- III -

1

5

2

6

3

7

9

4

8

10

Contents

Purpose of use and application -------- I

Important information --------------------- I

Operation manual------------------------- II

For disposal -------------------------------- II

Contents ----------------------------------- III

1 Function of Refrigeration Unit 1

2 Name of each part---------------3

Arrangement plan for main parts ----- 3

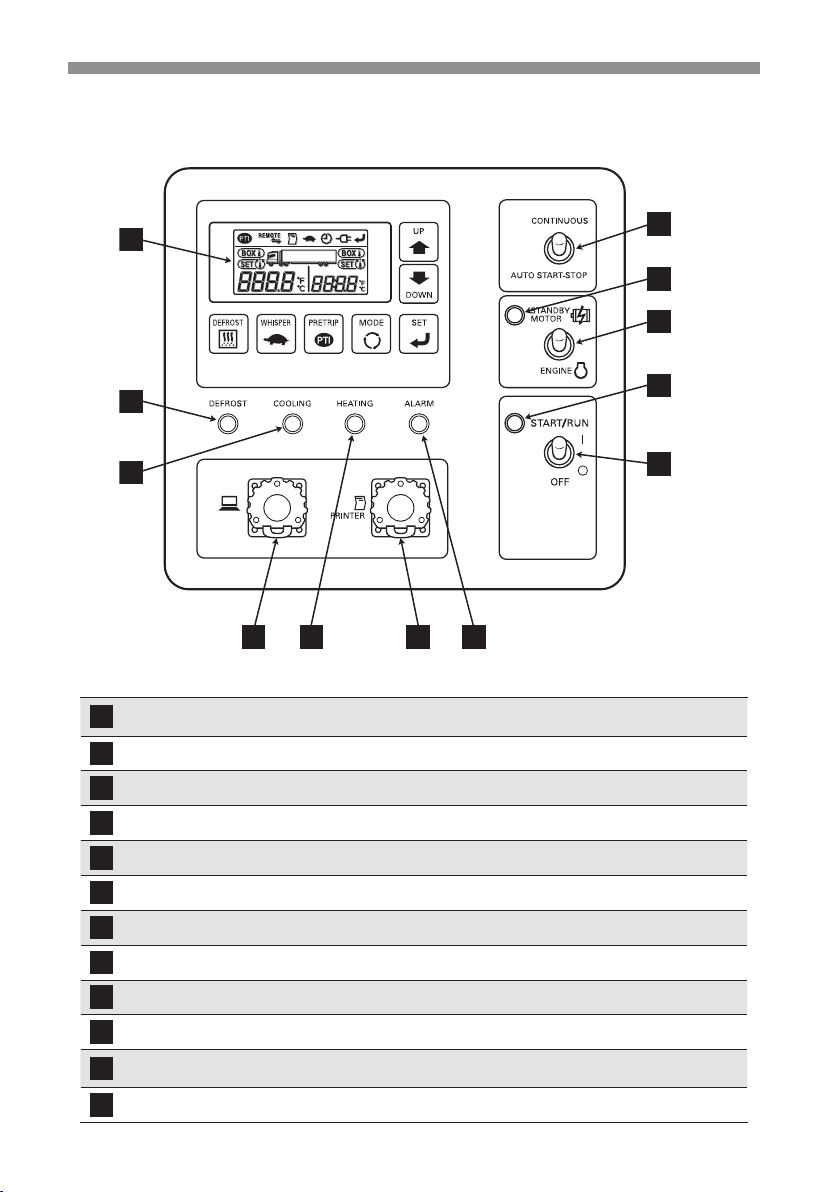

Control panel------------------------------- 5

Switches ------------------------------------ 6

Digital display area ----------------------- 7

Protective devices ------------------------ 8

3 Precaution for safety------------9

Signs on safety---------------------------- 9

Precautions--------------------------------10

General precautions-------------------------- 10

During and after the operation ------------- 11

Inspection/Cleaning/Repair----------------- 12

Loading ------------------------------------------ 12

Handling of electric equipment and power codes

13

Reinstallation of refrigeration unit --------- 14

Modication of the refrigeration unit and

specication change-------------------------- 15

Power supply equipment -------------------- 15

Emergency measure

------------------16

Handling of warning labels ------------18

Prevention of start during inspection work

--21

Clothing and protective equipment--21

Handling of grease and oil-------------21

When abnormal conditions are detected

21

For emergency ---------------------------21

4 Initial setting--------------------- 22

Mode displays and functions----------22

Outline of the user setting mode-----25

Setting the printer (Optional)----------27

Setting the defrost interval timer -----29

Sleep operation setting-----------------30

Resetting the cumulative time 1------31

Setting the clock -------------------------33

5 Operation ------------------------ 35

Power on-----------------------------------36

Switching the drive ---------------------37

Operating with the sub-engine------------- 37

Operating with the motor -------------------- 38

Switching the operation pattern ------39

Selecting the auto start/stop operation -- 39

Selecting the continuous operation------- 39

Operation ----------------------------------41

Stopping the operation -----------------43

Setting temperature ---------------------44

Whisper operation

(Only for of sub-engine drive)---------45

Manual defrost operation --------------46

Starting ------------------------------------------ 46

Stopping ----------------------------------------- 47

Setting the ON timer --------------------48

Setting the OFF timer-------------------50