sandpaper 500/3 0

- Carbon tube diameter 8 mm

- Carbon tube diameter 4 mm

- Carbon tube diameter mm

- Alcol etilico

- Ethyl alcohol

- Cloth for ethyl alcohol (for cleaning surfaces to be bonded)

Preparative surfaces before bonding:

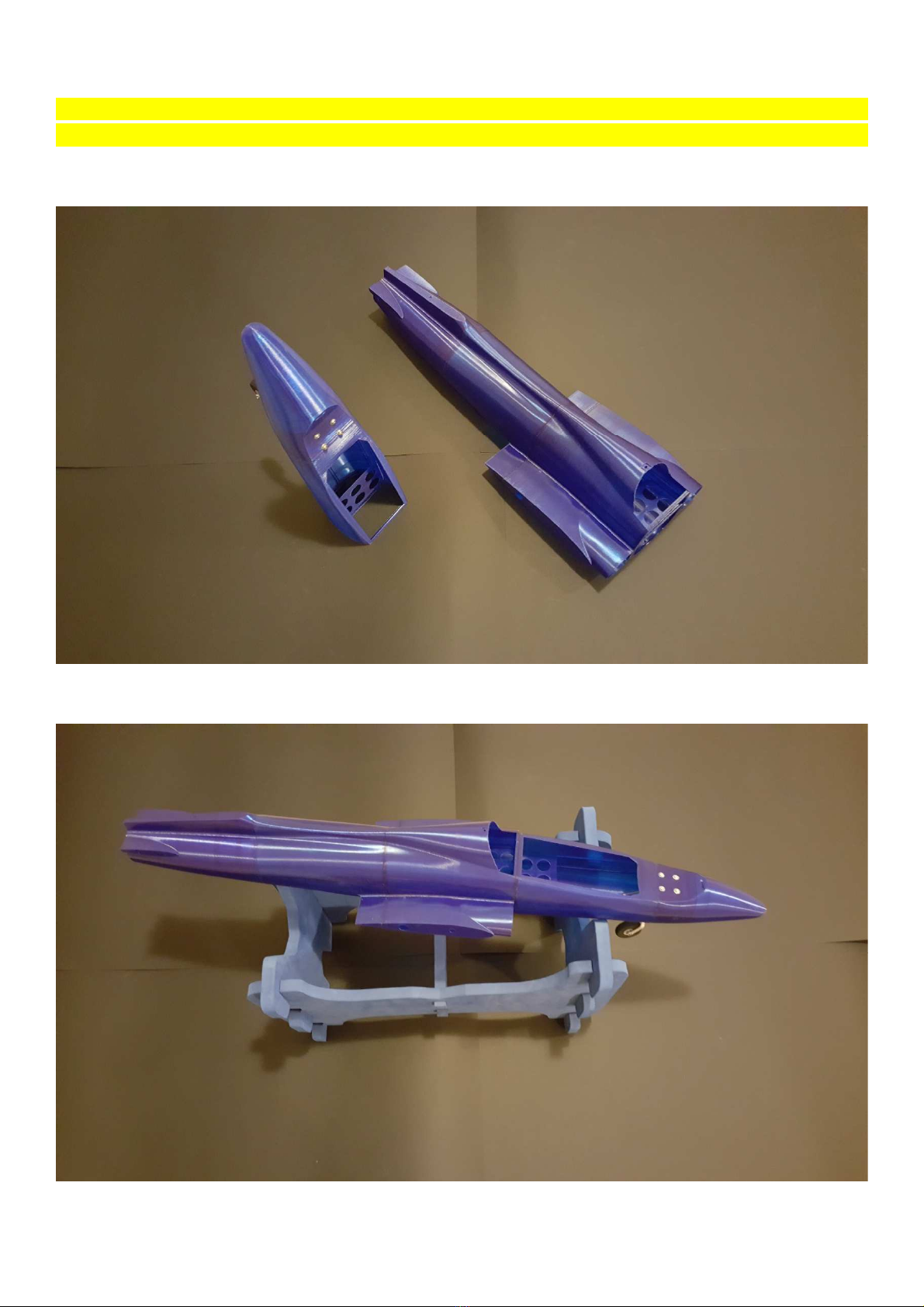

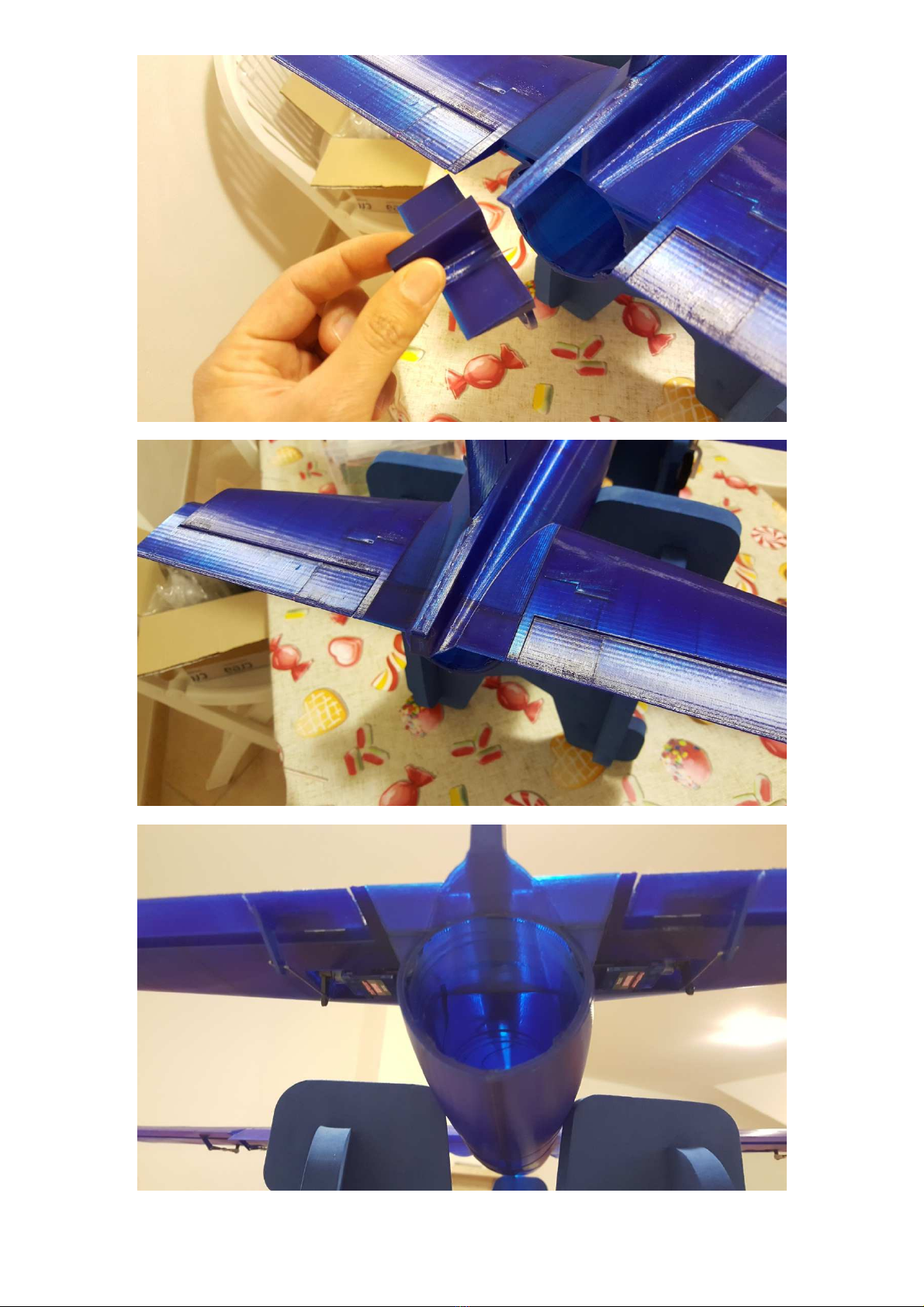

The MB339 model is composed of several sections, which need to be glued together

Each section before being glued must be sanded very quickly to further refine the plan already created by

the press, so that it is smooth and free of debris that might not do well pave surfaces. (Use abrasive paper

500/3 0).

Afterwards degrease with cloth soaked in ethyl alcohol the surfaces before bonding.

The above operations are very fast to perform, are indications to make the perfect job for the KIT assembly.

Use the cyanoacrylate medium to glue the sections between them, to avoid frittering of glue, use the cyan

spouts dispensers for medium cyan and apply the glue in the edge inside of the plane (not to exaggerate

with the amount, the cyanoacrylate on this type of materile has a strong seal and performs as a weld

between the glued parts) use the activator to accelerate the drying of the glue. It is important to use the

activator and nebulize in small quantities to avoid too rapid drying of the glue.