INC

TM

WWW.PEAKWORKS.CA

6

This tripod and all fall protection equipment should be stored in a clean dry environment

that is free of exposure to fumes or corrosive elements. If the tripod is being used in a

corrosive environment (example: near salt water), the tripod must be inspected more

frequently. Any build up of dirt or grime can seriously reduce the performance of the tripod

and in some cases may prevent the tripod from arresting a fall.

Regular cleaning of your tripod will ensure proper performance and will help extend its life.

Clean the tripod with a mild solution of water and mild soap or detergent with a neutral

pH. Wipe the tripod dry with a clean cloth. Do NOT lubricate the tripod. Allow the tripod to

dry naturally away from any source of heat.

Care and Storage

PeakWorks’ SRLs have no user serviceable parts and must not be disassembled or

adjusted except by the manufacturer or approved service agent. User maintenance is

limited to pre-use inspection, cleaning, drying and storage as described in these User

Instructions. When maintenance is required, consult the supplier/manufacturer. Do not

tamper with or adjust any part of the device. The device must not be engraved in any way.

Maintenance

Pre-Use Inspection

NOTE: This equipment and all components of a fall arrest system should be inspected before each use

according to the instructions supplied with the product at the time of shipment.

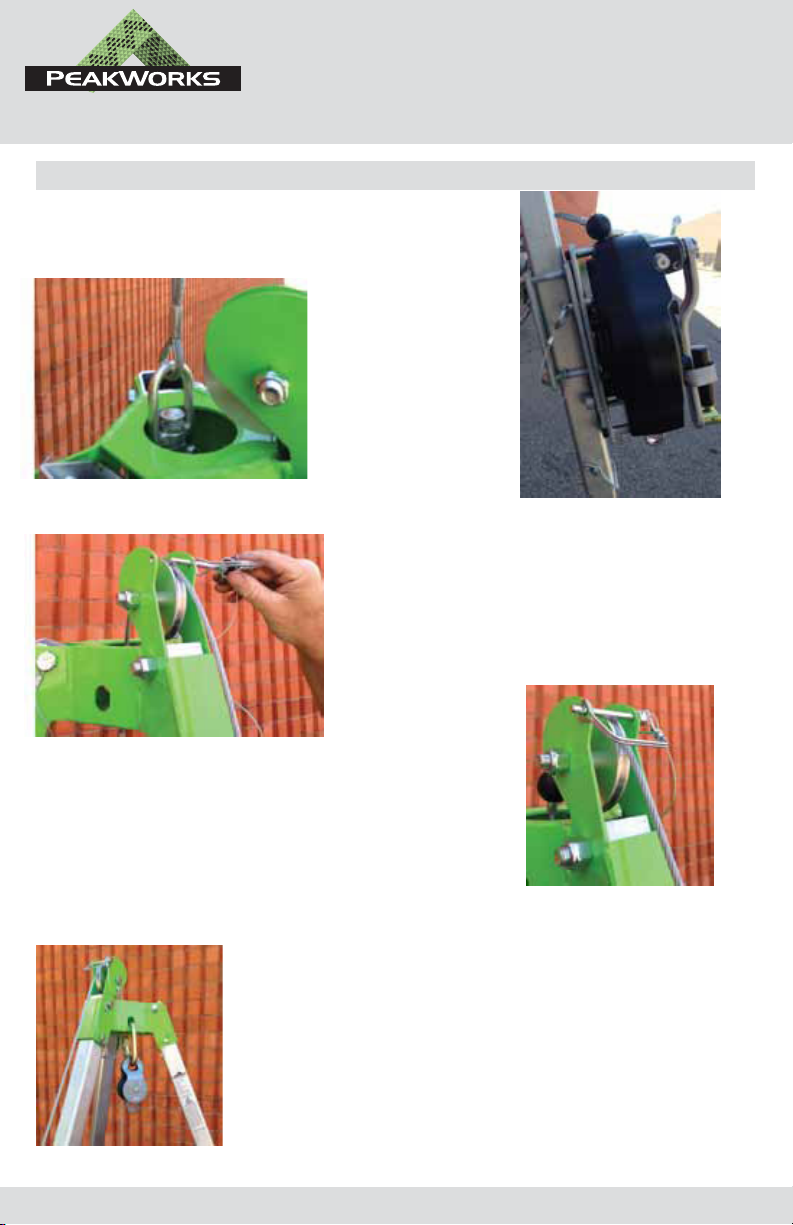

Visually inspect the tripod for the following (before each use):

•Check for corrosion on all parts

•Check for any signs of deterioration of any of the components

•Check to ensure all detent pins t tightly and are installed correctly

•Check to ensure detent pin on SRL bracket is installed correctly

•Check for misaligned, cracked or bent components

•Check to ensure the pulley runs freely and not bent or misaligned

•Check to ensure that the chain is not kinked or damages

•Check to ensure that any holes are not damaged

•Check to ensure that the inner leg moves freely inside the outer leg when not pinned

•Check to ensure the mounting bracket for the SRL-33303-50 is installed correctly

•Check to ensure that there are not signs that the product as been subjected to a fall arrest

If any deciencies are found that may aect the integrity or operation of the tripod please contact

The PeakWorks Tripod is designed for ONE person ONLY and is capable of supporting a 5,000 lbs. (22 kN)

static load or provides a 2:1 safety factor when using an approved PeakWorks self retracting lifeline or

3-way. The tripod should be set up on a stable surface capable of withstanding 5,000 lbs. (22 kN)

The top pulley is designed as a suitable anchorage connector. If necessary there is 3 slots on the side of the

tripod head that can be used as secondary anchorage connectors or for a connector for the top attendant.

Before Use