1General Information

2015/12 996404631-mub-en - V02 3

Contents

1General Information............................................................................................................. 4

1.1 Scope of these instructions............................................................................................ 4

1.2 About this product .......................................................................................................... 5

1.3 Designated use .............................................................................................................. 5

2Safety instructions............................................................................................................... 6

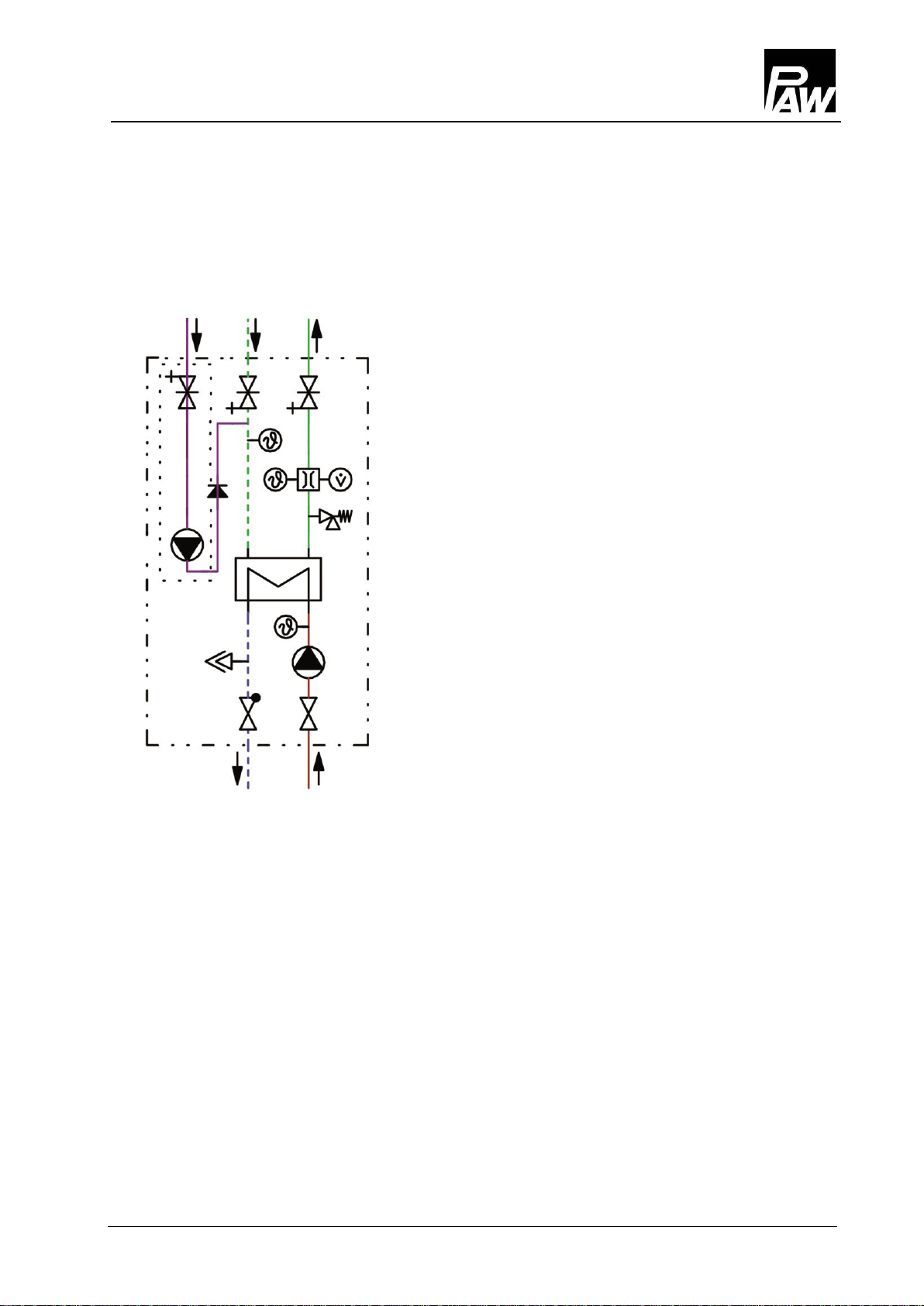

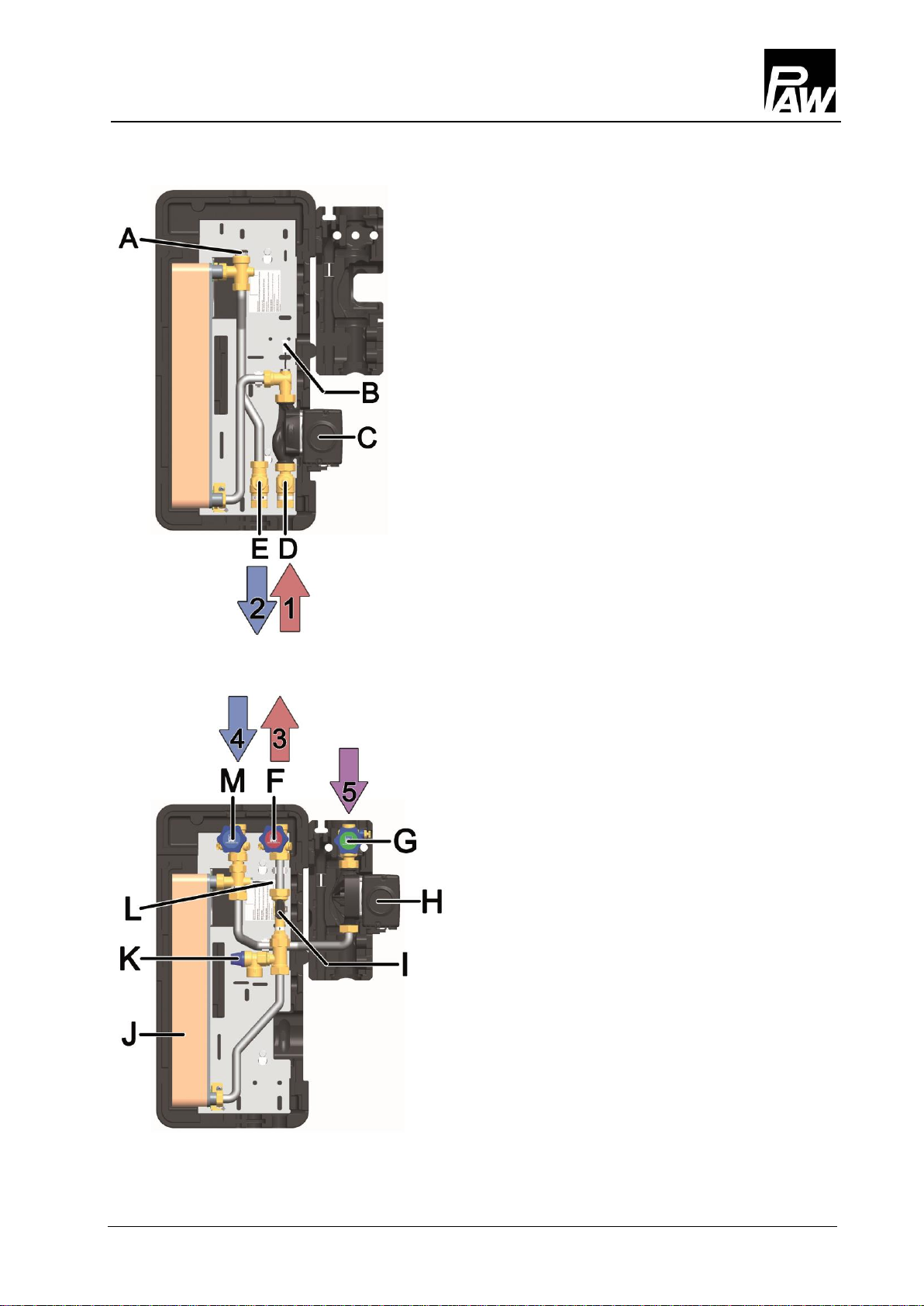

3Product description.............................................................................................................. 7

4Dimensioning and planning ................................................................................................. 8

4.1 Dimensioning of the tank ............................................................................................... 9

5Circulation mode ............................................................................................................... 10

6Assembly and installation [specialist] ................................................................................ 11

7Commissioning [specialist] ................................................................................................ 14

7.1 Filling the primary circuit .............................................................................................. 15

7.2 Commissioning of the controller................................................................................... 16

7.3 Maximum withdrawal flow rate..................................................................................... 18

7.4 Setting the temperature ............................................................................................... 20

8Maintenance [specialist] .................................................................................................... 21

9Spare parts [specialist] ...................................................................................................... 22

9.1 Spare parts primary circuit FriwaMini with circulation (6404631)....................................... 22

9.2 Spare parts primary circuit FriwaMini with circulation (6404631)....................................... 23

10 Technical data................................................................................................................... 24

10.1 Dimensional drawing FriwaMini with circulation........................................................... 25

10.2 Pressure drop characteristics FriwaMini with circulation ............................................. 25

11 Commissioning report ....................................................................................................... 26