®

Patio-Pal®Installation,Operation, Maintenance andParts Manual

6.1 MAINTENANCE

WARNING!WARNING!

WARNING!WARNING!

WARNING!

Disconnect all power sources related to the

installation before servicing any component.

Use protective glasses when cleaning the heater.

If the control assembly is not completely

disconnected from the manifold, the high air

pressure will cause the controls to become

defective.

It is recommended that the following become a

standard yearly procedure to obtain maximum

operating efficiency and trouble free operation.

9

Patio-PalPatio-Pal

Patio-PalPatio-Pal

Patio-Pal® Gas-Fired Infra-Red Patio Heater

Maintenance & Troubleshooting

Duringlongperiodsof non-usage,removeorcoverheater

withapolyethylene bag andshutoffgassupply. If further

service to the heater is desired, contact your

representative or the factory.

Main Burner

1. Use an air hose to blow any accumulated dust and/

or dirt off the heater. Air hose pressure should

not exceed 30 psig.

2. Pass the air hose over the entire exposed area of

the ceramic. A distance of 2’to 4’ from the unit is

recommended.

3. Place the air hose outlet into each venturi tube and

allow the air to flow for approximately one minute.

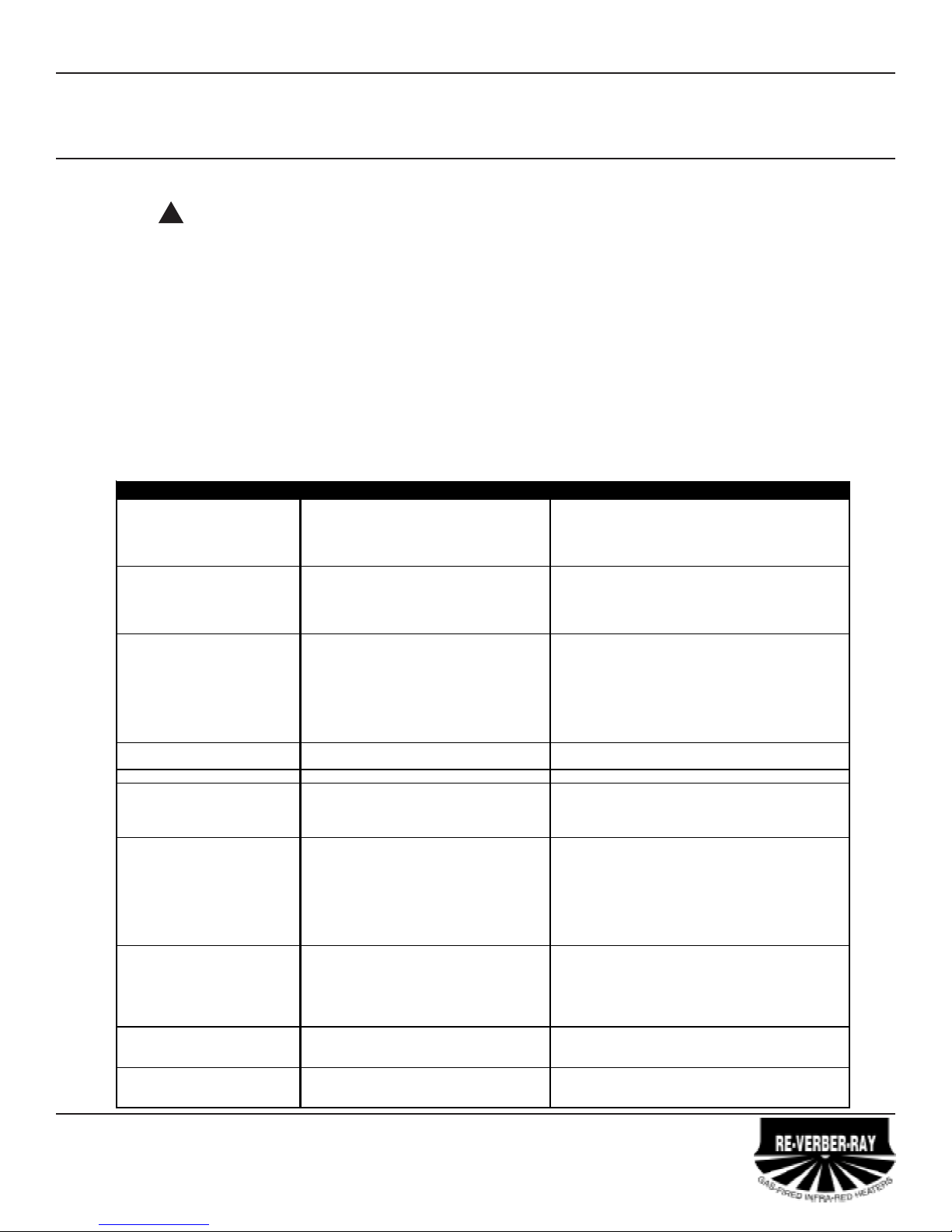

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

1. Heater mounted at incorrect angle. 1. Mounting angle 0º-30º.

2. Excessive drafts. 2. Relocate or shield from draft.

3. Gas leaking at orifice, spud, pilot tube. 3. Check with leak detector solution.

4. Separation of ceramic grids. 4. Replace burner.

5. Ceramic grids cracked. 5. Replace burner.

1. Electrode out of specification. 1. See Ignition System insert.

2. Low gas pressure. 2. See Section 3.1, Gas Supply.

3. Partially blocked orifice. 3. Clean or replace.

4. Improper orifice size. 4. Consult dealer.

5. Incorrect gas. 5. See unit nameplate.

1. Dirty or plugged burner ceramics. 1. See perodic maintenance instructions.

2. Partially blocked orifice. 2. Remove and clean.

3. Low inlet gas pressure. 3. See Section 3.1, Gas Supply.

4. High or Low manifold gas pressure. 4. Adjust main valve regulator as specified.

5. Foreign matter in venturi tube. 5. See periodic maintenance instructions.

6. Excessive dark spots on burner. 6. See periodic maintenance instructions.

7. Gas supply piping too small. 7. Increase inlet pressure or replace undersized piping.

8. Incorrect gas. 8. See unit nameplate.

1. Heater not mounted correctly. 1. Mounting angle 0º-30º. Level heater left to right.

2. Heater mounted too close to ceiling. 2. Observe clearance to combustibles

Gas odor. 1. Loose pipe connection. 1. Check all connections. Ti

hten as necessar

.

1. Heater located in drafty area. 1. Relocate or shield from draft.

2. Low gas pressure. 2. See Section 3.1, Gas Supply.

3. Thermostat located in drafty area. 3. Relocate thermostat.

5. Defective flame electrode or circuit board. 5. Replace.

1. Lack of 120V or 24V incoming voltage. 1. Check power supply.

2. Open high voltage wire. 2. Isolate and ohm for resistance, replace if 0.

3. Improper electrode gap. 3. See Ignition System specifications.

4. Loose or open wire connection. 4. Check all wires, tighten or replace.

5. Pressure switch not satisfied. 5. Verify fan operation. Remove obstructions.

6. Poor or no equipment ground. 6. Check all connections, provide positive earth ground.

7. Unit in "safety lockout" mode. 7. Interrupt power source, repeat trial for ignition.

8. Defective "Gaslighter" control. 8. Replace.

1. Poor or no equipment ground. 1. Check all connections, provide positive earth ground.

2. Polarity is reversed. 2. 120V to black, neutral to white.

3. Low gas pressure. 3. See Section 3.1, Gas Supply.

4. Electrode not sensing. 4. Relocate or replace if defective.

5. Heater mounted at incorrect angle. 5. Mounting angle 0º-30º.

6. Defective "Gaslighter" control. 6. Replace.

1. Gas valve in "OFF" position. 1. Turn to "ON" position.

2. Defective gas valve. 2. Isolate and check for resistance. Replace if 0.

3. Defective "Gaslighter" control. 3. Replace.

1. Defective thermostat or wiring. 1. Replace or repair.

2. Gas valve stuck open. 2. Replace.

3. Hi

h

as pressure. 3. See Section 3.1, Gas Suppl

.

Burning of gas-air mixture inside

plenum (flashback).

Delayed ignition.

Low ceramic surface temperature,

excessive rollout or soot on

rods.

Control system overheating.

Heater will not shut off.

Heater cycles repeatedly.

No spark; no ignition.

Spark is present. No main gas

operation. Unit "locks out".

Heater lights, and "locks out" after

approximately 10 seconds.

7.1 TROUBLESHOOTING

!