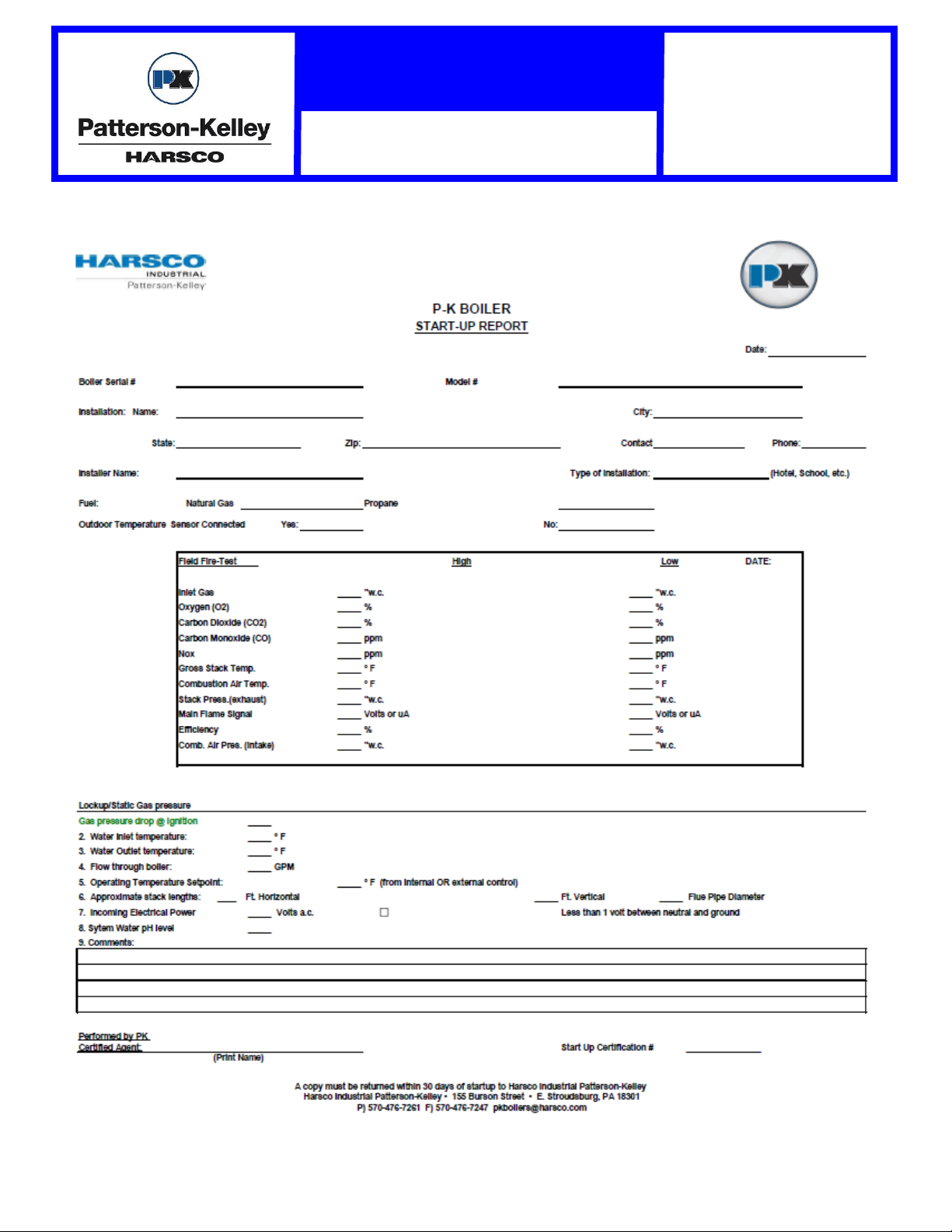

Patterson-Kelley MACH C1500 User manual

Other manuals for MACH C1500

1

This manual suits for next models

1

Other Patterson-Kelley Boiler manuals

Patterson-Kelley

Patterson-Kelley DVSCM-02 User manual

Patterson-Kelley

Patterson-Kelley MACH C-1500H Operating instructions

Patterson-Kelley

Patterson-Kelley MACH-05 User manual

Patterson-Kelley

Patterson-Kelley P-K MACH CM300 Operating instructions

Patterson-Kelley

Patterson-Kelley THERMIFIC MODU-FIRE Owner's manual

Patterson-Kelley

Patterson-Kelley P-K STORM ST-5000 Operating instructions

Patterson-Kelley

Patterson-Kelley SOLIS SL-1500 Operating instructions

Patterson-Kelley

Patterson-Kelley MACH C1500 Installation instructions

Patterson-Kelley

Patterson-Kelley MOD-04 Installation instructions

Patterson-Kelley

Patterson-Kelley TBIG-03 User manual

Patterson-Kelley

Patterson-Kelley STORM ST-2500 Operating instructions

Patterson-Kelley

Patterson-Kelley P-K STORM ST-1250 Operating instructions

Patterson-Kelley

Patterson-Kelley Thermific Operating instructions

Patterson-Kelley

Patterson-Kelley HARSCO MACH C1500V User manual

Patterson-Kelley

Patterson-Kelley MACH Series Operating instructions

Popular Boiler manuals by other brands

Bosch

Bosch GREENSTAR HEATSLAVE II EXTERNAL 12/18 instruction manual

Hoval

Hoval UltraGas 125 installation instructions

Guntamatic

Guntamatic Biocom series Planning and installation manual

Gorenje

Gorenje TGR 100 NG Instructions for use

Dizayn

Dizayn Kombimix User and installation manual

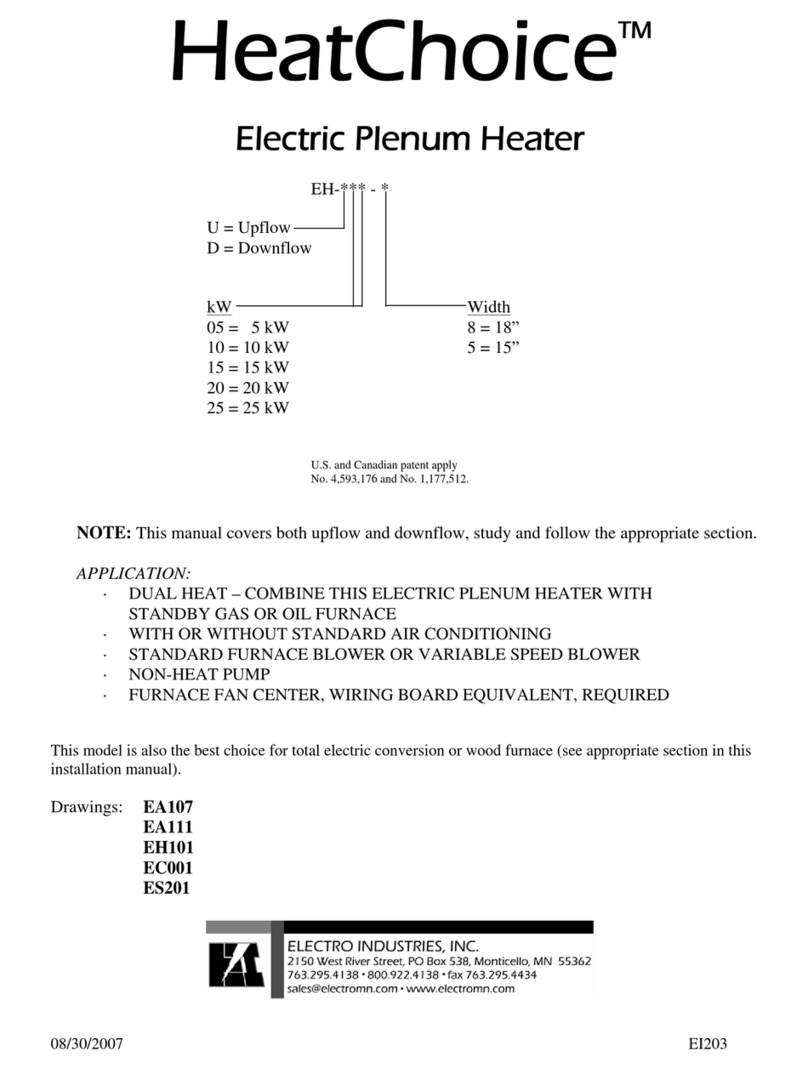

Electro Industries

Electro Industries HeatChoice EH Series manual

VOKERA

VOKERA Mynute 28e User instructions

NTI

NTI TFTN 085-399 Installation and operation manual

Beretta

Beretta POWER EVO-X Series installation manual

Worcester

Worcester GR8300iW 30 S Installation and maintenance instructions

Beretta

Beretta NOVELLA user manual

Potterton

Potterton Promax System HE Plus A Range User's guide and important warranty information