PB Heat TC Series Instruction manual

This manual suits for next models

15

Table of contents

Other PB Heat Boiler manuals

PB Heat

PB Heat PSC-06 Instruction manual

PB Heat

PB Heat mod-u-pak User manual

PB Heat

PB Heat 62-09 Instruction manual

PB Heat

PB Heat Peerless Combi 160 User manual

PB Heat

PB Heat Series GM Guide

PB Heat

PB Heat MI Series Guide

PB Heat

PB Heat SERIES 63 Guide

PB Heat

PB Heat PureFire PFC-625 Guide

PB Heat

PB Heat PSCII SERIES Guide

PB Heat

PB Heat PUREFIRE Guide

Popular Boiler manuals by other brands

Radiant

Radiant R1K 75 user manual

Ravenheat

Ravenheat HE 25 C COMPACT Instructions for use installation and servicing

A.O. Smith

A.O. Smith GW-300 Specification sheet

Granby

Granby B*C-3 sections Installation, operation and service manual

Lochinvar

Lochinvar EFFICIENCY+ E B N 150 Specifications

REMEHA

REMEHA Avanta Plus 28c user guide

Slant/Fin

Slant/Fin S-150 Installation and operating instructions

Biasi

Biasi M300V.2025 SM Service manual

Biasi

Biasi RCH 1500 Technical manual

Calomax

Calomax CASCADE-6TC Assembly, installation and operation instructions

Fondital

Fondital ANTEA CONDENSING Installation, use & maintenance manual

Nature's Comfort

Nature's Comfort GT-220 Installation and operating instructions

Rinnai

Rinnai E50C Installation & servicing instructions

Potterton

Potterton 360 Erection installation, commissioning & servicing instructions

DeDietrich

DeDietrich WHE 2.24 FF-3S user guide

Westinghouse

Westinghouse WBRC 140F Series Installation & start-up instructions

Myson

Myson Apollo 30Si Installation and servicing instructions

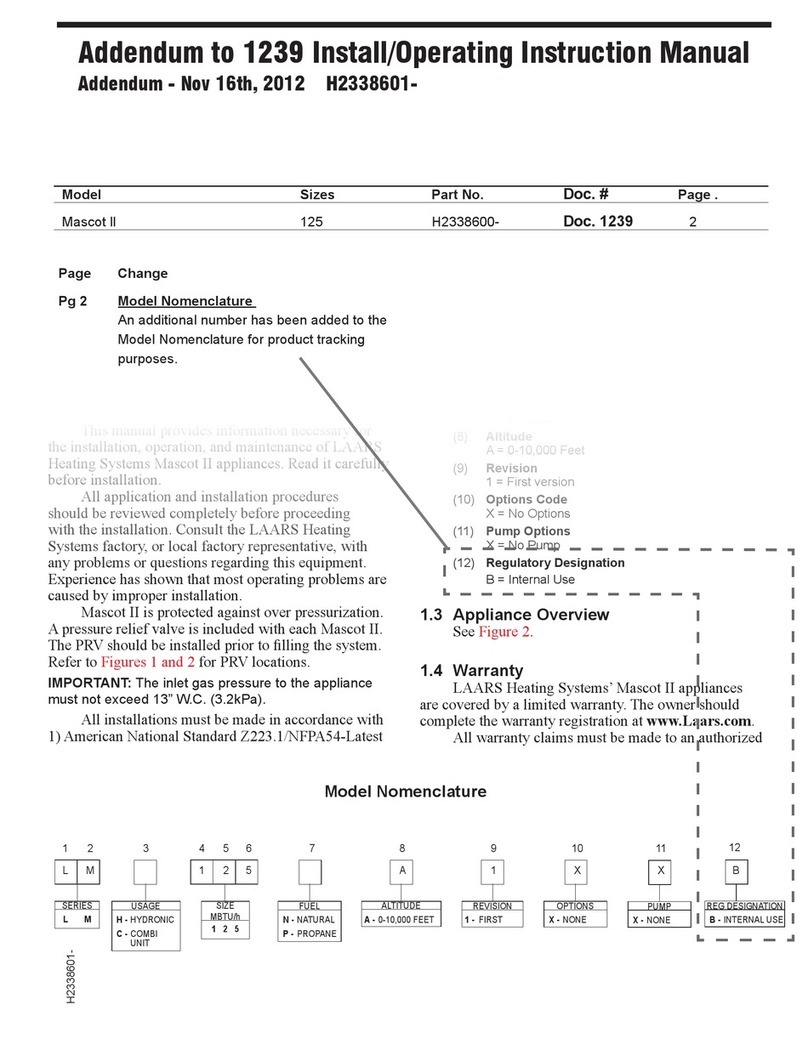

Laars

Laars LMH user manual